Thixocasting combination spanners using stainless steel X39CrMo17

来源期刊:中国有色金属学报(英文版)2010年第z3期

论文作者:M. BüNCK E. SUBASIC A. BüHRIG-POLACZEK K. JIANG S. MüNSTERMANN J. M. SCHNEIDER K. FICKERT H. J. GüNTHER

文章页码:998 - 1004

Key words:thixocasting; X39CrMo17 steel; casting; semi-solid; MAGMAsoft; simulation

Abstract: Forging is state-of-the-art for producing hand tools on an industrial scale. Due to high demands on the stiffness and the fracture toughness, high-strength forging steels were used to provide cavity-free components with high mechanical load capacity. Moreover, forging is a cost-effective mass production process but, in spite of all its advantages, it has its limitations, e.g. in the freedom of designs. However, because of the extreme thermal loading (particularly with regard to permanent moulds) and the frequently unavoidable casting defects, hand tools are not cast. By means of thixocasting steel, technical difficulties can be reduced and new options are provided which allow the manufacturing of components with much higher complexity than that using forging. Through near-net shape production, manufacturing steps and costs can be reduced. Furthermore, steels, which are difficult to forge but nonetheless have high potential for specific applications (such as high strength or corrosion resistant steels), can also be processed. In cooperation with industrial partners, X39CrMo17 stainless steel combination spanners with 17 mm width across flats were thixocast. Forming dies were designed and optimized by simulation, the hot forming X38CrMoV5 tool steel as well as the molybdenum alloy TZM were selected as the tool alloys. The dies were treated by a plasma nitriding process and subsequently coated with crystalline Al2O3 protective coatings by plasma-enhanced chemical vapor deposition (PECVD). During the experiments, combination spanners were successfully cast in the semi-solid state. Cast parts were heat-treated to enhance the toughness of components, which was subsequently measured by a standardized torque test. Moreover, a hypothetical approach of a possible, industrial batch process was carried out using the simulation software MAGMAsoft.

Trans. Nonferrous Met. Soc. China 20(2010) s998-s1004

M. B?NCK1, E. SUBASIC1, A. B?HRIG-POLACZEK1, K. JIANG2, S. M?NSTERMANN2, J. M. SCHNEIDER2, K. FICKERT3, H. J. G?NTHER4

1. Foundry Institute at RWTH Aachen University, Aachen, Germany;

2. Materials Chemistry at RWTH Aachen University, Aachen, Germany;

3. HAZET - Hermann Zerver GmbH & Co. KG, Remscheid, Germany;

4. PlaTeG GmbH, Siegen, Germany

Received 13 May 2010; accepted 25 June 2010

Abstract: Forging is state-of-the-art for producing hand tools on an industrial scale. Due to high demands on the stiffness and the fracture toughness, high-strength forging steels were used to provide cavity-free components with high mechanical load capacity. Moreover, forging is a cost-effective mass production process but, in spite of all its advantages, it has its limitations, e.g. in the freedom of designs. However, because of the extreme thermal loading (particularly with regard to permanent moulds) and the frequently unavoidable casting defects, hand tools are not cast. By means of thixocasting steel, technical difficulties can be reduced and new options are provided which allow the manufacturing of components with much higher complexity than that using forging. Through near-net shape production, manufacturing steps and costs can be reduced. Furthermore, steels, which are difficult to forge but nonetheless have high potential for specific applications (such as high strength or corrosion resistant steels), can also be processed. In cooperation with industrial partners, X39CrMo17 stainless steel combination spanners with 17 mm width across flats were thixocast. Forming dies were designed and optimized by simulation, the hot forming X38CrMoV5 tool steel as well as the molybdenum alloy TZM were selected as the tool alloys. The dies were treated by a plasma nitriding process and subsequently coated with crystalline Al2O3 protective coatings by plasma-enhanced chemical vapor deposition (PECVD). During the experiments, combination spanners were successfully cast in the semi-solid state. Cast parts were heat-treated to enhance the toughness of components, which was subsequently measured by a standardized torque test. Moreover, a hypothetical approach of a possible, industrial batch process was carried out using the simulation software MAGMAsoft.

Key words: thixocasting; X39CrMo17 steel; casting; semi-solid; MAGMAsoft; simulation

1 Introduction

Due to forming wear caused by the high temperature casting of steels in permanent moulds, steel is not currently industrially processed in high-pressure die casting. However, research into the high pressure die casting of steel with solid fractions up to 70%, which clearly lowers the processing temperatures with distinctly smaller reactivity, demonstrate a very high material and component potential[1-4]. Hence, components can be manufactured using only one process step with respect to a multistage forging procedure in thixocasting: this can lead to enormous reductions in costs. On the laboratory scale, complex cast parts have already been successfully manufactured with excellent surface quality in near net shapes without using complicated processes. The work presented here was carried out within the context of a government-funded thixoforming project with the aim of investigating the transferability of the results of previous research, principally obtained from cast parts and real components with close-to-production boundary conditions, to the industrial scale[5]. For this reason, the Foundry Institute and Material Chemistry Department of the RWTH Aachen University collaborated with the manufacturer of premium hand tools HAZET and the manufacturer of coating plants PlaTeG.

Currently, premium hand tools are manufactured solely by forging, using only a few suitable steel grades. When selecting new steels, particular attention must be paid to sufficient fracture toughness. Owing to the risk of injury, a sufficient deformation must precede component failure, i.e. if hand tools are used inappropriately. Brittle fracture always entails the danger of injuries from flying fragments. By implication, forged steels cannot be used for thixocasting since the process windows for induction reheating and their very high melting points, caused by low alloy and in particular low carbon contents, are mainly disadvantageous. Therefore, steel must be selected, which is particularly suitable for thixocasting but which nevertheless exhibits the demanded fracture toughness. The special advantage of hand tools made from stainless steel, as for example X39CrMo17, is that the pollution resulting from expensive chrome plating can be avoided. The X39CrMo17 steel is normally used in armatures, pumps and compressors, as well as for the production of surgical instruments. In the tempered condition, it features tensile strengths up to 950 N/mm2 and an elongation to fracture of approximate 12 %, which suggests high fracture toughness. With regard to the economics of thixocasting, the ready availability of X39CrMo17 on the market is beneficial. Moreover, no special thixo material must be manufactured since the billets from conventional hot-rolled round bars form globular grains during reheating because nucleation is caused by high dislocation densities. This phenomenon is used e.g. in the SIMA (Strain Induced Melt Activated) process[6].

Oxide coatings, one type of hard-coating, are frequently employed to improve the wear and corrosion resistance of cutting tools[7]. Alumina (Al2O3), in particular the α-modification, is preferred for such purposes due to its high hardness and chemical stability[8]. However, industrial low temperature deposition processes for α-Al2O3-coatings, allowing for the use of metallic substrates, e. g. steel, are currently not available. Recently, the deposition of α-Al2O3 on small and medium-sized steel substrates at temperatures as low as 560 °C, below the tempering temperature of most ferrous alloys, via plasma-enhanced chemical vapor deposition (PECVD) has been reported[9-10]. This non-directional coating technology permits the coating of geometrically complex substrates having grooves with high aspect ratios that cannot be coated via physical vapor deposition (PVD)[11]. Coated tools and tool segments performed well in various thixoforming experiments despite the harsh load profile acting on the dies[12-13]. However, large complex shaped thixo- forming moulds have previously not been deposited by using an industrial scale reactor. Here, the thixocasting performance of such coated tools was investigated.

As a demonstration for thixocasting hand tools, a combination spanner with 17 mm width across flats was chosen since this, on the one hand, features technological challenges for casting, such as long flow paths, but on the other hand, is closely comparable with forgings by a standardized torque test. Tensile and impact tests were carried out in preceding examinations. After heat treatment high strength over 1 600 MPa and elongations to fracture of about 2 % were measured. Unfortunately, very low fracture toughness, tested by Charpy-V impact tests, indicates that the steel is unsuitable for the use as hand tool material. In this regard, torque tests on thixocast and on forged combination spanners were carried out and compared.

In the preceding research, in particular α-Al2O3- coated steel as well as α-Al2O3-coated molybdenum basis alloy TZM (alloyed) with 0.5% titan, 0.08% and 0.03% zirconium carbon appeared to be just as promising[5]. The suitability of both materials has been examined within the context of this present work.

2 Experimental

In order to thixocast new steels, generally, the inductive heating must first be adapted. In recent years, the so-called Shot Through Cartridge (STC) system has been developed at the Foundry Institute[5,14]. The configuration of the STC and its mode of operation are described elsewhere[15].

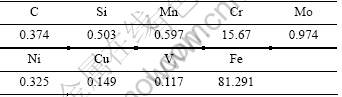

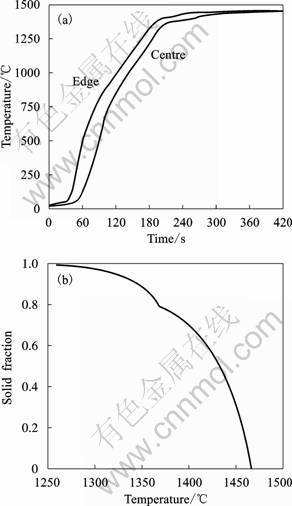

The reheating of the thixo-billets was accomplished in a horizontal induction device made by the company AEG Elotherm. In each case, the reheating lasted 420 s. Accordingly, the heating and the homogenization phases were adjusted with the aim of producing a homogeneously heated billet. Fig.1 demonstrates the success of this method. The measured temperatures at the billet center and edge converge during the heating and homogenization phases and coincide after 420 s. Fig.1 shows the solid fraction as a function of the temperature computed using ThermoCalc using TCFE 4 database. For the ThermoCalc computation, the initial material was analyzed by means of a spectrometer type SpectromaxX. Table 1 lists the average values of 10 measurements. After 420 s, the billet reaches a casting temperature of 1 453 °C which, according to ThermoCalc, corresponds to a solid fraction of 35 %. The semi-solid condition of the reheated precursor material was examined qualitatively with a slitter test. Slitting resistance and surface quality of the billet provide information regarding the thixo condition. The evaluation takes place on the basis of empirical values.

Table 1 Composition of X39CrMo17 precursor material (average values from 10 measurements)(mass fraction,%)

Fig.1 Measured temperatures (a) in center and edge during reheating of X39CrMo17 billet (left hand side) and fraction solid (b) vs temperature (computed with ThermoCalc)

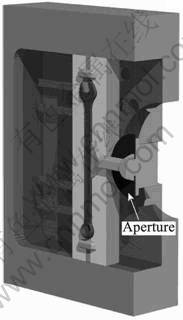

In order to test the two most promising materials TZM (molybdenum + 0.5% titanium, 0.08% zirconium, 0.03% carbon) and X38CrMoV5, which were both α-Al2O3 coated by PlaTeG GmbH, Siegen, Germany using a PECVD process specifically designed on the basis of a laboratory process developed at Materials Chemistry, RWTH Aachen University[9,16], the die was designed as two rotationally symmetric parts (Fig.2).

Details of the PECVD-reactor construction, process parameters, and coating properties are given elsewhere[16]. The dies’ coating thickness was measured to be 3.3±0.5 ?m, including the edges. A visual inspection revealed no spallation or coating defects. Phase analysis using X-ray diffraction (XRD) revealed significant amounts of α-Al2O3 as well as α-Al2O3 as constituents.

When thixocasting steel, it is particularly necessary to strip the scaled shell off the heated billet so that no oxides and insulation fibers are carried into the cast part during the mould filling. For this purpose, the billet is pressed through an aperture, consequently only the interior of the billet enters the cast part (Fig.2). Since the aperture is subjected to maximum stress caused by the heat energy and the shrinkage of the solidifying steel, it is recommended that the apertures are designed to be disposable. A practical solution is the use of apertures made from steel sheet (3 mm low alloyed steel was used here). Hence, no complex core slider technology is necessary. Moreover, the disposable-aperture controls the heat balance. On the one hand, it withdraws energy from the semi-solid steel, by which the die is protected from damage. On the other hand, if the aperture is heated, it functions as a hot runner, so that flow lengths are improved.

Fig.2 Schematic drawing of cover die section with cast part and aperture

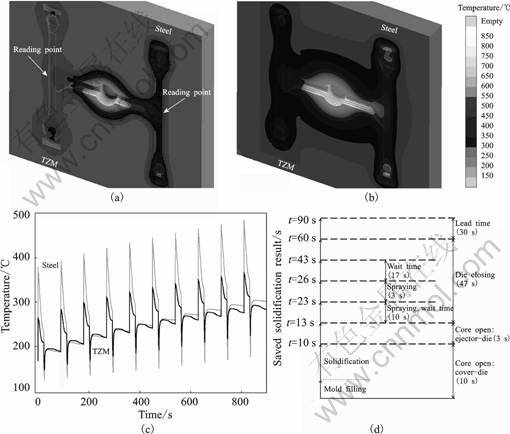

3 FDM simulation

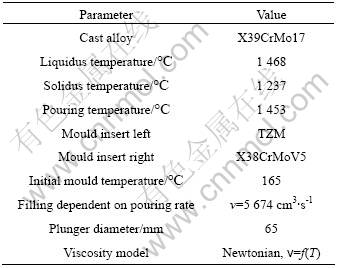

Before starting the casting experiments, the form filling and solidification of the cast parts were simulated using the thixo-module of the commercial casting simulation software MAGMAsoft. Among other things, this software provides information about shrinkage and the cooling behavior. The simulation parameters are given in Table 2. Besides the preliminary simulation for the casting experiments, which is described elsewhere[15], a hypothetical approach of a possible batch process was carried out using the same casting parameters. The process steps of the batch cycles are presented in Fig.8(c). As batch time for the hypothetical approach of a possible industrially scaled process, 90 s was chosen. Ten cycles were simulated. Virtual thermocouples were applied in TZM and steel inserts to compare the temperature history during the 10 process cycles.

Table 2 Simulation parameters

4 Casting experiments

After setting-up the high-pressure die-casting machine, all casting experiments were carried out using the same parameters. One of the main aims was the load test of the coated die inserts. The form filling took place at a constant speed of 0.8 m/s, whereby a maximum metal speed of about 35 m/s in the component resulted (data taken from MAGMAsoft). At this metal speed, no segregation was observed in the wake of the sponge effect[10]. In each case, the cast parts were fully formed after 7 s without any problems. The solidification time should always be as short as possible since this distinctly reduces the form’s load. Due to the comparatively long reheating phase of 420 s, the manual packing of the billets as well as the optical evaluation phase of the cast parts after each shot, the casting cycle was approximate 15 min in each case. Owing to the limits of the heater-cooler units, the dies were tempered by means of oil to a maximum of 165 °C. It is assumed that a higher die temperature is advantageous for the tool life since the thermal shock load is reduced. Commercial Al2O3-coated ejectors were used for both the steel and the TZM die inserts. Notwithstanding a thermal expansion value twice that of steel (αTZM≈7×10-6 K-1, αsteel≈13×10-6 K-1 between 20 and 700 °C), these ejectors led to no problems. In an initial series of tests, 10 cast parts were manufactured prior to plunger failure. The reason for the failure was the fact that the plunger did not translate the billet completely into the shot sleeve, and a small part remained in the cartridge. The water-cooled piston moved over the still semi-solid metal. Due to the resulting rapid solidification, very hard martensite fragments are produced. During the plunger’s reciprocating movement, these fragments were embedded into the plunger’s surface thus damaging the plunger. In the meantime, further basic experiments showed a suitable solution for this problem. By using a bigger shot sleeve with a plunger-diameter of 85 mm, the cartridge could be pressed together with the semi-solid billet. Due to the aperture the cartridge is separated from the SSM and stripped into the biscuit. First investigations show very promising results.

All components exhibit very good cast surfaces. The combination spanners show almost no tarnishing. This results from the high cooling rates and despite this, the cavity was filled completely. The combination spanners produced from the steel side tarnish slightly more than those from the TZM side. This was expected from the simulation due to the higher heat conductivity of TZM. Fig.3 shows a representative, finished and polished cast part.

Fig.3 Thixocast X39CrMo17-combination spanner (finished and polished; no chrome plating is necessary)

Owing to the high cooling rates, the cast steel partially forms martensite which leads to a high hardness value. For this reason, a hardening-processing step, which is necessary after forging, can be potentially omitted thus reducing costs.

In order to determine the mechanical properties, some finished combination spanners were tested in a standardized torque test. Metallographic samples were taken from a small number of combination spanners.

5 Results and discussion

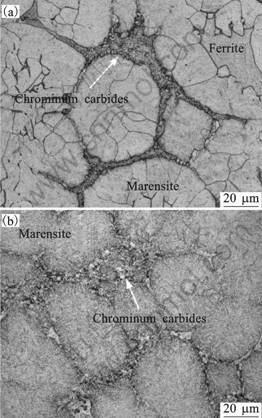

The etched samples exhibit a very fine, globular microstructure (see Fig.4).

At regions of high flow velocity, a shell formed from liquid melt was found, which is formed in the wake of the Magnus-effect and is typical for thixocasting ([14]). Advantages of the shell, which is mainly formed by the liquid phase, are the outstanding surface quality and reproduction of accuracy as well as its good burnishing properties (see. Fig.3).

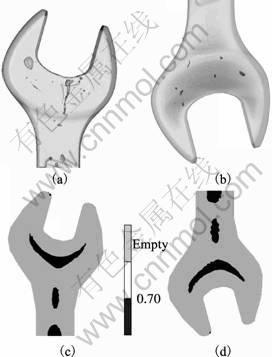

As expected, internal shrinkage occurs in the regions of material aggregation (Fig.5). However, further casting defects are not observed. Microhardness investigations of the phases clearly identify martensite (Fig.4). Whether at the edge or in the center, nearly all globules exhibit a ferrite core and a martensitic shell, which is verified by means of its hardness and EBSD. This microstructure results from the inductive heating and the subsequent quenching during the casting process. When X39CrMo17 billets are heated to 1453 °C, δ-ferrite-globules form. During solidification following casting, these δ-ferrite-globules form austenitic shells due to the decreasing temperature (Fig.5) and the austenite subsequently transforms into martensite at the Mf-temperature (Mf = martensite formation). Inside some globules, insular martensitic regions can be observed due to a partial transformation of ferrite into austenite which finally transforms into martensite. Moreover, chromium carbides, verified with SEM, form during the solidification of the liquid phase (Fig.4(a)). The ferrite was almost totally transformed into austenite during austenitization and subsequently transformed completely into martensite, which can be seen from Fig.4b. Thus the hardening appears to be successful.

Fig.4 Micrographs of thixocast X39CrMo17-samples taken from combination spanners: (a) As-cast microstructure: using EBSD, globule cores could be identified as ferrite; (b) Microstructure after heat treatment: ferrite was totally transformed into martensite

To improve the mechanical properties, five combination spanners were heat treated. Before heating the samples to the austenitizing temperature of 1020 °C in three steps (2 min, 400 °C; 2 min, 650 °C and 2 min, 850 °C), a soft-annealing at 820 °C under vacuum was accomplished. This was necessary because of the difficult machinability of the combination spanners. After 18 min austenitizing, the samples were quenched in compressed air and afterwards tempered at 575 °C for 3 h. The mechanical properties were then measured from torque tests (DIN ISO 1711-1). All tested combination spanners passed the DIN standard of 107 N. The deformation resistance of the thixocast samples was always as high as that of the forged samples (240 N). Unfortunately, due of the low cracking resistance of X39CrMo17 in the thixocast condition, brittle fracture results at about 280 N, whereas the forged samples did only deform at a force of about 290 N but not crack (Fig.6).

Fig.5 Results of CT scans (a, b) and MAGMAsoft? simulations (Niyama criteria, c, d): shown orientation of jaws equates to casting position; accordingly, gravity affects morphology of shrinkage holes (a)

Fig.6 Cracking behavior during torque-test of forged combination spanner (a, b) and thixocast combination spanners (c, e): (a), (c) Distortions at jaw; (b) Widening of jaw, no cracking; (d) Brittle fracture at shank; (e) Brittle fracture at jaw

As previously mentioned, part-ejection after thixocasting proved to be effortless, indicating negligible adhesion of the as-cast parts to the mould surface. Excellent surface quality of the cast combination spanners was observed (Fig.3) whilst the die tool coatings remained macroscopically undamaged following 10 shots (Fig.7).

Fig.7 Optical survey of coated steel dies’ surfaces before first casting (a), after 10 shots (b), no abrasion is observable

Tool examination after use revealed a thinning of the coating at sharp edges within the cavity that were exposed to both high thermal stresses as well as high flow stresses during mould filling[16].

6 Simulation of industrial batch process

The results from the simulations are shown in Fig.8. During 10 cycles the temperature of the inserts rises continuously. After the 10th cycle a steady state is almost reached. This can be derived from the flattening of the envelope. Due to an almost four times higher heat conductivity than the steel X38CrMoV5 (about 30 W/mK at 20 °C and 33 W/mK at 700 °C) TZM heats from 260 to maxima of 370 °C (Fig.8(b)) Accordingly, the steel temperature rises from 380 to 480 °C, which are critical values, due to possible softening effects. Regarding this, either the cooling of the inserts must be improved or the cycle times must be reduced.

Particularly in the range of the biscuit, the dies are extremely loaded by temperatures over 1 000 °C so that an additional cooling is indispensable in this die area. Alternatively, a special insert for the gating system must be manufactured from high heat resistant materials, for example from TZM or ceramic. Nonetheless, a well-thought-out heater-cooler system is also in this case necessary, to reduce thermo-shocks significantly.

Fig.8 Results from MAGMAsoft? simulation, regarding a conceivable, feasible batch process: (a,b) Temperature distribution after one and ten cycles; (c) Temperature curves of die-heating (reading points in (a)); (d) Process steps during one cycle

7 Conclusions

Regarding reproduction accuracy, surfaces as well as the mechanical properties, the quality of the cast parts is very good. Unfortunately, the fracture toughness is too low for the use as hand tool material.

The micrographs of X39CrMo17 show very fine globules, thus segregation can be avoided to a large extent. However, due to the high hardness, the cast parts are difficult to machine. For this reason, near net shape casting to reduce the finishing costs is of utmost importance.

Due to the coatings, the dies exhibit a distinctly increased resistance to the SSM (semi solid metal). Slight wear could be discerned only at the edges and corners. These are promising results. Additional combination spanners are to be thixocast using X39CrMo17 and other preselected steels assumed to possess high fracture toughness. A separate test series for casting at least 100 parts is planned for investigating the durability of the coated dies.

Moreover, the thixocast combination spanners will be heat-treated, tested using a standardized torque test and compared to series forged spanners. In this regard, the influence of the die material (steel or TZM) will be analyzed; notwithstanding this, TZM dies will not be tested in the near future.

To implement a manufacturing process on industrial scales, it is absolute necessary, to use a well-thought-out heater-cooler system. In this case, cycle times of less than 2 min seem to be possible. Particularly in the range of the biscuit, a high heat resistant material should be used, regarding naturally the thermo-shock load.

Acknowledgements

The authors thank the German Research Foundation (DFG), which supports this work within the framework of the collaborative research centre SFB 289.

References

[1] FlemingsM C, YoungK P. Thixocasting of stee [C]//9th SDCE International Die Casting Exposition an Congress, 1977: 1-8.

[2] BramannH, AfrathC, FehlbieRM, Bührig- PolaczekA. Casting of cold work steel alloy in semisolid state [J]. Journal of Materials Processing Technology, 2004, 55/56:155-156.

[3] BramannH, GrimmigT, AfrathC, FehlbierM, Bührig-PolaczekA. Casting of high alloy steels in the mushy state [J]. Steel Research International, 2004, 8/9: 537-544.

[4] HirtG, BelckW, Bührig-PolaczekA, ShimaharaH, PüttgenW, AfrathC. Semi solid casting and forging of steel [C]//. Proceedings of 9th International Conference on Semi-Solid Processing of Alloys and Composites. Pusan, 2006: 34-44.

[5] HirtG, KoppR. Thixoforming–Semi-solid metal processing [M]. Wiley-VCH, 2009.

[6] ChoiJ C, ParkH J. Microstructural characteristics of aluminium 2024 by SIMA process and effect of cold working [C]// Proceedings of the 5th International Conference of Semi-Solid Processing of Alloys and Composites. 1998: 457-464.

[7] AstrandM, SelinderT I, FietzkeF, KlostermanH. PVD-Al2O3-coated cemented carbide cutting tools [J]. Surf Coat Technol, 2004, 188/189: 186.

[8] KramerB M, JuddP K. Computational design of wear coatings [J]. Journal of Vacuum Science & Technology and Vacuum Surfaces and Films 1985, 3: 2439-2444.

[9] KYRYLOVO, KURAPOVD, SCHNEIDERJ M. Effect of ion irradiation during deposition on the structure of alumina thin films grown by plasma assisted chemical vapour deposition [J]. Applied Physics A, 2005, 80: 1657-1660.

[10] SnydersR, JiangK, MusicD, KonstantinidisS, MarkusT, ReinholdtA, MayerJ, SchneiderJ M. Composition-constitution-morphology relationship of Al2O3 thin films deposited by plasma assisted chemical vapor deposition [J]. Surf Coat Technol, 2009, 204: 215-221.

[11] SuryanarayanaC. Non-equilibrium processing of materials, Pergamon, 1999.

[12] KoppR, ShimaharaH, SchneiderJ M, KurapovD, TelleR, MunstermannS, LugscheiderE, BobzinK, MaesM. Characterization of steel thixoforming tool materials by high temperature compression tests [J]. Steel Research International, 2004, 75: 569-576.

[13] KurapovD, SchneiderJ M. Adhesion and thermal shock resistance of Al2O3 thin films deposited by PACVD for die protection in semi-solid processing of steel [J]. Steel Research International, 2004, 75: 577-580.

[14] KütheF, AfrathC, BünckM, Bührig-PolaczekA. Neue M?glichkeiten-Druckgie?en von St?hlen im teilflüssigen Zustand, 2007, 1/2: 48-51.

[15] BünckM, SubasicE, Bührig-PolaczekA, JiangK, MünstermannS, SchneiderJM, FickertK, GüntherH J. Thixocasting steel hand tools using Al2O3-coated steel and molybdenum dies [J]. Steel Research International, 2010 (5): 81.

[16] Jiang K, M?NSHERMANN S, G?NTHER H J, SCHNEIDER J M. Up-scaling of low temperature PACVD process for the deposition of α/g-nanocrystalline alumina coaked tools for thixocasting of 1. 2208 steel [J]. Steel Research Int. 2010, 81(7): 597-602.

[17] GulloG C. Thixotrope Formgebung von Leichtmetallen-Neue Legierungen und Konzepte [D]. Technische Wissenschaften ETH Zürich, Nr. 14154, 2001.

(Edited by LI Xiang-qun)

Corresponding author: Matthias Bünck; Tel: +49-241-80-95887; E-mail: m.buenck@gi.rwth-aachen.de