DOI:10.19476/j.ysxb.1004.0609.2019.06.14

表面毛化铝箔集流体的力学性能

王之桐1,王艳飞2

(1. 中国科学院力学研究所 先进制造工艺力学重点实验室,北京 100190;

2. 山东聚信新能源科技有限公司,滨州 256200)

摘 要:针对铝箔集流体表面改性的要求,基于激光毛化技术轧制13 μm厚的1070铝箔,研究表面毛化参数对铝箔的力学性能和作为锂离子电池正极集流体的加工性能的影响。表面毛化铝箔的表面粗糙度Ra达到0.7~1.0 μm,为常规铝箔的7.4~9.7倍,表面毛化坑诱导的应力集中效应使铝箔的屈服强度和拉伸强度降低4%~10%,而表面毛化坑造成的铝箔局部减薄和板型变化对伸长率的影响更加显著。采用相互分离的低密度毛化坑(分布参数140 μm×140 μm)时,表面毛化铝箔的伸长率仅降低约10%。而采用相切的高密度毛化坑(分布参数70 μm×70 μm)时,表面毛化铝箔的伸长率降低约50%。两种表面毛化铝箔制成的正极极片的LiCoO2涂层剥离强度均达到常规铝箔极片的1.6倍,分散性仅为常规铝箔极片的16%~32%。毛化铝箔的表面粗糙度Ra值在0.7 μm附近存在临界点,继续增大不能有效地提高涂层对铝箔集流体的剥离强度,反而损失其力学性能。模拟锂离子电池正极极片的辊压和烘干工艺后,表面毛化铝箔(分布参数140 μm×140 μm)的力学性能与常规铝箔的相当,但铝箔表面毛化坑诱导的应力集中现象能够促进铝箔均匀变形,抵抗局部损伤能力强,提高电池卷芯对整形压力的宽容度,有助于避免最内层极片的局部断裂现象。

关键词:激光表面毛化;铝箔集流体;力学性能;剥离强度

文章编号:1004-0609(2019)-06-1250-07 中图分类号:TM335.5 文献标志码:A

在电化学储能器件(锂离子电池、超级电容和锂离子电容等)中,铝箔是一种常用的正极集流体,起到承载活性材料和传输电子的作用。为了提高铝箔和活性材料涂层之间的结合强度,降低二者之间的接触电阻,需要对铝箔进行表面改性处理。目前,常用的铝箔表面改性方法包括:表面涂层化、表面多孔化和表面穿孔等。铝箔表面涂层化改性主要包括表面涂碳和涂石墨烯[1],能够提高电池的倍率放电性能和容量保持率,同时保护铝箔不被腐蚀[2],多用于LiPO4电池[3-4],在硫锂电池中也有应用报道[5-6]。铝箔表面多孔改性方法包括化学腐蚀、电化学腐蚀、表面氧化等多种方法。腐蚀铝箔能够提高碳包覆LiPO4电池的放电容量,具有良好的循环可逆性能[7]。同时,腐蚀铝箔的表面形貌与活性材料颗粒形状和尺寸的匹配关系决定了锂离子电池的性能[8]。腐蚀铝箔对超级电容的影响更加明显,能够提高超级电容的比电容和循环性能[9]。铝箔表面阳极氧化并高温沉积碳层,将表面多孔改性和涂层改性方法结合在一起,能够显著提高LiPO4电池的倍率性能[10]。铝箔表面穿孔属于特殊的表面改性方法,贯通孔提供了液体和离子的流动通道,并能够储存更多的活性材料,可用于超级电容[11]和聚合物锂电池[12]。

在锂离子电池和超级电容的生产过程中,涂布、辊压、卷绕、压芯整形等工艺要求铝箔集流体和极片保持完整,对铝箔集流体的拉伸强度、伸长率和折弯性能有一定的要求。为了提高锂离子电池的能量密度,集流体铝箔的厚度已经减薄到12~13 μm,表面多孔化会造成铝箔力学性能下降,无法满足极片制作工艺要求。涂碳铝箔表面涂层的厚度通常为微米级[1],已经达到集流体厚度的10%左右,涂层厚度不可忽略。冷轧是一种生产铝箔的常规方法。使用表面粗糙化处理的轧辊对铝箔表面轧制改性是一种有吸引力的方法[13]:1) 冷轧过程没有材料损失,铝箔的力学性能好;2) 冷轧能够在铝箔表面形成三维形貌,涂层结合强度高;3) 生产方法高效、环保。激光毛化技术可以在轧辊表面精确制备粗糙形貌,已经用于工业生产表面毛化钢板、钢带[14],但在铝加工行业只是用来改善表面质量[15]和增大摩擦因数[16],还未见该技术应用在铝箔集流体上的报道。本文针对铝箔集流体的轧制粗化改性要求,优化轧辊表面激光毛化技术[17],制备了表面毛化的铝箔集流体,研究表面毛化参数对铝箔集流体拉伸性能、锂离子电池正极极片涂层剥离强度和折弯性能的影响规律。

1 实验

1.1 表面毛化铝箔和正极极片的制备

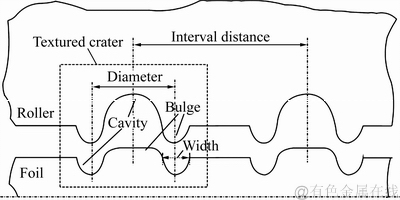

首先使用激光毛化机对轧辊进行表面毛化,然后对某铝厂生产的13 μm厚的1070H18双面光铝箔进行轧制。在毛化轧制过程中(见图1),辊面的环状凸起挤压铝箔表面形成凹坑,辊面环状凸起中央的凹坑容纳了铝箔的挤出物,在铝箔表面形成凸起。通过控制轧制力,保证轧制过程只复制轧辊表面形貌,而铝箔的平均厚度不变。在本文中,原料铝箔定义为样品1,表面毛化铝箔的毛化坑分布参数包括两种:样品2(140 μm×140 μm)和样品3(70 μm×70 μm)。将钴酸锂粉末(LiCoO2)、导电炭黑(SP)及聚偏氟乙烯在(PVDF)按质量比8:1:1在N-甲基吡咯烷酮(NMP)中混合均匀,涂覆在3种铝箔上,然后进行辊压、烘干制成正极极片。

图1 铝箔表面毛化轧制示意图

Fig. 1 Schematic diagram of surface texturing rolling of aluminum foil

1.2 铝箔单向拉伸实验

拉伸实验在ZQ-990A型拉伸实验机上进行,传感器量程为500N。根据GBT 16865-2013标准,铝箔采用定标距无头试样,试样宽度为15 mm,标距为100 mm,总长为140 mm。试样使用双刃试样切刀制备,保证试样边缘平滑、无毛刺。设计了试样对中夹具,保证试样轴线与拉伸机轴线平行。铝箔夹持部分双面垫纸,减轻夹口部分应力集中,保证试样在标距段断裂。拉伸应变率为1×10-3。每种铝箔测试5个样品,取平均值。模拟电极片的辊压、烘干过程。将铝箔试样拉伸到总伸长率1.2%后卸载,在热处理炉中150 ℃加热20 min后取出空冷,然后对铝箔试样进行拉伸,测试规范同上。

1.3 涂层剥离实验

极片涂层剥离实验在TSL-1002型实验机上进行。根据GBT 2792-2014,使用胶带粘接电极片涂层,粘接长度为100 mm。将铝箔的背面用双面胶粘接在1 mm厚的不锈钢板上,保证1800剥离角不变。从实验机读出剥离力数据处理成剥离强度,每种铝箔测试3个样品,数据取平均值。

1.4 铝箔形貌和极片检测

使用表面粗糙度仪TR-200测量铝箔的表面粗糙度,测量方向垂直轧制方向,给出轮廓算术平均偏差(Ra)、轮廓最大峰高(Rp)、轮廓最大谷深(Rv)和轮廓峰间距(Rs),每种铝箔测试5次取平均值。使用光学显微镜观察铝箔表面形貌。制备铝箔截面金相样品,观察表面毛化铝箔的截面形貌。将正极极片与隔膜、负极极片卷绕成电池芯,压芯整形后取出最内层正极极片,背光观察极片的折弯断裂情况。

2 结果和分析

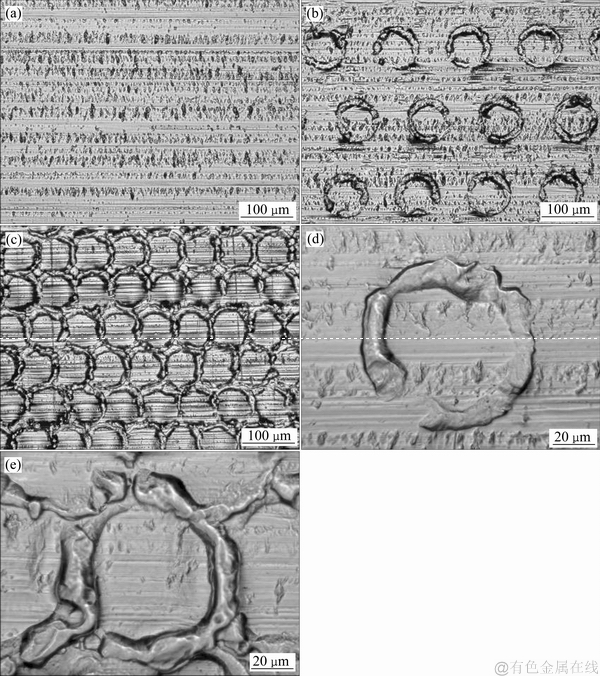

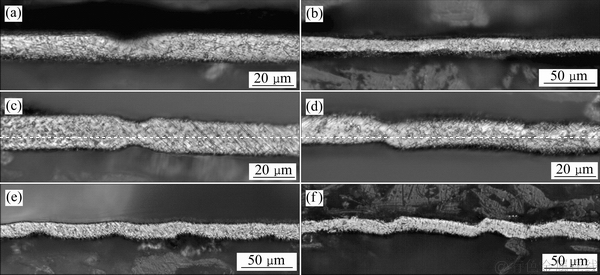

铝箔表面粗糙度如表1所列,图2所示为铝箔样品的表面照片。常规铝箔样品1的表面(见图2(a))存在平行轧向的摩擦痕迹,是一种典型的精密轧制铝箔表面形貌,Ra为0.094 μm,Rp和Rv基本相等。铝箔样品2(见图2(b))表面毛化坑的直径在75 μm左右,Ra为样品1的7.4倍,Rv值大于Rp值。铝箔样品3的表面毛化坑相切,Ra为样品1的9.7倍,Rp和Rv比样品2的略有增大,Rs基本等于毛化坑的直径。样品2和样品3的环状毛化坑宽度都在10 μm左右(见图2(d)和2(e))。图3所示为两种表面毛化铝箔样品的截面照片。样品2(见图3(a))的毛化坑分布稀疏,两面毛化坑相重叠的现象不明显,由于铝箔的刚度不够,箔面呈现轻微波浪状(见图3(b))。样品3的毛化坑密度是样品2的4倍,双面毛化坑重叠严重,局部减薄变得明显,最薄处铝箔厚度变为8 μm(见图3(c)和3(d))。由于基准平面被破坏,样品3出现明显的波浪状(见图3(e))和锯齿状形貌(见图3(f))。

表1 铝箔表面粗糙度

Table 1 Surface roughness of aluminum foil

图2 铝箔表面照片

Fig. 2 Surface photos of aluminum foils of Sample 1 (a), Sample 2 ((b), (d)) and Sample 3 ((c), (e))

图3 铝箔截面照片

Fig. 3 Cross-section photos of aluminum foils of Sample 2 ((a), (b)) and Sample 3 ((c), (d), (e), (f))

在图4中给出了铝箔单向拉伸曲线,力学性能数据在表2中给出。在表面毛化坑应力集中效应的影响下[18],低密度毛化坑样品2的屈服强度σ0.2和拉伸强度σb下降了约4%,高密度毛化坑样品3的屈服强度σ0.2和拉伸强度σb下降了约10%。根据表1的铝箔表面粗糙度数据和图3的截面照片分析,单面毛化坑使铝箔局部厚度从13μm减薄到10.5 μm,而双面重叠的毛化坑将使铝箔局部厚度减薄到8 μm。铝箔变薄后,协调变形能力变差,导致伸长率下降[19]。样品2的毛化坑分布较稀疏,双面毛化坑重叠的概率低,局部多为单面减薄。相对于常规铝箔样品1,样品2的均匀变形阶段缩短,而颈缩阶段变长,断后伸长率δ下降了约10%。而样品3表面完全被毛化坑覆盖,双面毛化坑相互重叠,铝箔呈现高密度的局部减薄。样品3没有出现颈缩阶段,表现为脆性断裂,断后伸长率δ下降了约50%。此外,铝箔的板形也会在更大的尺寸上导致变形不均匀,影响铝箔的力学性能。而样品3的板形比样品2的更差,这也是样品3伸长率大幅下降的原因之一。

图4 铝箔的拉伸曲线

Fig. 4 Tensile curve of aluminum foil

表2 铝箔的力学性能

Table 2 Mechanical property of aluminum foils

表3所列为正极极片LiCO2涂层对铝箔集流体的剥离强度。表面毛化样品2的涂层剥离强度是常规铝箔样品1的1.6倍,但是分散性大幅下降,仅为样品1的16%。表面毛化样品3的表面粗糙度Ra是样品2的1.32倍,但是剥离强度与样品2基本相等。这说明表面粗糙度Ra在0.7 μm附近存在临界点,继续增大Ra值不能有效提高涂层剥离强度,反而损失铝箔的力学性能。

表3 正极极片LiCO2涂层对铝箔集流体的剥离强度

Table 3 Peeling strength of LiCO2 coating on positive electrode for aluminum foil collector

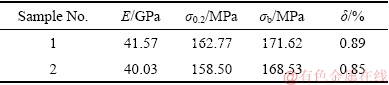

通常,锂离子电池正极极片制备工艺要求铝箔的伸长率大于1.5%,显然表面毛化样品3的伸长率过低,因此,对常规铝箔样品1和表面毛化样品2进行塑性变形1%后150 ℃保温20 min,模拟极片的辊压和烘干过程。模拟极片制备工艺后的铝箔样品力学性能在表4中给出。保温过程使样品1的组织发生软化,弹性模量变小。样品2通过拉伸塑性变形后,板形的波浪形貌得到改善,补偿了软化造成的弹性模量损失,因此样品2的弹性模量略有增大。板形改善后,样品2的伸长率与样品1的比值从0.9增大到0.96。背光观察锂电池卷芯压制后最内层的正极极片,发现常规铝箔样品1制备的两张极片中的一张已经出现多处局部断裂(见图5(a)中箭头所指),而表面毛化样品2制备的两张极片表面均保持完整(见图5(b))。考虑表4的力学性能数据,样品2的屈服强度低于样品1的,在同样应力水平下,样品2优先屈服,但样品2的伸长率与样品1的相当,因此在宏观尺度上样品2的力学性能不占优势。极片辊压后LiCoO2颗粒将镶嵌在铝箔表面[8],由于LiCoO2颗粒粒度的分散性,铝箔表面压痕的尺寸是不同的。这种不均匀的局部减薄导致样品1变形不均,电池卷芯压制后铝箔容易发生局部断裂。而样品2表面均匀分布的毛化凹坑诱导的应力集中效应促进铝箔整体变形均匀,附加的局部压痕对变形影响小,因此样品2制备的极片对电池卷芯整形压力的宽容度更高。

表4 模拟极片制备工艺后的铝箔力学性能

Table 4 Mechanical property of aluminum foil after simulation of electrode processing

图5 压芯整形后的最内层正极极片照片

Fig. 5 Photos of innermost positive electrode slice after pressing and shaping battery coil of Sample 1(a) and Sample 2(b)

3 结论

1) 表面毛化铝箔集流体粗糙度Ra达到0.7~1.0 μm,为常规铝箔的7.4~9.7倍,但是铝箔表面毛化坑诱导的应力集中效应使拉伸强度下降,而铝箔表面毛化坑造成的局部减薄和板型变化对伸长率的影响更加显著,表面毛化坑的密度越高对铝箔集流体的力学性能影响越大。

2) 正极极片的LiCO2涂层对表面毛化铝箔的剥离强度是常规铝箔的1.6倍,分散性仅为常规铝箔的16%~32%。毛化铝箔的表面粗糙度Ra在0.7 μm附近存在临界点,继续增大不能有效地提高极片涂层的剥离强度,反而损失铝箔的力学性能。

3) 模拟锂离子电池正极极片的辊压和烘干工艺后,表面毛化铝箔(分布参数140 μm×140 μm)的力学性能与常规铝箔相当,但铝箔表面毛化坑诱导的应力集中现象能够促进铝箔变形均匀,抵抗局部损伤能力强,对电池卷芯整形压力的宽容度更高,有助于避免最内层极片的局部断裂现象,提高电池的一致性和安全性。

REFERENCES

[1] 贾亚峰, 尚玉明, 王 莉, 李建军, 何向明. 锂离子电池集流体功能化改性研究进展[J]. 新材料产业, 2016, 20(7): 35-40.

JIA Ya-feng, SHANG Yu-ming, WANG Li, LI Jiang-jun, HE Xiang-ming. Development of functionalized modification on current collector of lithium-ion battery[J]. Advanced Materials Industry, 2016, 20(7): 35-40.

[2] 庄 林. 石墨烯增强锂离子电池铝箔集流体的抗腐蚀性[J]. 物理化学学报, 2018, 34(6): 557-558.

ZHUANG Lin. Graphene-armored aluminum foil for anticorrosion- enhanced battery anode current collector[J]. Acta Phys-Chim Sin, 2018, 34(6): 557-558.

[3] 邓龙征, 吴 锋, 高旭光, 谢海明, 杨智伟. 涂碳铝箔对磷酸铁锂电池性能影响研究[J]. 无机化学学报, 2014, 30(4): 770-778.

DENG Long-zheng, WU Feng, GAO Xu-guang, XIE Hai-ming, YANG Zhi-wei. Effects of coating carbon aluminum foil on the battery performance[J]. Chinese Journal of Inorganic Chemistry, 2014, 30(4): 770-778.

[4] STRIEBEL Kathryn, SHIM Joonpyo, SIERRA Azucena, YANG Hui, SONG Xiang-yun, KOSTECKI Robert, MCCARTHY Kathryn. The development of low cost LiFePO4-based high power lithium-ion batteries[J]. Journal of Power Sources, 2005, 146(1/2): 33-38.

[5] 李 涛, 洪 波, 曹华伟, 刘业翔, 闫霄林, 黄子欣. 涂碳铝箔在锂硫电池中的应用[J]. 中国有色金属学报, 2017, 27(4): 732-738.

LI Tao, HONG Bo, CAO Hua-wei, LIU Ye-xiang, YAN Xiao-lin, HUANG Zi-xin. Application of carbon-coated aluminum foil for Li-S secondary batteries[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(4): 732-738.

[6] LI Tao, HONG Bo, CAO Hua-wei, LAI Yan-qing, LIU Ye-qing. Carbon-coated aluminum foil as current collector for improving the performance of lithium sulfur batteries[J]. International Journal of Electrochemical Science, 2017, 12(3): 3099-3108.

[7] 柯 翔, 肖仁贵, 廖 霞, 王少丹, 马志鸣. 腐蚀Al箔集流体对球状LiFePO4/C复合材料电性能的影响[J]. 复合材料学报, 2018, 35(11): 3212-3218.

KE Xiang, XIAO Ren-gui, LIAO Xia, WANG Shao-dan, MA Zhi-ming. Effect of corrosion for Al foils on electrical performance of sphere LiFePO4/C composite[J]. Acta Materiae Compositae Sinica, 2018, 35(11): 3212-3218.

[8] NAKANISHI Shigeki, SUZUKI Takashi, CUI Qi, AKIKUSA Jun, NAKAMURA Kenzo. Effect of surface treatment for aluminum foils on discharge properties of lithium-ion battery[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(10): 2314-2319.

[9] 周海生, 何捍卫, 洪东升, 解东梅, 杨 良. 铝箔电化学与化学刻蚀对超级电容器性能的影响比较[J]. 粉末冶金材料科学与工程, 2013, 18(6): 840-845.

ZHOU Hai-sheng, HE Han-wei, HONG Dong-sheng, XIE Dong-mei, YANG Liang. Comparison of effects of aluminum foil electrochemical and chemical etching on supercapacitor performance[J]. Materials Science and Engineering of Powder Metallurgy, 2013, 18(6): 840-845.

[10] WU Hsien-chang, WU Hung-chun, LEE Eric, WU Nae-lih. High-temperature carbon-coated aluminum current collector for enhanced power performance of LiFePO4 electrode of Li-ion batteries[J]. Electrochemistry Communications, 2010, 12(3): 488-491.

[11] 徐启远, 徐永进, 朱永法, 姜冬冬. 锂离子电容器集流体用穿孔箔的研究进展[J]. 材料导报, 2013, 27(12): 28-31.

XU Qi-yuan, XU Yong-jin, ZHU Yong-fa, JIANG Dong-dong. Research progress on perforated foil of electrode collector for lithium ion capacitor[J]. Materials Reports, 2013, 27(12): 28-31.

[12] 胡建军, 刘侦德, 李宇明, 程建聪. 聚合物锂离子电池正极集流体材料的研制与应用[J]. 湖南有色金属, 2008, 24(5): 40-42.

HU Jian-jun, LIU Zhen-de, LI Yu-ming, CHENG Jian-cong. Research and application of material of positive pole current collectors of new polymer lithium-ion battery-preparation and application of pierced aluminum foils[J]. Hunan Nonferrous Metals, 2008, 24(5): 40-42.

[13] 本居徹也, 船户宁. 集电体用铝箔及其制造方法: 中国, 201280070741.6[P]. 2012-09-06.

MOTOI Tetsuya, FUNATO Yasushi. Aluminum foil for collectors and method for producing same: China, 201280070741.6[P]. 2012-09-06

[14] 杨明江, 彭林华, 李正阳. YAG激光毛化技术进展[J]. 应用激光, 2002, 22(3): 323-326, 316.

YANG Ming-jiang, PENG Lin-hua, LI Zheng-yang. Development of YAG laser texturing technology[J]. Applied Laser, 2002, 22(3): 323-326, 316.

[15] 徐 涛. 轧辊激光毛化及冷轧工艺对铝材表面亚光特性的影响[J]. 机械工程师, 2013, 45(7): 49-50.

XU Tao. Effect of laser texturing and rolling technology on surface characteristic of matte aluminum[J]. Mechanical Engineer, 2013, 45(7): 49-50.

[16] 刘 杰. 激光毛化技术及其在电解电容器铝光箔生产中的应用[J]. 新疆有色金属, 2014, 43(7): 175-177, 180.

LIU Jie. Application of laser texturing technology on aluminum foil of electrolytic condenser[J]. Xinjiang Nonferrous Metals, 2014, 43(7): 175-177, 180.

[17] 王之桐. 一种集流体铝箔的织构轧制方法: 中国, 201810165408.2[P]. 2018-02-28.

WANG Zhi-tong. A kind of surface textured rolling method for aluminum foil current collector[P]. 2018-02-28.

[18] 彭林华. YAG脉冲激光毛化钢板的性能和YAG脉冲激光表面涂覆的研究[D]. 北京: 中国科学院力学研究所, 1997: 94-96.

PENG Lin-hua. On properties of YAG laser textured steel sheets and cladding techniques by YAG pulse laser[D]. Beijing: Institute of Mechanics, Chinese Academy of Sciences, 1997: 94-96.

[19] 郭战胜, 王宇晖, 朱建宇, 冯捷敏. 铝箔力学性能的实验研究[J]. 实验力学, 2016, 31(4): 451-457.

GUO Zhan-sheng, WANG Yu-hui, ZHU Jian-yu, FENG Jie-min. Experimental research of mechanical properties for aluminum foil[J]. Journal of Experimental Mechanics, 2016, 31(4): 451-457.

Mechanical property of surface textured aluminum foil as current collector

WANG Zhi-tong1, WANG Yan-fei2

(1. Key Lab of Mechanics in Advanced Manufacturing, Institute of Mechanics, Chinese Academy of Science, Beijing 100190, China;

2. Shan Dong JU XIN Amperex Technology Ltd, Binzhou 256200, China)

Abstract: According to the requirement of surface modification of aluminum foil as current collector, a kind of 1070 aluminum foil with the thickness of 13 μm was rolled by laser texturing technology. The effects of surface texturing parameters on the mechanical properties of aluminum foil and its processing properties as a positive electrode current collector for lithium-ion battery were studied. The Ra value of surface textured aluminum foil is about 0.7-1.0 μm, which is 7.4-9.7 times than that of normal aluminum foil. It is found that the stress concentration effect induced by the surface textured craters reduced the yield strength and tensile strength of aluminum foil from 3.4%-11.5%, and the local thinning of aluminum foil and the change of plate shape caused by the surface texturing craters have more significant effect on the elongation of aluminum foil. With the separated low density surface textured craters (distribution parameter 140 μm×140 μm), the elongation of the aluminum foil is only reduced about 10%. However, with the tangential high density surface textured crater (distribution parameter 70 μm×70 μm), the elongation of the aluminum foil is reduced by about 50%. The adhesion strength of LiCoO2 coating of positive electrode slice to the surface textured aluminum foil is 1.6 times than that to the normal aluminum foil, and the mean squared error of the former is only 16%-32% than the latter. It is a critical point of surface roughness about Ra 0.7 μm for the surface textured aluminum foil that higher Ra than it can not effectively improve the adhesion strength of the positive electrode coating to aluminum foil as current collector, but loses the mechanical properties of aluminum foil. After simulating the rolling process and drying process of the positive electrode slice of lithium-ion battery, the mechanical properties of the surface textured aluminum foil (distribution parameter 140 μm×140 μm) are similar with those of the normal aluminum foil. However, the uniform deformation of aluminum foil is promoted by the stress concentration phenomenon induced by textured craters on the surface of aluminum foil to have strong resistance to local damage of aluminum foil and higher tolerance to the shaping pressure of the battery coil. It is helpful to avoid the local fracture phenomenon of the innermost positive electrode splice.

Key words: laser surface texturing; aluminum foil current collector; mechanical property; adhesion strength

Foundation item: Project(11372322) supported by the National Natural Science Foundation of China

Received date: 2018-05-08; Accepted date: 2019-05-28

Corresponding author: WANG Zhi-tong; Tel: +86-10-82544258; E-mail: ztwang@imech.ac.cn

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(11372322)

收稿日期:2018-05-08;修订日期:2019-05-28

通信作者:王之桐,副研究员,博士;电话:010-82544258;E-mail:ztwang@imech.ac.cn