文章编号:1004-0609(2011)01-0095-07

多弯道蛇形管浇注法制备半固态A356铝合金浆料

陈正周, 毛卫民, 吴宗闯

(北京科技大学 材料科学与工程学院,北京100083)

摘 要:采用多弯道蛇形管浇注技术制备半固态A356铝合金浆料。结果表明:在浇注温度为640~680 ℃的条件下,当弯道数量为3且直径为20 mm时,可获得形状因子F为0.72~0.85和晶粒直径D为55~75 μm的半固态浆料;当弯道数量为5且直径为20 mm时,可获得形状因子F为0.86~0.92和晶粒直径D为44~58 μm的半固态浆料;当弯道数量为5且直径为25 mm时,可获得形状因子F为0.76~0.90和晶粒直径D为48~68 μm的半固态浆料。弯道数量增加或弯道直径减小,可以改善初生α(Al)晶粒的形貌和尺寸。弯道内的合金熔体具有“自搅拌”的作用,可使初生晶核逐渐演变为球形或近球形晶粒。

关键词:半固态; A356铝合金; 多弯道蛇形管; 初生α(Al); 微观组织

中图分类号: TG249.9; TG146.2 文献标志码:A

Semi-solid A356 Al-alloy slurry prepared by serpentine pipe with multiple curves casting

CHEN Zheng-zhou, MAO Wei-min, WU Zong-chuang

(School of Materials Science and Engineering, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: Using serpentine pipe with multiple curves casting process, semi-solid A356 Al-alloy slurry was prepared. The results show that, at pouring temperatures of 640-680 ℃, when the number of the curves is 3 and their diameters are 20 mm, the semi-solid A356 Al-alloy slurry with shape factor of 0.72-0.85 and grain diameter of 55-75 μm can be prepared. When the number of the curves is 5 and their diameters are 20 mm, the semi-solid A356 Al-alloy slurry with shape factor of 0.86-0.92 and grain diameter of 44-58 μm can be prepared. When the number of the curves is 5 and their diameters are 25 mm, the semi-solid A356 Al-alloy slurry with shape factor of 0.76-0.90 and grain diameter of 48-68 μm can be prepared. With increasing the number of the curves or decreasing their diameters, the morphology and size of the primary α(Al) grains will be improved. The alloy melt has the effect of “self-stirring” in the serpentine curve, which can make the primary nuclei gradually evolve into spherical and near-spherical grains.

Key words: semi-solid; A356 Al-alloy; serpentine pipe with multiple curves; primary α(Al); microstructure

半固态金属(Semi-solid melt, SSM)浆料的制备一直是半固态金属成形领域的一个热点。近年来,出现了一些用无搅拌装置来制备SSM浆料的技术,如倾斜板浇注工艺(New rheocasting, NRC)[1-4]、直管法[5]、转动斜管法[6]、阻尼冷却管法[7-8]和波浪型倾斜板[9]等。这些工艺的共同特点是不需要外加力场对浆料进行搅拌,因而可以节省搅拌设备的投资费用,降低制备成本。与传统的机械搅拌和电磁搅拌制浆法相比,上述制浆方法更简便、灵活,具有很大的发展潜力。

本文作者根据无搅拌装置制浆方法的基本原理(促进合金熔体在凝固初期大量形核,然后控制各种工艺参数使这些晶核向球晶演变),设计一种新颖的多弯道蛇形管浇注制备装置。在制备SSM浆料时,由于合金熔体是在具有一定弧度且封闭的蛇形弯道内流动并多次改变流动方向,合金熔体具有一定的“自搅拌”功能,所以,采用这种方法制备SSM浆料的效果要比上述无搅拌装置的方法制备SSM浆料的效果要好。本文作者采用具有3弯道和5弯道的蛇形管制备半固态A356铝合金浆料,并研究弯道数量和弯道直径对半固态淬火浆料中初生α(Al)的影响,初步探讨该工艺条件下初生晶核的球化规律。

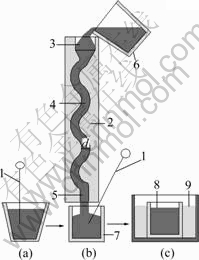

1 实验

以商用A356铝合金为实验材料,其成分(质量分数)为:Si 7.1%,Mg 0.31%,Fe<0.20%,Mn<0.10%,Zn<0.10%,其余为Al;其液相线温度为615 ℃,二元共晶温度为577 ℃。多弯道蛇形管的结构及浆料制备原理如图1所示。蛇形管的材质为石墨。熔化设备为坩埚电阻炉。浆料的收集坩埚材质为不锈钢,其尺寸为d 127 mm×250 mm,壁厚为1.5 mm。采用Ni-Cr/ Ni-Si型热电偶测量液态铝合金和半固态浆料的温度,温度显示精度为±1 ℃。

半固态A356铝合金浆料的制备工艺流程分为3个步骤:首先控制A356铝合金的浇注温度,然后进行浇注并测量浆料的出口温度,最后立即将浆料放入冷水中淬火。制备浆料的工艺参数如表1所列。浇注前,蛇形管和收集坩埚都处于室温状态。将完全凝固

的淬火浆料从心部区域取出一片厚度约为10 mm的扇形试样进行粗磨、精磨,抛光后用0.5% (体积分数)HF水溶液腐蚀,然后用Neuphoto光学显微镜对这些试样分别进行观察。利用公式D=2(A/π)1/2 和F=4πA/P2分别计算初生α(Al)的晶粒直径D和形状因子F,公式中A和P分别为晶粒的面积和周长。

图1 多弯道蛇形管浇注工艺制备半固态A356铝合金浆料的示意图

Fig.1 Schematic diagram of preparing semi-solid A356 Al-alloy slurry by serpentine pipe with multiple curves casting process: (a) Controlling pouring temperature of alloy; (b) Pouring; (c) Slurry quenched; 1—K-thermocouple; 2—Serpentine pipe; 3—Pouring cup; 4—Serpentine curve; 5—Diversion pipe; 6—Melting crucible; 7—Collection crucible; 8—Slurry; 9—Cold water

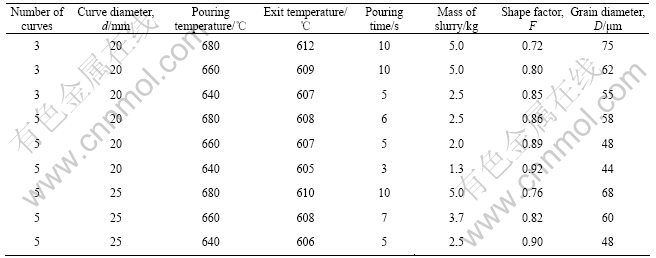

表1 制备半固态A356铝合金浆料的工艺参数及淬火浆料的特征

Table 1 Process parameters of preparing semi-solid A356 Al-alloy slurries and characteristics of quenched slurries

2 结果与分析

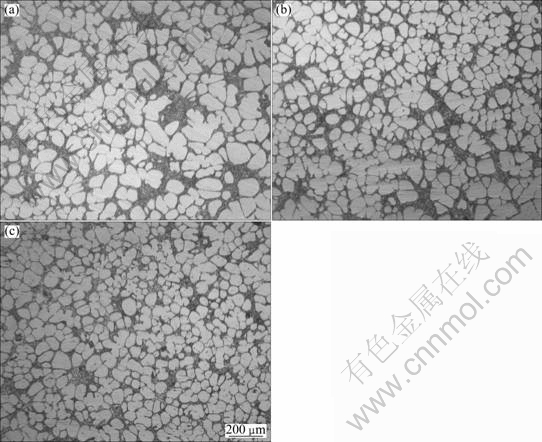

2.1 3个弯道的蛇形管在不同浇注温度下淬火浆料的特征

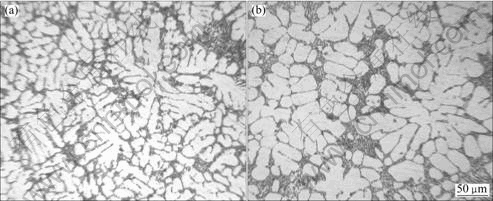

图2所示为采用具有3个弯道且弯道直径为20 mm的蛇形管在不同浇注温度下制备半固态A356铝合金淬火浆料在淬火后的微观组织,其特征如表1所列。图2中,白色颗粒为初生α(Al),灰色部分为剩余液相的凝固组织。在680 ℃浇注时(见图2(a)),初生α(Al)中蔷薇状晶粒和近球形晶粒几乎各占一半,其形状因子F为0.72,晶粒直径 D为75 μm。在660 ℃浇注时(见图2(b)),大部分初生α(Al)由球形和近球形晶粒组成,蔷薇状晶粒很少,其形状因子F为0.80,晶粒直径D为62 μm。在640 ℃浇注时(见图2(c)),初生α(Al)几乎全部由球形和近球形晶粒组成,其形状因子F提高到0.85,晶粒直径D减小到55 μm。此实验结果表明,当蛇形管的弯道数量为3时,只要弯道直径和浇注温度选择合理,就可以制备出组织优良、数量较多的半固态A356铝合金浆料。

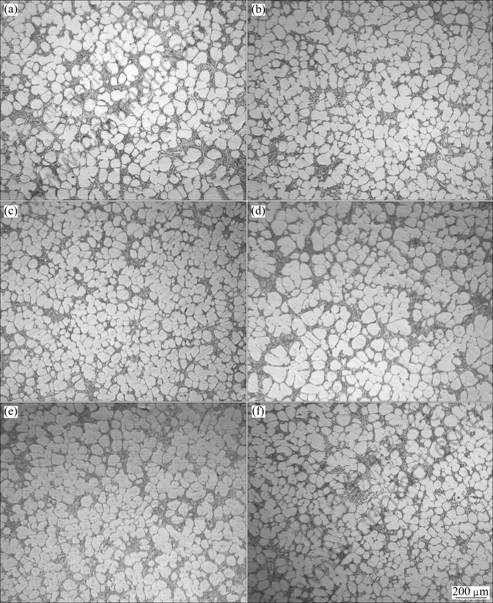

2.2 5个弯道的蛇形管在不同浇注温度下淬火浆料的特征

图3所示为采用具有5个弯道的蛇形管在不同浇注温度下制备半固态A356铝合金淬火浆料的微观组织,其特征如表1所列。图3(a)~(c)所示分别为弯道直径为20 mm和浇注温度为680~640℃条件下浆料的微观组织,浆料质量为1.3~2.5 kg。从图3(a)可以看出,绝大部分初生α(Al)由球形和近球形晶粒组成,蔷薇状晶粒极少,其形状因子F为0.86,晶粒直径D为58 μm。在图3(b)和(c)中,初生α(Al)几乎全部由球形和近球形晶粒组成,其形状因子F分别为0.89和0.92,晶粒直径D分别为48和44 μm。图3(d)~(f)所示分别为弯道直径为25 mm和浇注温度为680~640 ℃条件下浆料的微观组织,浆料质量为2.5~5.0 kg。图3(d)和(e)中,初生α(Al) 由球形晶粒和蔷薇状晶粒共同组成,其形状因子F分别为0.76和0.82,晶粒直径D分别为68和60 μm。在图3(f)中,初生α(Al)几乎全部由球形和近球形晶粒组成,其形状因子F为0.90,晶粒直径D为48 μm。此实验结果表明,采用具有5个弯道的蛇形管,如果弯道直径和浇注温度选择合理,也可以制备出一定数量且微观组织优良的半固态A356铝合金浆料。

图2 采用具有3个弯道且直径为20 mm的蛇形管在不同浇注温度下制备半固态A356铝合金淬火浆料在淬火后的微观组织

Fig.2 Microstructures of semi-solid A356 Al-alloy quenched slurries prepared by using serpentine pipe with 3 curves and curve diameter of 20 mm at different pouring temperatures: (a) 680 ℃; (b) 660 ℃; (c) 640 ℃

图3 采用具有5个弯道的蛇形管在不同弯道内径和浇注温度条件下制备半固态A356铝合金淬火浆料在淬火后的微观组织

Fig.3 Microstructures of semi-solid A356 Al-alloy quenched slurries prepared by using serpentine pipe with 5 curves under conditions of different curve diameters and pouring temperatures: (a) 20 mm, 680 ℃; (b) 20 mm, 660 ℃; (c) 20 mm, 640 ℃; (d) 25 mm, 680 ℃; (e) 25 mm, 660 ℃; (f) 25 mm, 640 ℃

3 讨论

3.1 弯道内合金熔体的形核及演变

关于半固态金属浆料中初生球形晶粒的形成机制,概括起来有两种观点:一种观点认为是从破碎的枝晶演变而来[10-14];另一种观点认为球形晶粒可以直接从过冷的合金熔体中演变而来[15-16]。本文作者认为多弯道蛇形管浇注法中球晶的演变过程属于后一种 机制。

在蛇形弯道内,初生晶核的形成以异质形核为主。由于弯道内壁处的合金熔体具有较大的过冷度,大大降低了结晶时的形核功,临界晶核半径也将减小,这将有利于更多的原子集团成为晶核。更重要的是,蛇形弯道的通道内壁为凹面,能促进形核,这种形核效率比倾斜板的形核效率高得多。这些因受弯道内壁激冷而形成的晶核一部分将游离到弯道内整个熔体的内部,成为新晶核的衬底或者继续长大;另一部分将留在弯道内壁上继续长大或结壳。图4所示为采用具有5个弯道且直径为25 mm的蛇形管在680 ℃浇注10 s后弯道内凝固壳的照片。弯道内合金熔体的浓度梯度、温度梯度和固-液界面前沿的扰动情况决定初生晶核的生长形态。弯道内流动的合金熔体将受到本身的重力和管壁的摩擦力作用。如图5(a)所示,当合金熔体从A处流动到B处时,其速率时刻都在变化。由于受到流体内摩擦力的作用,合金熔体各处的位移大小也不一样,这必然使合金熔体内部产生剪切力,且剪切力的大小和方向随合金熔体位置的改变而改变。由于弯道内合金熔体在中心区域与管壁处的密度不均匀,必将引起相互间的对流,对流不仅将型壁处的部分晶核带到熔体的其他区域,如图5(b)所示,这是晶粒游离的主要动力来源,而且将使合金熔体的浓度梯度和温度梯度显著减小。由于晶核不断进行游离运动,所以晶核的固-液界面也在不断发生变化。此结果表明,采用多弯道蛇形管浇注工艺,合金熔体具有“自搅拌”的作用,这种作用有力地促进了初生晶核向球形晶粒的演变。

图4 具有5个弯道且直径为25 mm的蛇形管在680 ℃浇注10 s后弯道内凝固壳的照片

Fig.4 Photograph of solidified shell after casting at 680 ℃ for 10 s by using serpentine pipe with 5 curves and curve diameter of 25 mm

图6所示为图4中凝固壳a和b位置处的微观组织。图6(a)中初生晶核主要由比较细小的树枝晶和不规则细小晶粒组成。图6(b)中初生晶核主要由蔷薇状和近球形的晶粒组成,它们的晶粒直径比图6(a)中晶粒直径粗大。这个结果进一步表明:合金熔体在经过弯道的作用后,熔体内部的对流、剪切和“自搅拌”作用阻碍了初生激冷晶核进一步向枝晶的演变,而倾向于直接演化成球形晶粒。可以推断,图6(b)中初生 α(Al)的形貌与导流管出口处半固态浆料中初生α(Al)

图5 弯道内合金熔体的状态及晶核游离示意图

Fig.5 Schematic diagrams of status of alloy melt and nuclei drifting in serpentine curve: (a) Status of alloy melt; (b) Nuclei drifting (Unit: mm)

图6 图4中凝固壳a和b位置处的微观组织

Fig.6 Microstructures of solidified shell marked places “a” and “b” in Fig.4: (a) Marked place “a”; (b) Marked place “b”

的形貌相近,但是与收集坩埚里淬火浆料的组织仍有区别,这可以通过与图3(d)的比较看出。这是因为当浆料流进收集坩埚时,在本身的重力作用下得到进一步的搅拌,浆料的温度场和浓度场分别得到进一步的均匀化,浆料中的初生α(Al)有充分的时间进行粗化(熟化),所以,收集坩埚里淬火浆料初生α(Al)的形貌要比导流管出口处初生α(Al)的形貌要圆整得多。

3.2 弯道数量对浆料的影响

合金熔体每经过一个弯道,“自搅拌”作用就会越剧烈,晶粒游离会更加频繁,合金熔体的浓度梯度和温度梯度就越小,固-液界面前沿的干扰频率也会增大。这些都是初生晶核向球晶演变的有利条件。弯道数量越多,这些有利条件就会加强,还会生成更多的初生α(Al)晶核。比较在具有3个弯道和5个弯道的蛇形管条件下制备的半固态浆料的初生α(Al)组织,在弯道直径和浇注温度都相同的情况下,在具有5个弯道的蛇形管条件下制备的初生α(Al)晶粒的形貌和尺寸比前者的改善了很多,这说明适当增加弯道数量可以改善半固态浆料的组织。但是,也有不利的一面,如能够获得的浆料的数量减少。

3.3 弯道直径对浆料的影响

从表1中看到,在弯道数量和浇注温度都相同的情况下,若弯道直径从25降至20 mm,晶粒的形状因子有所提高,晶粒直径也有所减小。根据以上讨论结果,若弯道直径变小,至少带来以下3个有利的结果:第一,弯道内表面的曲率变大,弯道内壁越有利于形核;第二,给定容积的合金熔体,在弯道内流过的时间增加,与弯道内壁接触的表面积增大,这样就有利于散热和形核;第三,合金的过热热量和部分结晶潜热能较快地传递给蛇形弯道的型壁。但是,弯道直径变小,凝固壳容易在管壁处形成并向管道中心发展,因此容易发生堵塞,获得半固态浆料的数量减少。

4 结论

1) 采用多弯道蛇形管浇注法制备半固态A356铝合金浆料,在浇注温度为640~680 ℃的条件下,当弯道数量为3且直径为20 mm时,可获得初生α(Al)形状因子F为0.72~0.85和晶粒直径D为55~75 μm的半固态浆料;当弯道数量为5且直径为20 mm时,可获得初生α(Al)形状因子F为0.86~0.92和晶粒直径D为44~58 μm的半固态浆料; 当弯道数量为5且直径为25 mm时,可获得初生α(Al)形状因子F为0.76~0.90和晶粒直径D为48~68 μm的半固态浆料。

2) 在弯道直径和浇注温度都相同的情况下,弯道数量越多,初生α(Al)晶粒的形貌越好、直径越小;在弯道数量和浇注温度都相同的情况下,弯道直径越小,初生α(Al)晶粒的形貌越好、直径越小。同时,能够获得半固态浆料的数量减少。

3) 采用多弯道蛇形管浇注工艺制备半固态合金浆料,合金熔体具有“自搅拌”的作用,可使初生晶核演变为球形或近球形晶粒。

References

[1] LUKASSON M, APELIAN D, DASGUPTA R. Alloy characterization for the new UBE rheocasting process[J]. AFS Transactions, 2002, 110: 271-284.

[2] EASTON M A, KAUFMANN H, FRAGNER W. The effect of chemical grain refinement and low superheat pouring on the structure of NRC castings of aluminium alloy Al-7Si-0.4Mg[J]. Materials Science and Engineering A, 2006, 420(1/2): 135-143.

[3] CARDOSO L E, ATKINSON H V, JONES H. Cooling slope casting to obtain thixotropic feedstock. Ⅰ: Observations with a transparent analogue[J]. Journal of Materials Science, 2008, 43(16): 5448-5455.

[4] LEGORETTA E C, ATKINSON H V, JONES H. Cooling slope casting to obtain thixotropic feedstock. Ⅱ: Observations with A356 alloy[J]. Journal of Materials Science, 2008, 43(16): 5456-5469.

[5] YANG Xiao-rong, MAO Wei-min, PEI Sheng. Preparation of semi-solid A356 alloy feedstock cast through vertical pipe[J]. Materials Science and Technology, 2007, 23(9): 1049-1053.

[6] GUO H M, YANG X J, HU B. Rheocasting of aluminum alloy A356 by low superheat pouring with a shear field[J]. Acta Metallurgica Sinica (English Letters), 2006, 19(5): 328-334.

[7] XIE S S, HUANG G J, ZHANG X L, YANG H Q. Study on numerical simulation and experiment of fabrication magnesium semisolid slurry by damper cooling tube method[J]. AIP Conference Proceedings, 2007, 908(1): 557-562.

[8] 张小立, 谢水生, 李廷举, 杨浩强, 金俊泽. 阻尼冷却管法制备A356铝合金半固态浆料的研究[J]. 稀有金属材料与工程, 2007, 36(5): 915-919.

ZHANG Xiao-li, XIE Shui-sheng, LI Ting-ju, YANG Hao-qiang, JIN Jun-ze. A356 aluminum alloy semisolid slurry prepared by damper cooling tube process[J]. Rare Metal Materials and Engineering, 2007, 36(5): 915-919.

[9] 管仁国, 李建平, 陈礼清, 王 超. 波浪型倾斜板振动过程中合金组织的形成机理[J]. 材料研究学报, 2008, 22(4): 363-368.

GUAN Ren-guo, LI Jian-ping, CHEN Li-qing, WANG Chao. Mechanism of alloy microstructure formation during vibrating wavelike sloping plate process[J]. Chinese Journal of Materials Research, 2008, 22(4): 363-368.

[10] FLEMINGS M C. Behavior of metal alloys in the semi-solid state[J]. Metall Trans A, 1991, 22(4): 957-981.

[11] CHUTT J E, STJOHN D H, DAHLE A K. Equiaxed solidification of Al-Si alloys[J]. Materials Science and Technology, 1999, 15: 495-500.

[12] DOHERTY R D, LEE H I, FEEST E A. Microstructure of stir-cast metals[J]. Materials Science and Engineering A, 1984, 65(1): 181-189.

[13] HELAWELL A. Grain evolution in conventional and rheocasting[C]//Proceedings of the 4th International Conference on Semi-Solid Processing of Alloys and Composites. Sheffield (English): University of Sheffield Press, 1996: 60-65.

[14] 毛卫民, 赵爱民, 崔成林, 钟雪友. 电磁搅拌对半固态AISi7Mg合金初生α(Al)的影响规律[J]. 金属学报, 1999, 35(9): 971-974.

MAO Wei-min, ZHAO Ai-min, CUI Cheng-lin, ZHONG Xue-you. The formation mechanism of non-dendritic primary α(Al) phases in semi-solid AiSi7Mg alloy[J]. Acta Metallugica Sinica, 1999, 35(9): 971-974.

[15] JI S, FAN Z. Solidification behavior of Sn-15% Pb alloy under a high shear rate and high intensity of turbulence during semisolid processing[J]. Metallurgical and Materials Transactions A, 2002, 33(11): 3511-3520.

[16] 李 涛, 黄卫东, 林 鑫. 半固态处理中球晶形成与演化的直接观察[J]. 中国有色金属学报, 2000, 10(5): 635-639.

LI Tao, HUANG Wei-dong, LIN Xin. Formation of globular structure during semi-solid material processing[J].The Chinese Journal of Nonferrous Metals, 2000, 10(5): 635-639.

(编辑 陈卫萍)

基金项目:国家高技术研究发展计划资助项目(2006AA03Z115); 国家重点基础研究发展计划资助项目(2006CB605203); 国家自然科学基金资助项目(5077400)

收稿日期:2010-04-02;修订日期:2010-06-01

通信作者:陈正周,博士研究生; 电话: 13426472778, 010-62332882; E-mail: chzz19710425@126.com