文章编号:1004-0609(2008)10-1769-06

6082铝合金热变形的本构模型

李雪松,陈 军,张鸿冰

(上海交通大学 国家模具CAD工程研究中心,上海 200030)

摘 要:利用Gleeble-1500热模拟机,研究6082铝合金在变形温度为300~500 ℃以及应变速率为0.01~10 /s下高温单道次压缩过程的热变形流变应力行为。结果表明:6082铝合金高温单道次压缩下的热变形经历了从应变硬化阶段过渡到稳态变形阶段的过程,其软化机制主要为动态回复。该合金流变应力的大小受变形温度、应变速率的强烈影响,它随变形温度升高而降低,随应变速率提高而增大,说明该合金是一个正应变速率敏感的材料。该合金高温流变应力σ可采用Zener-Hollomon参数的函数来描述,函数表达式中参数A、α和n的值分别为3.97×1011 s-1、0.01 MPa-1、9.16;其热变形激活能Q为143.89 kJ/mol。

关键词:6082铝合金;热压缩变形;本构模型

中图分类号:TG 146.2 文献标识码:A

Constitutive model for hot deformation of 6082 aluminum alloy

LI Xue-song, CHEN Jun, ZHANG Hong-bing

(National Die & Mold CAD Engineering Research Center, Shanghai Jiao Tong University, Shanghai 200030, China)

Abstract: The flow stress behavior of 6082 aluminum alloy was studied by single-pass high temperature compression experiment on Gleeble-1500 thermal-mechanical simulator, over a range of temperature of 300-500 ℃ and a range of strain rate of 0.01-10 /s. The results demonstrate that the hot deformation behavior of 6082 aluminum alloy exhibits strain-hardening to a steady-state, and the softening mechanism was mainly controlled by dynamic recovery (DRV). The value of flow stress is significantly affected by deformation temperature and strain rate, which decreases as temperature becomes higher and as strain rate becomes lower, indicating that 6082 aluminum alloy is a positive strain rate sensitive material. The flow stress of this alloy can be represented by Zener-Hollomon parameter function , and values of related parameters A, α and n, are 3.97×1011 s-1, 0.01 MPa-1 and 9.16, respectively. Its activation energy for hot deformation Q is 143.89 kJ/mol.

Key words: 6082 aluminum alloy; hot compression; constitutive model

6082铝合金属于Al-Mg-Si系,是一种可热处理强化的变形铝合金,具有良好的可成形性,耐腐蚀性好,强度中等,用其制造的模锻件被广泛用于航空航天、建筑、汽车等行业。目前对于6082铝合金热塑性方面的研究主要集中在两个方面:一个方面是研究不同的热处理制度(回火、退火、固溶)对于该材料力学性能的影响[1-5];另一方面是研究该合金的成分以及热加工工艺(热轧、热挤压)对最终产品力学性能的影响,通过合理设计合金成分及生产工艺,使产品达到较高的综合性能[6-9]。对6082铝合金原始挤压棒材高温下的力学性能的研究报道较少。

目前,数值模拟技术已经广泛应用于铝合金加工工艺中,该技术的应用可以减少传统生产工艺中的试模次数,缩短生产周期,降低生产成本。材料的本构模型是描述材料的流动应力与应变、应变速率和温度之间的关系,是影响数值模拟结果准确性的重要因素之一。

本文作者对6082铝合金进行了高温单道次压缩实验,研究其高温流变应力行为,建立能够准确描述该合金流动特性的本构模型,从而为制定该合金的高温塑性成形工艺提供理论依据。

1 实验

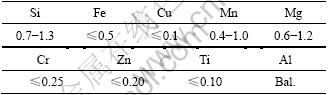

实验所用的材料为上海汇众汽车制造有限公司提供的6082铝合金挤压棒材,其化学成分见表1。为了获取成分均匀的试样,用线切割从棒材的中径处割取尺寸为d10 mm×15 mm的圆柱体试样,如图1所示。

表1 6082铝合金化学成分

Table 1 Chemical compositions of 6082 aluminum alloy (mass fraction, %)

图1 试样制备示意图

Fig.1 Preparation of specimen: (a) Cutting specimen from cylindrical billet; (b) Dimension of specimen

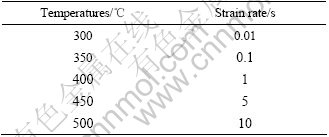

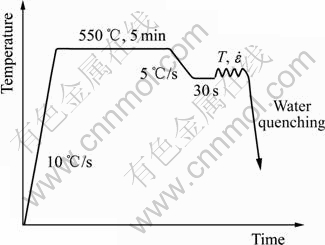

实验设备采用Gleeble-1500热力模拟机,润滑剂为石墨加机油[10-11],实验取的变形温度为300~500 ℃ ,应变速率为0.01~10/s,如表2所示。总的压缩量达到真应变值0.7,即总变形程度为50%左右,压缩量不能过大,否则试样两端摩擦的影响会增大,从而降低实验的准确度。具体的实验方案如图2所示,试样以10 ℃/s的加热速度加热至550 ℃,保温5 min以获得均匀的微观组织,然后以5 ℃/s的冷却速度冷却至实验温度,停留30 s使得试样的温度分布均匀,随后在指定的温度和应变速率下进行压缩变形,变形终了立即水淬,以便保留高温微观组织。

表2 6082铝合金实验参数

Table 2 Experimental parameters of 6082 aluminum alloy

图2 高温压缩实验方案

Fig.2 Scheme of high temperature compression experiment

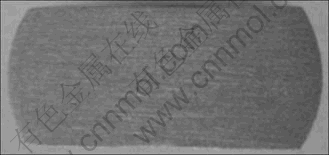

压缩后试样腰部发生“鼓肚”,试样纵截面如图3所示。为了衡量单向热压缩实验的有效性,文献[12] 推荐英国国家物理实验室的评判标准,该实验室经过大量对比实验及组织观察,提出膨胀系数B这一物理量,即:

(1)

(1)

式中 B为膨胀系数;L0、d0为试样原始高度和直径,mm;Lf为压缩后试样平均高度(取试样两端部中心及圆周每隔120?的3个点,共测量试样4个高度值进行平均),mm;df为压缩后试样平均直径(腰部和端部相平均),mm。英国学者认为,当B≥0.9时,单向热压缩实验的结果是有效的;当B<0.9时,单向热压缩实验的结果需要进行修正。经测定和计算,Lf=7.48 mm,df=14.71 mm,膨胀系数B=0.927,说明实验的结果是有效的,不需要修正。

图3 热压缩后试样的纵截面

Fig.3 Vertical section of specimen after hot compression

2 结果与分析

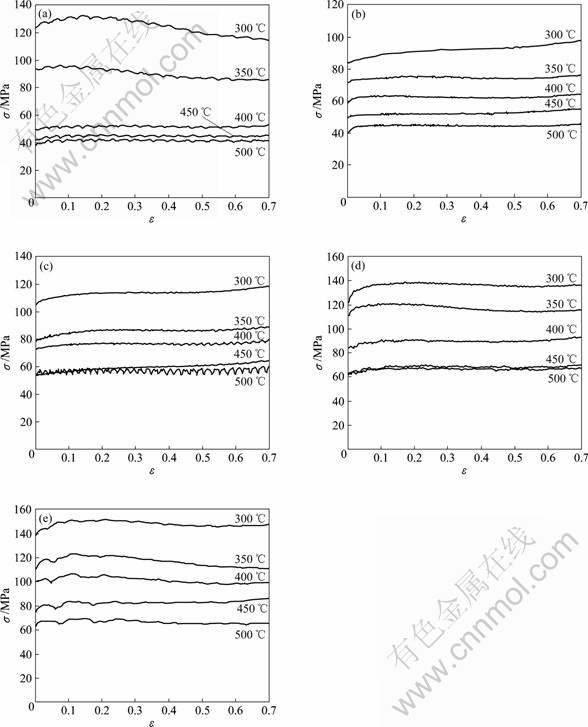

6082铝合金高温单道次压缩变形的真应力—真应变曲线如图4所示。由图4曲线的形态可以发现,6082铝合金的热变形可以分为应变硬化和稳态变形两个阶段。由于铝合金属于高层错能的金属,扩展位错较窄,利于发生交滑移,因此一般认为铝合金在热变形过程中的主要软化机制是动态回复[13]。在应变硬化阶段,流变应力随形变量的增加迅速上升,位错不断增殖,位错间的交互作用增大了位错运动的阻力,交滑移引起的软化作用不足以克服位错密度增加带来的硬化,因此,在峰值应力之前加工硬化占主导。流变应力达到峰值以后,进入稳态变形,随着应变的增加,真应力基本不变。稳态变形的实质是位错增殖引起的应变硬化和异号位错之间的相互销毁以及位错的重排引起的软化之间达到了动态平衡。由于位错运动速度极快,在其热加工过程中,硬化和软化过程几乎同时完成,其硬化和软化可以在瞬间达到动态平衡,从而其应力—应变曲线几乎为一直线 [14]。

图4 6082铝合金在不同应变速率下高温单道次压缩变形的真实应力—应变曲线

Fig.4 True stress—true strain curves of 6082 aluminum alloy by high temperature single-pass compression experiment at different strain rates: (a) 0.01/s; (b) 0.1/s; (c) 1/s; (d) 5/s; (e) 10/s

由图4可见该合金流变应力的大小受变形温度和应变速率的强烈影响。在同一变形速率下,6082铝合金的流变应力和峰值应变(峰值应力对应的应变值)随变形温度的升高而降低。产生这一现象的物理本质可能是:随着温度的升高,材料热激活作用增强,金属原子平均动能和扩散速率增加,导致由动态回复引起的软化作用增强,从而使得材料的加工硬化作用与软化作用在达到平衡时,流变应力值和峰值应变值减小。

在同一变形温度下,6082铝合金的流变应力和峰值应变(峰值应力对应的应变值)随应变速率的增加而增加,这说明该合金为正应变速率敏感材料。

3 本构模型的建立

在热变形过程中,材料在任何应变或稳态下的高温流变应力σ取决于变形温度T和应变速率 。对不同热加工数据的研究表明,σ和

。对不同热加工数据的研究表明,σ和 、T之间的数学关系表达式主要有以下3种情况[15-16]:

、T之间的数学关系表达式主要有以下3种情况[15-16]:

低应力水平时

高应力水平时

整个应力范围

式中 A1、A2、A、n1、n、α、β均为与温度无关的常数,A 为结构因子,s-1;n为应力指数;α、β为应力水平参数,MPa-1;α和β、n1之间满足α=β/n1;Q为变形激活能,J/mol,其值反映了材料热变形的难易程度,也是材料在热变形过程中重要的力学性能参 数,其值通常与激活焓?H相等;R为摩尔气体常数,J/(mol?K);σ为峰值应力或稳态流变应力,或相应于某指定应变量时对应的流变应力,MPa。

ZENER和HOLLOMON提出并验证了应变速率 和温度T的关系可用下式来表示[17]:

和温度T的关系可用下式来表示[17]:

联立式(4)和(5),可得Z和σ之间的关系式为

对式(2)和(3)两边取对数可得

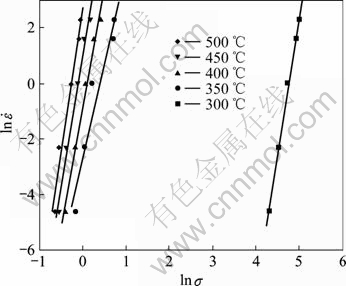

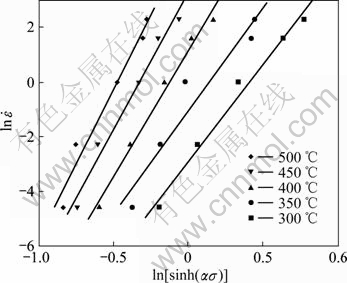

用数学软件Origin作线性回归处理,得到ln — ln σ关系曲线如图5 所示,ln

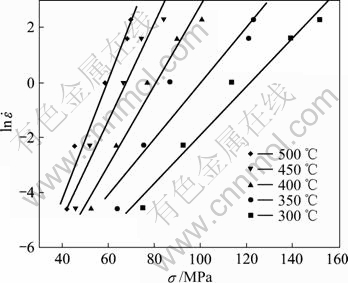

— ln σ关系曲线如图5 所示,ln —σ关系曲线如图6 所示。由式(7)和(8)可知,当温度一定时,n1和β分别为ln

—σ关系曲线如图6 所示。由式(7)和(8)可知,当温度一定时,n1和β分别为ln —ln σ、ln

—ln σ、ln —σ曲线的斜率。n1值取图5中峰值应力较低,即温度为400、450、500 ℃的3条直线斜率的平均值,得n1=9.58;β值取图6中峰值应力较高,即温度为300、350 ℃的两条直线斜率的平均值,得β=0.095 MPa-1;则α=β/n1=0.01 MPa-1;

—σ曲线的斜率。n1值取图5中峰值应力较低,即温度为400、450、500 ℃的3条直线斜率的平均值,得n1=9.58;β值取图6中峰值应力较高,即温度为300、350 ℃的两条直线斜率的平均值,得β=0.095 MPa-1;则α=β/n1=0.01 MPa-1;

从式(9)可以确定:

当温度恒定时,

当应变速率恒定时,

图5 ln —ln σ关系

—ln σ关系

Fig.5 Relationships between ln and ln σ at different temperatures

and ln σ at different temperatures

图6 不同温度下ln —σ关系

—σ关系

Fig.6 Relationships between ln and σ at different temperatures

and σ at different temperatures

图7 不同温度下ln —ln[sinh(ασ)]关系

—ln[sinh(ασ)]关系

Fig.7 Relationships between ln and ln[sinh(ασ)] at different temperaturtes

and ln[sinh(ασ)] at different temperaturtes

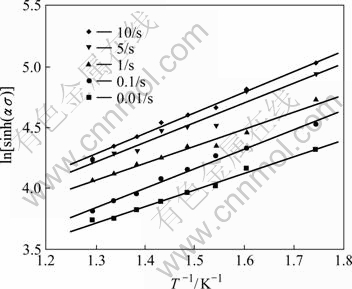

图8 不同温度下ln[sinh(ασ)]—1/T关系

Fig.8 Relationships between ln[sinh(ασ)] and 1/T at different temperatures

根据式(10)和(11),取σ为峰值应力,将图4 中不同温度下6082铝合金变形时的峰值应力、应变速率值和所求的α值代入式(9),用数学软件Origin作线性回归处理,绘制出相应的 —

— 关系曲线如图7 所示;

关系曲线如图7 所示; —1/T关系曲线如图8 所示。n和Q/Rn分别为

—1/T关系曲线如图8 所示。n和Q/Rn分别为 —

— 、

、 —1/T曲线的斜率,由此,可求得变形激活能Q以及应力指数n,其值分别为:Q=143.89 kJ/mol,n=9.16。铝合金6082的应变激活能Q值比纯铝的自扩散激活能值要大,这是由于Mg、Si等原子的溶入,产生了强化所致。

—1/T曲线的斜率,由此,可求得变形激活能Q以及应力指数n,其值分别为:Q=143.89 kJ/mol,n=9.16。铝合金6082的应变激活能Q值比纯铝的自扩散激活能值要大,这是由于Mg、Si等原子的溶入,产生了强化所致。

由图7可知,ln 和ln[sinh(ασ)]较好地满足了线性关系,即6082铝合金高温压缩变形时的应力—应变速率满足双曲正弦函数关系,可用双曲正弦函数关系描述该合金整个应力水平下的流动应力和应变速率之间的关系,为通过控制应变速率来控制热加工的应力水平和力学性能的加工工艺制定提供了理论依据。由图8可知,ln[sinh(ασ)]和1/T较好地符合了线性关系,从而证实了6082铝合金高温变形时应力和变形温度之间的关系属于Arrhenius关系,即可用包含Arrhenius项的Z参数描述该合金在高温压缩变形时的流变应力行为。这种关系同时说明,6082铝合金热变形是受热激活控制的。

和ln[sinh(ασ)]较好地满足了线性关系,即6082铝合金高温压缩变形时的应力—应变速率满足双曲正弦函数关系,可用双曲正弦函数关系描述该合金整个应力水平下的流动应力和应变速率之间的关系,为通过控制应变速率来控制热加工的应力水平和力学性能的加工工艺制定提供了理论依据。由图8可知,ln[sinh(ασ)]和1/T较好地符合了线性关系,从而证实了6082铝合金高温变形时应力和变形温度之间的关系属于Arrhenius关系,即可用包含Arrhenius项的Z参数描述该合金在高温压缩变形时的流变应力行为。这种关系同时说明,6082铝合金热变形是受热激活控制的。

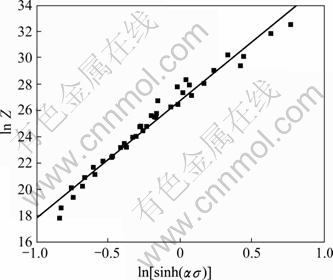

对式(6)两边取对数可以得到

ln Z=ln A+nln[sinh(ασ)] (13)

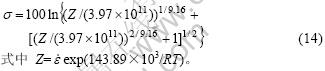

用数学软件Origin作线性回归处理,得ln Z—ln[sinh(ασ)]关系曲线,如图9所示。显然6082铝合金ln Z和ln[sinh(ασ)]之间满足线性关系。求取该直线的截距为 ln A=26.75,则材料常数A值为3.97×1011。

图9 ln Z—ln[sinh(ασ)]关系

Fig.9 Relationship between ln Z and ln[sinh(ασ)]

根据式(6)以及反双曲正弦函数的定义,可将流变应力表达为Zener-Hollomon参数Z值的函数,并将以上所求的α、A、n值代入得

4 结论

1) 6082铝合金高温单道次压缩下的流变应力经历了从应变硬化阶段过渡到稳态变形阶段,高温软化机制主要是动态回复。

2) 在同一应变速率下,6082铝合金的流变应力和峰值应变随温度的升高而降低。

3) 在同一温度下,6082铝合金的流变应力和峰值应变随应变速率的增大而提高,说明该合金是正应变速率敏感材料。

4) 可采用Zener-Hollomon参数的双曲正弦函数来描述6082铝合金高温流变应力σ。

REFERENCES

[1] SPIGARELLI S, EVANGELISTA E, MC QUEEN H J. Study of hot workability of a heat treated AA6082 aluminum alloy[J]. Scripta Materialia, 2003, 49: 179-183.

[2] ZHANG B, BAKER T N. Effect of the heat treatment on the hot deformation behavior of AA6082 alloy[J]. Journal of Materials Processing Technology, 2004, 153/154: 881-885.

[3] BIROL Y. The effect of processing and Mn content on the T5 and T6 properties of AA6082 profiles[J]. Journal of Materials Processing Technology, 2003, 173: 84-91.

[4] GARRETT R P, LIN J, DEAN T A. An investigation of the effects of solution heat treatment on mechanical properties for AA 6XXX alloys: Experimentation and modeling[J]. International Journal of Plasticity, 2005, 21: 1640-1657.

[5] 邹永恒, 陶 红, 徐国明, 李永佳, 朱浩峰. 6082铝合金热处理工艺参数的研究[J]. 金属热处理, 2007, 32(10): 71-76.

ZOU Yong-heng, TAO Hong, XU Guo-ming, LI Yong-jia, ZHU Hao-feng. Research on heat treatment parameters of 6082 aluminum alloy[J]. Heat Treatment of Metals, 2007, 32(10): 71-76.

[6] 马英义, 宛亚坤, 王景新. 6082铝合金热轧工艺研究[J]. 轻合金加工技术, 2000, 28(6): 11-13.

MA Ying-yi, WANG Ya-kun, WANG Jing-xin. The hot rolling process of 6082 aluminum alloy[J]. Light Alloy Fabrication Technology, 2000, 28(6): 11-13.

[7] 周 霞. 影响6082合金棒材性能的因素[J]. 有色金属加工, 2007, 36(3): 38-40.

ZHOU Xia. Factors Influencing properties of 6082 alloy bar[J]. Nonferrous Metals Processing, 2007, 36(3): 38-40.

[8] 罗 均, 倪 希. 6082铝合金挤压铝型材生产工艺研究[J]. 冶金丛刊, 2007(4): 4-5.

LUO Jun, NI Xi. Research on production technology of 6082 Al-alloy extrusion section bar[J]. Metallurgical Collections, 2007(4): 4-5.

[9] 金 曼, 孙保良, 李 晶, 邵光杰. 微量元素Zr对6082铝合金高温软化性能的影响[J]. 金属热处理, 2005, 30(7): 6-9.

JIN Man, SUN Bao-liang, LI Jing, SHAO Guang-jie. Effect of Zr addition on high temperature softening of 6082 Al-Mg-Si alloy[J]. Heat Treatment of Metals, 2005, 30(7): 6-9.

[10] 李慧中, 张新明, 陈明安, 周卓平. 2519铝合金热变形流变行为[J]. 中国有色金属学报, 2005, 15(4): 621-625.

LI Hui-zhong, ZHANG Xin-ming, CHEN Ming-an, ZHOU Zhuo-ping. Hot deformation behavior of 2519 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(4): 621-625.

[11] 吴文祥, 孙德勤, 曹春艳, 王战峰, 张 辉. 5083铝合金热压缩变形流变应力行为[J]. 中国有色金属学报, 2007, 17(10): 1667-1671.

WU Wen-xiang, SUN De-qing, CAO Chun-yan, WANG Zhan-feng, ZHANG Hui. Flow stress behavior of 5083 aluminum alloy under hot compression deformation[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(10): 1667-1671.

[12] CHEN W. Gleeble system and application[M]. New York: Gleeble System School, 1998

[13] 王祝堂, 田荣璋. 铝合金及其加工手册[M]. 长沙: 中南大学出版社, 2005: 127-130.

WANG Zhu-tang, TIAN Rong-zhang. Aluminum alloys and manual of its manufacture[M]. Changsha: Central South University Press, 2005: 127-130.

[14] MC QUEEN H J, FRY E, BELLING J. Comparative constitutive constants for hot working of Al-4.4Mg-0.7Mn (AA5083)[J]. Journal of Materials Engineering and Performance, 2001, 10(2): 164-172.

[15] JONAS J, SELLARS C M, TEGART W J, MC G. Strength and structure under hot working condition[J]. International Metal Reviews, 1969, 14(130): 1-4.

[16] SHI H, MCLAREN A J, SELLARS C M, SHAHANI R, BOLINGBROKE R. Constitutive equations for high temperature flow stress of aluminum alloys[J]. Material Science and Engineering, 1997, 13: 210-216.

[17] ZENER C, HOLLOMON J H. Effect of strain rate upon the plastic flow of steel[J]. Journal of Applied Geophysics, 1944, 15(1): 22-32.

基金项目:国家重点基础研究发展计划资助项目(2006CB705401)

收稿日期:2008-03-12;修订日期:2008-06-02

通讯作者:李雪松,博士研究生;电话:021-62813430-8313;E-mail: steven_sjtu@sjtu.edu.cn

(编辑 何学锋)