DOI:10.19476/j.ysxb.1004.0609.2018.01.15

二次铝灰烧结制备钙铝黄长石/镁铝尖晶石复相材料

张 勇,郭朝晖,王 硕,肖细元,韩自玉,黄 博,聂云飞

(中南大学 冶金与环境学院,长沙 410083)

摘 要:以再生铝行业二次铝灰为主要原料,开展二次铝灰烧结制备钙铝黄长石/镁铝尖晶石复相材料的研究。热力学计算表明,二次铝灰添加氧化钙和氧化镁,理论上可以制备出钙铝黄长石/镁铝尖晶石复相材料。结果表明,当二次铝灰、氧化钙和氧化镁质量分数依次为70.80%、18.58%和10.62%,在1100~1500 ℃范围内,均能制备出钙铝黄长石/镁铝尖晶石复相材料;随烧结温度升高,钙铝黄长石/镁铝尖晶石复相材料纯度和结晶度明显提高,抗压强度呈升高趋势,显气孔率呈下降趋势。当烧结温度为1500 ℃时,所制备出钙铝黄长石/镁铝尖晶石复相材料显气孔率和抗压强度分别为33.87%和40.18 MPa。

关键词:二次铝灰;烧结;钙铝黄长石/镁铝尖晶石;复相材料

文章编号:1004-0609(2018)-01-0334-06 中图分类号:TF09 文献标志码:A

随金属铝、电解铝熔炼及铝合金生产规模不断扩大,铝灰产生量也不断增大。2008年,中国再生铝行业产生大约59.6万t铝灰,然而大部分铝灰并未充分回收,约95%未做安全处置而直接堆放[1]。铝灰中铝含量(质量分数)在10%~80%不等,如能经济有效地利用和治理铝灰,对实现铝二次资源的有效循环利用具有积极意义。由于铝灰来源不同,铝灰成分差异明显。电解原铝及铸造等不添加盐熔剂过程中产生的一次铝灰主要成分为金属铝和铝氧化物的混合物,铝含量可达15%~70%;经盐溶液处理回收一次铝灰或铝合金精炼产生的二次铝灰主要成分为氯化钠、氯化钾、氟化物、氧化铝和铝的混合物[2-3]。尽管二次铝灰中铝含量较一次铝灰低,二次铝灰中依然含有大量金属铝、氧化铝,以及一定量的镁铝尖晶石和氮化铝,直接堆放、填埋或作为路基材料受到雨水淋溶后不仅有可能造成环境污染,而且造成资源浪费,迫切需要找到一种高效、环境友好的综合利用途径解决二次铝灰的出路问题。

根据二次铝灰原料特点,可以稍加改变配料成分,将其制备耐火材料[4-5],实现其资源化利用。近年来,美国、日本等国相继开发以黄长石相结合高熔点相,制备既有耐火材料特质(高强度)、又能质量减轻的轻质耐火材料[6-7]。镁铝尖晶石(MgAl2O4或MgO·Al2O3)是一种熔点高(2135 ℃)、抗热震性好、抗冲击、电绝缘性能好、抗碱侵蚀能力强的镁铝氧化物材料[8-9]。黄长石(Melilite)是由含铝、镁、铁的硅酸钙/硅酸钠组成的硅酸盐类矿物中的一类矿物,化学成分通式(Ca, Na)2(Al, Mg, Fe)[(Al, Si)SiO7]。钙铝黄长石(Gehlenite,Ca2Al(Al, Si)O7)和镁黄长石(Akermanite,Ca2Mg(Si2O7))是黄长石族中两种重要矿物。黄长石密度小,热膨胀系数小,热导率低,尽管其熔点不高很少作为耐火材料主晶相,但有助于提高材料抗压强度和抗水化性能[10]。若能以二次铝灰为主要原料制备主晶相为镁铝尖晶石,结合相为黄长石的耐火材料,一方面可以减轻二次铝灰对环境的潜在危害,另一方面又可以拓宽耐火材料制备领域。本文作者以再生铝行业产生的二次铝灰为主要原料,采用氧化钙和氧化镁为调配剂,研究氧化钙和氧化镁加入量和烧结温度对制备钙铝黄长石/镁铝尖晶石复相材料物相和性能的影响,为二次铝灰资源化利用提供技术支撑。

1 实验

1.1 二次铝灰

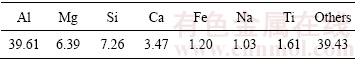

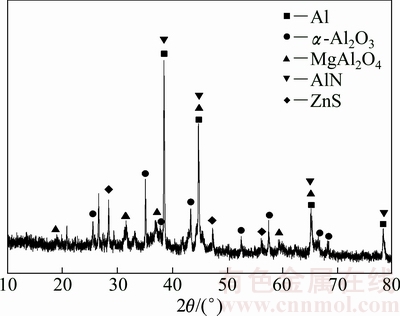

供试铝灰来自江西某铝业公司废铝熔炼工艺产生的二次铝灰。将供试铝灰置于刚玉研钵中磨细,过75 μm筛后保存备用。二次铝灰主要化学成分见表1。XRD分析进一步表明(图1),铝灰中主要物相为金属铝、刚玉、镁铝尖晶石,同时含有氮化铝等成分。对铝灰中含铝物相化学分析,金属铝占铝灰质量的23.67%,刚玉占铝灰质量的23.57%,镁铝尖晶石占铝灰质量的9.10%,氮化铝占铝灰质量的2.19%。

表1 二次铝灰化学成分

Table 1 Chemical compositions of secondary aluminum dross (mass fraction, %)

图1 二次铝灰XRD谱

Fig. 1 XRD pattern of secondary aluminum dross

1.2 实验设计

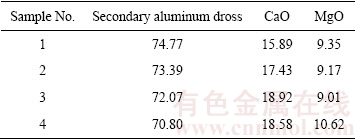

本实验温度范围设计为1100~1500 ℃。在此温度范围内,二次铝灰中铝主要以Al2O3存在[11-13],因此,后续体系中不再出现金属铝。在MgO-CaO-Al2O3-SiO2体系计算中,依据镁铝尖晶石中Al2O3/MgO理论质量比2.53,钙铝黄长石中Al2O3/CaO理论质量比0.91,结合二次铝灰原料中物质含量,设计二次铝灰、氧化钙和氧化镁原料配比。本研究共设计4种配料质量比例(样品1~样品4),具体配料质量分数见表2。

表2 样品配料比例

Table 2 Raw materials contents of samples (mass fraction, %)

在上述质量配比条件下,于1200 ℃烧结3 h,探究不同配比对钙铝黄长石/镁铝尖晶石复相材料物相影响。然后,根据适宜的原料配比,在不同温度(1100、1200、1300、1400和1500 ℃)烧结制备复相材料,进一步探讨烧结温度对复相材料性能的影响。具体操作如下:按照上述配料比例进行配料(具体试验中固定二次铝灰加入量,调控氧化钙和氧化镁质量),将混合物料置于强力振动混凝机混炼3 min,混炼物料外加3%聚乙烯醇(PVA)溶液作为粘结剂,采用半干成型法压制成型为圆柱试样,试样置于105 ℃烘箱干燥,试样恒重后置于设置温度管式烧结炉(合肥科晶GSL-1700X)中烧结,反应结束样品随炉自然冷却,取出物料待测。管式炉中心部分为刚玉管反应器,刚玉管中心为加热核心区域。

1.3 测试方法

铝灰元素及含量采用AXIOS型X荧光光谱仪(荷兰PANalytical生产)[14-15],含铝物相及含量采用化学物相分析,物相组成采用D/MAX 2500X型X射线衍射仪(日本理学公司生产)[16]。成型采用YLJ-40T压力机;显气孔率与体积密度采用阿基米德排水法(GB1996-80);抗压强度采用TYA-100C型电液式抗折抗压试验机。

2 结果与分析

2.1 MgO-CaO-Al2O3-SiO2体系生成钙铝黄长石/镁铝尖晶石热力学计算

根据热力学计算方法结合298 K物质热力学数据[17],该体系生成镁铝尖晶石和钙铝黄长石可能发生的反应方程式:

MgO+Al2O3=MgAl2O4 (1)

CaO·SiO2+CaO·Al2O3=Ca2Al2SiO7 (2)

1/2Al2O3+1/2CaO+SiO2=1/2CaAl2Si2O8 (3)

Al2O3+2CaO+SiO2=Ca2Al2SiO7 (4)

Al2O3+CaO+SiO2=CaAl2SiO6 (5)

1/3Al2O3+CaO+SiO2=1/3Ca3Al2Si3O12 (6)

Al2O3+2CaO+SiO2=Ca2Al2SiO7 (钙铝黄长石) (7)

由图2热力学计算表明,反应(1)~(7)的标准Gibbs自由能在本实验温度范围内皆为负值,说明这些反应在热力学上可以进行。从平衡观点分析,反应(1)~(7)生成三元化合物的标准Gibbs自由能按由小到大的顺序排列如下:反应(7)<反应(6)<反应(5)<反应(4)<反应(3)<反应(2)。因此,Ca2Al2SiO7 (钙铝黄长石)产物最有可能发生。综合上述热力学计算,表明二次铝灰添加氧化钙和氧化镁,理论上可以制备钙铝黄长石/镁铝尖晶石复相材料。

图2 反应式(1)~(7)的吉布斯自由能与温度的关系

Fig. 2 Relationship between Gibbs free energy and temperature in reactions (1)-(7)

2.2 二次铝灰制备钙铝黄长石/镁铝尖晶石复相材料的原料配比优化

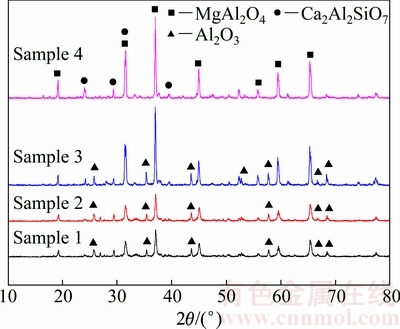

不同原料配比在1200 ℃烧结并保温3 h的烧成样品物相组成如图3所示。由图3可知,样品1和样品2的谱线中出现了较弱的钙铝黄长石相和镁铝尖晶石相衍射峰,两样品中均留有刚玉相;而样品3的复相衍射峰明显高于样品1和样品2的,但仍留有刚玉相;样品4的谱线中,刚玉相反应完全,仅出现了钙铝黄长石相和镁铝尖晶石相衍射峰,且衍射峰峰形尖锐。

图3 不同配比下钙铝黄长石/镁铝尖晶石复相材料XRD谱

Fig. 3 XRD patterns of gehlenite/magnesia-alumina spinel composites with different proportion of original materials

上述结果说明,氧化钙和氧化镁不足时,在1200 ℃保温3 h后,样品物相中同时存在钙铝黄长石、镁铝尖晶石和刚玉相,所添加的氧化钙和氧化镁还不足以与铝灰中刚玉、二氧化硅反应完全。当二次铝灰、氧化钙和氧化镁的质量分数分别为70.80%、18.58%和10.62%时,可以实现制备钙铝黄长石/镁铝尖晶石复相材料,说明在此配料比例下合成反应进行得较为完全。

2.3 烧结温度对钙铝黄长石/镁铝尖晶石复相材料性能的影响

2.3.1 物相组成

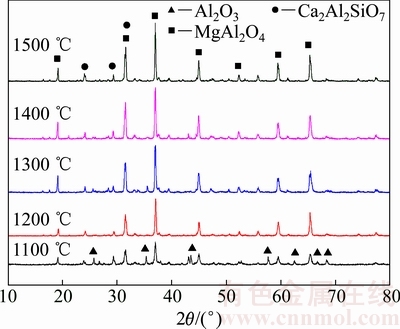

根据上述1200 ℃烧结3 h的XRD谱确定较优配比,最终确定二次铝灰、氧化钙和氧化镁的质量分数分别为70.80%、18.58%和10.62%。前期实验探索证明,温度为影响复相材料制备的主要因素。不同烧结温度下制备的复相材料物相变化如图4所示。由图4可知,1100 ℃烧结3 h后复相材料中出现钙铝黄长石和镁铝尖晶石相,但刚玉相依然存在;在1100~1200 ℃烧结3 h后复相材料中钙铝黄长石和镁铝尖晶石晶化反应进一步得到加强;在1300 ℃烧结3 h后复相材料中钙铝黄长石和镁铝尖晶石晶体发育逐渐完整,衍射峰强度明显升高,峰宽变窄衍射峰也由1100~1200 ℃的宽、散逐渐变化为高耸、尖锐、强烈的衍射峰;在1400~1500 ℃烧结3 h后复相材料中钙铝黄长石和镁铝尖晶石的衍射峰强度达到最高,尖锐突出,同时复相材料中刚玉相已不存在,说明钙铝黄长石和镁铝尖晶石晶体已经充分发育长大。上述结果表明,采用样品4的原料配比制备钙铝黄长石/镁铝尖晶石复相材料时,适宜的烧结温度为1400~1500 ℃。

图4 不同温度下钙铝黄长石/镁铝尖晶石复相材料XRD谱

Fig. 4 XRD patterns of gehlenite/magnesia-alumina spinel composites at different temperatures

2.3.2 材料形貌

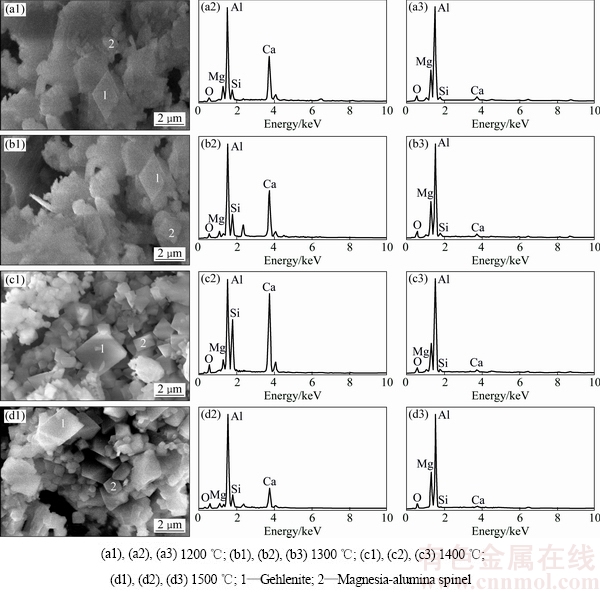

不同烧结温度(1200、1300、1400和1500 ℃)下复相材料的SEM像和EDS分析结果如图5所示。由图5可知,在1200~1500 ℃烧结3 h制备出的复相材料中出现了大块平板状晶体,经EDS微区元素含量测试并结合XRD分析,表明该大块平板状晶体主要物相为钙铝黄长石。这与梁祥济等研究报道铝黄长石为常见四方板状,偶见短柱状,晶体发育完善相一致[18-19]。同时所有制备出的复相材料中均含有大量八面体结构相,根据XRD谱图并结合EDS分析,该八面体结构为镁铝尖晶石晶体结构。随烧结温度的提高,复相材料中黄长石相和镁铝尖晶石相晶粒逐渐长大,形貌清晰,而复相材料的晶粒长大完善有利于材料抗压强度的提高。

2.3.3 显气孔率和抗压强度

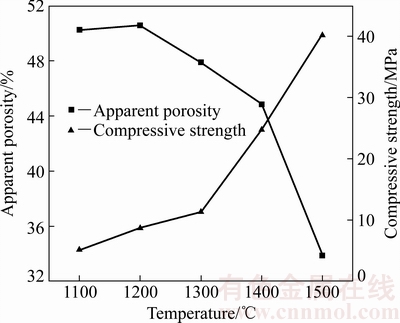

图6所示为样品4经不同烧成温度对样品显气孔率和抗压强度的影响。由图6可知,1100~1200 ℃烧结3 h,样品显气孔率未见明显下降,烧结温度超过1200 ℃,显气孔率下降明显,1300 ℃烧结后样品的显气孔率47.87%,随烧结温度继续升高至1400 ℃时,显气孔率为44.84%,温度升高至1500 ℃,显气孔率为33.87%。显气孔率下降是因为烧结温度的提高,气体被不断排出,烧结温度提高的同时使得晶粒逐渐发育长大,从而提高样品密度。样品抗压强度随烧结温度提高,复相材料抗压强度增大,这与显气孔率变化规律相符合。烧结温度为1100~1200 ℃时,复相材料抗压强由5.16 MPa提升到8.68 MPa,提升幅度不大。烧结温度超过1300 ℃时,抗压强度明显提高,烧结温度为1400 ℃时复相材料抗压强度为24.76 MPa,已经达到国家行业标准《粉煤灰砖》(JC239—91)强度级别10[20],即抗压强度≥10 MPa。烧结温度为1500 ℃时,复相材料抗压强度为40.18 MPa。随烧结温度升高,晶粒不断长大,钙铝黄长石/镁铝尖晶石晶体发育良好,同时样品的显气孔率降低,体积密度上升,结果样品抗压强度升高,由此可以看出,适当提高烧结温度可以提高复相材料的抗压强度。

图5 不同烧结温度下钙铝黄长石/镁铝尖晶石复相材料SEM像和EDS谱

Fig. 5 SEM images and EDS patterns of gehlenite/magnesia-alumina spinel composites at different sintering temperatures

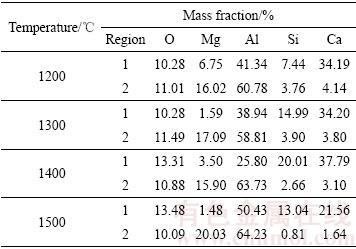

表3 不同烧结温度钙铝黄长石/镁铝尖晶石复相材料中钙铝黄长石和镁铝尖晶石EDS分析

Table 3 EDS analysis of C2AS and MA in gehlenite/ magnesia- alumina spinel composites with different sintering temperature

图6 钙铝黄长石/镁铝尖晶石复相材料显气孔率和抗压强度与烧结温度关系曲线

Fig. 6 Effects of sintering temperature on apparent porosity and compressive strength of gehlenite/magnesia-alumina spinel composites

3 结论

1) 热力学计算表明,在MgO-CaO-Al2O3-SiO2体系中,理论上可以制备镁铝尖晶石,同时,三元化合物中生成钙铝黄长石的可能性较大,理论上可以制备钙铝黄长石/镁铝尖晶石复相材料。

2) 以再生铝行业产生的二次铝灰、氧化钙和氧化镁为原料,当三者质量分数分别为70.80%、18.58%和10.62%时,在1100~1500 ℃下,均可制备出钙铝黄长石/镁铝尖晶石复相材料。复相材料中镁铝尖晶石晶粒呈现八面体结构,而钙铝黄长石晶粒呈现大平板状。升温利于钙铝黄长石/镁铝尖晶石结晶和生长。

3) 随烧结温度提高,样品的显气孔率降低,抗压强度相应提高。二次铝灰、氧化钙和氧化镁的质量分数分别为70.80%、18.58%和10.62%时,经1500 ℃烧结、保温3 h后得到的钙铝黄长石/镁铝尖晶石复相材料显气孔率为33.87%,抗压强度为40.18 MPa,复相材料抗压强度达到国家行业标准《粉煤灰砖》(JC239—91)强度级别10。

REFERENCES

[1] HONG Jia-ping, WANG Jun, CHEN Hai-yan, SUN Bao-de, LI Jia-jing, CHEN Chong. Process of aluminum dross recycling and life cycle assessment for Al-Si alloys and brown fused alumina[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(11): 2155-2161.

[2] MURAYAMA N, MAEKAWA I, USHIRO H, MIYOSHI T, SHIBATA J, VALIX M. Synthesis of various layered double hydroxides using aluminum dross generated inaluminum recycling process[J]. International Journal of Mineral Processing, 2012(110/111): 46-52.

[3] FUHRER M, HEY A, LEE W E. Microstructural evolution in self-forming spinel/calcium aluminum-bondedcastable refactories[J]. Journal of the European Ceramic Society, 1998, 18(7): 813-820.

[4] DASH B, DAS B R, TRIPATHY B C, BHATTACHARYA I N, DAS S C. Acid dissolution of alumina from waste aluminum dross[J]. Hydrometallurgy, 2008, 92(1/2): 48-53.

[5] DAVID E, KOPAC J. Hydrolysis of aluminum dross material to achieve zero hazardous waste[J]. Journal of Hazardous Materials, 2012, 209/210(4): 501-509.

[6] SHINZATO M C, HYPOLITO R. Solid waste from aluminum recycling process: characterization and reuse of its economically valuable constituents[J]. Waste Management, 2005, 25(1): 37-46.

[7] TAN R, KHOO H H. An LCA study of a primary aluminum supply chain[J]. Journal of Cleaner Production, 2005, 13(6): 607-618.

[8] TAVANGARIAN F, EMADI R. Synthesis and characterization of pure nanocrystalline magnesium aluminate spinel powder[J]. Journal of Alloys & Compounds, 2010, 489(2): 600-604.

[9] BONNEFONT G, FANTOZZI G, TROMBERT S, BONNEAU L. Fine-grained transparent MgAl2O4 spinel obtained by spark plasma sintering of commercially available nanopowders[J]. Ceramics International, 2012, 38(1): 131-140.

[10] 吕常胜, 王家伟, 贾永真. 赤泥加入量对赤泥烧结砖的影响[J]. 安全与环境学报, 2013, 13(4): 98-100.

Lü Chang-sheng, WANG Jia-wei, JIA Yong-zhen. Effects of red mud content on the sintered red mud bricks[J]. Journal of Safety and Environment, 2013, 13(4): 98-100.

[11] 卢红霞, 曾昭桓, 侯铁翠, 张 锐. 纳米Al粉反应特性的研究[J]. 人工晶体学报, 2007, 36(3): 639-640.

LU Hong-xia, ZENG Zhao-huan, HOU Tie-cui, ZHANG Rui. Thermo reaction properties of nanometer aluminium powders[J]. Journal of Synthetic Crystals, 2007, 36(3): 639-640.

[12] 王 谋, 梁慧敏, 徐 静. 片状铝粉氧化DSC/DTG分析[J]. 安全与环境学报, 2013, 13(2): 207-208.

WANG Mou, LIANG Hui-min, XU Jing. Research on the oxidation characteristics of aluminum flakes of DSC/DTG method[J]. Journal of Safety and Environment, 2013, 13(2): 207-208.

[13] 张佩灿. 高铝钢脱氧工艺和造渣技术研究[M]. 沈阳: 东北大学出版社, 2011: 16-17.

ZHANG Pei-can. Study on deoxidation process and slagging technology in high aluminum steel[M]. Shenyang: Northeastern University Press, 2011: 16-17.

[14] ZHU F, LIAO J X, XUE S G, HARTLEY W, ZOU Q, WU H. Evaluation of aggregate microstructures following natural regeneration in bauxite residue as characterized by synchrotron-based X-ray micro-computed tomography[J]. Science of the Total Environment, 2016, 573(24): 155-163.

[15] XUE S G, KONG X F, ZHU F, HARTLEY W, HUANG N, LI X F. Proposal for management and alkalinity transformation of bauxite residue in China[J]. Environmental Science and Pollution Research, 2016, 23(13): 12822-12834.

[16] LI M, PENG B, CHAI L Y, PENG N. Recovery of iron from zinc leaching residue by selective reduction roasting with carbon[J]. Journal of Hazardous Materials, 2012, 237/238: 323-330.

[17] DEAN J A. 兰氏化学手册[M]. 北京:科学出版社, 2003.

DEAN J A. Lange’s Chemistry Handbook[M]. Beijing: Science Press, 2003.

[18] 梁祥济, 乔 莉. 水热交代实验形成的铝黄长石的特征和物理化学条件[J]. 地质评论, 1988, 34(2): 147-149.

LIANG Xiang-ji, QIAO Li. The characteristics of gehlenite formed in the experiments of hydrothermal metasomatism and physico-chemical conditions for the formation[J]. Geological Review, 1988, 34(2): 147-149.

[19] 毛若卿, 熊家国, 潘国耀, 张惠玲. F, Cl, SO3对C2AS形成的影响[J]. 武汉理工大学学报, 1997, 19(4): 14-18.

MAO Ruo-qing, XIONG Jia-guo, PAN Guo-yao, ZHANG Hui-ling. Influence of existences of F, Cl, SO3 on C2AS formation[J]. Journal of Wuhan University of Technology, 1997, 19(4): 14-18.

[20] 李辕成, 祝 星, 祁先进. 铜冶炼污泥固化剂优选试验研究[J]. 安全与环境学报, 2013, 13(6): 85-90.

LI Yuan-cheng, ZHU Xing, QI Xian-jin. Optimization research of the treating agents for solidifying the sludge in a copper metallurgical plant[J]. Journal of Safety and Environment, 2013, 13(6): 85-90.

Sintering fabrication of gehlenite/magnesia-alumina spinel composites by secondary aluminum dross

ZHANG Yong, GUO Zhao-hui, WANG Shuo, XIAO Xi-yuan, HAN Zi-yu, HUANG Bo, NIE Yun-fei

(School of Metallurgy and Environment, Central South University, Changsha 410083, China)

Abstract: Gehlenite/magnesia-alumina spinel composites from the secondary aluminum dross were studied using sintering. Thermodynamic calculation shows that the secondary aluminum dross adding MgO and CaO can prepare the gehlenite/magnesia-alumina spinel composites in theory. The results show that gehlenite/magnesia-alumina spinel composites can be obtained under the sintering temperature from 1100 ℃ to 1500 ℃ when the mass ratio of aluminum dross, CaO and MgO is 70.80%, 18.58% and 10.62%, respectively. The purity and crystallinity of gehlenite/magnesia- alumina spinel composites are improved significantly, and the compressive strength is also increased, while the apparent porosity decreases with increasing of the sintering temperature. When the sintering temperature is 1500 ℃, the apparent porosity of gehlenite/magnesia-alumina spinel composites is 33.87% and the compressive strength is 40.17 MPa.

Key words: secondary aluminum dross; sintering; gehlenite/magnesia-alumina spinel; composite material

Foundation item: Project([2016]59-3) supported by the Environment Protection Scientific Research Project of Hunan Province, China

Received date: 2016-11-29; Accepted date: 2017-06-01

Corresponding author: GUO Zhao-hui; Tel: +86-731-88879325;E-mail:zhguo@csu.edu.cn

(编辑 何学锋)

基金项目:湖南省环保科研项目(湘财建指[2016]59号)

收稿日期:2016-11-29;修订日期:2017-06-01

通信作者:郭朝晖,教授,博士;电话:0731-88879325;E-mail:zhguo@csu.edu.cn