文章编号:1004-0609(2007)01-0105-06

电磁连铸对AZ31镁合金组织及力学性能的影响

张世斌1,李伟轩1,邓 康1,王业双2,房中学2,任忠鸣1,徐 河2

(1. 上海大学 材料与工程学院,上海 200072;

2. 北京维恩克集团临沂公司,济南 273400)

摘 要:通过电磁连铸和普通连铸方法对AZ31镁合金进行连铸实验,对比分析有、无电磁场作用下的铸坯凝固宏观、微观组织和力学性能,并利用扫描电镜分析镁合金的断裂机理。结果表明:当表观直流电流为40~50 A时获得最佳磁场分布,此时电磁连铸的镁合金组织细小、均匀,树枝晶呈破碎状,其力学性能尤其是塑性变形能力显著提高,常温抗拉强度、屈服强度和伸长率较普通连铸分别提高17%,50%和81%,断口形貌显示其断裂具有韧性断裂的特性。

关键词:AZ31镁合金;电磁连铸;凝固组织;力学性能

中图分类号:TG 149.7; TG 146.2+2 文献标识码:A

Effect of electromagnetically continuous casting on structure and mechanical properties of magnesium alloy AZ31

ZHANG Shi-bin1, DENG Kang1, LI Wei-xuan1, WANG Ye-shuang2, FANG Zhong-xue2, REN Zhong-ming1, XU He2

(1. School of Materials and Engineering, Shanghai University, Shanghai 200072, China;

2. Beijing Winca Group Co. Ltd., Ji’nan 273400, China)

Abstract: A test of electromagnetically continuous casting (EMC) was used to cast AZ31 alloy to study the effect of electromagnetic field on the billets, in which the solidification structure and mechanical properties of the billets cast with or without electromagnetic field were examined. The result shows that the optimum distribution of magnetic induction intensity is obtained at the apparent direct current of 40-50 A, and the grain size obtained by EMC is fine and uniform, the dendritic crystal are fragmentated. The mechanical properties of the billet casted by EMC are improved obviously compared with those casted by the traditional casting, and the tensile strength, yield strength and elongation are increased by about 17%, 50% and 81%, respectively. AZ31 magnesium alloy casted by EMC usually shows flexible fracture.

Key words: AZ31 magnesium alloy; electromagnetically continuous casting; solidification structure; mechanical property

镁合金是目前最轻的金属结构材料,具有低密 度,高比强度和比刚度,优良的阻尼减震性能、导热性能、电磁屏蔽效果、机械冷加工性能和零件尺寸的稳定性能以及易于回收再利用等优点,在航空、航 天、汽车、计算机、电子、通讯和家电等行业有多年应用历史。但镁合金的密排六方晶体结构决定了其塑性变形能力较差,在铸造、挤压等热加工过程中易开裂,从而形成缺陷[1-3]。如何提高镁合金的成型和塑性加工 性能,是镁合金及其制备的关键问题之一。实践证明,细小的等轴晶粒组织能改善镁合金的塑性变形能力[4]。因此,细化镁合金铸锭的显微组织,提高其力学性能受到广泛的重视。1987年,Vives[5]提出CREM工艺,在结晶器外设置电磁感应线圈,通过工频电流形成的电磁场,改变连铸中铸坯内部的流速场和温度场,有效细化了铝坯的晶粒。该设想近年来多次被应用到镁合金连铸实验中,取得许多有益的结果[6-8]。人们期望通过在镁合金连铸中施加电磁搅拌使凝 固组织细化,提高镁合金的力学性能,满足后续热加工的需要。

在镁合金的电磁连铸(EMC)中,镁的低密度特性使电磁搅拌作用得到很好发挥,起到了均匀成分和细化组织的作用。但本文作者在实验和工业试验中也发现,CREM工艺所用的工频电磁场的电磁渗透深度较大,镁液被强烈搅拌,其表面液膜易被破坏,并在弯月面边部等处形成漩涡,产生卷渣或拉裂现象,影响铸坯质量[9]。另一方面,在镁合金电磁连铸中使用的高频磁场将受到结晶器的严重屏蔽,产生很大的热损耗,使能耗增加[10]。基于上述结果,本文作者在实验和现场工业试验中采用1.5~8 kHz的中频磁场(其电磁渗透深度约为5mm),并通过冷坩埚式结晶器提高磁场的渗透效果,进行AZ31镁合金电磁连铸实验。在此基础上,对电磁连铸工艺及镁铸坯凝固组织、力学性能的影响进行了分析。

1 实验

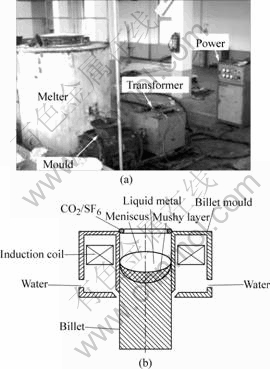

实验装置示意图如图1(a)所示,主要由熔化炉与浇注系统、气体保护系统、电磁成型与冷却系统、拉坯控制系统组成,其中结晶器结构示意图如图1(b)所示,内径d166 mm,高度165 mm。实验材料为AZ31镁合金,其化学成分列于表1。铸坯尺寸为d162 mm×5 m,与实际生产时的要求相同。

图1 镁合金电磁连铸实验装置

Fig.1 Photo of electromagnetic continuous casting (EMC) of magnesium alloys: (a) Photo of experimental facility; (b) Schematic diagram of EMC process

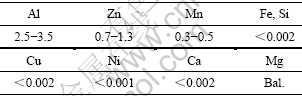

表1 实验AZ31镁合金化学成分

Table 1 Chemical composition of magnesium alloy AZ31 (mass fraction, %)

实验中,镁合金在电阻炉中熔化并调配,连铸时,镁液通过CO2和SF6混和气体保护的流槽注入结晶器,实验拉坯速度范围为8~10 cm/min。在结晶器拉速稳定后开始施加中频磁场,对镁熔体和凝固前沿区进行电磁搅拌和软接触凝固。实验中,镁液的浇注温度为720 ℃,结晶器冷却水压在0.3 MPa,水温4 ℃。

实验后对铸坯取样。取样方法如下:对不同强度电磁场作用下的铸坯进行分段,再进行横向和纵向切片,分别制作宏、微观组织试样和力学性能试样。其中,宏观组织实验样品取自整个铸坯的横截面,并用等离子发射光谱仪测量铸坯横断面上合金元素分布;金相试样则取自铸坯横断面的中心处和距中心40 mm的位置,在金相显微镜下观察分析铸坯凝固组织变化;而拉伸试样则沿铸坯纵向取自距轴心1/2半径处,通过CMT5305万能实验机进行拉伸实验和数据处理,得到铸坯铸态组织的力学性能,然后对断口进行扫描电镜分析,观察其形貌并判断断裂机理。

2 结果与讨论

2.1 铸态组织

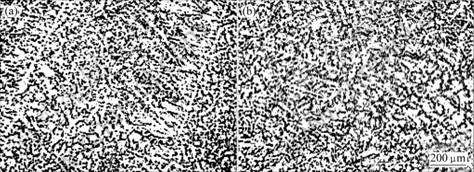

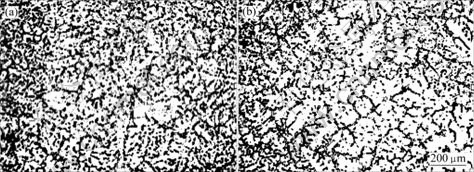

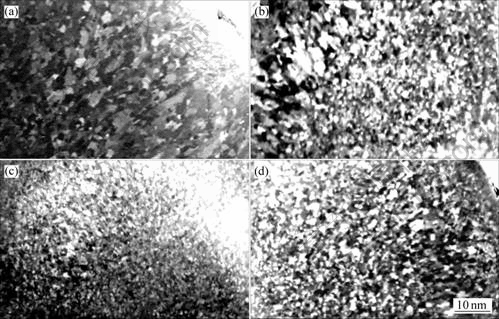

普通连铸时AZ31镁合金锭的显微照片见图2。由图可见,传统的镁合金铸锭的枝晶粗大并有较发达的二次枝晶。而在电源表观直流电流为30、40和50 A的电磁连铸中,AZ31镁合金的凝固组织分别由图3~5所示。对比图2可知,在适当强度电磁场作用下,树枝晶被打碎,镁合金的晶粒组织可得到细化,消除了粗大的树枝晶组织并使得晶粒尺寸均匀(图4)。比较图3和图5可知,当表观直流电流在30和50 A时,前者晶粒组织尚显粗大,而后者的晶粒已形成大块的“蔷薇”状组织,分别为电磁搅拌不足和过度所致。应此,比较以上电磁连铸结果,结晶组织与普通连铸相比均得到改善,但在表观直流电流为40 A时,其细化效果最好。

图2 普通半连铸AZ31铸锭的显微组织

Fig.2 Microstructures of AZ31 alloy billet cast in normal DC casting: (a) 40 mm from billet center; (b) Billet center

图3 电流30 A时电磁连铸AZ31铸锭组织的显微照片

Fig.3 Microstructures of AZ31 alloy billet cast in EMC at 30 A: (a) 40 mm from billet center; (b) Billet center

图4 电流40 A时电磁连铸AZ31铸锭组织的显微照片

Fig.4 Microstructures of AZ31 alloy billet cast in EMC at 40 A: (a) 40 mm from billet center; (b) Billet center

图5 电流50 A时电磁连铸AZ31铸锭组织的显微照片

Fig.5 Microstructures of AZ31 alloy billet cast in EMC at 50 A: (a) 40 mm from billet center; (b) Billet center

AZ31镁合金在普通连铸和电磁连铸下,铸坯横截面的宏观组织如图6所示。由图可见,在其它工艺条件(浇注温度、拉速、冷却强度等)不变的情况下,改变电磁连铸的电磁场强度(在工艺中即表现为改变电源的表观直流电流强度),能够显著改变铸坯的宏观组织。普通连铸下,铸坯靠近边部是一层细小的等轴晶,大约厚度是4 mm,中心为粗大的等轴晶粒,在中心和边缘为柱状晶。而在电磁连铸中,电流为30 A时,铸坯中心的等轴晶变的细小,柱状晶区域变窄,随着电流的继续增大到40 A时,整个铸坯都变为细小的等轴晶粒,电流为50 A时,晶粒呈变粗的趋 势,这与微观组织是相对应的。

图6 不同条件下镁合金电磁连铸的宏观组织

Fig.6 Macrostructures of AZ31 alloy billet cast under different technological conditions: (a) Normal DC; (b) EMC with 30 A; (c) EMC with 40 A; (d) EMC with 50 A

电磁连铸使铸坯凝固组织细化的原因是电磁搅拌形成的强迫对流使熔体形核率增加,非匀质晶核数量提高必然带来晶体尺寸的细化。首先,镁液浇入结晶器后,靠近结晶器壁面的熔体会迅速在冷却壁面上形成富镁晶核。这些晶核具有高于熔体数倍的导电率[11],在交变磁场作用下会受到高于周围熔体的交变电磁力,该力对新生晶核的振荡作用使新生晶核松动,并被电磁搅拌作用卷入铸坯液芯。其次,电磁搅拌对树枝晶冲刷作用也会使其发生折断和熔蚀现象,从而形成枝晶碎片,也成为晶核。电磁连铸提高了镁合金熔体的形核率,导致其凝固组织细化。电磁连铸下的交变磁场在铸坯表层(集肤层厚度内)形成感应电流,其加热作用使铸坯表层温度梯度降低,这也使柱状晶和树枝晶的生长受到抑制,易于形成等轴晶。同时,电磁连铸时的搅拌作用,使液穴内镁合金的温度趋于均匀,液-固相的界面变得平坦,晶粒在整个截面上的分布则趋于均匀。

实验结果同时也显示,电磁连铸中镁合金铸坯的感应热源集中在铸坯外表层。由电磁理论分析可知,该热源的强度Q与感生电流的平方成正比,亦与铸坯表面磁感应强度B和电磁场频率ω乘积的平方成正比,即Q∝J2∝ω2B2。这样,在镁液浇注温度、拉速、冷却强度等连铸工艺参数不变的条件下,电磁场强度(即实验中电源的表观直流电流强度)的增加使铸坯表层的温度梯度呈逐渐下降趋势,因此在电磁场强度(亦即输入电流)过大时,会引起铸坯晶粒(等轴晶)粗化现象。从电磁连铸实验的结果看,随电磁场强度增加,镁合金凝固组织的变化规律表现为:树枝晶→柱状晶→等轴晶→大块等轴晶。

2.2 力学性能

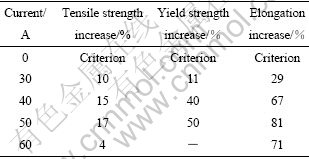

采用CMT5305精密型万能实验机进行试样拉伸实验,结果见图7。由图可见,AZ31镁合金铸坯在电磁连铸条件下,其抗拉强度、屈服强度和伸长率均比普通连铸的同牌号镁合金铸坯有所提高,其中抗拉强度提高17%,屈服强度可提高50%,而伸长率则可提高81%(以上数据均为最大值)。当电流超过50A时,合金的抗拉强度、屈服强度和伸长率均呈下降趋势。

图7 电流对铸坯力学性能的影响

Fig.7 Mechanical properties of billets in different conditions of EMC: (a) Relationship between tensile strength and current; (b) Relationship between yield strength and current; (c) Relationship between elongation and current

由Hall-Petch关系式σy = σ + ky d1/2可知,当晶粒尺寸减小时,晶体比表面积增加,使表面力(表面张力和与周围晶粒的相互作用力)增加[12]。表面张力和周围晶粒的相互作用力会引起晶粒表面层晶格的歪扭。由于表面力的影响, 使接近晶粒界面处产生了阻碍晶体变形的难变形区。对多晶体来说,晶粒越细则相应的难变形区越大,要使其产生滑移,需加较大的力,即表现为变形抗力增加。变形抗力增加即意味着材料强度、伸长率等力学性能提高。但电磁连铸工艺来说,电磁场强度(即电流强度)达到某一临界值以后,镁液弯月面处的搅拌过大使液面波动剧烈,易造成镁液面保护膜破裂而卷渣,这使铸坯质量和性能下降。表2 所列均为在不同电磁连铸条件下,AZ31镁合金坯的力学性能变化幅度。由该表可见,当电磁场过强时,AZ31镁合金铸态组织的力学性能将会由上升转为下降。

表2 不同电流条件下铸坯力学性能增幅

Table 2 Mechanical properties variation of billets under different conditions of EMC

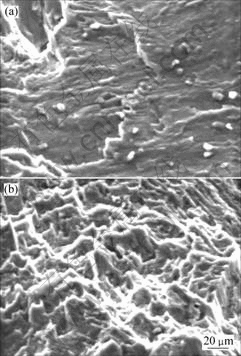

2.3 断裂机理

试样断口的扫描电镜分析见图8。由图可见,无论是普通连铸或是电磁连铸,镁合金试样的断裂方式均属沿晶断裂,图8(a)所示为普通连铸坯试样SEM断口形貌,从中可以看出存在着明显的解理断裂平台,而解理断裂属于脆性断裂,表明材料的塑性变形能力较差;而图8(b)所示为电流40 A时电磁连铸的铸坯试样SEM断口形貌,从图上可见,断口具有明显呈45°倾斜的“凸起的峰”,且在断面上分布有很多韧窝,表明该断裂具有明显的韧性断裂特性,合金断口中的韧窝基本是均匀且较深的,韧窝通过撕裂棱相互联结起来,说明此时AZ31镁合金铸态组织比普通连铸时具有较好的塑性变形能力。

图8 拉伸试样断口扫描照片

Fig.8 Fractographs of sample after tensile test: (a) Normal DC; (b) EMC (40 A)

3 结论

1) 电磁连铸实验中,中频电磁场的搅拌和振荡作用,可细化镁合金连铸坯的凝固组织,使镁合金的抗拉强度、屈服强度和伸长率分别提高了17%、50%和81%。

2) 电磁连铸中,镁合金凝固组织随电磁场强度增加,呈现树枝晶→柱状晶→等轴晶→大块等轴晶转变,同时拉伸实验也由脆性断裂转变为以韧性断裂为主的复合断裂,表明电磁场的作用使镁合金组织塑性性能提高。这些结果有利于改善镁合金的后续加工性能。

3) 电磁连铸中,所施加的电磁场强度有最佳范围。本实验中,在电源表观直流电流为40 A时,镁合金的凝固组织最好;当电流在40~50 A时,镁合金铸态组织的力学性能最高。当所施加的电流强度超出上述范围时,铸坯的凝固组织和力学性能显示电磁连铸的电磁场强度不足或过度,表现为镁合金凝固组织的细化程度和力学性能偏离峰值。

REFERENCES

[1] 陈振华. 镁合金[M]. 北京: 化学工业出版社, 2004.

CHEN Zhen-hua. Magnesium Alloys[M]. Beijing: Chemical Industry Press, 2004.

[2] Westengen H K. Magnesium die casting: from ingots to automotive parts[J]. Light Metal Age, 2000, 58(3/4): 44-52.

[3] Luo A, Pekguleryuz M O. Review cast magnesium alloys for elevated temperature applications[J]. Journal of Materials Science, 1994, 29(20): 5259-5271.

[4] 汪凌云, 黄光胜, 范永革, 黄光杰. 变形AZ31镁合金的晶粒细化[J]. 中国有色金属学报, 2003, 13(3): 594-598.

WANG Ling-yun, HUANG Guang-sheng, FAN Yong-ge, HUANG Guang-jie. Grain refinement of wrought AZ31 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(3): 594-598.

[5] Vives C. CREM: a new casting process part Ⅰ: fundamental Aspect[J]. Light Metals, 1987: 769-778.

[6] GUO Shi-jie, CUI Jian-zhong. The effect of alternating magnetic field on the process of semi-continuous casting for AZ91 billets[J]. Materials Letters, 2005, 59(31): 1841-1844.

[7] 包卫平,许光明,郑佳伟,崔建忠. 不同磁场作用对AZ31镁合金凝固组织的影响[J]. 材料与冶金学报, 2003, 2(3): 216-219.

BAO Wei-ping, XU Guang-ming, ZHENG Jia-wei, CUI Jian-zhong. Effect of magnetostatic field on the microstructure of magnesium alloy AZ31[J]. Journal of Materials and Metallurgy, 2003, 2(3): 216-219.

[8] 许光明,郭世杰,崔建忠. 镁合金电磁铸造的电磁场分析[J]. 有色矿冶, 2002, 18(5): 42-45.

XU Guang-ming, GUO Shi-jie, CUI Jian-zhong. Simulation of magnetic field on the magnetic casting of magnesium alloys[J]. Nonferrous Mining and Metallurgy, 2002, 18(5): 42-45.

[9] 张志峰,李廷举,温 斌,金俊泽. 复合电磁场对连铸结晶器弯月面金属液运动行为及铸坯质量的影响[J]. 钢铁研究学报, 2000, 12(9): 36-40.

ZHANG Zhi-feng, LI Ting-ju, WEN Bin, JIN Jun-ze. Effect of multi-electromagnetic field on motion state at meniscus and quality of continuous casting metals[J]. Journal of Iron and Steel Research, 2000, 12(9): 36-40.

[10] 任忠鸣, 邓 康,蒋国昌. 软接触电磁连铸技术的发展[J]. 钢铁研究学报, 2002, 2(14): 58-64.

REN Zhong-ming, DENG Kang, JIAN Guo-chang. Development of electromagnetic continuous casting processing with soft-contact mold[J]. Journal of Iron and Steel Research, 2002, 2(14): 58-64.

[11] 房灿峰,贾 非,金俊泽,亓 峰,李廷举. 铝合金软接触电磁连铸研究[J]. 铸造, 2004, 53(5): 350-353.

FANG Can-feng, JIA Fei, JIN Jun-ze, QI Feng, LI Ting-ju. Research on soft-contact electromagnetic continuous casting of Al alloys[J]. Foundry, 2004, 53(5): 350-353.

[12] Kubota K, Mabuchi M, Higashi K. Review processing and mechanical properties of fine-grained magnesium alloys[J]. Journal of Materials Science, 1999, 34(10): 4311-4320.

收稿日期:2006-05-29;修订日期:2006-11-05

通讯作者:邓 康,教授;电话:021-56331102; E-mail: dengk2000@163.com

(编辑 龙怀中)