电弧收缩电流频率对航空航天合金钨极氩弧焊薄板拉伸性能和显微组织演变的影响

来源期刊:中国有色金属学报(英文版)2021年第2期

论文作者:Tushar SONAR Sudersanan MALARVIZHI Visvalingam BALASUBRAMANIAN

文章页码:456 - 474

关键词:收缩电弧钨极氩弧焊;电弧收缩电流频率;718合金板;拉伸性能;显微组织演变;Laves相

Key words:constricted arc TIG welding; arc constriction current frequency; Alloy 718 sheet; tensile properties; microstructural evolution; Laves phase

摘 要:研究电弧收缩电流频率(ACCF )对收缩电弧钨极氩弧焊(CA-TIG)焊接航空航天718合金板(厚度为2 mm)拉伸性能和显微组织演变的影响。实验设计每次一个变量,即采用从4 kHz到20 kHz之间5个不同的ACCF,其他参数保持不变。结果显示,采用4 kHz ACCF的接头具有良好的拉伸性能,焊接效率可达99.20%。这是由于熔化区的晶粒细化导致枝晶间析出更细小、离散的Laves相。ACCF高于12 kHz时熔化区发生严重晶粒长大和粗大 Laves相演变。718合金焊缝在较高的ACCF下由于冷却速度较慢,Nb偏析和Laves相形成的趋势更明显。当 ACCF为20 kHz时,Laves相的体积分数比4 kHz时提高62.31%,因此,接头的拉伸性能降低。这主要是由于当ACCF增加时,焊接热循环中热输入的叠加。

Abstract: The main objective of this investigation is to study the influence of arc constriction current frequency (ACCF) on tensile properties and microstructural evolution of aerospace Alloy 718 sheets (2 mm in thickness) joined by constricted arc TIG (CA-TIG) welding process. One variable at a time approach of design of experiments (DOE) was used, in which ACCF was varied from 4 to 20 kHz at an interval of 5 levels while other parameters were kept constant. The joints welded using ACCF of 4 kHz exhibited superior tensile properties extending joint efficiency up to 99.20%. It is attributed to the grain refinement in fusion zone leading to the evolution of finer, discrete Laves phase in interdendritic areas. An increase of ACCF above 12 kHz caused severe grain growth and evolution of coarser Laves phase in fusion zone. Alloy 718 welds showed more obvious tendency for Nb segregation and Laves phase formation at higher levels of ACCF due to the slower cooling rate. The volume fraction of Laves phase was increased by 62.31% at ACCF of 20 kHz compared to that at 4 kHz, thereby reducing the tensile properties of joints. This is mainly due to the stacking of heat input in weld thermal cycles at increased levels of ACCF.

Trans. Nonferrous Met. Soc. China 31(2021) 456-474

Tushar SONAR, Sudersanan MALARVIZHI, Visvalingam BALASUBRAMANIAN

Centre for Materials Joining and Research (CEMAJOR), Department of Manufacturing Engineering, Annamalai University, Annamalai Nagar 608002, Tamil Nadu State, India

Received 1 April 2020; accepted 15 October 2020

Abstract: The main objective of this investigation is to study the influence of arc constriction current frequency (ACCF) on tensile properties and microstructural evolution of aerospace Alloy 718 sheets (2 mm in thickness) joined by constricted arc TIG (CA-TIG) welding process. One variable at a time approach of design of experiments (DOE) was used, in which ACCF was varied from 4 to 20 kHz at an interval of 5 levels while other parameters were kept constant. The joints welded using ACCF of 4 kHz exhibited superior tensile properties extending joint efficiency up to 99.20%. It is attributed to the grain refinement in fusion zone leading to the evolution of finer, discrete Laves phase in interdendritic areas. An increase of ACCF above 12 kHz caused severe grain growth and evolution of coarser Laves phase in fusion zone. Alloy 718 welds showed more obvious tendency for Nb segregation and Laves phase formation at higher levels of ACCF due to the slower cooling rate. The volume fraction of Laves phase was increased by 62.31% at ACCF of 20 kHz compared to that at 4 kHz, thereby reducing the tensile properties of joints. This is mainly due to the stacking of heat input in weld thermal cycles at increased levels of ACCF.

Key words: constricted arc TIG welding; arc constriction current frequency; Alloy 718 sheet; tensile properties; microstructural evolution; Laves phase

1 Introduction

Alloy 718 is a high-performance nickel-based aerospace superalloy originally developed for gas turbine engine applications in late 1950s [1]. It is of great interest in aerospace sector for high temperature applications due to its excellent mechanical properties and weldability. It exhibits high strength, exceptional creep resistance and stress rupture life, good oxidation and corrosion resistance at elevated temperatures up to 650 °C [2]. It contains Ti, Al and Nb as primary strengthening elements for the precipitation of Ni3(Al,Ti) and Ni3Nb hardening precipitates [3]. It offers greater resistance to strain aged cracking owing to its slow response to aging heat treatment [4]. It finds significant applications in gas turbine and rocket engines for lightweight frames, other parts and assemblies [5]. Tungsten inert gas (TIG) welding process is typically practised for joining Alloy 718 sheets in manufacturing and service repair jobs for aero-engine components as it provides clean, precise and high-quality welds. Nevertheless, the weldability of Alloy 718 is mainly constrained by the segregation and evolution of coarse thick Laves phase film in weld metal as a result of high heat input in TIG welding process [6,7]. The Laves phase evolution is detrimental to the weld tensile properties and joint performance [8,9]. It leads to premature failure of aeroengine components. Alloy 718 also shows extreme propensity for hot cracking problems such as liquation cracking in HAZ [10]. Moreover, the joining of metal sheets is more challenging to attain good weld without any defect, porosity and distortion [11]. In this work, a recently emerged constricted arc TIG (CA-TIG) welding process was employed to join Alloy 718 sheets. It is the prominent configuration of TIG welding process principally differentiated by magnetic constriction of arc attained by arc constriction current (ACC) accentuating at high frequencies up to 20 kHz [12]. The high heat input in TIG welding process is mainly associated with its low energy density due to the wider arc. Thus, an effort has been made to curtail the heat input and advance the energy density by magnetic constriction of arc. Arc constriction current frequency (ACCF) is a significant parameter in controlling the magnetic constriction of arc. It controls the rise and fall time of welding arc. Hence, the study of ACCF on weldability of Alloy 718 sheets is important for its viability in aerospace applications.

The published research work on welding of Alloy 718 mainly referred to tungsten inert gas [13-16], electron beam [17-20] and laser beam [21-23] welding processes. Few studies were reported on the application of current pulsing [24] and magnetic oscillation of arc [25] in TIG welding of Alloy 718. However, there is major research gap in literature about the application of CA-TIG welding process for joining of Alloy 718 sheets. Further, the information available on the effect of ACCF is very less. Hence, this work aims to study the influence of ACCF on microstructural evolution and mechanical properties of CA-TIG welded Alloy 718 joints.

2 Experimental

2.1 Materials and welding

The rolled Alloy 718 sheets (2 mm in thickness) in 980 °C solutionized state were selected for the present study. The base metal elemental composition and the respective mechanical properties are displayed in Table 1 and 2, separately. Initially, the sheets were sliced to the required dimensions by abrasive cutting wheel. The edge surfaces to be welded were machined with cylindrical grinding machine. The surface oxide film was first removed by steel wire brushing and emery paper. The sheets were then cleaned chemically before welding by lint-free cloth immersed in acetone solution to eliminate the surface contaminants. These sheets were welded in butt joint design of size 150 mm × 150 mm × 2 mm using an InterPulse CA-TIG welding machine (Make: VBC UK; Model: IE175i).

The welding was done in transverse direction of rolling. Shielding was provided with pure argon gas at a constant flow rate of 10 L/min. A tungsten electrode (EWTh-2) with a diameter of 1.6 mm and a tip angle of 60° was used at an arc length of 0.8 mm. One variable at a time strategy of experimentation was selected to investigate the direct effect of ACCF on the weldability of Alloy 718. The joints welded using an ACCF below 4 kHz showed bead appearance similar to those of pulsed current TIG and incomplete penetration. So, the ACCF was varied from 4 to 20 kHz at 5 distinct levels while other parameters were kept constant. Table 3 shows the CA-TIG welding parameters used in this investigation. Number of trials were done to set the minimum and maximum working limits of ACCF to produce defect-free sound welds.

2.2 Mechanical properties measurement

The smooth and notch tensile specimens were cut from the welded sheets in transverse direction as per specified dimensions according to ASTM standard of E8M—05. Tensile testing was executed by employing 50 kN servo-monitored tensile testing machine. The tensile loading was applied to the tensile specimens at 2 mm/min crosshead speed. The average of 3 readings was reported in tensile properties. The estimation of tensile elongation was performed by marking 50 mm gauge length. The approximation of yield strength was done by applying 0.2% offset strain approach on stress-strain curve. The analysis of tensile fractured surface was executed by scanning electron microscope (SEM).

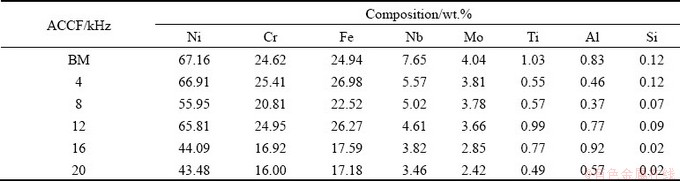

Table 1 Chemical composition of base metal (wt.%)

Table 2 Mechanical properties of base metal

Table 3 Process parameters for CA-TIG welding of Alloy 718 sheets

The Vickers microhardness measurement was performed on the mirror finished cross-sectional area of welded specimen at specified load of 0.5 kg and dwell time of 15 s according to ASTM standard of E384—17. The microhardness distribution was recorded from weld centre to base metal region at 0.1 mm distance. The microhardness values were measured for different regions in the weld (FZ and HAZ) and reported as final reading.

2.3 Macrostructure and microstructure analysis

The cross-sectional area of metallographic specimens was carefully mirror-polished and etched with Kalling’s reagent. The macrostructure was recorded using Stereozoom microscope. The microstructure was analyzed by optical microscope and SEM. The weld bead characteristics, secondary dendrite arm spacing (SDAS) and volume fraction of Laves phase were measured by ImageJ software.

2.4 EDS analysis

Energy dispersive X-ray spectroscopy (EDS) technique was used for qualitative and quantitative estimation of elemental composition. Nb mapping of fusion zone was performed to determine the degree of Nb segregation occurred during solidification. The elemental compositions of Laves phase and dendrite core were analyzed by EDS point scan analysis.

The heat input (Hi, J/mm) was estimated using Eq. (1):

(1)

(1)

where Imean is mean of main current and arc constriction current (A), V is arc voltage (V), S is welding speed (mm/min), and η is process efficiency (60%).

The cooling rate in fusion zone was approximated from SDAS, which is governed by the thermal gradient, G (K/mm), and solidification growth rate, R (mm/s), as expressed by the following equation [26]:

(2)

(2)

where d2 is SDAS (μm), v is cooling rate (K/s), A is material constant, and n is constant with a value between 0.25 and 0.5. For Alloy 718, MEHRABIAN et al [27] calculated the values of A and n to be 141 and 0.4, separately. Putting these values into Eq. (2), cooling rate was calculated.

3 Results

3.1 Macrostructure

Table 4 presents the effect of ACCF on weld bead characteristics. All the welded joints were recorded to be free from defects except minor undercutting observed at 8 kHz. Full penetration was observed in all joints. The weld bead shows a cup shape with narrowing bottom at each joint. An increase in ACCF from 4 to 20 kHz renders a rise in weld bead characteristics.

The weld bead area is raised by 20.28% at 20 kHz compared to that at 4 kHz. The weld bead width and HAZ width increase at increased levels of ACCF. The joints made at 4 kHz show an appropriate weld bead geometry. Results show that weld bead characteristics are sensitive to the changes in levels of ACCF. Thus, the optimal selection of ACCF is important in producing the preferable weld bead geometry. Also, smaller weld bead geometry results in lower Laves phase content and reduced microfissuring tendency of joints.

Table 4 Influence of ACCF on weld bead geometrical features

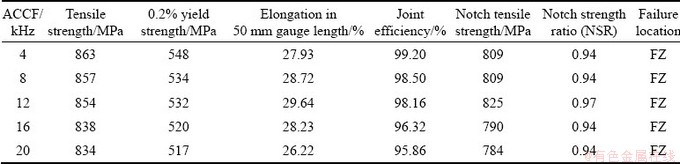

3.2 Tensile properties

The fractured smooth and notch tensile specimens showing failure in fusion zone at all levels of ACCF are presented in Fig. 1. JANAKI RAM et al [24] and MADHUSUDHAN REDDY et al [28] reported the similar trend of failure of specimens in fusion zone of Alloy 718 joints. This infers that fusion zone is lower in strength than base metal region and tensile properties of joints are governed by fusion zone only. The tensile properties of CA-TIG welded Alloy 718 joints at increased levels of ACCF are enumerated in Table 5. The welded joints exhibit lower strength and ductility compared with the base metal. As ACCF increases from 4 to 20 kHz, tensile properties decrease. The decrement in tensile strength is insignificant up to 12 kHz. Also, slight variation is observed in elongation of joints at increased levels of ACCF. Better tensile properties were manifested by the joints made at ACCF of 4 kHz. It showed 0.80% and 26.50% reduction in tensile strength and elongation respectively relative to those of base metal. However, the tensile strength and elongation of joints are decreased by 4.13% and 31% at 20 kHz compared to those of base metal. The base metal and welded joints exhibit notch sensitivity. CAI et al [29] imputed the notch sensitivity of Alloy 718 to the precipitation of δ phases. The notch tensile strength increases with the rise in ACCF up to 12 kHz. Moreover, a further increase in ACCF causes significant declination in notch tensile strength of joints. The welded joints become more notch brittle at 20 kHz, resulting in 9.88% decrease in strength of joints compared to base metal indicating the influence of Laves phase on tensile behavior of material at the notch.

RODRIGUEZ et al [14] showed that the tensile strength and elongation of TIG-welded Alloy 718 joints were drastically reduced to 22.35% and 45.90% in comparison with those of base metal. SUDARSHAN RAO et al [15] reported 22% reduction in tensile strength and 50% reduction in elongation of Alloy 718 TIG joints relative to those of base metal. However, the joints fabricated at an optimum level of 4 kHz show 20%-30% improvement in tensile properties of joints over TIG welding process. It is correlated to the lower heat input attained by increased energy density of arc through magnetic constriction.

Fig. 1 Fractured tensile specimens showing failure in fusion zone

Table 5 Effect of ACCF on tensile properties of CA-TIG welded Alloy 718 joints

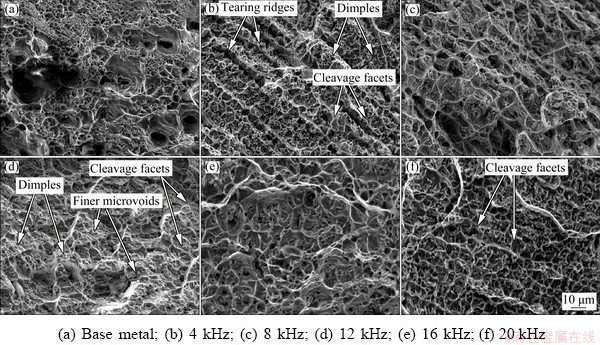

3.3 Fractographs

The SEM fractographs of smooth and notch tensile specimens of welded joints at increased levels of ACCF are presented in Figs. 2 and 3, respectively. The fractured surface of base metal showed no preferential fracture path and revealed completely dimple regions. However, shallower and coarser dimples were observed in notch tensile specimens of base metal, indicating declination in tensile strength due to the existence of notch. The fractograph of weld tensile specimens showed dendritic pattern and disclosed preferential fracture path. It showed the presence of cleavage facets and dimples. Flat and irregular quasi cleavage facets evidenced that the failure was initiated arbitrarily in vicinity of Laves phase at all levels of ACCF. The notch tensile fractograph exhibited larger cleavage facet regions and few dimples which contribute to notch brittleness. The presence of microcracks might be due to the brittleness of Laves phase. The fracture in interdendritic region is due to the presence of hard and brittle Laves phases [30]. Finer microvoids were observed at 12 kHz, imparting higher ductility because the fine and distinct Laves phase particles got pulled off, absorbing some strain energy during rupture. The joints made at 20 kHz showed coarser and shallower dimples with large cleavage facet regions. The presence of microcracks and large cleavage facets indicated excessive brittleness due to the evolution of coarser and interconnected Laves phase in fusion zone. Flat and irregular quasi cleavage facets indicated that the failure was initiated predominantly by brittle fracture at higher levels of ACCF.

Fig. 2 SEM fractographs of smooth tensile specimens

Fig. 3 SEM fractographs of notch tensile specimens

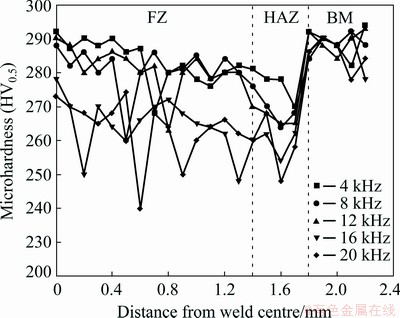

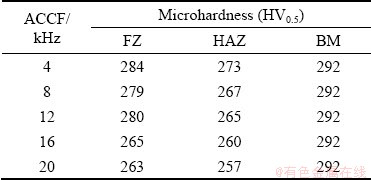

3.4 Microhardness

The influence of ACCF on microhardness distribution of weld joints is shown in Fig. 4. It elucidates the microhardness gradient representing the difference between the points nearby, which could show the uniformity of microstructure. The microhardness gradient increases at increased levels of ACCF from 4 to 20 kHz. Lower microhardness values noticed in weld metal mainly account for tensile failure in fusion zone (FZ) only. It is imputed to partitioning of solute elements in interdendritic areas of fusion zone, leading to the depreciation of solute elements from dendrite core leaving behind weaker regions in fusion zone.

The mean microhardness of different regions (FZ and HAZ) of weld is compiled in Table 6 and compared with that of base metal. The microhardness of base metal is higher than that of FZ and HAZ. The weld region micro- hardness followed similar trend of tensile strength at increased levels of ACCF. The microhardness in FZ and HAZ decreases with an increase in ACCF. There is no appreciable change in microhardness of weld region up to 12 kHz. The joints made at 4 kHz show 2.74% and 6.51% decrease in hardness of FZ and HAZ compared with the base metal, respectively. However, they decrease by 9.93% and 11.99% at 20 kHz, respectively. The reduction in hardness of HAZ at increased levels of ACCF is mainly due to the dissolution and coarsening of Nb carbides across the grain boundaries.

Fig. 4 Effect of ACCF on microhardness distribution of welded joints

Table 6 Effect of ACCF on microhardness of different regions of joints

3.5 Microstructure

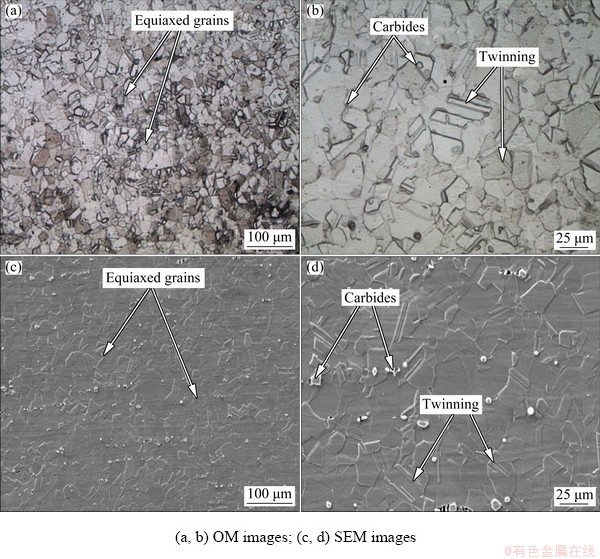

Fig. 5 Microstructures of base metal at lower and higher magnifications

Fig. 6 EDS spectrum of niobium carbides (NbCs) in base metal

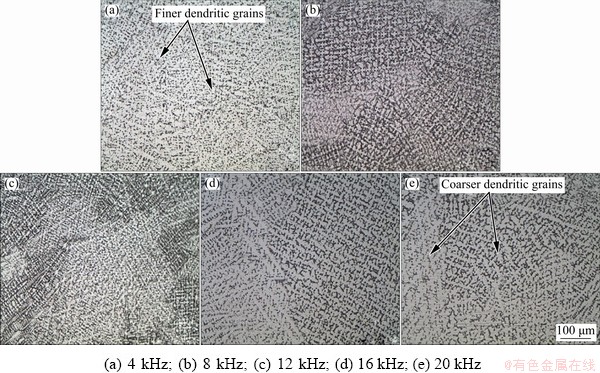

Figure 5 shows optical and SEM micrographs of base metal solutionized at 980 °C. The micro- structure consists of equiaxed austenitic grains with randomly distributed Nb carbides across the grain boundaries. Figure 6 shows EDS spectrum of carbides consisting of the peaks of Nb and C. Figure 7 shows the optical micrographs of fusion zone at increased levels of ACCF. The fusion zone solidification occurs in cast form. Increase in ACCF up to 12 kHz shows fusion zone grain refinement. Further increase aggravates dendritic grain growth. Figure 8 shows the influence of ACCF on cooling rate and SDAS of fusion zone. The fusion zone is much finer at 4 kHz compared with that at 20 kHz. The cooling rate decreases from 3004 to 1359 K/s with a corresponding increase in SDAS from 5.73 to 7.87 μm when ACCF increases from 4 to 20 kHz. A 54.76% decrease in cooling rate and a 37.34% increase in grain size of fusion zone at 20 kHz are observed relative to those at 4 kHz. The cooling rate and corresponding SDAS have significant influence on Laves phase evolution in interdendritic areas of fusion zone.

Fig. 7 OM images showing influence of ACCF on microstructure of fusion zone

Fig. 8 Influence of ACCF on cooling rate (a) and SDAS (b) of fusion zone

Fig. 9 SEM images showing influence of ACCF on Laves phase evolution in fusion zone

Figure 9 shows the scanning electron micro- graphs of fusion zone at higher magnification revealing the influence of ACCF on the evolution of Laves phase. The Laves phase appears to be much fine, distinct and uniformly distributed in fusion zone up to 12 kHz. Nevertheless, it appears to be coarser at ACCF of 20 kHz. The coarser Laves phases have detrimental effects on weld mechanical properties [21,24]. The influence of ACCF on Laves phase evolution is quantified and plotted in Fig. 10. The increase in ACCF extends the increase in size and volume fraction of Laves phase. The mean size and volume fraction of Laves phase increase from 2.54 μm and 5.28% to 5.86 μm and 8.57% when ACCF increases from 4 to 20 kHz, respectively, showing 62.31% increase in volume fraction of Laves phase at 20 kHz. JANAKI RAM et al [24] recorded 8% volume fraction of Laves phase in pulsed current welds compared to 14.2% in constant current TIG welds of Alloy 718. MANIKANDAN et al [31] diminished the volume fraction of Laves phase in TIG welds of Alloy 718 from 35.7% to 18.9% by employing compound current pulsing technique. However, the CA-TIG welded joints made by applying ACCF of 4 kHz showed 5.28% volume fraction of Laves phase in weld metal, indicating superior tensile properties of joints.

Fig. 10 Influence of ACCF on mean size (a) and volume fraction (b) of Laves phase

Fig. 11 OM images showing influence of ACCF on partially melted zone (PMZ)

Fig. 12 SEM images showing influence of ACCF on heat affected zone (HAZ)

The optical micrographs of partially melted zone (PMZ) at increased levels of ACCF are shown in Fig. 11. The FZ and HAZ are apparently separated by the partially melting of base metal grains at the weld interface. Figure 11 shows long columnar dendritic grains extending from fusion zone interface to centre of weld. The incremental levels of ACCF lead to the reduced heat transfer between the base metal and fusion zone due to the stacking of heat input in weld pool associated with rapid thermal oscillation. The steep temperature gradient between the centre of weld and base metal is established, which raises the peak temperature between solidus and liquidus temperature ranges of alloy in the area surrounding the weld puddle. This gives rise to partial melting of grains and increased width of PMZ. PMZ is observed to be narrow about 234.89 μm at 4 kHz. However, it widens up to 264.56 μm at 20 kHz. There is 12.63% increase in the width of PMZ at 20 kHz. It is inferred that the peak temperature at the fusion boundary is increased due to the rise in stacking of heat input in weld thermal cycles. The increased width of PMZ is not desirable as it favors the formation of low melting point liquation film at grain boundaries and leads to hot cracking. Figure 12 shows the scanning electron micrographs of heat affected zone (HAZ) at increased levels of ACCF. An increase in ACCF from 4 to 20 kHz leads to an increase in width of HAZ from 370 to 561 μm, showing a 51.62% increase in width of HAZ at 20 kHz relative to that at 4 kHz. The tendency for grain boundary liquation in Alloy 718 welds is severer in coarse grains of HAZ than in fine grains [32]. Acute growth of grains in HAZ of welded joints results in softening. It is consistent with dissolution of Nb carbides in HAZ, which has potential for liquation. However, no liquation cracking is observed in HAZ and PMZ of CA-TIG Alloy 718 welds.

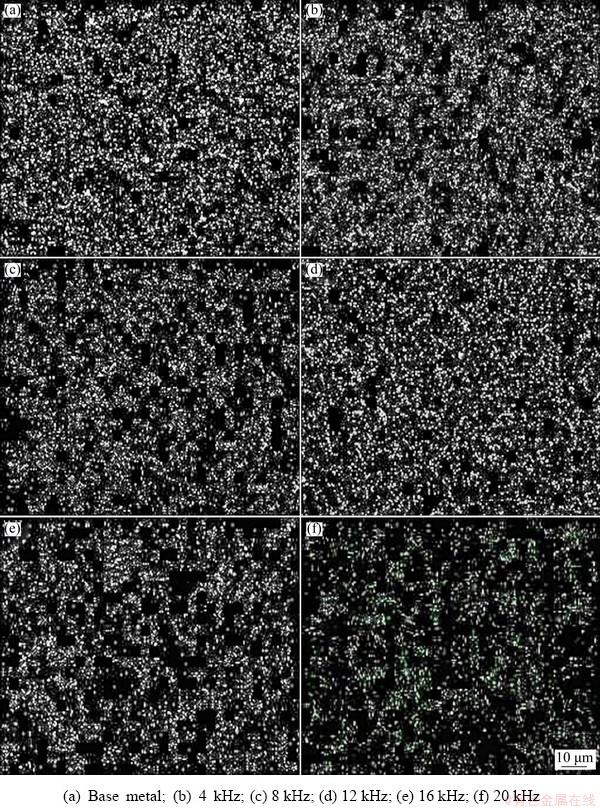

3.6 EDS analysis

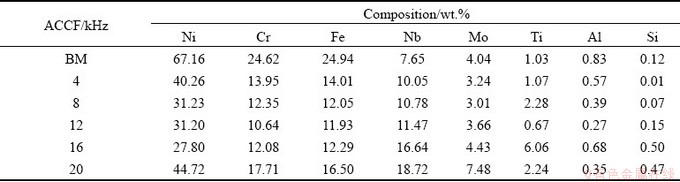

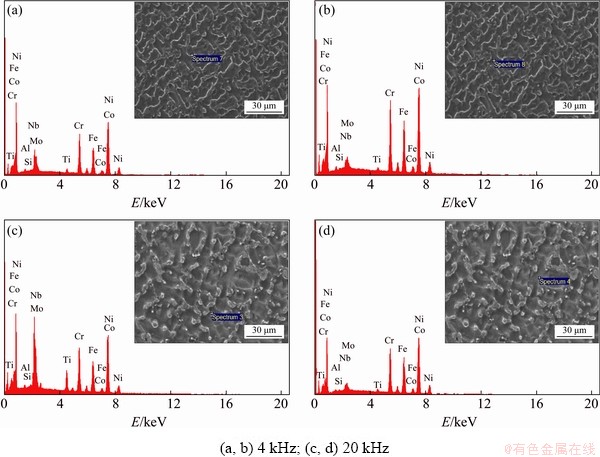

The EDS mapping of Nb in fusion zone at increased levels of ACCF is presented in Fig. 13. The elemental maps show uniform distribution of Nb. Nevertheless, it appears to be segregated in cast dendritic structure of weld metal. An increase in ACCF promotes Nb segregation in fusion zone. The Nb distribution is uniform up to ACCF of 12 kHz. However, it appears to be much segregated at ACCF of 20 kHz. The elemental compositions of Laves phase and dendrite core regions at increased levels of ACCF are displayed in Tables 7 and 8, respectively. Figure 14 shows the EDS spectra of Laves phase and dendrite core at lower and higher levels of ACCF. Laves phase is rich in Mo, Nb, Si and Ti, leaving behind the depleted dendrite core regions. These results are in agreement with the finding reported by SOHRABI et al [33] and ZHANG et al [34].

Fig. 13 EDS mapping showing influence of ACCF on Nb segregation in fusion zone

Table 7 Effect of ACCF on elemental compositions of Laves phase

Table 8 Effect of ACCF on elemental compositions of dendrite core

Fig. 14 EDS spectra of Laves phase (a, c) and dendrite core (b, d) of fusion zone at different levels of ACCF

The Nb content in Laves phase increases with an increase in ACCF. The joints made by applying ACCF of 4 kHz shows lower Nb content up to 10.05% in Laves phase resulting in enrichment of Nb up to 5.57% in dendrite core. The Nb consumption is much higher (about 18.72%) in Laves phase at 20 kHz, resulting in lower Nb content up to 3.46% in dendrite core. RADHAKRISHNA and PRASAD RAO [7] viewed 2% Nb in dendritic core and 26% Nb in inter- dendritic regions of constant current TIG welds. JANAKI RAM et al [24] disclosed that Nb content of Laves phase was reduced to 14.62% using current pulsing technique when compared with 19.54% in constant current TIG welds. The Nb content of Laves phase in CA-TIG welds is much lower at ACCF of 4 kHz owing to the rapid cooling rate experienced by the weld pool as compared to constant current and pulsed current TIG welding processes. However, the beneficial effects of magnetic constriction of arc and current pulsing were not observed at 20 kHz due to the moderate cooling rate, resulting in more segregation of Nb and coarser Laves phase evolution.

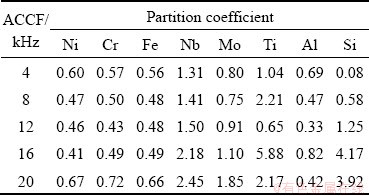

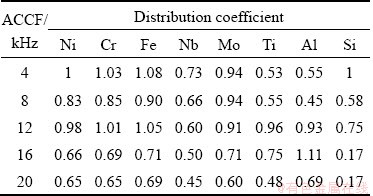

Furthermore, the influence of welding processes on the partitioning tendency of solute elements was well reported by ODABASI et al [35]. KNOROVSKY et al [36] estimated the tendency of alloying elements towards the Laves phase evolution using partition coefficient (P). It is defined as the Laves phase composition per unit nominal composition of base metal. The higher the partition coefficient (P) is, the more the partitioning tendency of particular alloying element for Laves phase evolution during solidification will be. CIESLAK et al [37] quantified the degree and order of microsegregation during weld metal solidification by the distribution coefficient (k). It is defined as the dendrite core composition per unit base metal composition. The distribution coefficient close to 1 is desirable and indicates that the alloying element does not segregate strongly during solidification. The partition and distribution coefficients of alloying elements at increased levels of ACCF are shown in Tables 9 and 10, respectively. Nb, Mo, Ti, and Si have greater tendency to segregate in interdendritic areas for Laves phase evolution. The partition coefficients of Nb, Mo, Ti, and Si augment with an increase in ACCF. The joints made at 20 kHz showed greater partition coefficient and smaller distribution coefficient for Nb with respect to those at 4 kHz, indicating more segregation tendency in Laves phase evolution and depletion of Nb in dendrite core areas. The partition and distribution coefficients of Nb calculated from the investigation of JANAKI RAM et al [24] were calculated to be 3.84 and 0.27 for CC-TIG welds and 2.50 and 0.43 for PC-TIG welds, respectively. The partition coefficient (P) is much larger (about 4.2) in the study of RADHAKRISHNA and PRASAD RAO [7] for Alloy 718 TIG welds. However, CA-TIG welds at 4 kHz showed lower partition coefficient of 1.31 and higher distribution coefficient of 0.73 for Nb. This disclosed that CA-TIG welding process reduces the Nb segregation in Alloy 718 welds significantly than CC- and PC-TIG welding processes.

Table 9 Effect of ACCF on partition coefficient (P) of alloying elements

Table 10 Effect of ACCF on distribution coefficient (k) of alloying elements

4 Discussion

4.1 Effect of ACCF on macrostructure

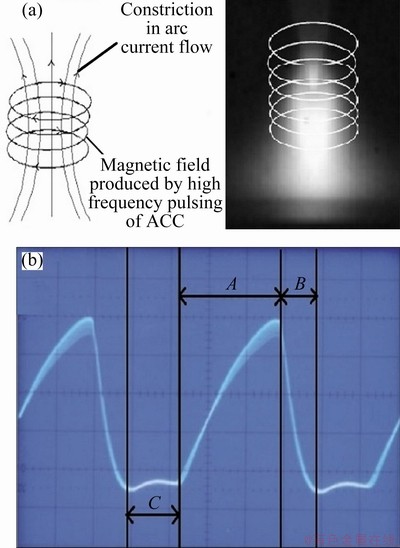

Constricted arc TIG (CA-TIG) is the modified TIG welding configuration in which energy density of welding process is increased by implementing the technique of constriction of arc. The magnetic field is induced around welding arc by superimposing arc constriction current (ACC) on main current for compressing the arc. Figures 15(a) and (b) illustrate the basic principle of magnetic constriction of arc and arc wave form in CA-TIG welding. ACC pulses with main current at high frequency within 20 kHz in sawtooth wave form rather than square wave form in pulse current TIG welding, as shown in Fig. 16. As ACC waves periodically with main current, it slowly constricts the arc in rise time. Once rise time is completed, the magnetic constriction is released quickly and the arc widens. Due to the arc constriction, the heat intensity of arc increases. Less heat is dissipated on the outermost flare. This allows for better heat management on welds whilst attaining full penetration with low heat input. The magnetic constriction of arc is mainly amenable for the localized heating of metal at joint seam. The ACCF modifies the magnetic field around the arc for arc constriction. The changes in magnetic field are associated with changes in rise and fall of the magnetic constriction of arc. As ACCF increases from 4 to 20 kHz, the rise time and fall time of arc decrease appreciably, which results in less time available for the magnetic constriction and release of arc. This results in less arc constriction effect and lower energy density at higher levels of ACCF. The localized fusion of metal at joint seam is reduced, leading to the rise in weld bead size at increased levels of ACCF.

Fig. 15 Magnetic constriction of arc (a) and arc wave form (b) in CA-TIG welding (A represents rise time; B represents fall time; C represents agitation)

Fig. 16 Pulsing characteristics of ACC

4.2 Effect of ACCF on tensile properties

The solidification conditions, elemental composition, and microstructural characteristics have significant influence on tensile properties of joints. The tensile properties of joint are lower than those of base metal, which are correlated to the evolution of Laves phase in interdendritic areas of weld microstructure. The hard and brittle natures of Laves phase do not manifest tensile deformation along with austenitic matrix during tensile loading. Laves phase evolution, aside from consuming the solute elements from matrix, diminishes the interfacial strength between matrix and Laves phase, which aids in easy initiation of crack and provides a low energy fracture path for rapid crack propagation [24,25].

The tensile strength is higher at ACCF of 4 kHz. This is correlated to the optimum thermal oscillation and heat input experienced by the molten pool, leading to the evolution of finer dendritic fusion zone microstructure. Nb has low partition and high distribution coefficients at 4 kHz as a result of the rapid solidification rate experienced by the weld pool. This results in less segregation tendency of Nb in fusion zone and reduced Laves phase evolution, thereby contributing to strengthening of welded joints. The joint strength and elongation decrease with an increase in ACCF. It is mainly imputed to the severe dendritic grain growth at increased levels of ACCF. The dendritic grain growth increases the interdendritic areas which are privileged locations for solute segregation and subsequent Laves phase evolution in weld metal. Consequently, there is an increased depreciation of solute elements from matrix. The Laves phase evolution and growth are severe when the sample is welded at ACCF above 12 kHz. This results in considerable moderation in tensile strength of joints by void formation in the Nb-depleted regions. Thus, the benefits of current pulsing were not obtained at 20 kHz owing to the predominant heat input repercussions. The increased volume fraction and growth of Laves phase in interdendritic areas decrease the coherency between solidification sub-grain boundaries (SSGBs) and deteriorate the performance of welded joints. However, due to the pulsing effect, the morphology of Laves phase appears to be globular, which results in less detrimental effects on the ductility of joints.

The thick interconnected Laves phase has great adverse effects on joint strength and elongation. The Laves phase also acts as a plastic constraint at the notch and induces the condition of triaxial stress state, thereby reducing the notch tensile strength. The cleavage facet regions observed in tensile fracture surface are due to the evolution of coarser Lave phase in interdendritic areas of fusion zone. It does not absorb the strain energy associated with plastic deformation and provides energy for rapid initiation and propagation of crack. Hence, the joints made at 20 kHz showed substantial decrement in tensile properties.

4.3 Effect of ACCF on microhardness

The weld metal hardness of Alloy 718 joints mainly depends on the solidification conditions (heat input, fluid flow and weld cooling rate) during welding, which imparts consequential influence on the partitioning of alloying elements during solidification. The Nb content in dendrite core regions of fusion zone is significantly lower relative to that of base metal in all joints. This causes lower microhardness values of fusion zone relative to base metal. The microhardness survey of weld metal disclosed deviation in microhardness away from weld centre. It is mainly due to the heterogeneous segregation of solute elements in fusion zone. This results in degrading the microhardness values in Nb-depleted areas of fusion zone. The region where strengthening solute elements are less has lower hardness values. Thus, failure in fusion zone lays upon the lower microhardness values recorded near the weld centre.

The cooling rate is reduced drastically from 3004 K/s at 4 kHz to 1359 K/s at 20 kHz as a result of the piling of heat input at increased levels of ACCF which promotes depreciation of solute elements from dendrite core towards Laves phase evolution and weakens the matrix. The higher hardness in fusion zone recorded at 4 kHz is imputed to the higher Nb content in dendrite core regions. However, the coarse dendritic structure evolved at 20 kHz showed more depreciation of Nb from dendrite core contributing to lower hardness of fusion zone. The Laves phases are incoherent in nature, and contribute very little to the increase in the hardness [38]. HAZ shows lower microhardness value than FZ and base metal region. The stacking of heat input in weld thermal cycle at increased levels of ACCF slows down the cooling rate and establishes the steep temperature gradient between the centre of weld and fusion zone interface at increased levels of ACCF. This leads to more heating of base metal region near the fusion zone, and results in coarsening of Nb carbides through dissolution of finer Nb carbides in the austenitic matrix. The finer Nb carbides act as pinning agent and restrict the grain growth. However, the dissolution of finer Nb carbides across the grain boundaries causes severe grain growth in HAZ. Thus, dissolution of Nb carbides, severe grain growth and reduced Nb content in HAZ lower the hardness of HAZ region. The coarsening of Nb carbides in HAZ increases the potential for liquation of grain boundaries. However, no liquation cracking was found in the HAZ and PMZ of CA-TIG welded Alloy 718 joints.

4.4 Effect of ACCF on microstructure

Solidification in Alloy 718 commences with primary liquid→ γ reaction, resulting in segregation of Nb, Mo, Ti, Si, and C in interdendritic liquid. The subsequent liquid→(γ+NbC) eutectic reaction consumes most of the carbon available in the material until another eutectic type reaction, liquid→(γ+Laves) proceeds, thereby completing the solidification process [30]. Solute segregation and subsequent Laves phase transformation during solidification of weld metal are substantially prompted by the welding process, technique, and input parameters that control the weld heat input and subsequent solidification rate [39]. LONG et al [40] reported that the Nb segregation and subsequent Laves phase evolution can be supressed by faster cooling rate. Magnetic constriction and pulsing of arc significantly control the solidification conditions during welding. The CA-TIG welding process showed less segregation of solute and Laves phase evolution in weld metal compared with constant current and pulsed current TIG welding due to the lower heat input requirement for complete penetration. The faster cooling rate encountered in CA-TIG welding leads to the evolution of finer dendritic structure in fusion zone. The refinement in grains of fusion zone minimizes the interdendritic areas which are favourable locations for segregation and subsequent Laves phase evolution in weld metal. It accounts for minimized Nb segregation and hence, a small amount of Laves phase and less depreciation of Nb from dendrite core regions. CA-TIG welding process is mainly featured by the magnetic constriction and release of arc. The magnetic field is imposed on the arc and periodically reversed. As a result, it generates circular internal flow in the weld puddle around the electrode axis. It causes stirring of the molten metal and reduces solute segregation during solidification. The constriction and release of arc also advance the solidification rate by enhancing the fluid flow in weld pool, which gives rise to significant supercooling in the solidifying weld metal as a result of the enhanced cooling rates and reduced thermal gradients in the molten weld pool. This results in surface nucleation which aids in the refinement of FZ microstructure. The ACC pulsing increases puddle agitation and causes breaking of dendritic grains. The broken dendrites provide favourable conditions for heterogeneous nucleation and cause refinement in grains of fusion zone [24]. The refinement is recorded within ACCF of 12 kHz.

Nevertheless, the positive effects of magnetic constriction and pulsing of arc were not observed at 20 kHz. This clearly manifests predominant heat input influence at increased levels of ACCF. The stacking of heat input in weld thermal cycles at incremental levels of ACCF is mainly associated with high frequency arc constriction and release phenomenon, rapid thermal oscillation and over- lapping of the weld pool which provides less time for the effective heat transfer between the fusion zone and base metal. The high frequency arc constriction and release phenomenon reduces the effectiveness of arc constriction. In CA-TIG welding, arc constriction occurs during rise time and arc release occurs during fall time. At incremental levels of ACCF, the rise time and fall time decrease appreciably. As the time required for arc constriction is greater than that for arc release, the arc constriction is reduced at 20 kHz, which leads to the widening of bead and reduced heat transfer rate between weld pool and base metal. As ACCF increases, the time interval between the adjacent peaks of ACC decreases. This, in turn, increases the temperature oscillation of molten pool per unit cycle, and decreases the time interval of thermal cycle of weld. Also, there is significant overlapping of molten weld pool at increment levels of ACCF. Thus, shorter time is accessible for the molten weld pool for the effective heat transfer during weld thermal cycle. It accounts for stacking of heat input in molten weld pool and slow cooling rate which offers adequate time for dendritic grain growth and increase in interdendritic areas. Also, the remelting of homogeneous nuclei advancing to the solid-liquid interfacial region makes the refinement of dendritic grains difficult due to the raised temperature of molten pool. This provides adequate time for solute redistribution and promotes high partitioning of alloying elements in interdendritic liquid, thus, increasing coarsening and volume fraction of Laves phase in weld metal at 20 kHz. The high temperature material such as Alloy 718 that is heavily alloyed with strengthening elements, shows higher sensitivity towards these consequences due to the high partitioning tendency of Nb with increase in heat input.

5 Conclusions

(1) Arc constriction current frequency (ACCF) showed significant influence on tensile properties and microstructural evolution of constricted arc TIG (CA-TIG) welded Alloy 718 joints. Hence, the optimal selection of ACCF is important to achieve the potential advantages of magnetic constriction and pulsing of arc.

(2) The joints welded by using ACCF of 4 kHz yielded superior tensile strength and elongation extending joint efficiency up to 99.20%. It is imputed to the optimum level of heat input and thermal oscillation experienced by the weld pool, which imparts fusion zone grain refinement, leading to the evolution of finer, discrete Laves phase in interdendritic areas.

(3) The increase in ACCF from 4 to 20 kHz extended dendritic grain growth and increased volume fraction of Laves phase in fusion zone, which degraded the tensile properties of joints. It is mainly related to the stacking of heat input in weld thermal cycles at increased levels of ACCF.

(4) The stacking of heat input in weld thermal cycles at higher levels of ACCF is mainly associated with rapid thermal oscillation and overlapping of the weld pool, which provides less time for the effective heat transfer between the fusion zone and base metal.

(5) Alloy 718 welds showed more tendency for Nb segregation and Laves phase formation at higher levels of ACCF due to the slower cooling rate.

(6) The segregation of Nb was severe at ACCF above 12 kHz. The volume fraction of Laves phase was increased by 62.31% at ACCF of 20 kHz compared to that at 4 kHz, thereby reducing tensile strength and elongation of joints.

Acknowledgments

This work was supported by the Indian Space Research Organization (ISRO), Department of Space, India, under ISRO RESPOND scheme (Project No. ISRO/RES/3/728/16-17).

References

[1] FU S H, DONG J X, ZHANG M C, XIE X S. Alloy design and development of Inconel 718 type alloy [J]. Materials Science and Engineering A, 2009, 499: 215-220.

[2] CHAI Lin-jiang, YUAN Shan-shan, HUANG Wei-jiu, YANG Xu-sheng, WANG Fang-jun, WANG Dong-zhe, WANG Jun-jun. Microstructural characterization of Inconel 718 alloy after pulsed laser surface treatment at different powers [J]. Transactions of Nonferrous Metals Society of China, 2018, 28: 1530-1537.

[3] CHATURVEDI M C, HAN Y F. Strengthening mechanisms in Inconel 718 superalloy [J]. Metal Science, 1983, 3: 145-149.

[4] MANIKANDAN S G K, SIVAKUMAR D, KAMARAJ M. Welding the Inconel 718 alloy [M]. Amsterdam: Elsevier, 2019.

[5] XU Xiao-yan, MA Xiang-dong, WANG Hong, YE Zhang, CHANG Jian-wei, XU Yao, GAO Yu-kui. Characterization of residual stresses and microstructural features in an Inconel 718 forged compressor disc [J]. Transactions of Nonferrous Metals Society of China, 2019, 29: 569-578.

[6] HERNANDEZ M, AMBRIZ R R, CORTES R, GOMORA C M, PLASCENCIA G, JARAMILLO D. Assessment of gas tungsten arc welding thermal cycles on Inconel 718 alloy [J]. Transactions of Nonferrous Metals Society of China, 2019, 29: 579-587.

[7] RADHAKRISHNA C H, PRASAD RAO K. The formation and control of Laves phase in superalloy 718 welds [J]. Journal of Materials Science, 1997, 32: 1977-1984.

[8] JANAKI RAM G D, VENUGOPAL REDDY A, PRASAD RAO K, MADHUSUDHAN REDDY G. Microstructure and mechanical properties of Inconel 718 electron beam welds [J]. Materials Science Technology, 2005, 21: 1132-1138.

[9] MADHUSUDHAN REDDY G, SRINIVASA MURTHY C V, SRINIVASA RAO K, PRASAD RAO K. Improvement of mechanical properties of Inconel 718 electron beam welds—Influence of welding techniques and post weld heat treatment [J]. International Journal of Advanced Manufacturing Technology, 2009, 43: 671-680.

[10] HUANG C A, WANG T H, LEE C H, HAN W C. A study of the heat-affected zone (HAZ) of an Inconel 718 sheet welded with electron-beam welding (EBW) [J]. Materials Science and Engineering A, 2005, 398: 275-281.

[11] FRENCH R, MARIN-REYES H, RENDELL-READ A. A robotic re-manufacturing system for high-value aerospace repair and overhaul [C]//Proc Transactions on Intelligent Welding Manufacturing 2017. Singapore: Springer, 2017: 36-47.

[12] LEARY R K, MERSON E, BIRMINGHAM K, HARVEY D, BRYDSON R. Microstructural and microtextural analysis of InterPulse GTCAW welds in Cp-Ti and Ti-6Al-4V [J]. Materials Science and Engineering A, 2010, 527: 7694-7705.

[13] KUMAR H, AHMAD G N, SINGH N K. Activated flux TIG weldings of Inconel 718 superalloy in presence of tri-component flux [J]. Materials and Manufacturing Processes, 2019, 34: 216-223.

[14] RODRIGUEZ N K, BARRAGAN E R, LIJANOVA I V, CORTES R, AMBRIZ R R, MENDEZ C, JARAMILLO D. Heat input effect on the mechanical properties of Inconel 718 gas tungsten arc welds [C]//Proc 17th International Conference on New Trends in Fatigue and Fracture 2017. Cancún, MExico: Springer, 2017: 255-262.

[15] SUDARSHAN RAO G, SARAVANAN K, HARI- KRISHNAN G, SHARMA VMJ, NARAYAN P R, SREEKUMAR K, SINHA P. Local deformation behaviour of Inconel 718 TIG weldments at room temperature and 550 °C [J]. Materials Science Forum, 2012, 710: 439-444.

[16] CORTES R, BARRAGAN E R, LOPEZ V H, AMBRIZ R R, JARAMILLO D. Mechanical properties of Inconel 718 welds performed by gas tungsten arc welding [J]. International Journal of Advanced Manufacturing Technology, 2018, 94: 3949-3961.

[17] MEI Yun-peng, LIU Yong-chang, LIU Chen-xi, LI Chong, YU Li-ming, GUO Quian-ying, LI Hui-jun. Effect of base metal and welding speed on fusion zone microstructure and HAZ hot-cracking of electron-beam welded Inconel 718 [J]. Materials & Design, 2016, 89: 964-977.

[18] KWON S I, BAE S H, DO J H, JO C Y, HONG H U.Characterization of the microstructures and the cryogenic mechanical properties of electron beam welded Inconel 718 [J]. Metallurgical and Materials Transactions A, 2015, 47: 777-787.

[19] ABDUL JAWWAD K, STRANGWOOD M, DAVIS C L. Microstructural modification in full penetration and partial penetration electron beam welds in Inconel-718 and its effect on fatigue crack initiation [J]. Metallurgical and Materials Transactions A, 2005, 36: 1237-1247.

[20] GAO Peng, ZHANG Kai-feng, ZHANG Bing-gang, JIANG Shao-song, ZHANG Bao-wei. Microstructures and high temperature mechanical properties of electron beam welded Inconel 718 superalloy thick plate [J]. Transactions of Nonferrous Metals Society of China, 2011, 21(S): s315-s322.

[21] JANAKI RAM G D, VENUGOPAL REDDY A, PRASAD RAO K, MADHUSUDHAN REDDY G, SARIN SUNDAR J K. Microstructure and tensile properties of Inconel 718 pulsed Nd-YAG laser welds [J]. Journal of Materials Processing Technology, 2005, 167: 73-82.

[22] QU Feng-sheng. LIU Xu-guang, XING Fei, ZHANG Kai-feng. High temperature tensile properties of laser butt-welded plate of Inconel 718 superalloy with ultra-fine grains [J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 2379-2388.

[23] REZAEI M A, NAFFAKH-MOOSAVY H. The effect of pre-cold treatment on microstructure, weldability and mechanical properties in laser welding of superalloys [J]. Journal of Manufacturing Processes, 2018, 34: 339-348.

[24] JANAKI RAM G D, VENUGOPAL REDDY A, PRASAD RAO K, MADHUSUDHAN REDDY G M. Control of Laves phase in Inconel 718 GTA welds with current pulsing [J]. Science and Technology of Welding and Joining, 2004, 9: 390-398.

[25] SIVAPRASAD K, RAMAN S G S, MASTANAIAH P, MADHUSUDHAN REDDY G. Influence of magnetic arc oscillation and current pulsing on microstructure and high temperature tensile strength of alloy 718 TIG weldments [J]. Materials Science and Engineering A, 2006, 428: 327-331.

[26] VISHWAKARMA K R. RICHARDS N L, CHATURVEDI M C. Microstructural analysis of fusion and heat affected zones in electron beam welded ALLVAC 718PLUSTM superalloy [J]. Materials Science and Engineering A, 2008, 480: 517-528.

718PLUSTM superalloy [J]. Materials Science and Engineering A, 2008, 480: 517-528.

[27] MEHRABIAN R, KEAR B H, COHEN M. Rapid solidification processing: Principles and technologies [M]. Baton Rouge, LA: Claitor’s Publication Division, 1978.

[28] MADHUSUDHAN REDDY G, SRINIVASA MURTHY C V, VISWANATHAN N, PRASAD RAO K. Effects of electron beam oscillation techniques on solidification behaviour and stress rupture properties of Inconel 718 welds [J]. Science and Technology of Welding and Joining, 2007, 12: 106-114.

[29] CAI Da-yong, ZHANG Wei-hong, NIE Pu-lin, LIU Wen-cheng, YAO Mei. Dissolution kinetics of δ phase and its influence on the notch sensitivity of Inconel 718 [J]. Materials Characterization, 2007, 58: 220-225.

[30] CAO X, RIVAUX B, JAHAZI M, CUDDY J, BIRUR A. Effect of pre- and post-weld heat treatment on metallurgical and tensile properties of Inconel 718 alloy butt joints welded using 4kW Nd:YAG laser [J]. Journal of Materials Science, 2009, 44: 4557-4571.

[31] MANIKANDAN S G K, SIVAKUMAR D, KAMARAJ M, PRASAD RAO K. Laves phase control in Inconel 718 weldments [J]. Materials Science Forum, 2012, 710: 614-619.

[32] AGILAN M, CHENNA K S, MANWATKAR S K, VINAYAN E G, SIVAKUMAR D, PANT B. Effect of welding processes (GTAW & EBW) and solutionizing temperature on microfissuring tendency in Inconel 718 Welds [J]. Materials Science Forum, 2004, 710: 603-607.

[33] SOHRABI M J, MIRZADEH H, RAFIEI M. Solidification behavior and Laves phase dissolution during homogenization heat treatment of Inconel 718 superalloy [J]. Vacuum, 2018, 154: 235-243.

[34] ZHANG Y N, CAO X, WANJARA P. Microstructure and hardness of fiber laser deposited Inconel 718 using filler wire [J]. International Journal of Advanced Manufacturing Technology, 2013, 69: 2569-2581.

[35] ODABASI A, UNLU N, GOLLER G, ERUSLU M N. A study on laser beam welding (LBW) Technique: Effect of heat input on the microstructural evolution of superalloy Inconel 718 [J]. Metallurgical and Materials Transactions A, 2010, 41: 2357-2365.

[36] KNOROVSKY G A, CIESLAK M J, HEADLEY T J, ROMIG A D, HAMMETTER W F. Inconel 718: A solidification diagram [J]. Metallurgical Transactions A, 1989, 20: 2149-2158.

[37] CIESLAK M J, HEADLEY T J, ROMIG A D, KOLLIE T. A melting and solidification study of alloy 625 [J]. Metallurgical Transactions A, 1988, 19: 2319-2331.

[38] BANSAL A, SHARMA A K, DAS S, KUMAR P. Characterization of microstructure and strength of microwave welded Inconel 718 joints at 2.45 GHz frequency [J]. Metallic Materials, 2016, 54: 27-35.

[39] MANIKANDAN S G K, SIVAKUMAR D, PRASAD RAO K, KAMARAJ M. Effect of weld cooling rate on Laves phase formation in Inconel 718 fusion zone [J]. Journal of Materials Processing Technology, 2014, 214: 358-364.

[40] LONG Yi-tong, NIE Pu-lin, LI, Zhu-guo, HUANG Jian, LI Xiang, XU Xin-mei. Segregation of niobium in laser cladding Inconel 718 superalloy [J]. Transactions of Nonferrous Metals Society of China, 2016, 26: 431-436.

Tushar SONAR, Sudersanan MALARVIZHI, Visvalingam BALASUBRAMANIAN

Centre for Materials Joining and Research (CEMAJOR), Department of Manufacturing Engineering, Annamalai University, Annamalai Nagar 608002, Tamil Nadu State, India

摘 要:研究电弧收缩电流频率(ACCF )对收缩电弧钨极氩弧焊(CA-TIG)焊接航空航天718合金板(厚度为2 mm)拉伸性能和显微组织演变的影响。实验设计每次一个变量,即采用从4 kHz到20 kHz之间5个不同的ACCF,其他参数保持不变。结果显示,采用4 kHz ACCF的接头具有良好的拉伸性能,焊接效率可达99.20%。这是由于熔化区的晶粒细化导致枝晶间析出更细小、离散的Laves相。ACCF高于12 kHz时熔化区发生严重晶粒长大和粗大 Laves相演变。718合金焊缝在较高的ACCF下由于冷却速度较慢,Nb偏析和Laves相形成的趋势更明显。当 ACCF为20 kHz时,Laves相的体积分数比4 kHz时提高62.31%,因此,接头的拉伸性能降低。这主要是由于当ACCF增加时,焊接热循环中热输入的叠加。

关键词:收缩电弧钨极氩弧焊;电弧收缩电流频率;718合金板;拉伸性能;显微组织演变;Laves相

(Edited by Wei-ping CHEN)

Corresponding author: Tushar SONAR; E-mail: tushar.sonar77@gmail.com

DOI: 10.1016/S1003-6326(21)65509-7

1003-6326/ 2021 The Nonferrous Metals Society of China. Published by Elsevier Ltd & Science Press

2021 The Nonferrous Metals Society of China. Published by Elsevier Ltd & Science Press