DOI: 10.11817/j.ysxb.1004.0609.2021-39752

柱状晶Cu70.8Al18.6Mn10.6形状记忆合金在热压缩中的动态再结晶行为

史博文,刘记立,刘 津

(武汉理工大学 新材料力学理论与应用湖北省重点实验室,武汉 430070)

摘 要:为了研究高性能柱状晶Cu-Al-Mn形状记忆合金的高温大变形加工能力,采用Gleeble 3500热模拟试验机,在变形温度700~850 ℃和应变速率0.01~10 s-1条件下,对柱状晶Cu70.8Al18.6Mn10.6形状记忆合金进行热压缩变形,分析合金的动态再结晶行为。结果表明:随着变形温度升高和应变速率的增大,合金逐渐在晶界处以晶界弓弯的形核开始机制发生动态再结晶,且动态再结晶晶粒个数和尺寸不断增加。根据Zener-Hollomon参数分析可得,合金的热变形激活能为Q=113.55 KJ/mol。当应变速率因子 <8时,合金发生动态再结晶;当8≤

<8时,合金发生动态再结晶;当8≤ ≤16.34时,合金可能发生或不发生动态再结晶;当

≤16.34时,合金可能发生或不发生动态再结晶;当 >16.34时,合金不发生动态再结晶。结合合金的热加工图得到其热加工最佳工艺参数:变形温度和应变速率区间分别为725~825 ℃和0.08~1 s-1。对比分析高温轧制前后合金组织和性能发现,合金在820 ℃轧制变形75%后不发生动态再结晶,且轧后合金在室温下仍具有8%左右的超弹性应变,同时马氏体相变开始应力和峰值应力均提高2倍多。因此,合金在稍低于动态再结晶温度下进行大变形加工后,不仅可以提高合金的强度,而且还可以较好地保留铸态合金的优异记忆性能。

>16.34时,合金不发生动态再结晶。结合合金的热加工图得到其热加工最佳工艺参数:变形温度和应变速率区间分别为725~825 ℃和0.08~1 s-1。对比分析高温轧制前后合金组织和性能发现,合金在820 ℃轧制变形75%后不发生动态再结晶,且轧后合金在室温下仍具有8%左右的超弹性应变,同时马氏体相变开始应力和峰值应力均提高2倍多。因此,合金在稍低于动态再结晶温度下进行大变形加工后,不仅可以提高合金的强度,而且还可以较好地保留铸态合金的优异记忆性能。

关键词:Cu-Al-Mn形状记忆合金;柱状晶组织;动态再结晶;应变速率因子;高温轧制

文章编号:1004-0609(2021)-08-2171-14 中图分类号:TG146.1;TG139 文献标志码:A

引文格式:史博文,刘记立,刘 津. 柱状晶Cu70.8Al18.6Mn10.6形状记忆合金在热压缩中的动态再结晶行 为[J]. 中国有色金属学报, 2021, 31(8): 2171-2184. DOI: 10.11817/j.ysxb.1004.0609.2021-39752

SHI Bo-wen, LIU Ji-li, LIU Jin. Dynamic recrystallization behavior of columnar-grained Cu70.8Al18.6Mn10.6 shape memory alloy in hot compression[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(8): 2171-2184. DOI: 10.11817/j.ysxb.1004.0609.2021-39752

形状记忆合金(Shape memory alloys,SMAs)材料由于其优异的形状记忆效应和超弹性特征而受到学者们越来越多的关注[1-4]。SMAs首次应用在工程中是在1971年,美国将Ni-Ti SMA管接头用于F-14战斗机的液压管连接[5]。经过几十年的发展,SMAs已经广泛应用于医疗器械[6]、航空航天[7]、土木工程[8]以及日常生活[9]等各个领域。常用SMAs可以分为Ni-Ti基、Cu基和Fe基三大类。其中Cu基合金是除Ni-Ti基合金之外较具应用前景的SMAs,而且价格相对低廉,可大规模应用[10]。但普通等轴多晶Cu基合金的性能较差,容易在应力诱导马氏体相变完成前就发生晶间脆性断裂。采用定向凝固方法制备的柱状晶组织(Columnar-grained,CG)Cu-Al-Mn SMAs,具有轴向强 取向和低能平直晶界的特征;当沿凝固方向拉伸时,其室温塑性可达40%,超弹性应变可达到10%以上,双程形状记忆效应也达到单晶水平,克服了普通等轴多晶Cu基合金由于变形协调能力差导致性能较差的问题[11-12]。在实际应用中,除了将优异性能的柱状晶组织铸态合金产品直接应用外,还有较多情况需要用到薄板细丝产品,这就需要对合金进行后续成形加工处理。但是SMAs的内部微观组织对其各项性能影响显著[13-14],在成形加工及后处理过程中由于温度、变形量等因素的影响会改变合金内部组织结构,从而影响合金的性能[15-17]。CG SMAs在低温塑性变形时,较低变形量(10%以下)加工会由于超弹性而发生卸载恢复,较高变形量加工会使合金记忆性能消失[18]。为了恢复合金的记忆性能,需要进行退火处理消除冷变形组织,但合金在退火热处理过程中会发生再结晶行为,使原来的柱状晶组织变为等轴晶组织,合金的记忆性能会恶化[19],故合金常在高温下进行大变形加工。研究发现,控制合金塑性加工温度和退火热处理温度低于合金再结晶温度时,可以避免合金因再结晶而产生等轴晶组织,从而使合金保留其优异的加工能力和记忆性能[20]。因此,研究CG Cu-Al-Mn SMAs的动态再结晶行为及其机制,对大变形条件下合金的加工制造及材料成型有重要意义。

取向和低能平直晶界的特征;当沿凝固方向拉伸时,其室温塑性可达40%,超弹性应变可达到10%以上,双程形状记忆效应也达到单晶水平,克服了普通等轴多晶Cu基合金由于变形协调能力差导致性能较差的问题[11-12]。在实际应用中,除了将优异性能的柱状晶组织铸态合金产品直接应用外,还有较多情况需要用到薄板细丝产品,这就需要对合金进行后续成形加工处理。但是SMAs的内部微观组织对其各项性能影响显著[13-14],在成形加工及后处理过程中由于温度、变形量等因素的影响会改变合金内部组织结构,从而影响合金的性能[15-17]。CG SMAs在低温塑性变形时,较低变形量(10%以下)加工会由于超弹性而发生卸载恢复,较高变形量加工会使合金记忆性能消失[18]。为了恢复合金的记忆性能,需要进行退火处理消除冷变形组织,但合金在退火热处理过程中会发生再结晶行为,使原来的柱状晶组织变为等轴晶组织,合金的记忆性能会恶化[19],故合金常在高温下进行大变形加工。研究发现,控制合金塑性加工温度和退火热处理温度低于合金再结晶温度时,可以避免合金因再结晶而产生等轴晶组织,从而使合金保留其优异的加工能力和记忆性能[20]。因此,研究CG Cu-Al-Mn SMAs的动态再结晶行为及其机制,对大变形条件下合金的加工制造及材料成型有重要意义。

本文以CG Cu-Al-Mn SMA为研究对象,采用Gleeble 3500热模拟试验机,在不同变形温度和应变速率条件下进行热压缩实验,构建合金热变形的动力学方程和热加工图,观察合金热变形中力学行为和微观组织变化规律及机理,探究其动态再结晶规律,确定合金热加工工艺参数,为合金制定高效的大变形加工制度提供参考依据。

1 实验

图1 CG Cu70.8Al18.6Mn10.6 SMA的制备示意图、宏观组织图、金相显微组织图和DSC热流-温度曲线

Fig. 1 Preparation schematic diagram(a), macro organization chart(b), metallographic micrograph(c) and DSC heat flow curve(d) of CG Cu70.8Al18.6Mn10.6 SMA

实验材料采用定向凝固制备的Cu-Al-Mn形状记忆合金,使用电子探针显微分析仪(EPMA,JXA-8230/JXA-8230)测试合金成分的平均摩尔比为n(Cu):n(Al):n(Mn)=70.8:18.6:10.6,定义该合金为Cu70.8Al18.6Mn10.6 SMA。制备的示意图如图1(a)所示。首先,将原料在电磁感应炉中熔炼并保温20 min后,将熔体浇铸入内径为d 60 mm×200 mm的圆柱型石墨结晶器中,结晶器四周加热到1100 ℃保温;结晶器底部与通有室温冷却循环水的铜模接触,冷却水流量为1000 L/h;合金熔液从结晶器底部逆着热流方向凝固,待合金全部凝固后,当结晶器温度降到850 ℃时将铸锭取出迅速水冷淬火。将铸锭从中间剖开,用硝酸+盐酸的混合酸液腐蚀剖开后的截面得到的铸锭宏观组织如图1(b)所示,从右至左为合金凝固方向,铸锭左端为等轴多晶组织,右端为细晶组织,中间大部分为柱状晶组织。

使用金相显微镜(OM,上海光学仪器一厂102XB-PC)观察合金金相组织,金相试样经过粗磨、细磨、抛光、侵蚀等一系列步骤获得,其中侵蚀使用的侵蚀液配比为5 g FeCl3、10 mL HCl、100 mL H2O。获得的铸态合金中部柱状晶组织段的金相如图1(c)所示。从图中观察可知,合金沿着凝固方向(Solidification direction)晶界平直,具有高长径比的粗大柱状晶晶粒。用差示扫描量热仪(DSC, Mettler-Toledo DSC3)测得的合金的热流-温度曲线如图1(d)所示。分析得到马氏体相变开始温度Ms = -4.9 ℃,马氏体相变结束温度Mf =-48.4 ℃,奥氏体相变开始温度As=-21.7 ℃,奥氏体相变结束温度Af =6.6 ℃。因此本文所制备的CG Cu70.8Al18.6Mn10.6 SMA在常温下全为奥氏体相,室温下具有超弹性性能。

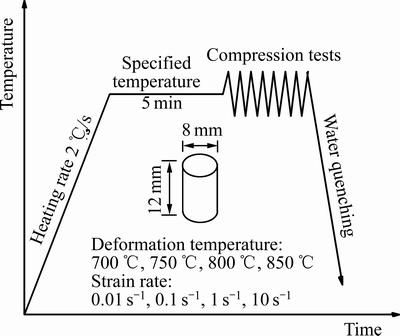

在合金铸锭中间区域沿柱状晶生长方向切取长度为12 mm、直径为8 mm的圆柱形试样,试样沿高度方向为柱状晶组织。将切好的试样在Gleeble 3500型热模拟试验机上进行热压缩实验。首先以2 ℃/s的升温速率加热至不同压缩温度(700、750、800和850 ℃),保温5 min后,再以不同的应变速率(0.01、0.1、1和10 s-1)压缩试样;当试样变形量达到70%时停止变形,并迅速水冷至室温保留变形组织。将压缩后试样沿轴向剖开制备金相试样,观察其金相组织。通过分析试样热压缩过程的流变真应力-真应变曲线和分析压缩后试样的微观组织变化得出合金动态再结晶的热动力学条件。热压缩变形工艺图如图2所示。

从合金铸锭中间部分上切取长度沿柱状晶生长方向、尺寸为60 mm×30 mm×8 mm的板材试样进行高温轧制实验。首先,将试样在马弗炉中加热到820 ℃保温30 min,取出后立刻放入二辊轧机中进行单道次高温轧制,轧制变形量为75%,随后立即水冷。然后,采用循环累加拉伸加载-卸载的方法在MTS-810型万能实验机上测试轧制前后试样在室温下沿轧制方向的力学性能,所用狗骨形板状拉伸试样定径段尺寸为25 mm×5 mm×3 mm,应变速率为5×10-4 s-1,应变数据采15 mm引伸计获得。

图2 热压缩变形工艺图

Fig. 2 Scheme of hot compression process

2 结果与分析

2.1 合金不同变形条件下的真应力-真应变曲线

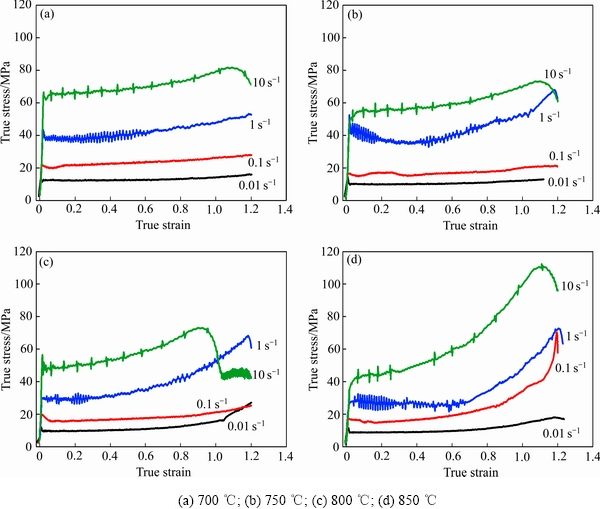

真应力-真应变曲线是材料在变形过程中微观组织演变和力学性能变化的宏观表现。合金在不同温度和不同应变速率下热压缩变形时的真应力-真应变曲线如图3所示,曲线中的一些热变形特征参数列于表1中。表1中, 为弹性阶段峰值应力,

为弹性阶段峰值应力, 为压缩过程峰值应力,

为压缩过程峰值应力, 为动态再结晶开始应变,

为动态再结晶开始应变, 为屈服强度。由图3和表1可以看出,变形温度和应变速率显著影响合金在热压缩过程中的应力、应变。

为屈服强度。由图3和表1可以看出,变形温度和应变速率显著影响合金在热压缩过程中的应力、应变。

真应力变化的根本原因是合金在热压缩过程中,由于塑性变形引入的位错增殖等导致的加工硬化以及由于动态回复和动态再结晶导致的软化两种机制相互作用,使得合金内部组织发生了变化,从而表现出宏观真应力-真应变曲线的变化。图3中所示真应力-真应变曲线变化过程可以分为4个阶段:加工硬化阶段,过渡阶段,稳态变形阶段,发生动态再结晶阶段。合金在变形初期,也即应变量较小时,加载应变速率从零迅速增加,应变诱导位错缠结,位错密度快速增加,且引入位错间的交互作用会阻碍位错运动,从而表现出加工硬化的特点。在此阶段由于合金应变量较小,变形产生的形变储能较低,使得合金内部发生动态回复的驱动力不足,所以在此阶段加工硬化占据主导地位,真应力随真应变的增加呈线性增加。当加工硬化阶段应力达到峰值后,应力突然降低,这种应力突降现象为屈服点现象[21]。随着压缩应变量的增大,试样进入过渡阶段,此时合金内部位错、空位等缺陷和形变储能不断增加,为位错攀移提供了驱动力,位错发生重排和湮灭,动态回复的作用逐渐增强,加工硬化和动态回复软化两种机制相互作用,使应力呈现锯齿状的波动现象。当动态回复和加工硬化的作用达到平衡时,合金进入稳态变形阶段,真应力随真应变的增加逐渐趋于稳定。随着应变量的持续增加,部分合金试样进入动态再结晶阶段,此时随真应变的增加,真应力先增加后降低。应变速率越高时,合金内部组织变化越快,峰值应力的出现就越早,对应的真应变值就越小。通常认为,当真应力达到峰值后出现下降时就表示试样可能发生动态再结晶过程[22]。由于合金内部发生动态再结晶,导致应力在一定范围内产生波动现象,且随着应变速率增大,波动更加剧烈,表明此时合金动态再结晶的区域扩大,动态再结晶的软化作用更加明显。

图3 在不同温度热压缩变形时CG Cu70.8Al18.6Mn10.6 SMA的真应力-真应变曲线

Fig. 3 True stress-true strain curves of CG Cu70.8Al18.6Mn10.6 SMA during hot compression deformation at different temperatures

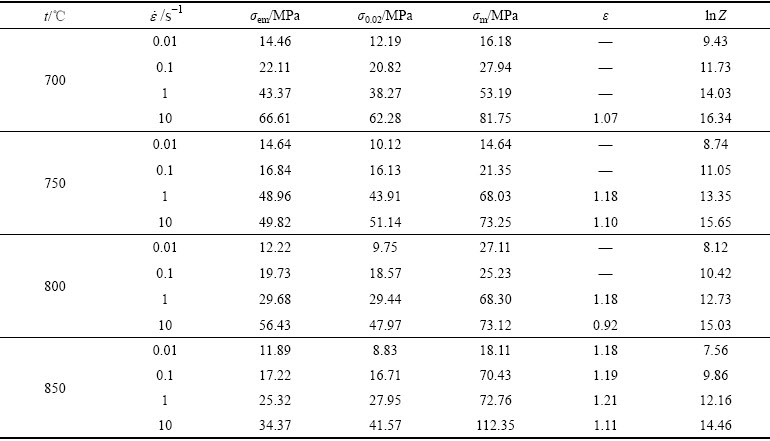

表1 CG Cu70.8Al18.6Mn10.6 SMA热压缩变形力学参数

Table 1 Thermal compression deformation mechanical parameters of CG Cu70.8Al18.6Mn10.6 SMA

由图3和表1所示可知,CG Cu70.8Al18.6Mn10.6 SMA在热压缩过程中真应力呈正的应变速率敏感性和负的温度敏感性。在变形温度一定时,随着应变速率的升高,试样热压缩过程中的真应力也随之增大。如当实验温度为700 ℃,变形量为70%时,4种不同应变速率条件下的真应力分别为:15.93 MPa(700 ℃,0.01 s-1),27.89 MPa(700 ℃,0.1 s-1),52.69 MPa(700 ℃,1 s-1),71.07 MPa(700 ℃,10 s-1)。这是因为当应变速率较低时,合金有足够的时间来储存能量,发生再结晶、晶粒长大以及位错攀移、湮灭等过程概率也越大,从而表现出真应力较小;当应变速率增高,合金内部位错增殖加快,位错相互交割缠结作用越来越显著,进一步阻碍位错的运动,使得变形越困难,表现为真应力值增大[23]。另外,在高应变速率下,合金内部变形组织发生动态再结晶的程度不完全,还存在许多变形的晶粒和未长大的再结晶晶粒,故真应力值较高。当变形速率一定时,随着实验温度的升高,试样真应力不断减小。如当压缩变形速率为10 s-1、真应变为0.02时不同温度对应的屈服强度σ0.02为:62.283 MPa(700 ℃,10 s-1),51.135 MPa(750 ℃,10 s-1),47.966 MPa(800 ℃,10 s-1),41.570 MPa(850 ℃,10 s-1)。这是由于变形温度升高导致合金内部原子间的结合力降低,位错、空位等缺陷运动能力增强,使得位错更容易发生攀移和湮灭,并且在较高的温度下,引发合金动态再结晶所需的驱动力会减小,合金更容易发生再结晶形核和晶粒长大,使得动态软化机制作用更加明显,从而导致真应力降低。

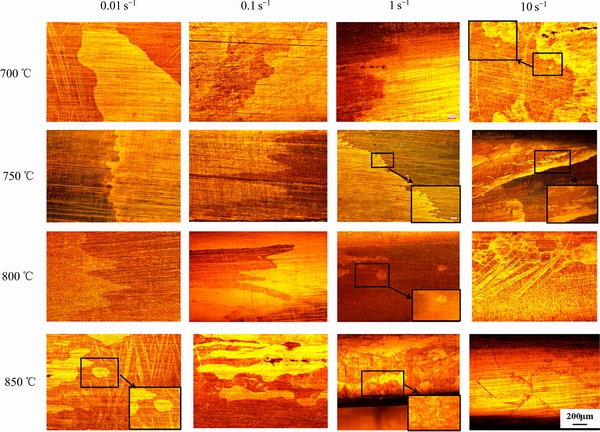

2.2 合金不同变形条件下的显微组织变化

图4所示为试样在不同变形温度和应变速率下压缩后试样中部纵截面的金相组织。由图4可知,在变形温度700、750和800 ℃下,当应变速率分别为0.01和0.1 s-1时,可观察到试样内部存在大量的变形组织,原来柱状晶组织变为沿垂直压缩方向延伸的不规则变形组织,并未发现明显的动态再结晶晶粒;当应变速率达到1和10 s-1时,可在试样晶界附近发现少量的动态再结晶晶粒,且发生动态再结晶区域较小,晶粒尺寸较小,此时试样在压缩变形过程中的变形软化机制主要为动态回复机制。部分区域发生动态再结晶的现象是由于试样在压缩过程中发生绝热温升效应[24],使得试样内部实际温度已经达到动态再结晶温度。当试验温度达到850 ℃时,4个不同变形速率的试样均可观察到内部出现了尺寸和数量不等的动态再结晶晶粒。随着压缩速率增大,动态再结晶区域不断扩大,再结晶晶粒尺寸也不断增大,动态再结晶晶粒呈片团状出现。此时试样在压缩变形过程中的变形软化机制主要为动态再结晶机制。这是由于应变速率增大,单位时间内变形量增加,试样内部不均匀变形越剧烈,从而积累的畸变能就越大,位错密度越高,从而使得合金发生动态再结晶的驱动力增大,形核速率加快。同时,变形温度也会影响合金动态再结晶的发生。合金发生动态再结晶的过程是一个热激活的过程,温度越高,晶界迁移速率就越快,使得动态再结晶晶粒尺寸和数量越大。由于常规的合金热加工变形工艺,如轧制、挤压、拉拔、冲压等,应变速率为0.1~1 s-1之间,同时由于加工模具的散热,结合上述分析,合金的热加工动态再结晶温度可设置为850 ℃。

在经历塑性变形过程中,CG Cu70.8Al18.6Mn10.6 SMA会引入大量位错,但是晶界对于变形过程中的位错移动起到阻碍作用;当位错密度达到一定量时,会在晶界附近产生局部应力集中,使得晶界朝着一个方向移动,产生晶界弓弯现象[25]。在热压缩后的合金试样中部纵截面金相组织中可以观察到大量的晶界弓弯现象(见图5),这些锯齿状的晶界在随后的热变形过程中可以成为动态再结晶晶粒潜在的形核位置[26]。当合金塑性变形中引入位错的密度积累达到临界值时,动态再结晶以晶界弓弯机制开始形核,细小的动态再结晶晶粒沿着原始晶粒紧密排列,形成了项链状的晶粒链,随后再结晶晶粒还会继续长大使铸态柱状晶组织变为等轴多晶组织。

图4 不同变形温度及应变速率下压缩后CG Cu70.8Al18.6Mn10.6 SMA试样中部纵截面金相组织

Fig. 4 Metallographic structures of central longitudinal section of CG Cu70.8Al18.6Mn10.6 SMA samples after compression at different deformation temperatures and compressive strain rates

图5 CG Cu70.8Al18.6Mn10.6 SMA热压缩后试样中的晶界弓弯现象和动态再结晶晶粒链

Fig. 5 Grain boundary bowing(a) and dynamic recrystallization(b) of CG Cu70.8Al18.6Mn10.6 SMA after hot compression

2.3 合金动态再结晶动力学行为研究

合金热变形过程中的动态再结晶是一个热激活过程,易受自身材料性质和外界条件等的影响,其中应变速率和温度对合金热变形行为的影响可用指数型的Zener-Hollomon参数[27-28]来表示,如式(1)所示:

(1)

(1)

式中:Z为有温度补偿的应变速率因子; 为合金变形过程中的应变速率(s-1);Q为材料的热变形激活能(kJ/mol),表示原子在跃迁时所需要克服的能垒大小,用来反映材料变形的难易程度,其大小受应变速率、变形温度、流变应力等影响;R为摩尔气体常数(8.314 kJ/(mol·K));T为变形温度(K)。

为合金变形过程中的应变速率(s-1);Q为材料的热变形激活能(kJ/mol),表示原子在跃迁时所需要克服的能垒大小,用来反映材料变形的难易程度,其大小受应变速率、变形温度、流变应力等影响;R为摩尔气体常数(8.314 kJ/(mol·K));T为变形温度(K)。

研究发现,材料在高温塑性变形时的应力水平和应变速率、变形温度满足如式(2)中的指数关系:

(2)

(2)

式中: 为材料在一定温度和应变速率条件下的真应力;ε为对应的真应变;σ0(T)和m(T)为与变形温度相关的常数。

为材料在一定温度和应变速率条件下的真应力;ε为对应的真应变;σ0(T)和m(T)为与变形温度相关的常数。

峰值应力和应变速率的关系式如下:

(3)

(3)

是流变应力的函数,在低应力水平和高应力水平下可分别如式(4)和式(5)所示:

是流变应力的函数,在低应力水平和高应力水平下可分别如式(4)和式(5)所示:

低应力水平 <0.8时,

<0.8时,

(4)

(4)

高应力水平 >1.2时,

>1.2时,

(5)

(5)

式中: 、n、β、A为材料常数,且满足

、n、β、A为材料常数,且满足 。在低应力水平和高应力水平下,式(2)还可以分别表示为式(6)和式(7):

。在低应力水平和高应力水平下,式(2)还可以分别表示为式(6)和式(7):

(6)

(6)

(7)

(7)

式中:B1和B2为常数,对式(6)和(7)两边分别取对数可得式(8)和式(9):

(8)

(8)

(9)

(9)

对式(3)两边微分可求得热变形激活能的表达式,如式(10)所示:

(10)

(10)

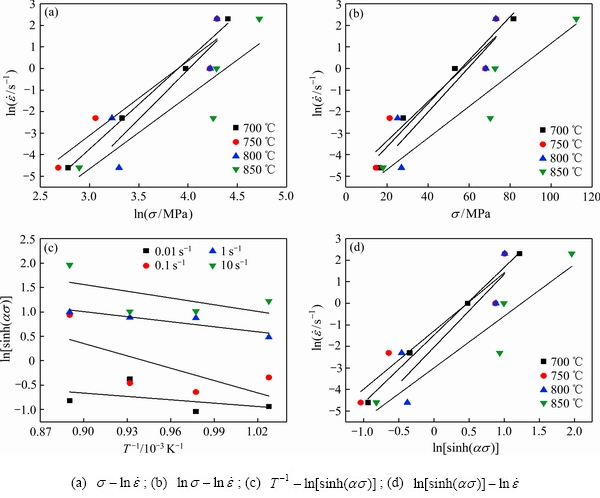

参考其他合金在热压缩实验中热变形激活能的求解方法[29-31],结合表1中CG Cu70.8Al18.6Mn10.6 SMA热压缩变形时的实测峰值应力数据,可得图6所示关系图,由图6(a)和(b)所示的拟合线平均斜率可求得到参数β=0.0923675,n=3.900845,此时对应的 =0.023679;然后再根据图6(c)和(d)即可求得CG Cu70.8Al18.6Mn10.6 SMA的热变形激活能为Q=113.55 kJ/mol。将不同变形温度和应变速率代入式(1),即可得到不同温度和应变速率下的

=0.023679;然后再根据图6(c)和(d)即可求得CG Cu70.8Al18.6Mn10.6 SMA的热变形激活能为Q=113.55 kJ/mol。将不同变形温度和应变速率代入式(1),即可得到不同温度和应变速率下的 值,结果列于表1中。

值,结果列于表1中。

对比图3、4和表1中的 值可以发现:变形温度为700 ℃时,仅应变速率10 s-1时试样发生了动态再结晶,此时

值可以发现:变形温度为700 ℃时,仅应变速率10 s-1时试样发生了动态再结晶,此时 =16.34; 9.43≤

=16.34; 9.43≤ ≤ 14.03时,试样则未发生动态再结晶。变形温度为750℃时,8.74≤

≤ 14.03时,试样则未发生动态再结晶。变形温度为750℃时,8.74≤ ≤11.05时,试样未发生动态再结晶,13.35≤

≤11.05时,试样未发生动态再结晶,13.35≤ ≤15.65时,试样发生了动态再结晶;变形温度为800℃时,8.12≤

≤15.65时,试样发生了动态再结晶;变形温度为800℃时,8.12≤ ≤10.42时,试样未发生动态再结晶,12.73≤

≤10.42时,试样未发生动态再结晶,12.73≤ ≤15.03时,试样发生了动态再结晶;变形温度为850℃时,7.56≤

≤15.03时,试样发生了动态再结晶;变形温度为850℃时,7.56≤ ≤14.46时,试样内部发生了动态再结晶。考虑到试样在热压缩过程中绝热温升效应的影响,可能会使试样内部温度高于试验温度,导致计算得到的

≤14.46时,试样内部发生了动态再结晶。考虑到试样在热压缩过程中绝热温升效应的影响,可能会使试样内部温度高于试验温度,导致计算得到的 偏高。所以综上可得,当

偏高。所以综上可得,当 <8时,CG Cu70.8Al18.6Mn10.6 SMA均已发生动态再结晶;当8≤

<8时,CG Cu70.8Al18.6Mn10.6 SMA均已发生动态再结晶;当8≤ ≤16.34时,合金可能发生动态再结晶,也可能未发生动态再结晶;当

≤16.34时,合金可能发生动态再结晶,也可能未发生动态再结晶;当 >16.34时,合金不会发生动态再结晶。

>16.34时,合金不会发生动态再结晶。

2.4 合金热加工图的构建

图6 CG Cu70.8Al18.6Mn10.6 SMA热压缩变形后峰值应力、变形温度、应变速率之间的关系

Fig. 6 Relationships among peak stress, deformation temperature and strain rate of CG Cu70.8Al18.6Mn10.6 SMA after hot compression deformation

根据动态材料模型(Dynamic Material Model,DMM)理论,认为材料在热加工过程中是一个能量耗散系统[32]。在热加工过程中外界输入的全部能量P会以两种形式耗散,一部分为材料塑性变形提供能量,用G表示;另一部分则被材料加工变形过程中组织演变消耗,用J表示,三者关系可用式(11) 表示[33-34]:

(11)

(11)

式中: 为瞬时流变应力,也即真应力;

为瞬时流变应力,也即真应力; 为应变速率。在给定的变形温度和应变速率条件下,可以用应变速率敏感系数m来描述两种功率变化的占比:

为应变速率。在给定的变形温度和应变速率条件下,可以用应变速率敏感系数m来描述两种功率变化的占比:

(12)

(12)

则应变速率敏感系数m和材料变形过程消耗的总能量P及组织演变所消耗能量J的关系可表示为

(13)

(13)

当应变速率敏感系数0<m<1时,材料处于非线性耗散状态;当m=0时,不发生能量耗散;当m=1时,材料处于理想线性耗散状态,此时J取最大值Jmax=P/2。功率耗散系数可以表示为

(14)

(14)

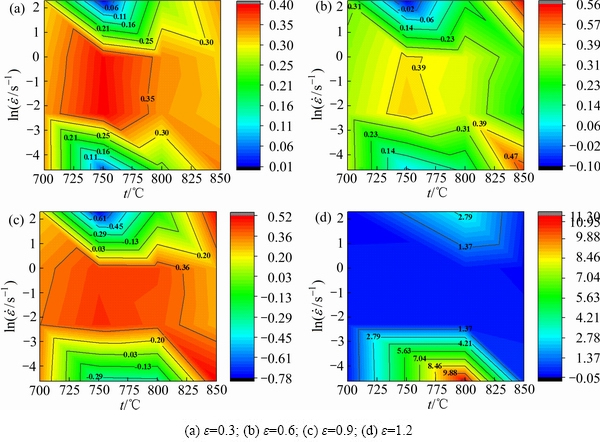

根据功率耗散系数η可以得到随变形温度和应变速率变化的功率耗散图。图7所示为当真应变分别为0.3、0.6、0.9、1.2时CG Cu70.8Al18.6Mn10.6 SMA的功率耗散图。图7中数值代表功率耗散系数,采用等高线的形式来表示功率耗散系数η的变化趋势。一般认为功率耗散系数η越高的区域,材料的加工性能越好。但在实际情况下,材料内部组织并非完全理想状态,可能会出现裂纹或者形成孔洞,在热加工过程中会出现流变失稳现象,使得材料的功率耗散系数偏大[35]。因此,根据PRASAD等[36]提出的基于大塑性变形不可逆热力学极值原理的不稳定判据(见式(15))来得到材料的流变失稳区域,将由此形成的失稳图与功率耗散图叠加即可得到材料的热加工图。

<0 (15)

<0 (15)

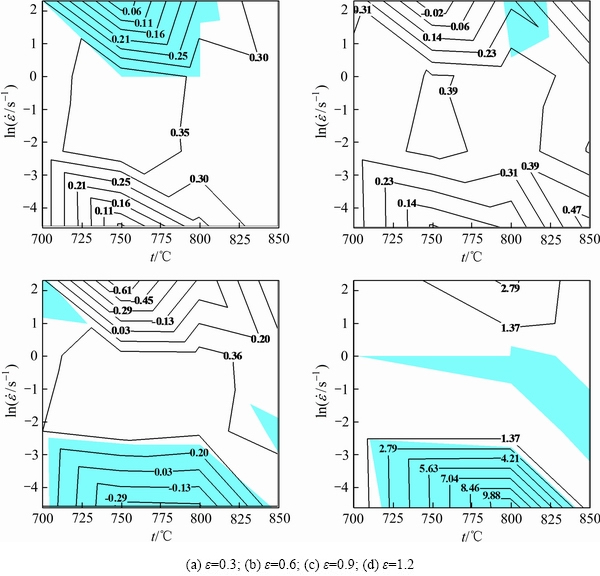

式中: 为应变速率;ξ为失稳系数。ξ随变形温度和应变速率的变化曲线构成了材料失稳图。当ξ<0时,材料在加工变形中发生失稳。图8所示为CG Cu70.8Al18.6Mn10.6 SMA在不同变形量下的热加工图。图8中,阴影部分为材料加工时流变失稳区域,其余部分则为安全区域。

为应变速率;ξ为失稳系数。ξ随变形温度和应变速率的变化曲线构成了材料失稳图。当ξ<0时,材料在加工变形中发生失稳。图8所示为CG Cu70.8Al18.6Mn10.6 SMA在不同变形量下的热加工图。图8中,阴影部分为材料加工时流变失稳区域,其余部分则为安全区域。

图7 不同真应变量下CG Cu70.8Al18.6Mn10.6 SMA的功率耗散图(图中数字为功率耗散系数)

Fig. 7 Power dissipation of CG Cu70.8Al18.6Mn10.6 SMA under different true strains (Numerical value in figures is power dissipation coefficient)

图8 不同真应变量下CG Cu70.8Al18.6Mn10.6 SMA的热加工图

Fig. 8 Processing maps of CG Cu70.8Al18.6Mn10.6 SMA under different true strains (Numerical value on line is instability coefficient)

由图7可以看出,当真应变小于0.9时,合金加工性能较好的区域位于中应变速率区(0.05< <2.72);当真应变为1.2时,合金加工性能较好的区域位于725~825 ℃及低应变速率区(

<2.72);当真应变为1.2时,合金加工性能较好的区域位于725~825 ℃及低应变速率区( <0.08)。由图8可知,随着应变量的增加,合金热加工时失稳区域逐渐由高应变速率区转向低应变速率区。当真应变为0.3时,合金热加工过程失稳区主要位于温度为700~815 ℃、应变速率为1~10 s-1范围内;当真应变为0.6时,失稳区主要位于温度为800~820 ℃、应变速率为1.65~10 s-1范围内;当真应变为0.9时,失稳区主要位于温度为705~840 ℃、应变速率为0.01~0.08 s-1范围内;当真应变为1.2时,失稳区主要位于温度为715~830 ℃、应变速率为0.01~0.08 s-1范围内。综上所述可知,对CG Cu70.8Al18.6Mn10.6 SMA进行热加工时,最佳变形工艺参数为725~825 ℃、0.08~1 s-1。

<0.08)。由图8可知,随着应变量的增加,合金热加工时失稳区域逐渐由高应变速率区转向低应变速率区。当真应变为0.3时,合金热加工过程失稳区主要位于温度为700~815 ℃、应变速率为1~10 s-1范围内;当真应变为0.6时,失稳区主要位于温度为800~820 ℃、应变速率为1.65~10 s-1范围内;当真应变为0.9时,失稳区主要位于温度为705~840 ℃、应变速率为0.01~0.08 s-1范围内;当真应变为1.2时,失稳区主要位于温度为715~830 ℃、应变速率为0.01~0.08 s-1范围内。综上所述可知,对CG Cu70.8Al18.6Mn10.6 SMA进行热加工时,最佳变形工艺参数为725~825 ℃、0.08~1 s-1。

2.5 高温轧制后合金组织性能分析

图9 CG Cu70.8Al18.6Mn10.6 SMA高温轧制后试样的金相组织

Fig. 9 Metallograph of CG Cu70.8Al18.6Mn10.6 SMA sample after high temperature rolling

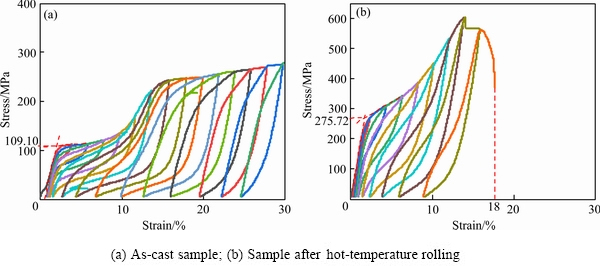

图10 CG Cu70.8Al18.6Mn10.6 SMA室温拉伸应力-应变曲线

Fig. 10 Tensile stress-strain curve of CG Cu70.8Al18.6Mn10.6 SMA at room temperature

基于上文分析获得的最佳热变形工艺参数,本文选择对CG Cu70.8Al18.6Mn10.6 SMA板材在820℃进行高温轧制,轧制应变速率约为0.5 s-1。轧制后合金试样的纵截面金相组织如图9所示。对铸态试样和高温轧制后试样分别都进行循环拉伸加载-卸载实验,得到两个试样的拉伸应力-应变曲线如图10所示。

由图9可以看出,铸态CG Cu70.8Al18.6Mn10.6 SMA的柱状晶组织在经过高温轧制后晶粒被拉长,但仍保持为粗大柱状晶粒的特征;局部区域出现与热压缩后试样相似的晶界弓弯现象,但未发现明显的再结晶现象。由图10可知,铸态合金马氏体相变开始应力为109.10 MPa,在拉伸过程中峰值应力为278.21 MPa;经过高温轧制后,合金马氏体相变开始应力变为275.72 MPa,在拉伸过程中峰值应力为606.59 MPa,相比铸态均提高了2倍多。另外,铸态合金在拉伸过程中的最大应变恢复为12%,而轧制后合金在拉伸过程中的最大应变恢复仍为8%。这表明经过820 ℃高温轧制后合金仍保持较好的超弹性性能。因此,在不发生明显动态再结晶的前提下, CG Cu70.8Al18.6Mn10.6 SMA经过高温轧制后仍较好地保留了铸态的优异性能,同时又由于加工硬化大幅度提高了合金的强度。

3 结论

1) 在变形温度700~850 ℃、应变速率0.01~10 s-1、压缩变形量70%条件下,随着变形温度升高和应变速率的增大,CG Cu70.8Al18.6Mn10.6 SMA逐渐开始在晶界处发生动态再结晶,动态再结晶晶粒个数增多,尺寸也不断增大。动态再结晶晶粒以晶界弓弯的机制形核,细小的动态再结晶晶粒会沿着原始晶粒排列成项链状的晶粒链,随后再结晶晶粒还会继续长大,变为等轴多晶组织。

2) CG Cu70.8Al18.6Mn10.6 SMA的热变形激活能为Q=113.55 KJ/mol。当应变速率因子 <8时,合金发生动态再结晶;当8≤

<8时,合金发生动态再结晶;当8≤ ≤16.34时,合金可能发生动态再结晶,也可能不发生动态再结晶;当

≤16.34时,合金可能发生动态再结晶,也可能不发生动态再结晶;当 >16.34时,合金不会发生动态再结晶。在常规的热加工变形速率下,合金的动态再结晶温度约为850 ℃。

>16.34时,合金不会发生动态再结晶。在常规的热加工变形速率下,合金的动态再结晶温度约为850 ℃。

3) 根据动态材料模型理论和大塑性变形不可逆热力学极值原理,构建了CG Cu70.8Al18.6Mn10.6 SMA在不同变形量下的热加工图,得到了合金热加工的最佳变形工艺参数:变形温度和应变速率区间分别为725~825 ℃、0.08~1 s-1。

4) CG Cu70.8Al18.6Mn10.6 SMA在820 ℃加热后轧制压下75%后不发生明显的动态再结晶,且轧后合金仍具有8%左右的超弹性应变,较好地保留了铸态时的优异记忆性能,同时合金的强度较铸态时提高2倍多。

REFERENCES

[1] 陈信任, 张 帆, 池梦媛, 等. 铜铝锰钛形状记忆合金的微观组织、超弹性和形状记忆效应[J]. 厦门大学学报(自然科学版), 2019, 58(1): 40-47, 58-61.

CHEN Xin-ren, ZHANG Fan, CHI Meng-yuan, et al. Microstructure, superelasticity and shape memory effect of Cu-Al-Mn-Ti shape memory alloy[J]. Journal of Xiamen University (Natural Science), 2019, 58(1): 40-47, 58-61.

[2] YAMAUCHI K. Shape memory and superelastic alloys: Technologies and applications[M]. Philadelphia: Woodhead Publishing, 2011.

[3] MOHAMMAD S E, A K. Superelastic behavior of nanostructured Ti50Ni48Co2 shape memory alloy with cold rolling processing[J]. Transactions of Nonferrous Metals Society of China, 2018, 28(7): 1351-1359.

[4] 娄明珠, 杨树林, 王碧文, 等. Cu-11.19Al-6.43Mn合金的形状记忆效应[J]. 中国有色金属学报, 2000, 10(3): 323-325.

LOU Ming-zhu, YANG Shu-lin, WANG Bi-wen, et al. Shape memory effect of Cu-11.19Al-6.43Mn alloy[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(3): 323-325.

[5] 赵可昕, 杨永民. 形状记忆合金在建筑工程中的应用[J]. 材料开发与应用, 2007, 22(3): 40-46.

ZHAO Ke-xin, YANG Yong-min. Application of shape memory alloy in building engineering[J]. Development and Application of Materials, 2007, 22(3): 40-46.

[6] 廖 赞, 汤京龙, 袁志山, 等. 钛镍形状记忆合金医疗器械评价方法研究进展[J]. 金属功能材料, 2020, 27(4): 55-60.

LIAO Zan, TANG Jing-long, YUAN Zhi-shan, et al. Research progress of assessment method for performance tests of NiTi shape memory alloy medical devices[J]. Metallic Functional Materials, 2020, 27(4): 55-60.

[7] 刘兵飞, 刘艳艳, 周 蕊. 航空发动机变形齿的新材料设计与力学性能[J]. 材料导报, 2020, 34(2): 2117-2122, 2158.

LIU Bing-fei, LIU Yan-yan, ZHOU Rui. Innovative material design and mechanical properties study of variable geometry chevron for aeroengine[J]. Materials Reports, 2020, 34(2): 2117-2122, 2158.

[8] 仝国芸, 王云龙, 董中奇. 形状记忆合金在土木工程中的阻尼特性研究[J]. 铸造技术, 2016, 37(12): 2553-2556.

TONG Guo-yun, WANG Yun-long, DONG Zhong-qi. Study on damping characteristics of shape memory alloy in civil engineering[J]. Foundry Technology, 2016, 37(12): 2553-2556.

[9] 黄海友, 王伟丽, 刘记立, 等. Cu基形状记忆合金的应用进展[J]. 中国材料进展, 2016, 35(12): 919-926.

HUANG Hai-you, WANG Wei-li, LIU Ji-li, et al. Progress on the applications of Cu-based shape memory alloys[J]. Materials China, 2016, 35(12): 919-926.

[10] 李 周, 汪明朴, 徐根应. 铜基形状记忆合金材料[M]. 长沙: 中南大学出版社, 2010: 203.

LI Zhou, WANG Ming-pu, XU Gen-ying. Materials of Cu-based shape memory alloys[M]. Changsha: Central South University Press, 2010: 203.

[11] XIE J X, LIU J L, HUANG H Y. Structure design of high-performance Cu-based shape memory alloys[J]. Rare Metals, 2015, 34(9): 607-624.

[12] LIU J L, HUANG H Y, XIE J X. The roles of grain orientation and grain boundary characteristics in the enhanced superelasticity of Cu71.8Al17.8Mn10.4 shape memory alloys[J]. Materials and Design, 2014: 64(12): 427-433.

[13] 谢建新, 王 宇, 黄海友. 连续柱状晶组织铜及铜合金的超延展变形行为与塑性提高机制[J]. 中国有色金属学报, 2011, 21(10): 2324-2336.

XIE Jian-xin, WANG Yu, HUANG Hai-you. Extreme plastic extensibility and ductility improvement mechanisms of continuous columnar-grained copper and copper alloys[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(10): 2324-2336.

[14] 芦 笙, 林萍华, 陈 静. 组织及相结构对Cu-Al-Be-B形状记忆合金阻尼与力学性能的影响[J]. 中国有色金属学报, 2002, 12(6): 1123-1129.

LU Sheng, LIN Ping-hua, CHEN Jing. Effects of microstructure and phase structure on damping and mechanical properties of Cu-Al-Be-B shape memory alloys[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(6): 1123-1129.

[15] 颜 莹, 金 伟, 周亭俊. 热轧Ni47Ti44Nb9形状记忆合金板材的织构及其对拉伸和恢复性能的影响[J]. 中国有色金属学报, 2010, 20(11): 2148-2153.

YAN Ying, JIN Wei, ZHOU Ting-jun. Texture and its influence on tensile and recoverable properties of hot-rolled Ni47Ti44Nb9 shape memory alloy sheet [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(11): 2148-2153.

[16] LI Y F, KANG X Y, YIN X Q, et al. Microstructure and mechanical properties of cold-rolled Ti50Ni47Fe3 shape memory alloy[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(9): 2890-2895.

[17] MOGHADDAM A O, KETABCHI M, BAHRAMI R. Kinetic grain growth, shape memory and corrosion behavior of two Cu-based shape memory alloys after thermomechanical treatment[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(10): 2896-2904.

[18] 于 能, 黎沃光, 余业球. 热型连铸超弹性CuAlMn合金的冷加工性能[J]. 材料研究与应用, 2007, 1(3): 195-198.

YU Neng, LI Wo-guang, YU Ye-qiu. The coldworking property of CuAlMn superelasticalloy cast by heated mold continuous casting[J]. Materials Research and Application, 2007, 1(3): 195-198.

[19] 蔡莲淑, 余业球, 黎沃光, 等. 柱状晶CuAlBe合金丝的性能[J]. 特种铸造及有色合金, 2007, 27(3): 238-240.

CAI Lian-shu, YU Ye-qiu, LI Wo-guang, et al. Properties of CuAlBe wires with columnar grain structure[J]. Special Casting & Nonferrous Alloys, 2007, 27(3): 238-240.

[20] 张 鸿, 谢建新, 王自东, 等. 连续定向凝固铜棒及其冷加工后的组织和力学性能[J]. 机械工程材料, 2004, 28(2): 31-33.

ZHANG Hong, XIE Jian-xin, WANG Zi-dong, et al. Microstructure and mechanical properties of continuous unidirectional solidification copper bar and cold processed wires[J]. Materials for Mechanical Engineering, 2004, 28(2): 31-33.

[21] KIM W J, JEONG H T. Pronounced yield drop phenomenon at high temperatures in Al-Mg alloys with high contents of Mg (5-13 wt%)[J]. Materials Science and Engineering, 2019, 743(16): 590-596.

[22] SHEN G, SEMIATIN S. L, ALTAN T. Investigation of flow stress and microstructure development in non-isothermal forging of Ti-6242[J]. Journal of Materials Processing Technology, 1993, 36(3): 303-319.

[23] 于雪梅. NiTi形状记忆合金热变形行为及变形机理的研 究[D]. 沈阳: 沈阳工业大学, 2019.

YU Xue-mei. Study on hot deformation behavior and deformation mechanism of NiTi shape memory alloys[D]. Shenyang: Shenyang University of Technology, 2019.

[24] 崔文芳, 洪 权, 刘春明, 等. Ti-1100/0.1Y高温钛合金等温热压缩变形行为[J]. 东北大学学报, 2003, 24(6): 572-575.

CUI Wen-fang, HONG Quan, LIU Chun-ming, et al. Hot deformation behaviours of Ti-1100/0.1Y alloy through isothermal hot compression tests[J]. Journal of Northeastern University, 2003, 24(6): 572-575.

[25] 余均武, 刘雪峰, 谢建新. 连续柱状晶铜基合金BFe10-1-1的动态再结晶研究[J]. 金属学报, 2011, 47(4): 482-488.

YU Jun-wu, LIU Xue-feng, XIE Jian-xin. Study of dynamic recrystallization of a Cu-based alloy BFe10-1-1with continuous columnar grains[J]. Acta Metallurgica Sinica, 2011, 47(4): 482-488.

[26] NING Y, YAO Z, FU M W, et al. Dynamic recrystallization of the hot isostatically pressed P/M superalloy FGH4096 in hot working process[J]. Materials Science and Engineering A, 2010, 527(26): 6968-6974.

[27] OU L, NIE Y, ZHENG Z. Strain compensation of the constitutive equation for high temperature flow stress of a Al-Cu-Li alloy[J]. Journal of Materials Engineering and Performance, 2014, 23(1): 25-30.

[28] SHI H, MCLAREN A J, SELLARS C M, et al. Constitutive equations for high temperature flow stress of aluminium alloys[J]. Materials Science and Technology, 1997, 13(3): 210-216.

[29] LIU W C, YUAN H. Effect of the δ phase on the hot deformation behavior of Inconel 718[J]. Materials Science & Engineering A, 2005, A408(1/2): 281-289.

[30] 刘德林, 陶春虎, 关文秀, 等. 镍铜合金NCu30-4-2-1电渣熔铸件的热变形行为[J]. 中国有色金属学报, 2013, 23(2): 389-395.

LIU De-lin, TAO Chun-hu, GUAN Wen-xiu, et al. Hot deformation behavior of nickel-copper alloy NCu30-4-2-1 electroslag castings[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(2): 389-395.

[31] 林高用, 周 佳, 张振峰, 等. BFe30-1-1铜合金热压缩流变应力行为[J]. 热加工工艺, 2007(13): 9-12.

LIN Gao-yong, ZHOU Jia, ZHANG Zhen-feng, et al. Flow stress behaviors of BFe30-1-1 copper alloy during hot compression[J]. Hot Working Technology, 2007(13): 9-12.

[32] PRASAD Y V R K. Processing maps: a status report[J]. Journal of Materials Engineering & Performance, 2003, 12(6): 638-645.

[33] LIN Y C, LI L T, XIA Y C, et al. Hot deformation and processing map of a typical Al-Zn-Mg-Cu alloy[J]. Journal of Alloys & Compounds, 2013, 550: 438-445.

[34] SRINIVASAN M, LOGANATHAN C, NARAYANASAMY R, et al. Study on hot deformation behavior and microstructure evolution of cast-extruded AZ31B magnesium alloy and nanocomposite using processing map[J]. Materials & Design, 2013, 47(5): 449-455.

[35] 张彦敏, 陈 赛, 葛学元, 等. 6082铝合金热变形行为及热加工图[J]. 塑性工程学报, 2018, 25(4): 113-121.

ZHANG Yan-min, CHEN Sai, GE Xue-yuan, et al. Hot deformation behavior and processing map of aluminum alloy 6082[J]. Journal of Plasticity Engineering, 2018, 25(4): 113-121.

[36] PRASAD Y V R K, GEGEL H L, DORAIVELU S M, et al. Modeling of dynamic material behavior in hot deformation: forging of Ti-6242[J]. Metallurgical Transactions A, 1984, 15(10): 1883-1892.

Dynamic recrystallization behavior of columnar-grained Cu70.8Al18.6Mn10.6 shape memory alloy in hot compression

SHI Bo-wen, LIU Ji-li, LIU Jin

(Hubei Key Laboratory of Theory and Application of Advanced Materials Mechanics, Wuhan University of Technology, Wuhan 430070, China)

Abstract: In order to study the high-temperature and large-deformation processing capability of high-performance columnar-grained Cu-Al-Mn shape memory alloys, the columnar-grained Cu70.8Al18.6Mn10.6 shape memory alloy was subjected to hot compression deformation (the deformation temperature of 700-850 ℃ and the strain rate of 0.01-10 s-1) to analyze the dynamic recrystallization behavior used the Gleeble 3500 thermal simulation testing machine. The results show that with the increase of deformation temperature and strain rate, dynamic recrystallization occurs at the grain boundary, and the number and size of dynamic recrystallized grains in the columnar-grained Cu70.8Al18.6Mn10.6 shape memory alloy increase. According to the Zener-Hollomon parameter analysis, it can be obtained that the thermal deformation activation energy of the alloy is Q=113.55 kJ/mol. When the strain rate factor  <8, the alloy undergoes dynamic recrystallization; when 8≤

<8, the alloy undergoes dynamic recrystallization; when 8≤ ≤16.34, the alloy may or may not undergo dynamic recrystallization; when

≤16.34, the alloy may or may not undergo dynamic recrystallization; when  >16.34, the alloy will not undergo dynamic recrystallization. Combining the hot working diagram of the alloy, the best process parameters of the hot working are obtained: the deformation temperature and strain rate ranges are 725-825 ℃ and 0.08-1 s-1, respectively. Comparative analysis of the structure and properties of the alloy before and after high temperature rolling shows that the alloy does not undergo dynamic recrystallization after 75% rolling deformation at 820 ℃. And the alloy still has a superelastic strain of about 8% after rolling, and the martensitic transformation critical stress and the peak stress are increased by more than 2 times at room temperature. Therefore, after large deformation at a temperature slightly lower than the dynamic recrystallization temperature, not only the strength of the alloy can be improved, but also the excellent memory performance of the as-cast alloy can be retained.

>16.34, the alloy will not undergo dynamic recrystallization. Combining the hot working diagram of the alloy, the best process parameters of the hot working are obtained: the deformation temperature and strain rate ranges are 725-825 ℃ and 0.08-1 s-1, respectively. Comparative analysis of the structure and properties of the alloy before and after high temperature rolling shows that the alloy does not undergo dynamic recrystallization after 75% rolling deformation at 820 ℃. And the alloy still has a superelastic strain of about 8% after rolling, and the martensitic transformation critical stress and the peak stress are increased by more than 2 times at room temperature. Therefore, after large deformation at a temperature slightly lower than the dynamic recrystallization temperature, not only the strength of the alloy can be improved, but also the excellent memory performance of the as-cast alloy can be retained.

Key words: Cu-Al-Mn shape memory alloy; columnar-grained structure; dynamic recrystallization; strain rate factor; high temperature rolling

Foundation item: Project (51974217) supported by the National Natural Science Foundation of China; Project (2020-Z13) supported by the supported by State Key Lab of Advanced Metals and Materials

Received date: 2020-09-07; Accepted date: 2021-05-08

Corresponding author: LIU Ji-li; Tel: +86-17786517529; E-mail: ljl0507@163.com

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51974217);新金属材料国家重点实验室开放基金资助项目(2020-Z13)

收稿日期:2020-09-07;修订日期:2021-05-08

通信作者:刘记立,副教授,博士;电话:17786517529;E-mail:ljl0507@163.com