文章编号:1004-0609(2007)10-1580-06

小电流镀铜对LC4铝合金阳极氧化膜的改性作用

孟 琳1,何业东1,张 巍1,姚红宇2,谢明立2

(1. 北京科技大学 北京市腐蚀、磨蚀与表面技术重点实验室, 北京100083;

2. 中国民用航空总局 航空安全技术中心,北京100028)

摘 要:将LC4铝合金进行硫酸阳极化处理,然后采用小电流密度(0.1 mA/cm2)进行镀铜处理。XRD和EDS分析表明,小电流镀铜的沉积产物为金属铜,沉积的位置位于氧化膜多孔层的底部。结果表明,小电流镀铜能够使自腐蚀电位正移从而改善阳极氧化膜的耐蚀性。根据交流阻抗谱提出小电流镀铜后阳极氧化膜的等效电路。沉积铜对阳极氧化膜的改性作用使材料具有铜的电化学特性,是耐蚀性提高的根本原因。小电流镀铜处理与传统的电解着色工艺有本质区别,是一种新颖的提高阳极化铝合金耐蚀性的后处理方法。

关键词:铝合金;阳极氧化膜;小电流镀铜;改性;电解着色

中图分类号:TG 174.4 文献标识码:A

Modification of copper plating at low current density on

anodic film of LC4 aluminum alloy

MENG Lin1, HE Ye-dong1, ZHANG Wei1, YAO Hong-yu2, XIE Ming-li2

(1. Beijing Key Laboratory for Corrosion, Erosion and Surface Technology

University of Science and Technology Beijing, Beijing 100083, China,

2. Center of Aviation Safety Technology, CAAC, Beijing 100028, China)

Abstract: Copper plating at a low current density (0.1 mA/cm2) was carried out on the anodic film of LC4 aluminum alloy. XRD and EDS results show that the deposition product is the metal of copper, which is deposited at the bottom of the porous layer of the anodic film. The polarization curves show that copper plating at a low current density (0.1 mA/cm2) can remarkably improve the corrosion resistance of the anodic film. The equivalent circuit of the anodic film after copper plating is presented according to the impedance spectroscopy. The primary cause of the improvement is that the material has the electrochemical characteristic of the copper by the modification of copper plating. Essential difference exists between the copper plating at the low current density (0.1 mA/cm2) and the traditional electrolytic coloring technology.

Key words: aluminum alloy; anodic film; copper plating at low current density; modification; electrolytic coloring

铝合金材料由于具有低密度、高强度以及易成形加工等优点,广泛应用于航空、汽车、建筑、制造等领域[1]。由于铝非常活泼,在空气中易被氧化,在恶劣的环境中极易受到腐蚀,严重影响铝合金的性能。因此,铝合金在使用前往往需经过各种表面处理以满足其对环境的适应性和安全性的要求[2]。采用阳极氧化处理提高铝合金耐蚀性是在工业中获得广泛应用的技术[3]。在多数情况下,铝合金生成的阳极氧化膜具有双层结构,由内部致密的阻挡层和外部的多孔层构成[4?7]。

铝合金阳极氧化后,经过封闭和着色处理后可以提高其耐腐蚀性、耐磨性和表面装饰效果[8]。常见的封闭方法有沸水封闭[9]、氟化镍冷封闭、重铬酸钾封闭,醋酸镍封闭[10]等。由于铝合金成分对形成的阳极氧化膜的成分与结构有很大的影响,因此采用同一种封闭方法对于不同铝合金阳极氧化膜耐蚀性的影响不同。

近年来,人们利用铝合金阳极氧化膜具有纳米级有序孔的特性,在孔内沉积出各种不同性质的物质(如金属、半导体、高分子材料、磁性材料等),获得各种功能性膜层[11?13];以铝合金阳极氧化膜纳米级有序孔为模板,通过电化学沉积制备出各种纳米阵列材料[14?16]。在这些研究的启发下,作者提出如下研究思想:在铝合金阳极氧化膜纳米级有序孔中电沉积致密的金属,改变铝合金阳极氧化膜的结构,有可能使铝合金阳极氧化膜的耐蚀性能得到显著的提高。

本文作者研究LC4铝合金阳极氧化后采用小电流电镀的方法在氧化膜的纳米孔中沉积金属铜,对阳极氧化膜的结构及其对耐蚀性的影响。

1 实验

1.1 实验材料

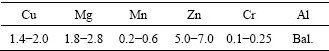

选用LC4铝合金作为实验材料,其化学成分列于表1。

表1 LC4铝合金的化学成分

Table 1 Chemical composition of LC4 (mass fraction, %)

铝合金经线切割为10 mm×10 mm×3 mm 的试片,然后将试样依次用水砂纸从300# 打磨至800#,丙酮脱脂除油,在常温1.25 mol/L NaOH溶液中进行碱性化学除油2 min,在常温3 mol/L的HNO3溶液中出光2 min。然后进行硫酸阳极氧化(H2SO4 1.6 mol/L,Al3+ 0.2 mol/L,电流密度:1.3 A/cm2,25 ℃,40 min)后,再用去离子水洗并用冷风吹干。阳极氧化电源为华泰WYK?6005直流稳压电源。

将阳极氧化后的部分试样进行小电流镀铜处理,采用的电镀液为CuSO4?5H2O(180 g/L)、H2SO4 (60 g/L),电流密度为0.1 mA/cm2,时间为10 min。

1.2 电化学实验方法

使用三电极体系,以饱和甘汞电极为参比电极,铂电极为辅助电极,采用PS168?B电化学测量系统测量不同试样在0.5 mol/L CH3COOH 溶液中的极化曲线;采用美国EG&G公司生产的273 A恒电位仪和英国SCHLUMBERGER生产的频响分析仪组成的电化学测试系统测量不同试样在0.5 mol/L CH3COOH 溶液中的交流阻抗谱(测试信号为幅值10 mV 的正弦波, 测量的频率为1×10?2~1×105 Hz)。

1.3 表面形貌观察与成分分析

采用场发射扫描电子显微镜(FEI XL30 S?FEG)观察镀铜前后阳极氧化膜的表面形貌,利用能量散射谱( EDS)分析镀铜前后成分变化,采用X射线衍射仪(日本理光公司D/MAX2500RB2+/PC X型)对镀铜前后阳极氧化膜的相组成进行分析。

2 结果与分析

2.1 表面形貌观察与成分分析

图1所示为LC4铝合金阳极氧化膜在小电流(0.1 mA/cm2,10 min)镀铜前后表面形貌的FESEM像。可以看出,镀铜之前阳极氧化膜的表面呈现多孔状,圆孔的孔径为15~20 nm;进行小电流镀铜处理后氧化膜表面仍为多孔状,但孔径有所增加,均在20 nm以上,但从膜的外观上来看与镀铜前相比没有发生变化。

图1 LC4铝合金阳极氧化膜的表面形貌

Fig.1 Surface morphologies of anodic film of LC4 aluminum alloy: (a) Before copper plating; (b) After copper plating(0.1 mA/cm2, 10 min)

图2所示为LC4铝合金在进行阳极化和小电流镀铜(0.1 mA/cm2,10 min)后的XRD谱,与图2(b)相比,从图2(a)可以看出经过阳极化和小电流镀铜后,在较低的衍射角范围(20?~35?)内,出现了明显的非晶带,说明有无定形的Al2O3相生成;在较高的衍射角范围内,除了有α-Al晶体的衍射峰之外,还出现了金属Cu的衍射峰,因此,小电流镀铜后的铝合金阳极氧化膜由无定形的Al2O3和电镀生成的金属Cu组成。

图2 不同试样的X射线衍射谱

Fig.2 XRD patterns of different samples: (a) LC4 aluminum alloy; (b) LC4 alloy after anodizing and copper plating (0.1 mA/cm2, 10 min)

图3所示为铝合金阳极氧化膜在小电流镀铜前后的元素沿截面深度变化的定性分析结果,可以看出在进行镀铜之后氧化膜在靠近合金基体的一侧几个μm的厚度范围内Cu元素的强度明显增加,而在其他区域Cu元素的强度很小。

图3 LC4铝合金阳极氧化膜的元素点分布

Fig.3 Element point distribution of anodic film of LC4 aluminum alloy: (a) Before copper plating; (b) After copper plating(0.1 mA/cm2, 10 min)

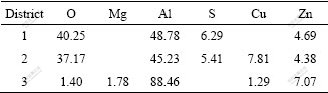

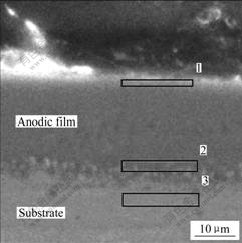

表2为对图4镀铜后的铝合金阳极氧化膜截面照片中的所示区域1,2,3进行EDS定量分析的结果,从表中可以看出区域2中的Cu元素含量(7.81%)明显高于基体中即区域1中的Cu含量(1.29%),而在氧化膜的外表面区域即区域1中,EDS并没有分析到元素Cu的存在。

表2 图4所示区域的元素含量EDS分析结果

Table 2 EDS result of district illustrated in Fig.4 (mass fraction, %)

图4 小电流镀铜(0.1 mA/cm2, 10 min)后的铝合金阳极氧化膜的截面照片

Fig.4 Cross section of anodic film after copper plating (0.1 mA/cm2, 10 min)

2.2 小电流镀铜对极化曲线的影响

从图5可以看出,经过阳极氧化处理后,铝合金的耐蚀性有明显提高,自腐蚀电位正移,腐蚀电流减小;在经过小电流镀铜之后,阳极化铝合金的耐蚀性得到进一步改善,同未镀铜的阳极化铝合金相比,其在0.5 mol/L CH3COOH溶液中的自腐蚀电位正移了超过200 mV,同时腐蚀电流密度明显减小,并出现钝化现象。

图5 不同试样在0.5 mol/L CH3COOH溶液中的极化曲线

Fig.5 Polarization curves of different samples in 0.5 mol/L CH3COOH solution: 1—LC4 aluminum alloy; 2—Anodic LC4 aluminum alloy; 3—Anodic LC4 aluminum alloy after copper plating(0.1 mA/cm2, 10 min)

2.3 交流阻抗谱的测定

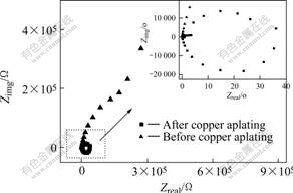

图6所示为LC4铝合金氧化膜镀铜前后在0.5 mol/LCH3COOH溶液中测得交流阻抗谱的Nyquist图,从图中可以看出镀铜之前在低频段出现了容抗弧;镀铜之后在低频段的容抗弧的半径变得很小,同时高频段出现了容抗弧和感抗弧。

图6 LC4铝合金氧化膜镀铜前后在0.5 mol/L CH3COOH溶液中的交流阻抗谱

Fig.6 Electrochemical impedance spectroscopy of anodic film of LC4 aluminum alloy in 0.5 mol/L CH3COOH solution

2.4 讨论与分析

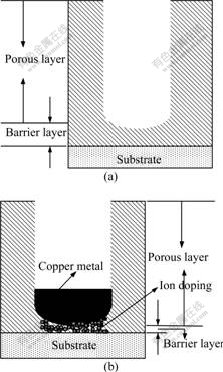

众所周知,铝的阳极氧化膜具有双层结构,由内层致密的阻挡层和外层的多孔层组成,如图7(a)所示。当进行小电流镀铜时,表面形貌照片显示外层多孔层的孔径有所增加,表明电镀液对阳极氧化膜有化学溶解作用。阳极氧化膜是离子导体,在通常情况下不可能使金属在表面沉积;但在镀铜溶液中进行阴极电解时,孔内溶液的碱性上升使阻挡层发生化学溶解,在电场的作用下使离子夹杂到阻挡层中,导致阻挡层的某些薄弱点具有了电子导体的性质,从而使Cu在该薄弱点的电沉积成为可能。在很小的电流密度下,由于避免了浓差极化的发生,可以在孔内形成致密的Cu镀层,达到封闭的效果。因此可提出在铝合金阳极氧化膜上进行小电流镀铜的模型示意图如图7(b)所示,即在进行小电流镀铜时,金属铜将在阳极氧化膜的孔内而非表面进行沉积,这同 XRD和能谱分析结果是一致的。

图7 铝合金阳极氧化膜及镀铜(0.1 mA/cm2,10 min)的示意图

Fig.7 Schematic diagram of anodic film (a) and copper plating (0.1 mA/cm2, 10 min) (b)

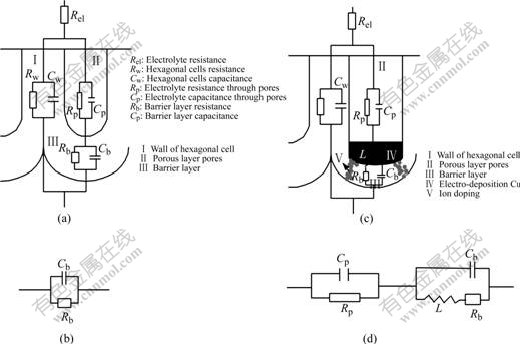

基于图7中所提出的模型,可将其各自对应的等效电路表示为图8所示的形式。对于传统的铝合金阳极氧化膜,其等效电路如图8(a)所示,该等效电路是由Hitizig等[17]提出的,并被广泛接受,在电解液进入孔内后,孔内电解液电阻Rp和电容Cp同孔壁电阻Rw和孔壁电容Cw存在关系:Rw≥Rp,Cw≤Cp,因此Rw和Cw可以被忽略,而阻挡层的电阻Rb和电容Cb同相比存在关系:Rb≥Rp,Cb≤Cp且二者为串联关系,因此在该情况下Rp和Cp也可被忽略,在不考虑孔外电解液电阻Rel的情况下,等效电路可被简化为图8(b)的形式,即只包含阻挡层的电阻Rb和电容Cb,这同阻抗谱中只存在低频段的容抗弧是相一致的;进行小电流镀铜后,根据图7(b)所示的模型,可将等效电路表示图8(c)的形式,同图8(a)相比,只是由于Cu的沉积并且Cu在阻挡层中的掺杂形成了活性点而增加了感抗L,但此时由于阻挡层被大量溶解,使Rb显著下降,Cb急剧增加,此时Rp和CP不能再被忽略,因此可将图8(c)简化为图8(d)所示的形式,此时交流阻抗谱中高频段的容抗弧对应于Cp,感抗弧对应于L,低频段半径很小的容抗弧对应于Cb。

图8 LC4铝合金阳极氧化膜的等效电路图

Fig.8 Equivalent circuit of anodic film of aluminum alloy LC4: (a) Before copper plating; (b) Equivalent circuit of (a) after simplification (c) After copper plating (0.1 mA/cm2, 10 min); (d) Equivalent circuit of (c) after simplification

小电流电镀方法和通常所说的电解着色工艺有较大的区别,电解着色往往采用交流电,所使用的电流比较大,一般在2 mA/cm2以上,由于电解液中主盐浓度比较低,因此离子在孔内的沉积受浓差极化控制。在电流密度很大时,沉积产物比较疏松,容易形成枝晶,并且沉积产物有可能为金属也有可能为金属的氧化物,并没有明确的结论。小电流电镀采用直流电源,电镀液的主盐浓度很高,电流非常小,沉积过程为电化学步骤控制,沉积产物为单一的金属而不含有氧化物,在孔内致密的堆叠,起到封闭作用。阳极化铝合金经过电解着色处理后当光线射到沉积离子上时,发生漫散射,而使氧化膜呈现颜色,起到表面装饰的作用,但不能提高其耐蚀性;而小电流电镀后氧化膜虽然在外观上并没有发生改变,但金属铜在孔内沉积后,其封闭作用和钝化作用,使铝合金阳极氧化膜表现出了铜的电化学特性,耐蚀性有明显改善,自腐蚀电位大幅度正移,腐蚀电流密度显著下降。因此小电流电镀在提高阳极氧化膜的耐蚀性方面是一种非常有效的后续处理步骤,并具有普遍适用性。

3 结论

1) LC4铝合金在进行硫酸阳极化后,再进行小电流镀铜(0.1 mA/cm2,10 min)处理,XRD结果和EDS分析表明,小电流镀铜时,金属铜在铝合金阳极氧化膜的孔内而非表面进行沉积。

2) 小电流镀铜后的阳极氧化铝合金在0.5 mol/L CH3COOH溶液中的极化曲线结果表明,小电流镀铜后,自腐蚀电位大幅度的正移,腐蚀电流密度显著下降。结合交流阻抗谱进行分析可知,膜内所沉积的金属铜的钝化以及封孔作用使铝合金阳极氧化膜表现出铜的电化学特性,是提高其耐蚀性的根本原因。

3) 小电流电镀方法同传统的电解着色工艺有很大区别。它采用高浓度、小电流密度(0.1 mA/cm2),不会改变阳极氧化膜的外观,沉积物为单一金属,是一种新颖的可有效提高阳极化铝合金耐蚀性的后处理方法。

REFERENCES

[1] Bellenger F, Mazille H, Idrissi H. Use of acoustic emission technique for the early detection of aluminum alloys exfoliation corrosion[J]. NDT&E International, 2002, 35: 385?392.

[2] 宋曰海, 郭忠诚, 李爱莲, 等. 铝及铝合金阳极氧化、着色及封闭的现状和发展趋势[J]. 电镀与涂饰, 2002, 21(6): 27?33.

SONG Yue-hai, GUO Zhong-cheng, LI Ai-lian, et al. Current status and development trend of anodic oxidation, coloring and sealing of aluminum and its alloys[J]. Electroplating & Finishing, 2002, 1(6): 27?33.

[3] Dasquet J P, Caillard D, Conforto E, Boninoa J P, Bes R. Investigation of the anodic oxide layer on 1050 and 2024 T3 aluminum alloys by electron microscopy and electrochemical impedance spectroscopy[J]. Thin Solid Films, 2000, 371: 183?190.

[4] Snogan F, Blanc C, Mankowski G, Pebere M. Characterization of sealed anodic films on 7075 T74 and 2214 T6 aluminum alloys[J]. Surface and Coating Technology, 2002, 154: 94?103.

[5] Scully J C. Treatise on materials science and technology [M]. London: Academic Presss, 1983: 23.

[6] Patermarakis G, Papandreadis N. Effect of the structure of porous anodic Al2O3 films on the mechanism of their hydrothermal treatment[J]. Electrochimica Acta, 1993, 38(10): 1413?1420.

[7] Lopez V, Otero E , Bautista A , et al. Sealing of anodic films obtained in oxalic acid baths[J]. Surface and Coatings Technology, 2000, 124(1): 76?84.

[8] 赵旭辉, 左 禹, 赵景茂. 铝阳极氧化膜在NaCl溶液中的电化学性能[J]. 中国有色金属学报, 2004, 14(4): 562?567.

ZHAO Xu-hui, ZUO Yu, ZHAO Jing-mao. Electrochemical properties of anodized aluminum films in sodium chloride solution[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(4): 562?567.

[9] 田连朋, 左 禹, 赵景茂, 熊金平, 等. LD7铝合金阳极氧化膜的不同封闭方法耐蚀性评价[J]. 中国腐蚀与防护学报, 2005, 25(6): 327?341.

TIAN Lian-peng, ZUO Yu, ZHAO Jing-mao, XIONG Jin-ping, et al. Evaluation of sealing methods on corrosion behavior of LD7 aluminum alloy anodic oxide films in NaCl solution[J]. Journal of Chinese Society for Corrosion and Protection, 2005, 25(6): 327?341.

[10] Hao L, Cheng B R. Sealing processes of anodic coatings - past, present and future[J]. Metal Finish, 2000, 12(8): 8?18.

[11] Masuda H, Asoh H, Watanabe H, et al. Square and triangular nanohole array architecture of anodic porous alumina[J]. Advanced Materials, 2001, 13(3): 189?192.

[12] Foss C A, Hornyak GL Jr, Stockert J A, et al. Optical properties of composite membranes containing arrays of nanoscopic gold cylinders[J]. Phys Chem, 1992, 96: 7497?7499.

[13] 朱立群. 功能膜层的电沉积理论与技术[M]. 北京: 北京航空航天大学出版社, 2005: 20?21.

ZHU Li-qun. The electro-deposition theory and technology of functional coatings [M]. Beijing: Buaa Express, 2005: 20?21.

[14] 李凌杰, 李 荻, 张胜涛, 等. 多孔阳极氧化铝膜在纳米功能材料制备中的应用[J]. 功能材料, 2002, 33(2): 148?151.

LI Ling-jie, LI Di, ZHANG Sheng-tao, et al. Application of porous aluminum anodic oxide films in fabricating nanostructure functional materials[J]. Functional Material, 2002, 33(2): 148?151.

[15] Cao H Q, Xu Z, Sang H, et al. Sol-gel template synthesis of an way of single crystal cols nanowires on a porous alumina template[J]. Advanced Materials, 2001, 13(18): 1393?1394.

[16] 吴玉程, 马 杰, 解 挺, 鄢 波, 黄新民, 李广海, 张立德. 氧化铝纳米有序阵列模板的制备工艺与应用[J]. 中国有色金属学报, 2005, 15(5): 680?687.

WU Yu-cheng, MA Jie, XIE Ting, YAN Bo, HUANG Xin-min, LI Guang-hai, ZHANG Li-de. Fabrication and application of alumina nanoscale ordered array template[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(5): 680?687

[17] Hitzig J, Junttner K, Lorenz W J. AC-Impedance measurements on corroded porous aluminum oxide films[J]. Electrochemical Science and Technology, 1986, 133(5): 887?892.

基金项目:国家自然科学基金资助项目(60472114)

收稿日期:2007-02-06;修订日期:2007-07-02

通讯作者:孟 琳,博士研究生;电话:010-62333957;E-mail: linmeng_1978@163.com

(编辑 陈爱华)