文章编号:1004-0609(2010)S1-s0572-05

热处理制度对Ti-1300合金组织和力学性能的影响

葛 鹏,周 伟,赵永庆

(西北有色金属研究院,西安 710016)

摘 要:研究了Ti-1300钛合金d160 mm棒材经β相变点下固溶时效及β退火加时效热处理的性能与组织演变。结果表明:通过热处理,Ti-1300合金在高的强度水平下具有良好的塑性及韧性,并且显示出深淬透性的特征。当采用β相变点下固溶时效处理时,可获得如下力学性能:抗拉强度≥1 250 MPa,伸长率≥8%。当采用β退火随炉缓慢冷却加时效处理时,尽管强度较低,但可获得更高的韧性,并且棒材的横向和纵向性能没有明显的差别,通过调整热处理参数,可获得如下力学性能:抗拉强度≥1 100 MPa,伸长率≥8%,断裂韧性≥70 MPa?m1/2。

关键词:Ti-1300合金;固溶时效;β退火;强度

中图分类号:TG 146.3 文献标志码:A

Influence of heat treatment on microstructure and mechanical properties of Ti-1300 alloy

GE Peng, ZHOU Wei, ZHAO Yong-qing

(Northwest Institute for Nonferrous Metal Research, Xi’an 710016, China)

Abstract: The mechanical properties and microstructures of Ti-1300 titanium alloy rod with diameter of 160 mm after solution plus aging treatment and β annealing plus aging treatment were investigated. The results show that good ductility and toughness could be achieved for Ti-1300 rod at high strength level after heat treatment. The alloy also presents deep quenching characteristics. After solution plus aging treatment, such mechanical properties (ultimate tensile strength no less than 1 250 MPa, elongation no less than 8%) could be achieved. After β annealing plus aging treatment, the strength is relatively low; however, the toughness is improved and there is no obvious difference of properties between longitudinal and transverse directions. By adjusting the parameters of heat treatment, the ultimate tensile strength, elongation and fracture toughness no less than 1 100 MPa, 8% and 70 MPa·m1/2, respectively, could be achieved.

Key words: Ti-1300 titanium alloy; solution plus aging; beta annealing; strength

近β钛合金由于具有比强度高、淬透性好、热加工性能优良等特点在航空工业中获得了重要应用,可用作大型飞机的大规格高强结构件。Ti-1023、VT-22合金是其中应用最多的商业合金,一般用于1 000~ 1 200 MPa的强度水平,断裂韧性大多在45~60 MPa·m1/2,很难进一步提高其强韧性匹配[1-4]。然而,航空飞行器的发展对高强结构钛合金的韧性、疲劳性能及淬透性提出了更高的要求。近几年,国外对新型高强韧结构钛合金的研究非常重视,代表性的合金是在VT-22合金的基础上改进设计开发出的Ti-5553 (Ti-5Al-5Mo- 5V-3Cr-0.4Fe)[5-7]。2005年,波音和空客分别宣布了关于B-787和A350XWB机身起落架组件的材料变化,都计划用Ti-5553合金取代Ti-1023钛合金[8]。该类合金以飞机起落架高强结构件为应用目标时,一般需在合金的β相变点下固溶加时效(STA)处理,以保证合金的强塑性匹配[9-10]。出于提高结构服役可靠性和寿命的需要,成功开发出另一种适用于Ti-5553合金的β退火后缓慢冷却时效热处理制度。该状态的合金强度略低但具有更高的损伤容限特性[11]。Ti-1300合金是西北有色金属研究院针对航空大型结构件应用开发的新一代深淬透性高强钛合金,其应用目标同Ti-5553合金相似,因此,研究该合金热处理的组织与性能对其应用具有重要的意义。

1 实验

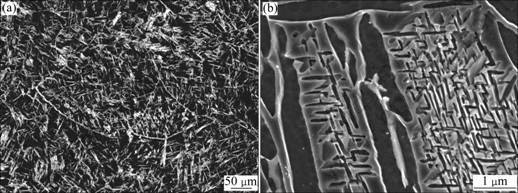

实验材料选用直径为160 mm的Ti-1300合金棒材。该棒材由真空自耗电弧3次熔炼的d 440 mm铸锭经β区开坯、α+β区锻造后获得,切取的棒样单段长度为200 mm。棒材加工态的组织如图1所示,原始晶界基本被破碎,晶内有较多的析出相存在。热处理在箱式电阻炉中进行,金相分析法表明:合金的β相变点在830 ℃左右。

图1 Ti-1300合金的锻态组织

Fig.1 Microstructure of as-forged Ti-1300 alloy

实验设定的β相变点下的固溶温度为760 ℃,β退火温度为870 ℃,保温时间为2.5 h。α+β固溶处理的棒样采用空冷和水冷两种方式,β退火后的棒样采用随炉冷却的方式。为了观察合金随炉冷却过程中的组织演变,从棒料上另切取金相试样用作分析。退火后的时效温度设定为540~570 ℃,时效时间为6 h。

金相样品的腐蚀剂为10% HF+30% HNO3+60% H2O。拉伸试样从热处理后的棒样上切取,分别取纵向和横向,其中横向样品取样位置在棒材R/2附近。拉伸试验在INSTRON1185万能拉伸机上进行。OM和SEM分析分别在OLYMPUS PMG3金相显微镜和JSML-6700扫描电子显微镜上进行。

2 结果与讨论

2.1 β相变点下固溶时效处理

表1列出Ti-1300合金棒材经760 ℃固溶加540 ℃时效后的拉伸性能。可以看出:该合金在相变点下固溶时效处理后可获得很高的强度水平,并且具有良好的塑性特征,尽管固溶后空冷的时效强化效果同水冷时效相比要略低一些,但其塑性更高。值得注意的是,不管固溶处理是采用空冷还是水冷,棒材各部位的强度差别都很小,说明该合金具有良好的淬透性。

2.2 β退火缓冷后时效处理

对于Ti-1300合金,β退火如果采用空冷,尽管可以通过控制时效温度获得合理的强塑性,但由于空冷速度对于构件的截面尺度有很大的依赖性,而实际构件的形状及截面具有较大的可变性,因此其适用范围较小;另一方面,飞行器对结构件的寿命及可靠性提出了越来越高的要求,这就需要结构件具有高的损伤容限特征并且其组织与性能具有良好的均一性。对于α+β型及近β型钛合金,在β区退火往往可以得到具有高疲劳裂纹扩展抗力及高断裂韧性,后随炉缓慢冷却可获得组织各向异性小、晶粒尺寸均匀的魏氏组织特征。这种状态的合金一般具有较高的断裂韧性,但由于其强化效应弱且对塑性不利,在现有的商业高强结构钛合金中尚未获得应用。Ti-1300合金含有较高含量的β稳定元素,因此具备了β退火缓冷后时效硬化的成分基础。图2中显示了Ti-1300合金试样以0.7

表1 Ti-1300合金棒材经760 ℃固溶加540 ℃时效处理后的拉伸性能

Table 1 Tensile properties of Ti-1300 rod after solution at 760 ℃ and aging at 540 ℃

图2 Ti-1300合金经870 ℃, 2.5 h炉冷到不同温度时的组织

Fig.2 Microstructures of Ti-1300 alloy after being annealed at 870 ℃ for 2.5 h and cooled to different temperatures in furnace: (a) 810 ℃; (b) 760 ℃; (c) 720 ℃; (d) 700 ℃; (e) 690 ℃; (f) 680 ℃

℃/min的冷却速度随炉冷却过程中的组织演变。当温度降低到810 ℃时,仅有少量的α相沿晶界及晶内的一些加工缺陷析出;当温度降低到760 ℃时,析出相明显增多并呈现针状,尽管析出α的比例不多但较均匀地分布于整个基体内;当温度继续降低时,α相的析出量进一步增多,并且呈现局域束状特征,无析出的区域越来越小。这种退火冷却过程中析出的α相对晶界及晶粒起到了一定程度的分割作用,可能有利于合金的塑性提高。

β退火后的出炉温度和后续的时效温度都会对合金的强韧性产生影响。从表2中性能数据可以看出:提高退火后的出炉温度或者降低后续的时效温度对于强化有利,但对于塑性的影响则相反。如图3所示,合金退火后保留的亚稳定β相在后续的时效过程中会析出次生α相。显然,出炉温度越高,合金中保留的亚稳定β相的量越多,时效后的强度就越高。而对于成分一定的亚稳定β相而言,时效温度越低,析出驱动力越大,且扩散能力降低,析出相的尺寸更加细小,时效的硬化效应提高,这符合钛合金时效强化的一般规律。对680 ℃出炉后550 ℃时效的样品进行了断裂韧性测试,其KIC值超过70 MPa?m1/2,显示出非常良好的韧性特征。结合该韧性水平下的强度和塑性指标,

表2 Ti-1300合金β退火缓冷时效后的力学性能

Fig.2 Mechanical properties of Ti-1300 alloy after β annealing+slow cooling+aging treatment

图3 Ti-1300合金β退火缓冷时效后的显微组织

Fig.3 Microstructures of Ti-1300 alloy treated by (870 ℃, 2.5 h, FC)→(700 ℃, AC)+(570 ℃, 6 h, AC)

该合金显示出比Ti-1023和VT-22合金更优的强韧性匹配。

3 结论

Ti-1300合金经β相变点下固溶时效处理后可在很高的强度水平下获得良好的塑性,尤其是采用空气冷却可保证较大截面尺寸的构件获得1 250 MPa以上的强度并且在不同截面位置显示出较小的差异,显示出合金深淬透性的特征。若采用β退火后随炉缓冷后时效处理,冷却过程中会析出较为粗大的片状α相,这种α相对晶界及晶内起到分割的作用,从而导致合金具有良好的塑性,而其强度则主要受出炉温度及附加时效温度控制,出炉温度越高或时效温度越低,合金的强度就越高。通过调节温度参数改变初生α相的分布、转变β相的体积比或转变β中析出相的尺寸,可以获得不同的性能组合。在1 100 MPa的强度水平下,其强韧性匹配超过Ti-1023和VT-22合金,与Ti-5553合金相当。

REFERENCES

[1] WILLIAMS J C, STARKE E A. Process in structural materials for aerospace systems [J]. Acta Materialia, 2003, 51: 5775-5799.

[2] BREWER W D, BIRD R K, WALLACE T A. Titanium alloys and processing for high speed aircraft [J]. Materials Science and Engineering A, 1998, 243: 299-304.

[3] BOYER R R, COTTON J D, CHELLMAN D J. Titanium for airframe applications: Present status and future trends [C]// L?TJERING G. ALBRECHT J. Ti-2003 Science and Technology. Germany: DGM, 2004: 2615-2626.

[4] BOYER R R. New titanium application on the Boeing 777 airplane [J]. Journal of Metals, 1992, 44(5): 23-25.

[5] FANNING J C, BOYER R R. Properties of TIMETAL 555—A new near-beta titanium alloy for airframes components [C]// L?TJERING G, ALBRECHT J. Ti-2003 Science and Technology. Germany: DGM, 2004: 2643-2650.

[6] JONES N G, DASHWOOD R J, JACKSON M, DYE D. β phase decomposition in Ti-5Al-5Mo-5V-3Cr [J]. Acta Materialia, 2009, 57: 3830-3839.

[7] JONES N G, DASHWOOD R J, JACKSON M, DYE D. Development of chevron-shaped precipitates in Ti-5Al-5Mo-5V- 3Cr [J]. Scripta Materialia, 2009, 60: 571-573.

[8] JONES N G, DASHWOOD R J, DYE D, JACKSON M. Thermomechanical processing of Ti-5Al-5Mo-5V-3Cr [J]. Materials Science and Engineering A, 2008, 490: 369-377.

[9] FANNING J C, NYAKANA S L, PATTERSON K M. Heat treatment, microstructure, and properties of TIMETAL 555s [C]// NINOMI M, AKIYAMA A, IKEDA M. Ti-2007 Science and Technology. Tokyo: The Japan Institute of Metals, 2008: 499-502.

[10] BOYER R R, SLATTERY K T, CHELLMAN D J, PHELPS H R. Recent titanium developments and applications in the aerospace industry. NINOMI M, AKIYAMA A , IKEDA M. Ti-2007 Science and Technology. Tokyo: The Japan Institute of Metals, 2008: 1255-1262.

[11] BRIGGS R D. Tough, high-strength titanium alloys: Methods of heat treating titanium alloys: US 20040250932 [P]. 2004-12-16.

(编辑 杨 兵)

基金项目:国家重点基础研究发展计划资助项目(2007CB613805);国家科技支撑计划资助项目(2007BAE07B01)

通信作者:葛 鹏;电话:029-86231078-414;E-mail: gepeng-1@163.com