压边圈类型对5182-O铝合金薄板室温拉深性能的影响

来源期刊:中国有色金属学报(英文版)2016年第5期

论文作者:王游根 黄光胜 刘定凯 陈 琳 韩廷状 彭 建 潘复生

文章页码:1251 - 1258

关键词:5182-O铝合金;拉深;压边圈;制耳;起皱

Key words:5182-O aluminum alloy; deep drawing; blank holder; earring; wrinkling

摘 要:采用平面和曲面两种压边圈来研究压边圈类型对5182-O铝合金板材室温拉深性能的影响。通过光学显微镜(OM)来研究铝合金板材的显微组织。结果表明:使用平面压边圈的极限拉深比为1.7,而且拉深杯出现了严重的制耳。相比之下,使用曲面压边圈,板材的极限拉深比提高到2.0。曲面压边圈提供的压边力能弱化制耳,阻止板材法兰起皱,这是因为板材在曲面压边圈作用下,在不同方向的流动更均匀。

Abstract: To study the influence of blank holder type on the drawability of 5182-O aluminum sheet at room temperature, the flat blank holder and curved blank holder were employed during the deep drawing process. The microstructures were characterized by optical microscopy (OM). The results reveal that the limiting drawing ratio (LDR) of 5182-O aluminum alloy sheet is 1.7 using the flat blank holder. The drawn cup have severe earring. Compared with using flat blank holder, the LDR of 5182-O aluminum alloy sheet is enhanced to 2.0 using curved blank holder. In addition, the earring ratio also reduces and flange wrinkling is prevented when the curved blank holder is used. These are due to a more uniform sheet flow in different directions with curved blank holder.

Trans. Nonferrous Met. Soc. China 26(2016) 1251-1258

You-gen WANG1, Guang-sheng HUANG1,2, Ding-kai LIU1, Lin CHEN1,

Ting-zhuang HAN1, Jian PENG1, Fu-sheng PAN1,2

1. State Key Laboratory of Mechanical Transmission, College of Materials Science and Engineering,

Chongqing University, Chongqing 400044, China;

2. Chongqing Academy of Science and Technology, Chongqing 401123, China

Received 4 June 2015; accepted 22 March 2016

Abstract: To study the influence of blank holder type on the drawability of 5182-O aluminum sheet at room temperature, the flat blank holder and curved blank holder were employed during the deep drawing process. The microstructures were characterized by optical microscopy (OM). The results reveal that the limiting drawing ratio (LDR) of 5182-O aluminum alloy sheet is 1.7 using the flat blank holder. The drawn cup have severe earring. Compared with using flat blank holder, the LDR of 5182-O aluminum alloy sheet is enhanced to 2.0 using curved blank holder. In addition, the earring ratio also reduces and flange wrinkling is prevented when the curved blank holder is used. These are due to a more uniform sheet flow in different directions with curved blank holder.

Key words: 5182-O aluminum alloy; deep drawing; blank holder; earring; wrinkling

1 Introduction

As the light metal structural materials, magnesium alloys and aluminum alloys have recently attracted a lot of research interests because of their potential application on lightweight structural components [1-4]. However, due to the limited available slip systems of a hexagonal close packed (HCP) crystal structure [5], the poor plasticity and ductility of magnesium alloy restrict its wide applications [6]. Different from magnesium alloy, the advantages of high specific strength, excellent mechanical properties and recycling potential make aluminum alloy become a promising light material [7]. Especially, the 5000 series aluminum alloys are suitable for the application of auto-industry [8], owing to their medium strength, molding properties, low density, weldability and excellent corrosion resistance. However, owning to the planar anisotropy, flange earring is an important forming defect in the deep drawing process [9]. Moreover, the room temperature formability restricts increasing use of aluminum alloys compared with steels [10].

Aluminum sheets produced by rolling processes exhibit a preferred orientation which leads to a plastic anisotropy, expressed by the r-value. It is known that the r-value influences not only the drawability of the sheet in deep drawing, but also the uniformity of deformation in stamping. NIRANJAN and CHAKKINGAL [11] found that the drawability of 1100 aluminum alloy increased with the increase of r-value in groove pressing experiment. GHOSH et al [12] found that the height of ears of aluminum alloy was reduced with increasing r-value in warm deep drawing experiments. Deep drawing is an important and popular forming process for the production of flat components. Therefore, many studies focused on improving the drawability of aluminum alloys. LANG et al [13,14] found that the drawing ratio of AL6016-T4 could reach 2.46 during the hydrodynamic deep drawing assisted by radial pressure. NAMOCO et al [15,16] investigated the mechanical properties of aluminum alloy sheets. They found that the technique of bulging and embossing improved the deep drawability and the bending strength of aluminum alloy sheet.

Although many studies have been conducted to improve the deep drawability of aluminum alloys at room temperature, the earring and wrinkling still cannot be avoided. MORI and TSUJI [17] demonstrated that the limiting drawing ratio (LDR) of rolled AZ31 magnesium alloy sheets increased to 1.75 by the ring-shaped projection provided by blank holder. ZHANG et al [18] found that flange edge fracture was prevented using a ring-shaped blank holder. These were because the curved blank holder could offer a pressure onto the edge of sheet passing through the die corner. Compared with magnesium alloys, the flange wrinkling and the flange earring appear more easily in aluminum alloys during deep drawing. However, the effect of blank holder type on the deformation behaviors of

aluminum alloy sheet in deep drawing is rarely researched, especially on the flange earring and the flange wrinkling. In this work, the effect of flat blank holder and curved blank holder on the deformation behaviors of 5182-O aluminum sheet in deep drawing at room temperature was investigated, and the microstructure evolution, LDR, thickness distribution, tool configuration, anisotropic effect, as well as wrinkling behavior and earring phenomenon were studied.

2 Experimental

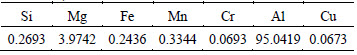

The as-rolled commercial 5182 aluminum alloy sheets with a thickness of 1 mm were provided by Southwest Aluminum Group Co., Ltd., of China. The 5182 aluminum sheets were annealed at 330 °C for 2 h followed by air cooling. The composition of this alloy is shown in Table 1.

Table 1 Main composition of 5182-O aluminum alloy (mass fraction, %)

According to General Administration of Quality Supervision, Inspection and Quarantine of China (AQSIQ) Standard GB/T228-2002, 5182-O sheets were cut into dumbbell-shaped tension specimens with 40 mm in gauge length, 10 mm in gauge width and 1 mm in gauge thickness which were machined at the angles of 0°, 45° and 90° along the rolling direction (RD). Uniaxial tensile tests were carried out on a CMT6305-300KN electronic universal testing machine with a strain rate of 1×10-3 s-1 at room temperature. The strain hardening exponent (n-value) is determined from the uniform plastic deformation region of the tensile stress-strain curve. The navg is the weighted average of n-values in three directions. This is defined as follows:

navg=(n0+2n45+n90)/4 (1)

where n0, n45 and n90 stand for the n-values along 0°, 45° and 90° to rolling direction, respectively. Lankford value (r-value) is calculated by the thickness strain and width strain at the deformed strain of 15%. The normal anisotropy coefficient ravg is the weighted average of r-values in three directions. This is defined as follows:

ravg=(r0+2r45+r90)/4 (2)

Δr is the planar anisotropy and defined by

Δr = (r0+r90)/2-r45 (3)

where r0, r45 and r90 stand for the r-values along 0°, 45° and 90° to rolling direction, respectively.

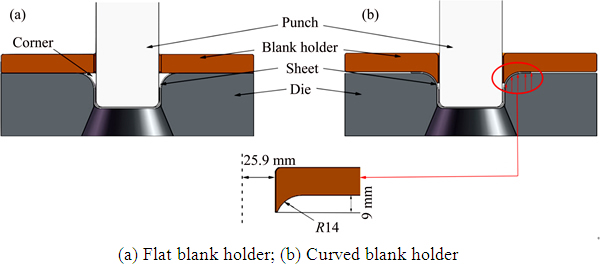

The circular blanks with different diameters were machined from 5182-O aluminum sheets for deep drawing tests. The schematic of deep drawing process is shown in Fig. 1, where the blank holders in Figs. 1(a) and (b) are flat blank holder and curved blank holder, respectively. Deep drawing tests were conducted using the flat blank holder with a constant force from 3 to 10 kN, which corresponded with different blank sizes. However, using the curved blank holder, the force was reduced to a constant value from 1.5 to 4 kN. The same stamping speed was set as v=5 mm/min. Anti-wear hydraulic oil was used as the lubricant. The diameter and the shoulder radius of the punch are 50.00 and 5.00 mm, respectively. The diameter of the die hole is 53.64 mm and the clearance between the punch and the die is 1.82 mm.

Fig. 1 Schematic of apparatus for deep drawing

3 Results and discussion

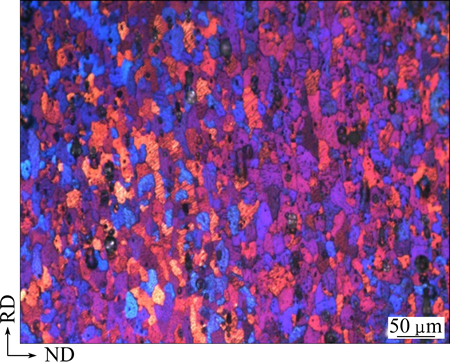

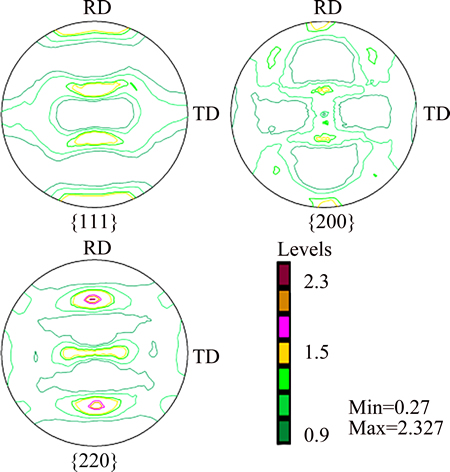

The grain sizes were measured by analyzing the optical micrograph using the line-intercept method. It can be seen from Fig. 2 that most grains are elongated along rolling direction (RD) and a few grains are nearly equiaxed after annealing. The average grain size in the rolling direction is 22.90 μm while the grain size normal to the rolling direction (ND) is 14.50 μm. Texture measurements were performed at quarter thickness of 5182-O aluminum sheet. The pole figures of 5182-O aluminum sheet are shown in Fig. 3 as a representative of annealed textures. It is observed that the typical rolling textures exist in the 5182-O aluminum sheet. It is consistent with the previous investigation [19] that the preferred orientations existing in recrystallized aluminum alloy sheets are mainly made up of retained texture, i.e., the rolling texture components Copper {112}<111>, S {123}<634> and Brass {011}<112>. Brass and Copper components are known to constitute a deformation texture, which is usually found during plane strain compression of FCC (face centered-cubic) metals.

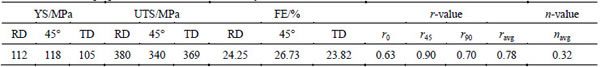

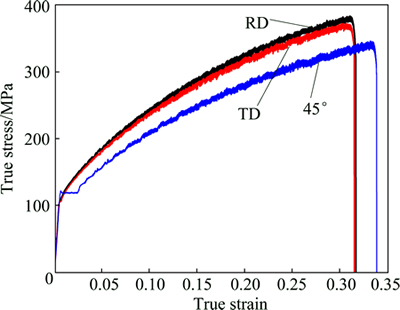

The true stress-strain curves of 5182-O aluminum sheets along RD, 45° direction and transverse direction (TD) are shown in Fig. 4. The 0.2% yield strength (YS), ultimate strength (UTS) and failure elongation (FE) are summarized in Table 2, and the r-values and n-values are included. As shown in Table 2, the YSs of 5182-O aluminum alloy are very close in three directions. The r-value of this alloy increases from 0.63 in RD to 0.90 in 45° direction, before it drops to 0.7 in TD. As well as r-value, the FE with the maximum of 26.73% is also obtained in 45° direction. It is observed that the true stress-strain curves of 5182-O aluminum alloy shown in Fig. 4 turn to be jagged after yield deformation. The serrations on the true stress-true strain curve are caused by dynamic strain aging and the Portevin-Le Chatelier (PLC) effect on 5182-O aluminum alloy [20,21]. It is well known for Al alloy with high Mg addition and the interaction between solute Mg and glide dislocations, referred to as dynamic strain aging, will result in PLC effect. Dynamic strain aging is associated with conditions when point defects can diffuse towards mobile dislocations and temporarily arrest them. The results of dynamic strain aging are higher flow stress and greater strain hardening at lower strain rates than those at higher ones, and further serrated stress-strain curves, discontinuous plastic flow and propagating, deformation bands can be conducted by dynamic strain aging [21]. The yield platform only appears in 45° direction. The specimens exhibit yield anisotropic in RD, 45° direction and TD. The yield strengths along RD and TD are all less than that along 45° direction. The mechanical properties along RD, 45° direction and TD exhibit a slight anisotropy. These may be related to the typical rolling texture: Brass {110}<112>, Copper {112}<111> and S {123}<634> textures. JATA and SINGH [22] found that a strong brass texture component was presented and it was responsible for the property anisotropy of rolled or extruded aluminum alloys. Due to the weakness of the overall texture, the anisotropy is not so obvious in 5182-O aluminum alloy.

Fig. 2 Optical micrograph of RD-ND plane of 5182-O aluminum sheet

Fig. 3 XRD pole figures of 5182-O aluminum sheet

Table 2 Mechanical properties of 5182-O aluminum alloy

Fig. 4 True stress-strain curves of 5182-O aluminum sheets at room temperature

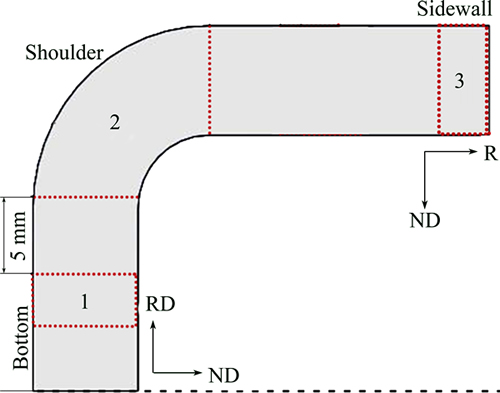

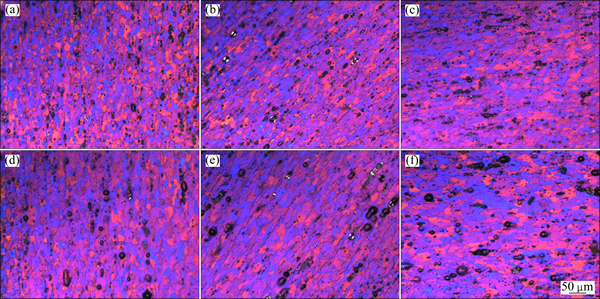

Three areas (1-3) on the cutting planes of the drawn cups are shown in Fig. 5, in which the optical microstructures are observed. Area 1 denotes the position at the bottom with the distance of 5 mm from the shoulder, Area 2 denotes the position at the shoulder, and Area 3 denotes the position at the top of sidewall. Figure 6 shows the microstructures of the cup specimens after deep drawing with flat blank holder and curved blank holder. Since the deformations of the shoulder of cup are bending, stretching and slipping during deep drawing, the grains at the shoulder (Area 2) are elongated and streamline emerges. As expected, the strain is the lowest at the center bottom of the cup and grains at the bottom of the cup almost maintain the original shape. The microstructure has no difference between Area 1 and Area 2. Since the curved blank holder cannot be used directly in deep drawing process because curved blank holder will damage the sheet. Therefore, at the initial stage of deep drawing process, let the punch move down more than 9 mm using the flat blank holder. Secondly, exchanging the flat blank holder by curved blank holder can offer curved blank holder force (CBHF) on blank during the subsequent deep drawing. Except being elongated, the grains at the top of sidewall (Area 3) do not appear difference though using two different blank holders. It is because the type of blank holder cannot change the deformation behaviors of aluminum metal.

Fig. 5 Profile of drawn cup used for microstructure observation

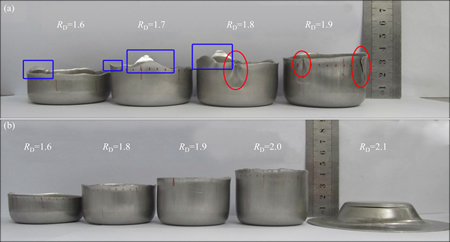

Drawing ratio (DR), RD, is commonly expressed by RD =d0/dp, where d0 and dp are the blank diameter and punch diameter, respectively. Figure 7 shows the deep drawing cups produced with two blank holders. It is obvious that the LDR of sheet equals 1.7 and the ears (in the blue rectangle box) occur when the flat blank holder is used. Wrinkling behavior (in the red oval) occurs when RD is greater than 1.7. This is because, at the initial stage of deep drawing process, the circular blank is always under blank holder force (BHF) using the flat blank holder. Since the stress state in the outer flange is pure circumferential compression, it is expected that the BHF prevents wrinkling. As the punch moves down, the blank will enter into the die corner where the BHF cannot be applied on the blank, as shown in Fig. 1. In deep drawing, the quality of the formed parts is affected by the volume of the blank passing through the die corner. Excessive metal-flow will cause wrinkles in the part while insufficient metal flow will result in the occurrence of tears or fracture. The blank holder force plays a key role in regulating the metal flow [23]. Therefore, the blank at die corner without BHF results in excessive metal flow and it will cause flange wrinkling. In order to prevent flange wrinkling and fracture, the flat blank holder can be replaced by curved blank holder which can offer curved blank holder force (CBHF) on blank at the intermediate stage of the deep drawing. The blank at the shoulder is always under CBHF until deep drawing is accomplished. The LDR of sheet using curved blank holder rises to 2.0. The flange earring phenomenon is weakened and the wrinkle-free cup is drawn. Therefore, the curved blank holder is employed after the blank passing through the shoulder, which is helpful to improve the flow uniformity of Al sheet.

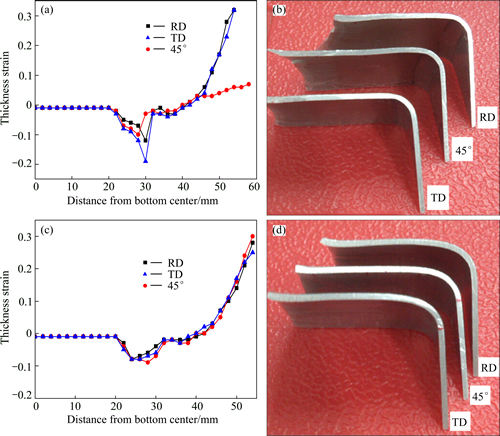

Thickness distribution is one of the quality criteria in sheet metal formed parts. Fracture in deep drawn parts usually occurs by thinning. Therefore, the thickness distribution was discussed. The drawn cups were sectioned along RD, 45° direction and TD and the thickness values of 28 or 30 points at uniform intervals from the center of the cup to the edge of the flange were measured. Significant difference in the measured strains in the two cases is exhibited in thickness strains, as shown in Fig. 8. The valleys of the curves represent the sections of the cup corners (the shoulder). It can be seen from Fig. 8(a) that the thickness distributions in RD, 45° direction and TD are different, which may be owing to the different degrees of metal flow caused by the anisotropy. Due to the occurrence of earring in the 45° direction, compared with RD and TD, the increase of thickness in 45° direction is not obvious. The use of curved blank holder in deep drawing process is to reduce thickness variation. The thickness distributions in three different directions with curved blank holder show the same trend. The influence of anisotropy on the thickness distribution is weakened by offering CBHF onto the shoulder of blank. The CBHF results in the uniform flowing of the metal. The thickness shows a minimum value at the beginning of the formation of cup and then increases. As expected, the thickness strains are the lowest at the center bottom of the cup and increase progressively towards the top of the cup. The thickness at the shoulder of the cup decreases while increases at the sidewall. This is mainly related to the different stress states at various positions. The thickness strains at the punch nose and the center bottom of the cup are tension strain, but they become compressive strain at the middle and top of the cup [24]. It is well known that the stress in the hoop directions around the flange of the cup results in the increase of thickness during deep drawing.

Fig. 6 Optical micrographs of cup specimens at bottom (a, d), shoulder (b, e) and sidewall (c, f) using flat blank holder (a-c) and curved blank holder (d-f)

Fig. 7 Drawn cups by flat blank holder (a) and curved blank holder (b)

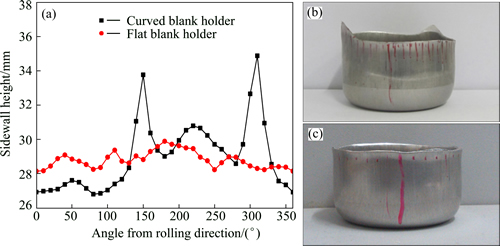

Figure 9 shows the sidewall height change of the cups from 0 to 360°. It can be seen that the number of ears is four. The curve indicates that, when flat blank holder is used, the earring mainly appears at angle of 45° relative to the rolling direction with a relatively large deviation of ±10° in each cup. The shapes of the earing profiles are consistent with the r-values reported in Table 2. Since the stress state in the outer flange is pure circumferential compression, it is expected that ears will occur along directions orthogonal to the maximum r-value directions, along 45° direction. It is in a good agreement with the result that the resulting cup height profiles exhibit a number of peaks and valleys, which equal the maxima and minima of the r-value, respectively [25]. The simulations were conducted based on B-L yield function and quasi-flow corner theory reported by HU et al [19], who discussed the effect of Δr on earring profile. As can be expected from the negative value of Δr, it makes the four earrings in 45° direction. For Brass and S textures, earring is also located at 45° direction. This phenomenon has been observed and verified by both experiment [26] and finite element simulation [27]. It can be obviously observed from Fig. 9 that the ears of the cup produced with flat blank holder are much higher than those produced with curved blank holder. Under the effect of CBHF in the die corner, the anisotropy will be weakened. The earring ratio, h, is given by

(4)

(4)

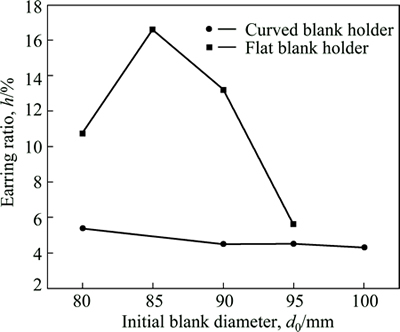

where  and

and  are the average values of the four maximum and four minimum heights of the drawn cup, respectively. The relationship between earring ratio and the initial blank diameter of drawn cups under two kinds of blank holder is shown in Fig. 10. The earring ratio shows the minimum value for an initial blank diameter of about 80 mm (a drawing ratio d0/dp of 1.6). The earring ratio decreases with the occurrence of wrinkling. Because CBHF on the shoulder of the blank makes the material flow into the die cavity uniformly, and the friction between the blank and the blank holder increases during the deep drawing process, the earring ratio is very low with curved blank holder. In addition to r-value, earing profile can also be influenced by the changes of friction condition between the blank and the tool surface as mentioned. The increase of the friction results in lower ears [12]. Therefore, the number of ears remains unchanged with the use of curved blank holder, but the height of ears is reduced.

are the average values of the four maximum and four minimum heights of the drawn cup, respectively. The relationship between earring ratio and the initial blank diameter of drawn cups under two kinds of blank holder is shown in Fig. 10. The earring ratio shows the minimum value for an initial blank diameter of about 80 mm (a drawing ratio d0/dp of 1.6). The earring ratio decreases with the occurrence of wrinkling. Because CBHF on the shoulder of the blank makes the material flow into the die cavity uniformly, and the friction between the blank and the blank holder increases during the deep drawing process, the earring ratio is very low with curved blank holder. In addition to r-value, earing profile can also be influenced by the changes of friction condition between the blank and the tool surface as mentioned. The increase of the friction results in lower ears [12]. Therefore, the number of ears remains unchanged with the use of curved blank holder, but the height of ears is reduced.

Fig. 8 Comparison of thickness strains (RD=1.8) using flat blank holder (a, b) and curved blank holder (c, d)

Fig. 9 Sidewall height of cup specimens after deep drawing (a), and drawn cups by flat blank holder (RD=1.8) (b) and curved blank holder (RD=1.8) (c)

Fig. 10 Relationship between initial blank diameter and earring ratio of drawn cups

4 Conclusions

1) The LDR of 5182-O aluminum alloy sheet is 1.7 when deep drawing using the flat blank holder. The 5182-O aluminum alloy sheet has a negative Δr because of slight anisotropy between RD, 45° direction and TD, which results in earring in 45° direction. Wrinkling behavior occurs when DR is greater than 1.7.

2) Earring phenomenon is weakened and wrinkling behaviors disappear by the adoption of curved blank holder. The LDR of 5182-O aluminum sheet increases to 2.0. It is suggested that the cold deep drawability of 5182-O aluminum sheet was improved using curved blank holder. The thickness distribution turns to be more uniform at the same time. These are mainly related to the force applied on the shoulder of blank by the curved blank holder.

Acknowledgment

The authors thank Southwest Aluminum Group Co., Ltd. of China for providing 5182 aluminum alloy sheet.

References

[1] ZHANG Hua, YAN Yan, FAN Jian-feng, CHENG Wei-li, ROVEN Hans  , XU Bing-she, DONG Hong-biao. Improved mechanical properties of AZ31 magnesium alloy plates by pre-rolling followed by warm compression [J]. Materials Science and Engineering A, 2014, 618: 540-545.

, XU Bing-she, DONG Hong-biao. Improved mechanical properties of AZ31 magnesium alloy plates by pre-rolling followed by warm compression [J]. Materials Science and Engineering A, 2014, 618: 540-545.

[2] ILANGOVAN M, BOOPATHY S R, BALASUBRAMANIAN V. Microstructure and tensile properties of friction stir welded dissimilar AA6061-AA5086 aluminium alloy joints [J]. Transactions of Nonferrous Metals Society of China, 2015, 25(4): 1080-1090.

[3] HUANG Guang-sheng, WANG Yan-xia, WANG Li-fei, HAN Ting-zhuang, PAN Fu-sheng. Effects of grain size on shift of neutral layer of AZ31 magnesium alloy under warm condition [J]. Transactions of Nonferrous Metals Society of China, 2015, 25(3): 732-737.

[4] HE Zhu-bin, FAN Xiao-bo, SHAO Fei, ZHENG Kai-lun, WANG Zhi-biao, YUAN Shi-jian. Formability and microstructure of AA6061 Al alloy tube for hot metal gas forming at elevated temperature [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(S2): s364-s369.

[5] ZHANG Hua, JIN Wei, FAN Jian-feng, CHENG Wei-li, ROVEN Hans  , XU Bing-she, DONG Hong-biao. Grain refining and improving mechanical properties of a warm rolled AZ31 alloy plate [J]. Materials Letters, 2014, 135: 31-34.

, XU Bing-she, DONG Hong-biao. Grain refining and improving mechanical properties of a warm rolled AZ31 alloy plate [J]. Materials Letters, 2014, 135: 31-34.

[6] ZHANG Hua, LIU Yang, FAN Jian-feng, ROVEN Hans  , CHENG Wei-li, XU Bing-she, DONG Hong-biao. Microstructure evolution and mechanical properties of twinned AZ31 alloy plates at lower elevated temperature [J]. Journal of Alloys and Compounds, 2014, 615: 687-692.

, CHENG Wei-li, XU Bing-she, DONG Hong-biao. Microstructure evolution and mechanical properties of twinned AZ31 alloy plates at lower elevated temperature [J]. Journal of Alloys and Compounds, 2014, 615: 687-692.

[7] XU Jun-li, ZHANG Jing, SHI Zhong-ning, GAO Bing-liang, WANG Zhao-wen, HU Xian-wei. Current efficiency of recycling aluminum from aluminum scraps by electrolysis [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(1): 250-256.

[8] SCHNEIDER R, GRANT R J, HEINE B,  R, BURGER S, ZOUAOUI Z. An analysis of the surface quality of AA5182 at different testing temperatures [J]. Materials and Design, 2014, 64: 750-754.

R, BURGER S, ZOUAOUI Z. An analysis of the surface quality of AA5182 at different testing temperatures [J]. Materials and Design, 2014, 64: 750-754.

[9] HU P, LIU Y Q, WANG J C. Numerical study of the flange earring of deep-drawing sheets with stronger anisotropy [J]. International Journal of Mechanical Sciences, 2001, 43(1): 279-296.

[10] TAMIMI S, CORREIA J P, LOPES A B, AHZI S, BARLAT F, GRACIO J J. Asymmetric rolling of thin AA-5182 sheets: Modelling and experiments [J]. Materials Science and Engineering A, 2014, 603: 150-159.

[11] NIRANJAN G G, CHAKKINGAL U. Deep drawability of commercial purity aluminum sheets processed by groove pressing [J]. Journal of Materials Processing Technology, 2010, 210(11): 1511-1516.

[12] GHOSH M, MIROUX A, WERKHOVEN R J, BOLT P J, KESTENS L A I. Warm deep-drawing and post drawing analysis of two Al-Mg-Si alloys [J]. Journal of Materials Processing Technology, 2014, 214(4): 756-766.

[13] LANG L H, DANCKERT J, NIELSEN K B. Investigation into hydrodynamic deep drawing assisted by radial pressure: Part I. Experimental observations of the forming process of aluminum alloy [J]. Journal of Materials Processing Technology, 2004, 148(1): 119-131.

[14] LANG L H, DANCKERT J, NIELSEN K B. Investigation into hydrodynamic deep drawing assisted by radial pressure: Part II. Numerical analysis of the drawing mechanism and the process parameters [J]. Journal of Materials Processing Technology, 2005, 166(1): 150-161.

[15] NAMOCO C S, IIZUKA T, HATANAKA N, TAKAKURA N, YAMAGUCHI K. Influence of embossing and restoration on the mechanical properties of aluminum alloy sheets [J]. Journal of Materials Processing Technology, 2007, 192-193: 18-26.

[16] NAMOCO C S, IIZUKA T, HATANAKA N, TAKAKURA N, YAMAGUCHI K. Effects of embossing and restoration process on the deep drawability of aluminum alloy sheets [J]. Journal of Materials Processing Technology, 2007, 187-188: 202-206.

[17] MORI K, TSUJI H. Cold deep drawing of commercial magnesium alloy sheets [J]. CIRP Annals—Manufacturing Technology, 2007, 56(1): 285-288.

[18] ZHANG Lei, HUANG Guang-sheng, ZHANG Hua, SONG Bo. Cold stamping formability of AZ31B magnesium alloy sheet undergoing repeated unidirectional bending process [J]. Journal of Materials Processing Technology, 2011, 211(4): 644-649.

[19] HU J G, IKEDA K, MURAKAMI T. Effect of texture components on plastic anisotropy and formability of aluminium alloy sheets [J]. Journal of Materials Processing Technology, 1998, 73(1): 49-56.

[20] ARETZ H. Numerical analysis of diffuse and localized necking in orthotropic sheet metals [J]. International Journal of Plasticity, 2007, 23(5): 798-840.

[21] ENGLER O. Texture and anisotropy in cold rolled and recovery annealed AA 5182 sheets [J]. Materials Science and Technology, 2015, 31(9): 1058-1065.

[22] JATA K V, SINGH A K. Texture and its effects on properties in aluminum-lithium alloys [M]. Boston: Butterworth-Heinemann, 2014: 139-163.

[23] RAJU S, GANESAN G, KARTHIKEYAN R. Influence of variables in deep drawing of AA 6061 sheet [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(10): 1856-1862.

[24] JAIN M, ALLIN J, BULL M J. Deep drawing characteristics of automotive aluminum alloys [J]. Materials Science and Engineering: A, 1998, 256(1): 69-82.

[25] YOON J W, BARLAT F, DICK R E, KARABIN M E. Prediction of six or eight ears in a drawn cup based on a new anisotropic yield function [J]. International Journal of Plasticity, 2006, 22(1): 174-193.

[26] LI J, LIU W C, YUAN H, GAO Y K. Comparison of earing behavior between continuous cast and direct chill cast AA 5182 aluminum alloys during cold rolling and annealing [J]. Journal of Materials Processing Technology, 2010, 210(14): 2007-2015.

[27] CHEN Y P, LEE W B, TO S. Influence of initial texture on formability of aluminum sheet metal by crystal plasticity FE simulation [J]. Journal of Materials Processing Technology, 2007, 192-193: 397-403.

王游根1,黄光胜1,2,刘定凯1,陈 琳1,韩廷状1,彭 建1,潘复生1,2

1. 重庆大学 材料科学与工程学院 机械传动国家重点实验室,重庆 400044;

2. 重庆市科学技术研究院,重庆 401123

摘 要:采用平面和曲面两种压边圈来研究压边圈类型对5182-O铝合金板材室温拉深性能的影响。通过光学显微镜(OM)来研究铝合金板材的显微组织。结果表明:使用平面压边圈的极限拉深比为1.7,而且拉深杯出现了严重的制耳。相比之下,使用曲面压边圈,板材的极限拉深比提高到2.0。曲面压边圈提供的压边力能弱化制耳,阻止板材法兰起皱,这是因为板材在曲面压边圈作用下,在不同方向的流动更均匀。

关键词:5182-O铝合金;拉深;压边圈;制耳;起皱

(Edited by Mu-lan QIN)

Foundation item: Project (CDJZR14130009) supported by the Fundamental Research Funds for the Central Universities, China

Corresponding author: Guang-sheng HUANG; Tel: +86-23-65112239; Fax: +86-23-65102821; E-mail: gshuang@cqu.edu.cn

DOI: 10.1016/S1003-6326(16)64225-5