水下搅拌摩擦加工纯铜及其合金的显微组织演变和摩擦性能

来源期刊:中国有色金属学报(英文版)2020年第4期

论文作者:A. MOAREF A. RABIEZADEH

文章页码:972 - 981

关键词:铜合金;搅拌摩擦加工;水下;磨损;显微组织

Key words:copper alloy; friction stir processing; underwater; wear; microstructure

摘 要:对工业纯铜(纯度99.8%)和铜锌合金(黄铜)进行水下搅拌摩擦加工。搅拌摩擦加工的刀具呈螺纹锥状,由碳化钨制成,其转速为1800 r/min,横移速度为4 mm/min,将试样浸泡在带循环系统的水箱中。为了评估加工次数对样品显微组织和力学性能的影响,进行6道次加工。采用光学显微镜对商业纯铜样品的显微组织进行研究,结果表明,加工后材料的晶粒尺寸明显减小。同时,样品横截面的硬度较母材增高。水下搅拌摩擦加工样品的X射线衍射谱与母金属的相比,其峰值更短、更宽,谱的背景增大,表明形成非晶/超细晶组织。采用针-盘法对试样的磨损行为进行研究,结果表明,与母材相比,加工后试样的摩擦因数降低。磨损和硬度试验结果表明,水下搅拌摩擦加工可显著提高工业纯铜和黄铜的耐磨性和硬度。

Abstract: Underwater friction stir processing was performed on commercially pure copper with a purity of 99.8% and a copper-zinc alloy (brass). The tool was made of tungsten carbide in the threaded cone form. Friction stir processing was performed at a tool rotational speed of 1800 r/min and a tool transverse speed of 4 mm/min while the samples were immersed in a water tank with a water circulation system. In order to evaluate the effect of the number of process passes on the microstructure and mechanical properties of the samples, this process was continued for up to 6 passes. Microscopic studies using light microscopy on commercially pure copper samples show significant decrease in grain size. Likewise, the hardness of the cross-sectional area shows an increase more than the base metal. The X-ray diffraction pattern of the underwater friction stir processed samples in comparison to that of the base metal exhibits shorter and wider peaks, while the background of the pattern is increased. The sum of these factors represents the formation of an amorphous/ultrafine grained structure. Also, the wear behavior of the samples was investigated by means of pin-on-disk method and the results show that the friction coefficient of processed samples is decreased compared to that of the base metal. The results of wear and hardness tests show that the underwater friction stir processing can significantly improve the wear resistance and hardness of commercially pure copper and brass.

Trans. Nonferrous Met. Soc. China 30(2020) 972-981

A. MOAREF1, A. RABIEZADEH2

1. Department of Mechanical Engineering, Shiraz Branch, Islamic Azad University, Shiraz, Iran;

2. Department of Materials Engineering, Shiraz Branch, Islamic Azad University, Shiraz, Iran

Received 22 June 2019; accepted 28 December 2019

Abstract: Underwater friction stir processing was performed on commercially pure copper with a purity of 99.8% and a copper-zinc alloy (brass). The tool was made of tungsten carbide in the threaded cone form. Friction stir processing was performed at a tool rotational speed of 1800 r/min and a tool transverse speed of 4 mm/min while the samples were immersed in a water tank with a water circulation system. In order to evaluate the effect of the number of process passes on the microstructure and mechanical properties of the samples, this process was continued for up to 6 passes. Microscopic studies using light microscopy on commercially pure copper samples show significant decrease in grain size. Likewise, the hardness of the cross-sectional area shows an increase more than the base metal. The X-ray diffraction pattern of the underwater friction stir processed samples in comparison to that of the base metal exhibits shorter and wider peaks, while the background of the pattern is increased. The sum of these factors represents the formation of an amorphous/ultrafine grained structure. Also, the wear behavior of the samples was investigated by means of pin-on-disk method and the results show that the friction coefficient of processed samples is decreased compared to that of the base metal. The results of wear and hardness tests show that the underwater friction stir processing can significantly improve the wear resistance and hardness of commercially pure copper and brass.

Key words: copper alloy; friction stir processing; underwater; wear; microstructure

1 Introduction

Nowadays, the need for metals with optimal mechanical properties has led to the production of various alloys; however, the lack of dissolution of many metals in one other caused the limitation in the production of alloy.

In order to solve these limitations, new methods of metal production with optimal mechanical properties have been proposed. In general, metals tend to be crystallized; therefore, to avoid this tendency they must be cooled at high speed so that the component parts do not have the opportunity to get into a regular structure. Nonetheless, achieving this rate of cooling reduces their production as a thin film. Some of the reasons for using fast metal cooling are improving mechanical properties, grains and phase refinement, increasing solubility, creating pseudo-crystalline structure, stability and uniform distribution of precipitates, enhancing magnetic resistance, improving hard and soft magnetic properties, increasing saturation magnetism, etc [1,2].

Friction stir processing (FSP) is a new surface engineering technology that improves the microstructure of the metals. Consequently, the hardness and ductility of the metal are enhanced, and the fatigue resistance and corrosion resistance as well as the plasticity and other features of the metals are increased. Friction stir processing can create ultrafine grain structures of the parts. The friction stir processing is a kind of hot work, during which a large amount of deformation is emerged through the tool pin and tool shoulder on the processed material. This deformation decreases as a result of exiting the stirred zone towards the thermo-mechanical affected zone and the heat-affected zone. This method is also used to homogenize the metal structure, microstructure refinement, and improve the mechanical properties. The method used in friction stir processing is similar to the method utilized in friction stir welding. One way to improve and refine the microstructure is to perform underwater friction stir processing [3-5]. Few studies investigated the performance of underwater friction stir welding/ processing on the aluminum-based alloys [6-18].

In the last five years, the FSP has been widely used and expanded as a solid-state refinement technique of the structure. In addition to the refinement of the structure by FSP, the effect of this process on the other properties of materials such as hardness, tensile strength, fatigue, super-plasticity, tribological behavior, and corrosion resistance, has been studied and analyzed.

As a result of friction stir processing, severe plastic and friction deformation occur in the material, which in turn contributes to the material flow around the tool. Moreover, due to the high friction between the tool and the material, a great deal of heat is generated which elevates the material temperature locally to about 0.6Tm (Tm: melting point). Extreme high-temperature plastic deformation provides the conditions for dynamic recovery and dynamic recrystallization of the material. Dynamic recovery leads to the formation of sub-grains that are subjected to misorientation. Furthermore, during the process, the temperature gradient between the processed area and its surrounding occurs, leaving the alloying elements out of the solid solution and causing precipitation with decreasing temperature. The dynamic recrystallization thus activates the dynamic recovery and produces fine and homogeneous grains through coalescence and sub-grains rotation. During dynamic recrystallization, fine-grained precipitations cause pinning of the grain boundaries, where with limited grain boundary migration, the grain growth is controlled. And despite the high temperature of the piece, a homogenous structure and fine grain remain after the process [11,18,19].

This study is an attempt to create a super-fine-grain or amorphous structure through cooling the segment rapidly and thus eliminating the grain growth conditions, in order to reduce the mobility of the grain boundaries after the recrystallization and to create a finer structure than what is created via friction stir processing in the air. Accordingly, the friction stir processing is performed under water to cool the segment rapidly.

This study investigated the microstructure and mechanical properties of the produced amorphous/ ultrafine grains layer on commercial pure copper and copper-zinc alloy by the underwater friction stir processing. The reason behind using this underwater processing is to achieve a higher cooling rate, amorphous/ultrafine grain production, and gain the good mechanical properties of copper and its alloys. This processing was used in this research because of its very good properties such as very low residual stresses, the lack of complex tools and equipment, lack of gas absorption and the absence of porosity in the welding structure. Based on the above-mentioned features in terms of friction stir processing, the production of amorphous/ ultrafine grains on the copper and its alloy via this method is more qualified and cost-effective than other relevant methods. Improvement of mechanical properties including strength and surface hardness, wear resistance and corrosion resistance, reduction of magnetic energy losses, increased wear life of components beget increased work periods and increased maintenance period; as a result, considerable savings are made at the expenses of the user’s industrial equipment.

2 Experimental

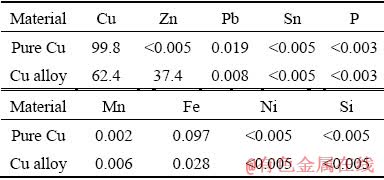

This work is an attempt to investigate the mechanical and tribological properties of commercially pure copper and copper-zinc alloy, which were produced by underwater friction stir processing (UWFSP). The raw material used in this study is pure commercial copper with a purity of 99.8% and brass alloy C28000. Both materials were sampled to determine the chemical composition and their chemical composition test was carried out using spectrometry method according to ASTM E414 standards (Table 1).

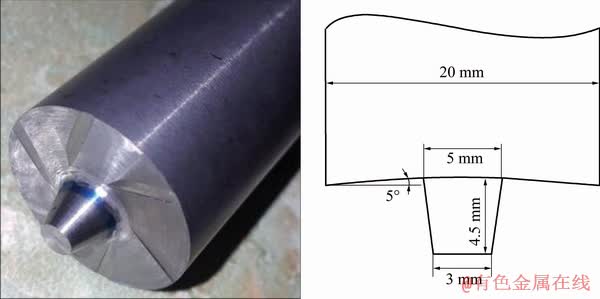

In this study, the friction stir processing was performed on a 5 mm-thick sheet. To this end, first, a sheet with dimensions of 70 mm × 150 mm was prepared. The tool used is tungsten carbide, as shown in Fig. 1. The pin was designed to be cone based on the results of previous studies. In order to do the process, the axis of the spindle was derivated by 5°. This angle causes the material forging behind the tool to be performed effectively to fill in the hole; therefore, the processed parts are free of any defect. In this case, the tool shoulder penetrates about 0.1-0.15 mm into the sheet. It is worth mentioning that the tool rotates clockwise and after each successful pass, the tool restarts at the starting point for the next pass and follows the same path as the previous one.

Table 1 Chemical compositions of pure and alloyed copper used in this research (wt.%)

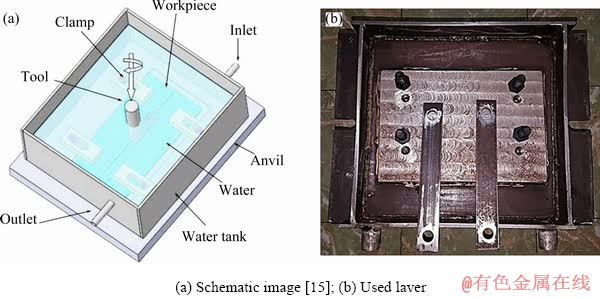

According to the previous studies, the tool rotational speed and the tool transverse speed in all processed parts was 1800 r/min and 4 mm/min, respectively. In order to cool the piece, and prevent the formation of a crystalline structure, a water tank with input and output for water pumping using steel plate ST37 with thickness of 20 mm was designed and constructed (Fig. 2).

In order to study microstructure, preparation of samples was done using 400 to 2000 sandpapers. Etching of metallurgical samples of copper-zinc was performed by an alcoholic-chloride solution (5 g FeCl3, 2 mL HCl and 95 mL C2H5OH) for 10 s. After the preparation, in order to evaluate the microstructures, the samples were imaged by optical microscopes. The hardness of the samples was determined by using the Vickers microhardness test (model: DHV-1000).

The hardness of different areas resulting from the FSP process in the samples was measured at the cross section of the parts. The amount of force and duration of power applied by the device were selected as 1 kg and 15 s, respectively. An X-ray diffractometer (Bruker D8) was used to evaluate the crystallization/amorphous microstructure.

Fig. 1 Tool used for friction stir processing

Fig. 2 Laver fixture

To measure the wear resistance and determine the friction coefficient of the samples, the pin-on- disk method was used. First, a cylindrical pin of 5 mm in diameter and a certain thickness of the piece were removed using a wire cutting machine with electrical drainage from the center of processed area of the samples. The conditions and variables required for wear test were considered in accordance with the ASTM G99 standard. These conditions were the force 10 N, the velocity 0.5 m/s, the slip distance 1000 m and the radius 15 mm. It is worth mentioning that the prepared pins were tested on a 52100 steel plate with a hardness of about HV 800.

3 Results and discussion

3.1 Visual inspection

The earliest method for evaluating processed samples is visual inspection, through which many of the imperfections of the samples can be found. So, before sampling for mechanical and tribological tests, the samples were examined by visual inspection. It was found that the samples prepared in the air had more distortion, higher apparent defects, and lower surface quality than samples prepared through the underwater method. This suggests that performing the underwater processing would reduce the working temperature and the oxidation of the metal during operations, which resulted in better surface quality and less distortion (Fig. 3).

3.2 Phase analysis

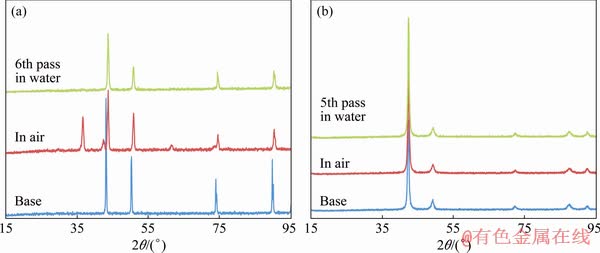

The diffraction patterns of some of the processed samples are shown in Fig. 4. Compared with the reference pattern of copper (ICDD No. 04-0836), by performing friction stir processing, the intensity of the peaks in the diffraction pattern is reduced and the width of these peaks is increased. This phenomenon is due to the severe plastic deformation and carrying out the underwater process, which prevents growth of the recrystallized grains and prohibits the completion of recrystallization. Increase in the background of diffraction patterns is one of the changes in the diffraction pattern of processed samples. The main reason for the decrease in the peaks intensity is increasing their width, increasing the background in the X-ray diffraction pattern, and the presence of amorphous/ultrafine grains. However, this process will continue with the increment of the number of passes. On the other hand, on some patterns, the copper oxide phase is also observed due to the high temperature of the part as a result of the process and its proximity to the air.

Fig. 3 Images of some processed samples

Fig. 4 X-ray diffraction patterns of copper (a) and brass (b)

In terms of brass samples, the analysis of the patterns was done by comparing them with the reference pattern of copper alloy (ICDD No. 50-1333). Due to the presence of alloying elements in the brass samples, the peaks in the pattern are slightly displaced. Similar to the diffraction pattern of pure copper samples, the copper alloy shows a decrease in peak intensity, an increase in the width of the peaks and an increase in the background of their diffraction pattern due to the formation of amorphous/ultrafine structure. It is worth mentioning that in copper sample prepared in the air, new peaks are observed which are associated with copper oxide. It can be concluded that as a result of the implementation of underwater friction stir processing, the oxidation of the piece is prevented by separating the sample from the environment. In the case of copper-zinc samples, there is no peak of oxides on the diffraction pattern of the processed sample in the air.

3.3 Microstructure

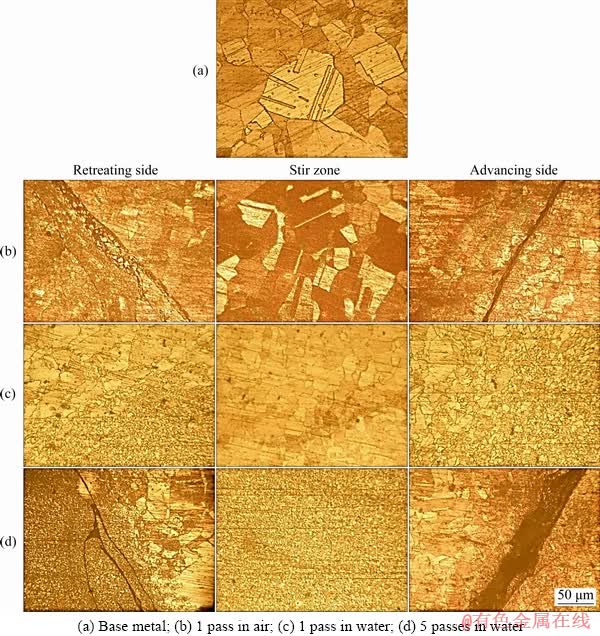

Metallographic images were utilized to explore the microstructure and grain size. In Fig. 5(b), which is related to a single-pass sample in the air in a pure copper, the thermal stress and strain caused by the friction stir processing changed the shape of the grains, but there was no significant change in their dimensions.

Fig. 5 Metallographic images of copper samples

In the samples of single-pass and three-pass in water (Figs. 5(c, d)), the high cooling rate of water and the absence of complete dynamic nucleation reduced the size of metal grains and uniformity in particle dispersion. Similar phenomena for processed brass samples are also shown in Fig. 6. Due to the thermo-mechanical nature of the friction stir process, the fine grain structure in the stirred zone is not uniform along the thickness of the piece [20-23].

The reduction in the observed grain size by increasing the number of process passes confirmed the results of X-ray diffraction patterns. As can be seen, as a result of the underwater friction stir processing and the high heat transfer of copper, the heat produced by friction is removed from the metal. Simultaneous severe plastic deformation and reducing the temperature of the piece do not result in a complete dynamic recrystallization and thus prevent the formation of very fine grains or their growth.

3.4 Microhardness

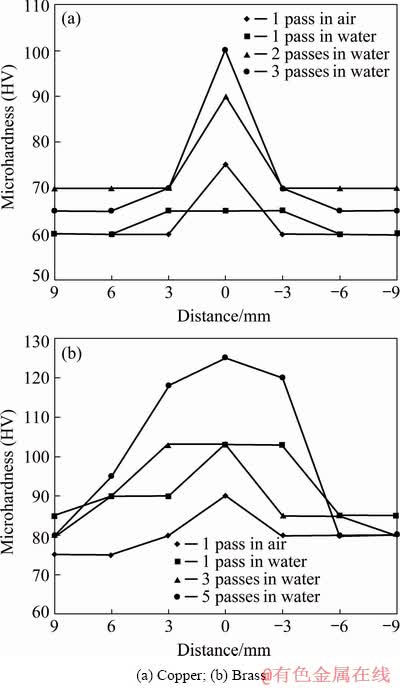

The results of microhardness measurement are shown in Fig. 7. The average hardness values equal HV 65 in a single-pass copper sample, HV 90 in a two-pass sample, and HV 100 in a three-pass sample. And in the brass sample, the hardness values equal HV 103 in a three-pass sample, and HV 125 in a five-pass sample. According to Fig. 7, each time in the friction stir processing by the increase in number of performed passes, the sample gets harder. By measuring the hardness, one can obtain an estimate the crystal distribution and the grain size as well. The hardness values of HV 60 of copper and HV 80 of brass samples are due to the work hardening done during the initial rolling process. Rolling operations mainly increase the density of dislocations in the sheet and increase its hardness. But the friction stir processing leads to the elimination of dislocations, which indicates that the effect of work hardening has disappeared after the recrystallization.

Fig. 6 Metallographic images of brass sample

Fig. 7 Microhardness profiles of samples

According to the Hall-Patch equation, with grain refinement in the stirred zone, the hardness of this area is increased in comparison to the raw material. Fluctuations in the hardness profile of the samples were resulted from temperature changes. This temperature changes were as a result of vaporized water which produced thermal imbalance and impaired cooling of the water. Water vapor is caused by the evaporation of water in the vicinity of the hot spot. In the higher number of passes of the tool, for example, in samples of two, three, and five passes, it has increased the hardness, since the water cooling rate prevents the growth of dynamic re-crystalized grains resulting from the severe plastic deformation of the friction stir processing and also prevents the grain boundary movement and the local area for further nucleation and ultimately fine grains in the matrix structure are provided. Previous researches suggest that a higher tool rotational speed and lower tool transverse speed can be used to achieve a finer structure, or, in other words, to increase the hardness in processed samples. In this research, with a tool rotational speed of 1800 r/min and a tool transverse speed of 4 mm/min, high amount of heat was generated. By preventing the grain growth in the stirred zone, the hardness distribution of the processed samples is improved, and this phenomenon is particularly evident in the five-pass sample with an increase in its hardness.

3.5 Wear resistance

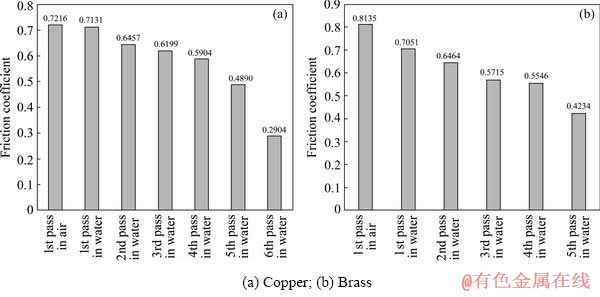

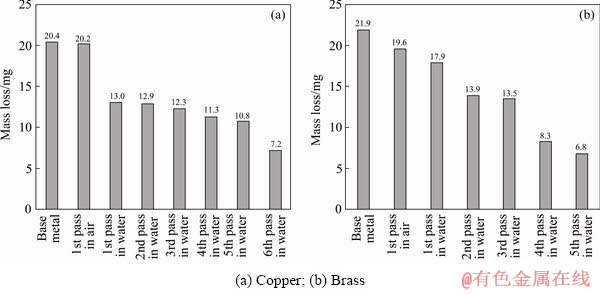

Due to the fact that the friction stir processing was done to reach the amorphous layer and improve the tribological properties of copper and copper alloy, the processed samples were subjected to wear test, and the results are reported in Figs. 8 and 9.

In all wear tests performed for all of the samples, after a slight sliding distance, the sliding reaches a steady state. In addition, through comparing the friction coefficient of samples, it was observed that the wear rate decreases with decreasing grain size, which can be attributed to the grain boundary strengthening and consequently to the stain hardening [24]. As the number of process passes increases, the amount of severe plastic deformation applied to the structure increases as well. On the other hand, by increasing the percentage of severe plastic deformation, the grain size decreased after recrystallization. The decrease in grain size observed in the metallographic images confirms this by increasing the number of process passes. At the same time, according to the Hall- Petch relationship, with decreasing grain size, the hardness and hence wear resistance increase. The reduction in the coefficient of friction or the amount of mass loss by increasing the number of process passes are according to this.

Improvement of abrasive behavior and reduction of friction coefficient have been reported by other investigators as a result of friction stir processing [25,26]. As the number of passes increases, the friction coefficient decreases, which is due to the grain refinement, especially in the sample of six passes of copper and the sample of five passes of brass. Homogeneous particle distribution reduces friction coefficient in higher passes during wear test. The analysis shows that the wear properties of copper and brass were improved, and in the sample of six passes of copper and five passes of brass, the abrasive properties were improved considerably.

Fig. 8 Friction coefficients of samples

Fig. 9 Mass losses of samples

4 Conclusions

(1) Underwater friction stir processing increases the heat transfer rate and reduces the temperature of the unit, which prevents the re-crystallization process in the severely cold- worked structure. It reduces the size of the grain and increases the wear resistance, hardness, and ductility.

(2) The presence of zinc alloying element in the proportion of 37.4 wt.% in brass alloys improves the production of amorphous/ultrafine layer. Therefore, the amount of amorphous/ultrafine phase in brass samples is higher than that in pure copper samples.

(3) The implementation of frictional stir processing by creating an amorphous/ultrafine structure and reducing dislocations leads to an increase in the hardness up to HV 125 in a five-pass brass sample.

(4) As for copper samples with an initial hardness of HV 60, when subjected to the friction stir process in the water, due to the decrease in grain size in the microstructure of the stirred area, its hardness is increased to HV 65 and has a friction coefficient of 0.7131. By increasing the number of process passes to 3, the hardness is increased to HV 100 and the friction coefficient decreases to 0.6199. This increase in hardness and decrease in friction coefficient can be attributed to the decrease in mean grain size in the stirred area. However, increasing the number of process passes to 6 also reduces the coefficient of friction to 0.2904.

(5) Similarly, for the brass sample, after the first pass the hardness increased from HV 75 to HV 103 and the coefficient of friction is 0.7051. By increasing the number of process passes to 6, the hardness and coefficient of friction are changed to HV 125 and 0.4234, respectively.

References

[1] GLEITER H. Nanostructured materials: Basic concepts and microstructure [J]. Acta Materialia, 2000, 48(1): 1-29.

[2] ZHAO Yan, WEI Xun-li, ZHANG Yan, WANG Jia-chun, HUO De-hong. Crystallization of amorphous materials and deformation mechanism of nanocrystalline materials under cutting loads: A molecular dynamics simulation approach [J]. Journal of Non-Crystalline Solids, 2016, 439: 21-29.

[3] MA Z Y. Friction stir processing technology: A review [J]. Metallurgical and Materials Transactions A, 2008, 39(3): 642-658.

[4] SUDHAKAR M, SRINIVASA RAO Ch, MEERA SAHEB K. Production of surface composites by friction stir processing—A review [J]. Materials Today: Proceedings, 2018, 5(1): 929-935.

[5] SHARMA V, PRAKASH U, MANOJ KUMAR B V. Surface composites by friction stir processing: A review [J]. Journal of Materials Processing Technology, 2015, 224: 117-134.

[6] WANG Kuai-she, WU Jia-lei, WANG Wen, ZHOU Long-hai, LIN Zhao-xia, KONG Liang. Underwater friction stir welding of ultrafine grained 2017 aluminum alloy [J]. Journal of Central South University, 2012, 19(8): 2081-2085.

[7] ZHANG Hui-jie, LIU Hui-jie, YU Lei. Thermal modeling of underwater friction stir welding of high strength aluminum alloy [J]. Transactions of Nonferrous Metals Society of China, 2013, 23(4): 1114-1122.

[8] FARROKHI H, HEIDARZADEH A, SAEID T. Frictions stir welding of copper under different welding parameters and media [J]. Science and Technology of Welding and Joining, 2013, 18(8): 697-702.

[9] ZHANG Jing-qing, SHEN Yi-fu, YAO Xin, XU Hai-sheng, LI Bo. Investigation on dissimilar underwater friction stir lap welding of 6061-T6 aluminum alloy to pure copper [J]. Materials and Design, 2014, 64: 74-80.

[10] IKRAM I M, ISMAIL A, ZAKARIA A, AWANG M, ROJAN M A, HAMID D A, MAKHTAR M F, SAID M T S M. A preliminary experimental study of underwater friction stir welding AA5083 plate butt joint [J]. Journal of Environmental Science and Technology, 2016, 9(6): 462-466.

[11] PATEL V V, BADHEKA V, KUMAR A. Friction stir processing as a novel technique to achieve superplasticity in aluminum alloys: Process variables, variants, and applications [J]. Metallography, Microstructure, and Analysis, 2016, 5(4): 278-293.

[12] WAHID M A, SIDDIQUEE A N, KHAN Z A, MAJEED T, SHARMA N. Friction stir welding of AA-5754 in water and air: A comparative study [J]. Materials Research Express, 2018, 6(1): 016545.

[13] WAHID M A, KHAN Z A, SIDDIQUEE A N, SHANDLEY R, SHARMA N. Analysis of process parameters effects on underwater friction stir welding of aluminum alloy 6082-T6 [J]. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 2018: 095440541878998.

[14] WAHID M A, SIDDIQUEE A N, KHAN Z A, SHARMA N. Analysis of cooling media effects on microstructure and mechanical properties during FSW/UFSW of AA 6082-T6 [J]. Materials Research Express, 2018, 5(4): 046512.

[15] WAHID M A, KHAN Z A, SIDDIQUEE A N. Review on underwater friction stir welding: A variant of friction stir welding with great potential of improving joint properties [J]. Transactions of Nonferrous Metals Society of China, 2018, 28(2): 193-219.

[16] SRIVASTAVA M, RATHEE S, MAHESHWARI S, SIDDIQUEE A N. Investigation on underwater FSP of Al-Mg-Si alloy surface composites [J]. Materials Research Express, 2018, 6(2): 026520.

[17] YANG Kang, LI Wen-ya, HUANG Chun-jie, YANG Xia-wei, XU Ya-xin. Optimization of cold-sprayed AA2024/Al2O3 metal matrix composites via friction stir processing: Effect of rotation speeds [J]. Journal of Materials Science and Technology, 2018, 34(11): 2167-2177.

[18] PATEL V, LI W Y, VAIRIS A, BADHEKA V. Recent development in friction stir processing as a solid-state grain refinement technique: Microstructural evolution and property enhancement [J]. Critical Reviews in Solid State and Materials Sciences, 2019, 44(5): 378-426.

[19] YAZDIPOUR A, SHAFIEI M A, DEHGHANI K. Modeling the microstructural evolution and effect of cooling rate on the nanograins formed during the friction stir processing of Al5083 [J]. Materials Science and Engineering A, 2009, 527(1): 192-197.

[20] PATEL V, LI Wen-ya, LIU Xi-chang, WEN Quan, SU Yu. Through-thickness microstructure and mechanical properties in stationary shoulder friction stir processed AA7075 [J]. Materials Science and Technology, 2019, 35(14): 1762-1769.

[21] PATEL V, LI Wen-ya, XU Ya-xin. Stationary shoulder tool in friction stir processing: A novel low heat input tooling system for magnesium alloy [J]. Materials and Manufacturing Processes, 2018, 34(2): 177-182.

[22] ABBASI M, GIVI M, BAGHERI B. Application of vibration to enhance efficiency of friction stir processing [J]. Transactions of Nonferrous Metals Society of China, 2019, 29(7): 1393-1400.

[23] CHEN Yu, DING Hua, MALOPHEYEV S, KAIBYSHEV R, CAI Zhi-hui, YANG Wen-jing. Influence of multi-pass friction stir processing on microstructure and mechanical properties of 7B04-O Al alloy [J]. Transactions of Nonferrous Metals Society of China, 2017, 27(4): 789-796.

[24] WANG Yun-peng, FU Rui-dong, JING Lei, LI Yi-jun, SANG De-li. Grain refinement and nanostructure formation in pure copper during cryogenic friction stir processing [J]. Materials Science and Engineering A, 2017, 703: 470-476.

[25] BARENJI R V, KHOJASTEHNEZHAD V M, POURASL H H, RABIEZADEH A. Wear properties of Al-Al2O3/TiB2 surface hybrid composite layer prepared by friction stir process [J]. Journal of Composite Materials, 2015, 50(11): 1457-1466.

[26] JANBOZORGI M, SHAMANIAN M, SADEGHIAN M, SEPEHRINIA P. Improving tribological behavior of friction stir processed A413/SiCp surface composite using MoS2 lubricant particles [J]. Transactions of Nonferrous Metals Society of China, 2017, 27(2): 298-304.

A. MOAREF1, A. RABIEZADEH2

1. Department of Mechanical Engineering, Shiraz Branch, Islamic Azad University, Shiraz, Iran;

2. Department of Materials Engineering, Shiraz Branch, Islamic Azad University, Shiraz, Iran

摘 要:对工业纯铜(纯度99.8%)和铜锌合金(黄铜)进行水下搅拌摩擦加工。搅拌摩擦加工的刀具呈螺纹锥状,由碳化钨制成,其转速为1800 r/min,横移速度为4 mm/min,将试样浸泡在带循环系统的水箱中。为了评估加工次数对样品显微组织和力学性能的影响,进行6道次加工。采用光学显微镜对商业纯铜样品的显微组织进行研究,结果表明,加工后材料的晶粒尺寸明显减小。同时,样品横截面的硬度较母材增高。水下搅拌摩擦加工样品的X射线衍射谱与母金属的相比,其峰值更短、更宽,谱的背景增大,表明形成非晶/超细晶组织。采用针-盘法对试样的磨损行为进行研究,结果表明,与母材相比,加工后试样的摩擦因数降低。磨损和硬度试验结果表明,水下搅拌摩擦加工可显著提高工业纯铜和黄铜的耐磨性和硬度。

关键词:铜合金;搅拌摩擦加工;水下;磨损;显微组织

(Edited by Bing YANG)

Corresponding author: A. RABIEZADEH; Tel: +98-7136191632; E-mail: rabieezadeh@iaushiraz.ac.ir

DOI: 10.1016/S1003-6326(20)65269-4