文章编号:1004-0609(2015)-11-3119-07

Sn-Ag-Cu无铅球栅阵列焊点塑性表征

杨淼森1, 2,孙凤莲1,孔祥霞1,周云芳1

(1. 哈尔滨理工大学 材料科学与工程学院,哈尔滨 150080;

2. 哈尔滨职业技术学院 机械工程学院,哈尔滨 150081)

摘 要:通过纳米压痕的方法,采用塑性应变与总应变的比值表征塑性,对SAC305/Cu、SAC0307/Cu和SAC0705BiNi/Cu这3种无铅焊点的动态硬度、抗蠕变性能及塑性进行了对比。3种焊点的动态硬度随深度变化趋势相同,随着压入深度的增加而降低。SAC0705BiNi/Cu的最终动态硬度最高,压痕深度最小,SAC305/Cu表现出应变硬化现象。3种焊点的抗蠕变能力由大到小依次为SAC0705BiNi/Cu、SAC305/Cu、SAC0307/Cu。SAC0705BiNi/Cu焊点的塑性与SAC305/Cu焊点的相当。与SAC305 和SAC0307两种钎料相比,无铅钎料SAC0705BiNi通过Bi和Ni元素的加入,提高钎料的硬度和抗蠕变性能,并且保持较好的塑性。

关键词:球栅阵列焊点;抗蠕变;塑性;纳米压痕

中图分类号:TG425.1 文献标志码:A

Plastic characterization and performance of Sn-Ag-Cu lead-free BGA solder joint

YANG Miao-sen1, 2, SUN Feng-lian1, KONG Xiang-xia1, ZHOU Yun-fang1

(1. School of Material Science and Engineering, Harbin University of Technology, Harbin 150080, China;

2. School of Mechanical Engineering, Harbin Vocational and Technical College, Harbin 150081, China)

Abstract: The nanoindentation was performed on the plasticity of Sn-Ag-Cu(SAC) lead-free ball grid array(BGA) solder joint. The ratio of plastic strain to total strain was used to characterize the solder plasticity. SAC305/Cu, SAC0307 /Cu and SAC0705BiNi/Cu component solder joints were compared in terms of dynamic hardness, creep resistance and plasticity. The dynamic hardness of three kinds of solder decreases with increasing the penetration depth. For SAC0705BiNi/Cu, the ultimate dynamic hardness is the highest, and the indentation depth is the smallest. Then, the strain hardening phenomenon of SAC305/Cu is more obvious than that of the others. Thus, the order of creep resistance from big to small is SAC0705BiNi/Cu, SAC305/Cu and SAC0307/Cu. The plasticities of SAC0705BiNi/Cu and SAC305/Cu solder joints are similar. Compared with the other two types of solder, through adding Bi and Ni elements, the hardness and solder creep resistance of SAC0705BiNi solder are improved, and the good plasticity is still maintained.

Key words: ball grid array solder joint; creep resistance; plasticity; nanoindentation

随着封装技术的不断发展,球栅阵列封装技术中,焊球的尺寸越来越小。常用的焊球直径只有几百微米,某些应用领域的焊球直径甚至达到50 μm以下。单一焊点在服役过程中所承受的力、电、热载荷(机械疲劳、热疲劳、冲击等)越来越大,其塑性性能直接影响焊点的可靠性。然而,受力学性能尺寸效应的影响,通过传统拉伸等方法获得的材料的变形规律已无法准确反映微焊点的塑性。因此,对BGA焊点的塑性性能的原位研究,对合理选择钎料和提高产品寿命有着重要意义。

纳米压痕法在材料微观力学性能研究方面有独特的优势[1-2],除获得硬度与弹性模量等材料性能指标外,研究者还通过定义新的塑性指标用来描述材料塑性,并通过数值模拟及在陶瓷和金属的纳米压痕实验中进行了验证[3-6]。

在微电子封装领域,纳米压痕技术在研究微小尺寸焊点的力学性能方面得到广泛应用,但多集中在压痕硬度和弹性模量等力学性能参数的测量与比较方面,对塑性的研究多集中蠕变性能分析方面[7-14],缺少对钎料对钎料塑性的直接比较。

针对以上问题,本文作者以BGA焊点为研究对象,使用纳米压痕实验方法,从动态硬度、蠕变特征及用塑性应变与总应变的比值3个方面来表征微焊点塑性,并对不同成分的BGA焊点塑性变形行为进行了比较。

1 力学参数的确定

加载和卸载的压痕过程中载荷-位移(p-h)曲线示意图如图1所示。图中pmax和hmax分别为最大载荷和最大压入深度,hf为卸载后的残余深度;S为弹性接触刚度,为试验中卸载曲线顶部斜率;hml为加载到最大载荷处位移;hmu为初始卸载点位移。切线与坐标轴的交点位移定义为hc。

图1 钎料合金的典型微载荷-深度曲线[9]

Fig. 1 Typical indentation load-depth curves of solder alloy[9]

压痕法测量材料的硬度和弹性模量的基本关系式为

(1)

(1)

式中:p是载荷;A是该载荷下投影接触面积。

对于Berkovich压头:

(2)

(2)

(3)

(3)

式中:h是压头和测试部分之间规定的接触深度;ε为压头形状修正系数,取决于压头几何形状,对三棱锥压头ε=0.75。

Er由压痕实验获得,定义为

(4)

(4)

式中:Er为压入折合模量;β为压头非对称的修正系数(对Berkovich压头,β=1.034 )[14]。

通过Er可以计算出材料的压痕弹性模量E:

(5)

(5)

式中:E、 分别为被测材料的弹性模量和泊松比;Ei、

分别为被测材料的弹性模量和泊松比;Ei、 分别为压头的弹性模量和泊松比。对于金刚石压头, Ei=1114 GPa,

分别为压头的弹性模量和泊松比。对于金刚石压头, Ei=1114 GPa, =0.07。

=0.07。

在最大载荷处保持一段时间所产生的蠕变过程中蠕变硬度可描述为[9]

(6)

(6)

Wcr和ΔVcr可分别表示为

(7)

(7)

(8)

(8)

式中:g为Berkovich压子的形状因子(取24.56);Hcr为蠕变硬度;Wcr为蠕变做功;ΔVcr为蠕变变形体积。

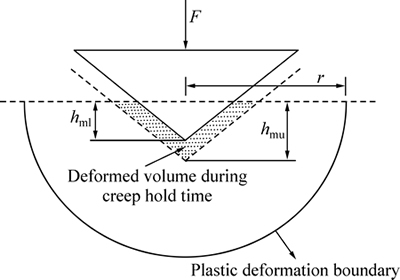

图2 压痕测试过程中蠕变做功示意图[9]

Fig. 2 Schematic diagram of creep deformed volume during hold time in indentation test[9]

整个压痕蠕变测试过程中材料所发生的塑性变形都处于一个塑性半球之内,其外侧则为纯弹性。塑性半球的半径r(见图2)可表示为[9]

(9)

(9)

式中:σy为屈服强度(σy=H/3)。在给定加载速率及Fm情况下,Hcr一定时,所产生的塑性半球也就固定。从而可以定义蠕变过程中的应变:

(10)

(10)

式中:Vp为塑性变形体积;Δt为蠕变时间。根据上述分析,通过F-h曲线可以得到不同加载速率条件下的lnHcr和lnεcr的线性关系,从而得到应力敏感指数n。

体钎料可以由拉伸实验得到的标准塑性特征,而在微观尺度很难得到传统的塑性特征曲线。通过纳米压痕实验中,可以对材料的塑性变形特征进行比较。MILLMAN等[6]提出了一种根据纳米压痕试验结果比较材料塑性的方法。其提出的塑性指标δH为一个无量纲参数,是塑性应变与总应变的比值,这个塑性的定义符合被广泛接受的对塑性的理解,即材料对变形的承受能力。对于压头锥面与轴线夹角为65.3°的Berkovich压头:

(11)

(11)

式中:ε、εp和εe分别为压痕总应变、塑性应变和弹性应变;E和 分别为被测材料的弹性模量和泊松比。

分别为被测材料的弹性模量和泊松比。

2 实验材料及方法

本研究中选用化学分析纯Sn、Ag、Cu、Bi 和Ni这5种元素,在纯氩气保护下,使用高频感应熔炼设备,在石英器皿中制备出Sn3Ag0.5Cu(SAC305)、Sn0.3Ag0.7Cu(SAC0307)和Sn0.7Ag0.5Cu3.5Bi0.05Ni- (SAC0705BiNi)钎料合金。

将合金制成直径为760 μm的BGA小球,置于690 μm铜焊盘上,使用松香酒精助焊剂,在T340C回流焊炉进行焊接得到BGA焊点。回流焊峰值温度为260 ℃,保温60 s,总焊接时间为560 s。

纳米压痕试验在岛津DUH-211S型纳米硬度仪上进行。试验采用115°Berkovich压头对焊点进行压痕试验。采用一次加载-卸载方式,压痕间距在5倍压痕尺寸以上,使用200 mN载荷,加载速率分别为5、10、15、20和50 mN/s;在最大载荷处保载时间为5s,卸载速率和加载速率相同,每个参数重复5次,取平均值。

3 结果与分析

3.1 回流焊BGA 焊点的压痕动态硬度

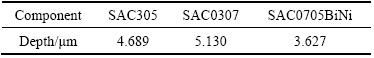

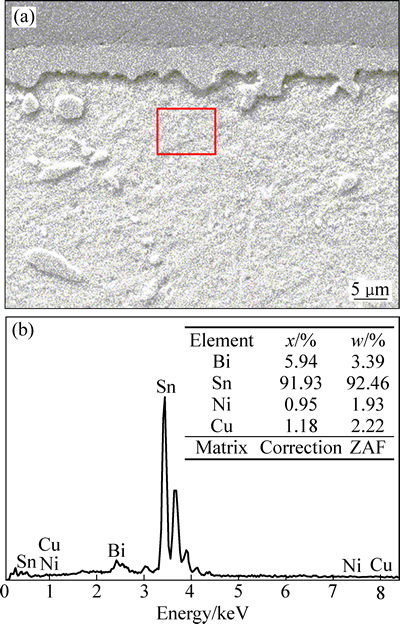

在加载过程中压头以脉冲加压的形式压入材料。纳米压痕动态硬度是根据JIS(日本工业标准)的标准,通过测量加载过程中载荷和瞬时压痕深度得到的。动态硬度反映了材料在复杂应力条件下的塑性变形抗力。图3所示分别为SAC305、SAC0307和SAC0705BiNi无铅钎料的BGA焊点动态硬度曲线。3种焊点的压痕深度如表1所列。

表1 不同成分BGA焊点的压痕深度

Table 1 Indentation depth of different component BGA solder joints

从图3中可以看出,在相同加载条件下,3种钎料硬度随着压痕深度的增加而减小,压痕面积越小硬度越高,表现出明显的压痕尺寸效应。3种钎料的动态硬度降低速度均在1.1 μm深度附近都发生了较明显的变化。这是由于在微观尺度,传统经典塑性理论不适于解释微观变形现象[15-17]。压痕深度较小时,应变梯度引起的几何必须位错(Geometrically necessary dislocation,GND),以及统计存储位错(Statistically stored dislocation,SSD)提高的变形阻力,材料得到强化,因而产生压痕尺寸效应[18-19]。

图3 不同成分BGA焊点压痕的动态硬度曲线

Fig. 3 Dynamic hardness-depth curves of BGA solder joints with different components

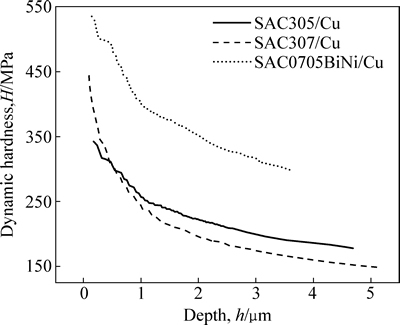

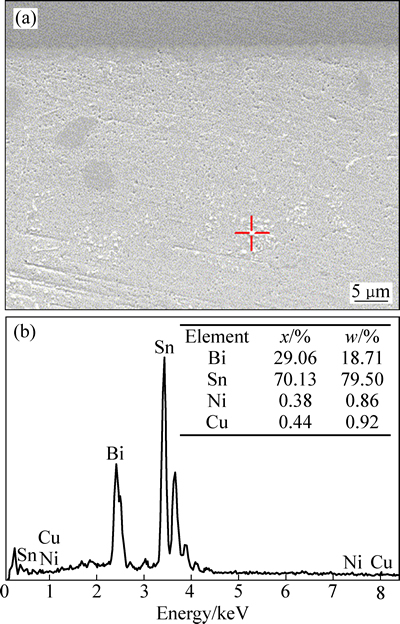

SAC0705BiNi/Cu焊点中,由于Bi元素的固溶强化作用(见图4),提高了材料的强度,富余的Bi元素形成富Bi颗粒分布于基体中(见图5),增加位错运动的阻力。SAC305/Cu焊点中的银含量高于SAC0307/Cu焊点中的,其基体中大量弥散分布的Ag3Sn起到弥散强化作用(见图6),因此,SAC305/Cu焊点的最终硬度高于SAC0307/Cu焊点的。随着压痕深度的增加,SAC305/Cu焊点的硬度的降低速率最小,说明在压头压入过程中,SAC305/Cu焊点产生了较明显的硬化现象。

图4 SAC0705BiNi/Cu的SEM像和EDX结果

Fig. 4 SEM image (a) and EDX results (b) of SAC0705BiNi/Cu

3.2 BGA焊点的抗蠕变性能

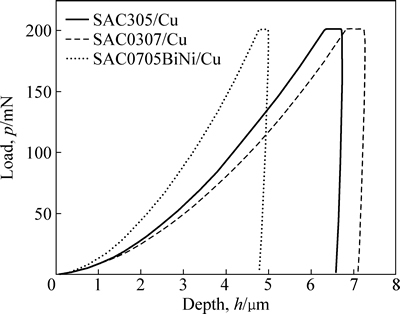

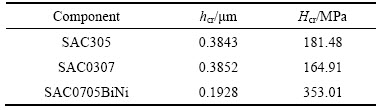

图7所示为3种无铅钎料BGA焊点在最大载荷为200 mN,加载速率为5 mN/s下的纳米压痕蠕变载荷-深度曲线,表2所列为它们的蠕变数据。

蠕变深度是载荷保载过程中,钎料压痕深度的变化。蠕变硬度反映了在蠕变过程中材料塑性变形的抗力。由表2可见,相同条件下,SAC0705BiNi钎料BGA焊点的蠕变深度最小,蠕变硬度远高于其他两种钎料的,表明其蠕变过程中的阻力较其他两种钎料中的大。

图5 焊点中富Bi颗粒的SEM像和EDX分析结果

Fig. 5 SEM image (a) and EDX results (b) of Bi-rich particles in joint

图6 Ag3Sn的SEM像和EDX分析结果

Fig. 6 SEM image (a) and EDX results (b) of Ag3Sn

图7 不同成分BGA焊点的载荷-深度曲线

Fig. 7 Indentation load-depth curves of different component BGA solder joint

表2 不同成分BGA焊点的压痕蠕变对比

Table 2 Comparison of creep of different component BGA solder joints

图8所示为加载速率-蠕变深度曲线。从图8中可以看出,压痕蠕变深度与加载速率正相关。在相同加载速率下,SAC0307/Cu钎料BGA焊点的蠕变深度最大,SAC305/Cu的次之,SAC0705BiNi/Cu钎料BGA焊点的蠕变深度最小。且当加载速率为50mN/s时,SAC0705BiNi/Cu焊点的蠕变深度没有明显增加。由此可见,SAC0705BiNi抗蠕变能力更强,并在高加载速率下具有较好的抗蠕变性能。

图8 不同成分BGA焊点的蠕变深度-加载速率曲线

Fig. 8 Creep depth-load rate curves of different component BGA solder joints

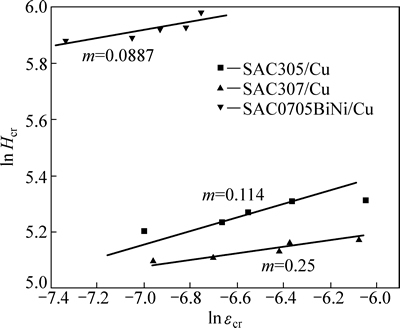

通过拟合得到SAC0307/Cu、SAC305/Cu、SAC0705BiNi/Cu焊点的应变速率敏感指数m分别为0.25、0.114、0.0887,对应的蠕变应力敏感指数n分别为4、8.772、11.274(见图9)。其中SAC305/Cu焊点的蠕变应变速率敏感指数与文献[7]中的0.1111相近。表明SAC0307/Cu焊点的蠕变机制是位错攀移机制,SAC305/Cu、SAC0705BiNi/Cu焊点为第二相颗粒增强机制,其蠕变受非基面位错运动的控制。无铅焊点的抗蠕变性能与钎料的成分与组织有关。三元合金SAC305中的银含量远高于SAC0307中的,Ag元素以金属间化合物的形式大量弥散分布在基体中,提高了基体的抗蠕变能力。对于低银多元合金SAC0705BiNi,合金元素Bi通过固溶强化作用显著提高了合金的硬度与抗蠕变性能。Ni元素与Cu元素的共同作用提高了合金中金属间化合物的含量,也有利于提高钎料的抗蠕变能力。

图9 不同成分BGA焊点蠕变应变速率敏感指数的拟合曲线

Fig. 9 Fitting curves of creep strain rate and hardness logarithm relation of different component of BGA solder joints

3.3 BGA焊点的塑性变形特征

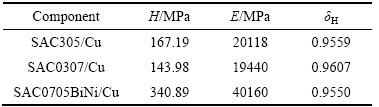

表3 不同成分BGA焊点δH值

Table 3 δH values of different component of BGA solder joint

表3所列为3种成分BGA焊点,根据最大加载力200 mN,加载速率10 mN/s的试验结果计算得到δH。从表3中数值对比可见,低银焊点SAC0307/Cu的塑性相对较好。SAC305/Cu与SAC0705BiNi/Cu焊点的塑性相当。焊点的塑性受其添加合金元素含量的影响,合金元素含量越低,焊点的塑性越好。3种钎料中,SAC0705BiNi通过加入Bi和Ni元素在提高钎料的硬度和弹性模量的同时,还保持了较好的塑性性能,获得了良好的综合力学性能。

在压痕产生的过程中,塑性应变与总应变的比值(δH)表征材料塑性在金属与陶瓷塑性研究中得到应用,SiC和WC等的δH为0.35~0.82,Fe、Au等几种常见纯金属的δH为0.92~0.99[20-21]。与陶瓷和纯金属相比,钎料成分复杂,由于晶粒大小、晶向及化合物分布等因素影响,使用纳米压痕方法钎料的H和E的数值较分散,但可以通过合理设计试验方案,严格控制实验条件,并通过数学方法对所得数据进行处理,对结果进行修正。

4 结论

1) 在纳米压痕实验中,使用塑性应变与总应变的比值作为塑性指标,表征3种成分焊点的塑性。比较不同成分BGA焊点的塑性,此方法简便可行。

2) 焊点中添加合金元素的含量对焊点的塑性变形能力有较大影响,SAC0705BiNi/Cu焊点与SAC305/Cu焊点的塑性相近。在压头动态压入的过程中,SAC305/Cu焊点表现出应变硬化现象。

3) 通过不同加载速率下的蠕变硬度和蠕变应变速率关系导出了SAC0307/Cu、SAC305/Cu、SAC0705BiNi/Cu焊点的应变速率敏感指数m分别为0.25、0.114、0.0887,对应的蠕变应力敏感指数n分别为4、8.772、11.274,表明SAC0307/Cu焊点的蠕变机制是位错攀移机制,SAC305/Cu、SAC0705BiNi/Cu焊点为第二相颗粒增强机制,其蠕变受非基面位错运动的控制。

REFERENCES

[1] 张志纯, 龙志林, 危洪清, 彭 建, 许 福, 李乡安. Fe-Co-B-Si-Nb-Cr 块体非晶合金在纳米压痕过程中的变形行为[J]. 中国有色金属学报, 2009, 19(7): 1300-1315.

ZHANG Zhi-chun, LONG Zhi-lin, WEI Hong-qing, PENG Jian, XU Fu, LI Xiang-an. Deformation behaviour of Fe-Co-B-Si- Nb-Cr bulk amorphous alloy during nanoindentation[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(7): 1300-1315.

[2] XU Fu, LONG Zhi-lin, DENG Xu-hui, ZHANG Ping. Loading rate sensitivity of nanoindentation creep behavior in a Fe-based bulk metallic glass[J]. Transaction of Nonferrous Metals Society of China, 2013, 23(6): 1646-1651.

[3] BELLEMARE S C, DAO M, SURESH S. A new method for evaluating the plastic properties of materials through instrumented frictional sliding tests[J]. Acta Materialia, 2010, 58(19): 6385-6392.

[4] HUANG Y L, LIU X F, ZHOU Y C, MA Z S, LU C S. Mathematical analysis on the uniqueness of reverse algorithm for measuring elastic-plastic properties by sharp indentation[J]. Materials Science and Technology, 2011, 27(7): 577-584.

[5] BAXEVANI E A, GIANNAKOPOULOS A E. The modified Rockwell test: A new probe for mechanical properties of metals[J]. Experimental Mechanics, 2009, 49: 371-382.

[6] MILLMAN Y V. Indentation of materials as a new method of micromechanical testing[J]. Powder Metallurgy & Metal Ceramic, 1999, 38(7/8): 396-402.

[7] 张国尚, 荆洪阳, 徐连勇, 魏 军, 韩永典. 纳米压痕法测量80Au/20Sn焊料热力性能[J]. 焊接学报, 2009, 30(9): 53-56.

ZHANG G S, JING H Y, XU L Y, WEI J, HAN Y D. Thermomechanical characterization of 80Au/20Sn solder using nanoindentation[J]. Transactions of the China Welding Institution, 2009, 30(9): 53-56.

[8] CHROMIK R R, VINCI R P, ALLEN S L, NOTIS, M R. Measuring the mechanical properties of Pb-free solder and Sn-based intermetallics by nanoindentation[J]. The Journal of the Minerals, Metals and Materials Society, 2003, 55(6): 66-69.

[9] 王凤江, 钱乙余, 马 鑫. 纳米压痕法测量Sn-Ag-Cu无铅钎料BGA焊点的力学性能参数[J]. 金属学报, 2005, 41(7): 775-779.

WANG Feng-jiang, QIAN Yi-yu, MA Xin. Measurement of mechanical properties of Sn-Ag-Cu bulk solder BGA solder joint using nanoindentation[J]. Acta Metall Sin, 2005, 41(7): 775-779.

[10] 姬 峰, 薛松柏, 刘 霜, 娄继源, 娄银斌. 纳米压痕法测量锌铝钎料的室温蠕变应力指数[J]. 焊接学报, 2013, 34(2): 75-78.

JI Feng, XUE Song-bai, LIU Shuang, LOU Ji-yu, LOU Yin-bin. Measurement of creep stress exponent of Zn-Al filler metal at room temperature by using nanoindentation[J]. Transactions of the China Welding Institution, 2013, 34(2): 75-78.

[11] 杨淼森, 孙凤莲, 邹鹏飞. 低银 SnAgCuBi-xNi/Cu 焊点塑性及蠕变性能[J]. 焊接学报, 2014, 35(3): 31-34.

YANG Mao-sen, SUN Feng-lian, ZOU Peng-fei. Plasticity and creep performance of low-Ag SnAgCuBi-xNi/Cu solder joint[J]. Transactions of the China Welding Institution, 2014, 35(3): 31-34.

[12] GAO F, NISHIKAWA H, TAKEMOTO T, QU J. Mechanical properties versus temperature relation of individual phases in Sn-3.0Ag-0.5Cu lead-free solder alloy[J]. Microelectronics Reliability, 2009, 49(3): 296-302.

[13] DUDEK M A, CHAWLA N. Nanoindentation of rare earth-Sn intermetallics in Pb-free solders[J]. Intermetallics, 2010, 18(5): 1016-1020.

[14] RAO B S S C, WENG J, SHEN L, LEE T K, ZENG K Y. Morphology and mechanical properties of intermetallic compounds in SnAgCu solder joints[J]. Microelectronic Engineering, 2010, 87(11): 2416-2422.

[15] NIX W D, M R. Mechanical properties of thin films[J]. Metall Trans A, 1989, 20: 2217-2245.

[16] NIX W D. Elastic and plastic properties of thin films on substrates: nanoindentation techniques[J]. Mater Sci Eng A, 1997, 234/236: 37-44.

[17] MCELHANEY K W, VLASSSAK J J, NIX W D. Determination of indentation tip geometry and indentation contact area of depth-sensing indentation experiments[J]. Mater Res, 1998, 13: 1300-1306.

[18] FLECK N A, MULLER G M, ASHBY M F, HUTCHINSON J W. Strain gradient plasticity: Theory and experiment[J]. Acta Metallurgica et Materialia, 1994, 42: 475-487.

[19] ASHBY M F. The deformation of plastically non-homogeneous alloys[J]. Philos Mag, 1970, 21: 399-424.

[20] MILMAN Y V, GALANOV B A, CHUGUNOVA S I. Plasticity characteristic obtained through hardness measurement[J]. Acta Metallurgica et Materialia, 1993, 41(9): 2523-2532.

[21] MILMAN, Y V, CHUGUNOVA S I, GONCHAROVA I V, GONCHARUK V A, YEFIMOV N A. Physics of deformation and fracture at impact loading and penetration[J]. International Journal of Impact Engineering, 2006, 33: 452-462.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51074069)

收稿日期:2015-03-30;修订日期:2015-07-10

通信作者:孙凤莲,教授,博士;电话:0451-86398791;E-mail:sunflian@163.com