Effect of pre-strain on microstructural evolution during thermal exposure of single crystal superalloy CMSX-4

B. G. CHOI, C. Y. JO, H. U. HONG, I. S. KIM, S. M. SEO, H. M. KIM

High Temperature Materials Group, Korea Institute of Materials Science,

797 Changwondaero, Changwon 641-010, Korea

Received 23 September 2010; accepted 16 December 2010

Abstract: Compressive and tensile pre-strains at room temperature were induced in the second generation single crystal superalloy CMSX-4 fully heat treated. Both compressive and tensile pre-strain generated shear bands in the single crystal CMSX-4. Thermal exposure for 10 h at 950 °C on the pre-strained single crystal CMSX-4 developed preferential coarsening of γ′ particles along the shear bands. γ′ particles on the shear band gradually invaded γ channel. Finally, the γ channels along the shear band disappeared. TCP-like particles appeared at the expense of γ channel disappearance. However, thermal exposure for 10 h of the normal single crystal CMSX-4 did not develop TCP precipitation or preferential coarsening of γ′ particles. Thermal exposure for 100 h of pre-strained CMSX-4 developed preferential coarsening of γ′ and TCP phase particles along the shear bands as well as coarsening of γ′ particles in the matrix.

Key words: pre-strain; microstructural evolution; superalloy; CMSX-4

1 Introduction

Single crystal turbine blades and vanes are widely used in the advanced gas turbines such as aero-jet engine and industrial gas turbine, with high performance during service due to their excellent mechanical properties. The elimination of grain boundary in the single crystal superalloys, which excludes grain boundary sliding and intergranular fracture at high temperature, improves the creep life tremendously.

Single crystal superalloys are very susceptible to recrystallization during the post-casting processes. Recrystallization may introduce new grain boundaries to the single crystal, which will drastically reduce the mechanical properties at high temperature [1]. Therefore, extreme care has to be paid in handling of the single crystalline components, especially to prevent plastic deformation or damage prior to solutionising. Plastic deformation can be caused by some manufacturing processes such as removing the ceramic mold and core material, stamping identification marks, grinding the airfoil and grit blasting the airfoil [2-3]. The cold deformation of single crystal components in the as-cast condition may cause recrystallization during subsequent solution treatment.

Several studies [1-13] on the recrystallization of Ni-base superalloys have been reported. Even though some of them studied the recrystallization of wrought and powder metallurgy superalloys [10-11], most of recent studies are focused on the recrystallization behavior of directionally solidified [12-13] or single crystal superalloys, especially around the solvus temperature of γ′ phase of the alloys. Recrystallization behaviors are known to depend on the temperature. At the temperature lower than solutionising temperature, cellular recrystallization was observed, while equiaxed recrystallized grains were observed above the gamma prime solvus temperature [4-5].

The service temperatures of the turbine blade or vanes are far below the solutionising temperature, recrystallization in the cold deformed single crystal airfoil would be hard to occur during service. However, little information is available about the microstructural evolution of cold deformed single crystal near service temperature.

In the present study, to understand the effect of cold deformation during service of single crystal components, the microstructural evolution of compressive and tensile pre-strained single crystal CMSX-4 was investigated during the thermal exposure at various temperature and time.

2 Experimental

The single crystal nickel-based superalloy CMSX-4 was chosen in the present study. The mother alloy was supplied by Cannon-Muskegon Co. The nominal composition of the alloy is shown in Table 1. CMSX-4 mother ingot was cast into single crystal bars (d 14 mm×200 mm) in a Bridgman type directional solidification furnace (ALD Vacuum Technologies: ISP 0.5 DS/SC/LMC VIM). The cast single crystal bars were solution treated at 1 320 °C for 2 h followed by two aging treatments at 1 140 oC for 2 h and at 870 oC for 20 h under vacuum.

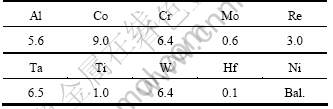

Table 1 Chemical composition of CMSX-4 (mass fraction, %)

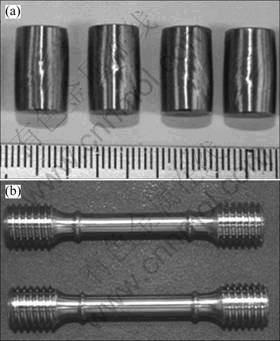

15% compressive pre-strain was induced in the compression specimen by hydraulic press at room temperature. The compressive pre-strained specimens are displayed in Fig. 1(a). Tensile tests were conducted to induce 1.5% tensile pre-strain in the creep specimen as shown in Fig. 1(b).

Fig. 1 Compressive pre-strained CMSX-4 specimens (a) and tensile pre-strained specimens (b)

Thermal exposure tests for the compressive pre-strained, tensile pre-strained, and the heat treated single crystal CMSX specimens were carried out at 950 oC for 5, 10 and 100 h under vacuum (0.266 Pa, Centorr M60).

The exposed specimens were sectioned parallelly to the longitudinal axis for microstructural studies. Metallographic specimens were prepared by metallographic polishing (grinding and mechanical polishing) followed by etching of swabbing with Kalling’s reagent and electrolytic chromic acid (10% CrO2 at 3.5 V for 10 s) for optical and scanning electron microscopy (SEM: JSM5800) observation. Thin foils for transmission electron microscopy (TEM: JEOL JEM-2100F at 200 keV) were mechanically ground down to about 50 μm in thickness. Disks of 3 mm in diameter were punched out of the thin sheets, and electro-polished to perforation with an 80% methanol and 20% perchloric acid electrolyte at -25 °C and 20 V, using a twin-jet electropolisher.

3 Results and discussion

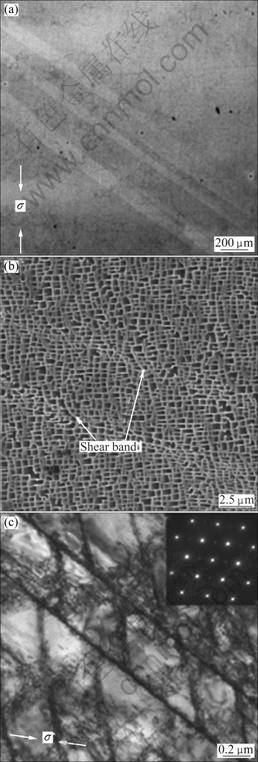

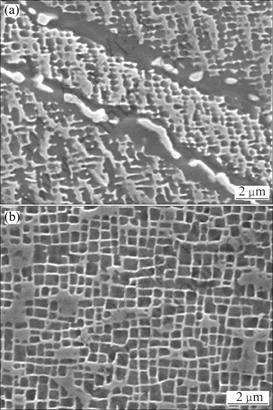

Compressive pre-strain at room temperature generated numerous deformation bands (shear bands) in single crystal CMSX-4 as shown in Fig. 1(a) and Fig. 2(a). Figure 2 (b) shows seriously deformed morphology of γ′ particles compared with normal shape of cuboidal γ′ particles. Figure 2(c) shows γ′ particles elongated nearly perpendicular to the loading axis and dislocations on the activated slip planes, shearing of γ′. No trace of twin or stacking fault is shown in this figure.

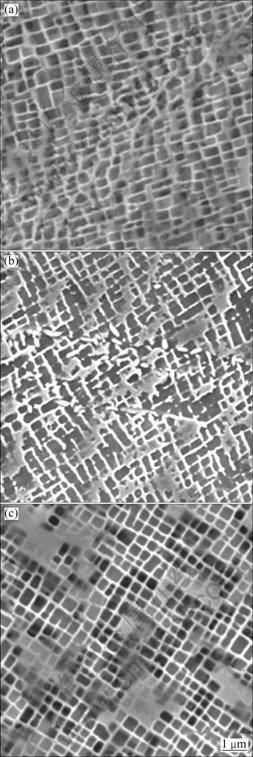

Thermal exposure of compressive pre-strained single crystal CMSX-4 at 950 °C for 5 h did not develop much microstructural evolution as shown in Fig. 3(a). However, thermal exposure for 10 h at the same temperature caused preferential coarsening of γ′ particles and precipitation of topologically close packed (TCP) phase on the shear bands as shown in Fig. 3(b). Compared with normal single crystal CMSX-4 in Fig. 3(c), γ′ particles on the shear bands of the compressive pre-strained single crystal CMSX-4 preferentially coarsened during thermal exposure. Because of the diffusion controlled γ′ coarsening [14], preferential coarsening of γ′ is favored on the shear band which has relatively high energy compared with normal area. Due to primary coarsening of the γ′ particles on the shear bands the γ channel on the bands gradually disappear, as shown in Fig. 3(b).

The nucleation rate of the TCP can be expressed as [15]

(1)

(1)

(2)

(2)

where ?Gm is the activation energy for atom migration; ?G* is the activation energy for phase transformation; ?Gv is the volume free energy, ?Gs is the strain energy; γis the interfacial energy. The dislocations on the slip traces can assist nucleation of TCP in several ways. One of the main effects of slip traces is to reduce the ?Gs contribution to ?G* by decreasing the total strain energy to remove the lattice distortion in the vicinity of dislocations on the slip traces. The dislocations can also assist the formation of TCP by providing a diffusion path with a lower ?Gm. Precipitation of TCP on the shear bands is also attributed to the growth of γ′. Gradual growth of γ′ particles on the shear bands can promote supersaturation of γ forming elements such as Re and W on slip traces. The enrichment of these elements increases the driving force for precipitation, because they are also the major constitutive elements of TCP in single crystal.

Fig. 2 Micrographs of compressive pre-strained shear bands

Fig. 3 SEM micrographs of CMSX-4 thermally exposed at 950 °C: (a) Compressive pre-strained, exposed for 5 h; (b) Compressive pre-strained, exposed for 10 h; (c) Normal CMSX-4, exposed for 10 h

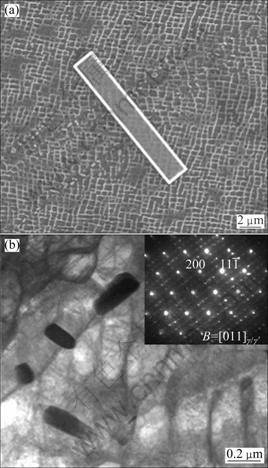

TEM foil across the shear band of the compressive pre-strained specimen exposed at 950 °C for 10 h was taken by focused ion beam (FIB) as indicated region in Fig. 4(a). Figure 4(b) reveals that the TCP is μ phase which is enriched by refractory elements and Cr.

Fig. 4 TEM foil across shear band prepared by FIB (a) and TEM micrograph showing particles on shear band and SAPD of particles (b)

The enrichment of the refractory elements and Cr in the γ phase is attributed to the disappearance of γ phase on the shear band due to the growth of neighbour γ′ particles. The μ phase is frequently observed in CMSX-4 aged or after service [16-17].

Figure 5(a) shows that the preferential coarsening of γ′ and the TCP precipitation on the shear bands are very obvious in the compressive pre-strained specimen exposed at 950 °C for 100 h. Coarsening of γ′ particles is found both on the shear band and in the normal matrix area. The degree of γ′ coarsening on the shear band is much higher than that in the specimen without pre-strain as shown in Fig. 5(b). Most of the γ′ particles linked together, especially the γ′ particles on the shear band formed film-like morphology which has TCP particles inside. The coarsening of TCP particles on the shear band also occurred due to the expansion of the γ′ film that invaded the neighbouring γ phase.

Fig. 5 SEM micrographs of CMSX-4 after thermal exposure at 950 °C for 100 h: (a) Compressive pre-strained specimen; (b) Normal single crystal CMSX-4

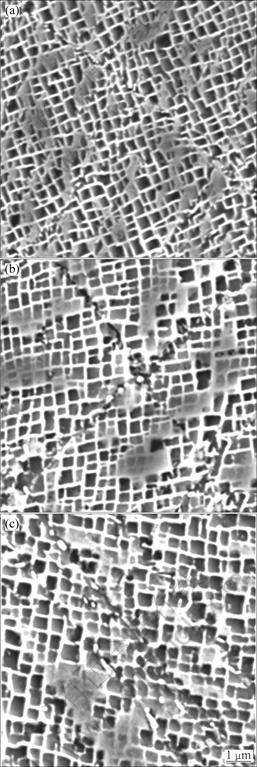

Tensile pre-strain also brought about the TCP precipitation and the coarsening of γ′ particles on the shear band during thermal exposure. TCP precipitation occurred after 5 h thermal exposure of the tensile pre-strained single crystal CMSX-4. Compared with the compressive pre-strained CMSX-4 of 15% deformation, the time to TCP precipitation was relatively short in the 1.5% tensile pre-strained CMSX-4. However, microstructural evolution was similar regardless of strain sense (tensile or compression). TCP precipitation on the shear band of the tensile pre-strained CMSX-4 is also attributed to the disappearance of γ phase and the coarsening of? γ′ particles. The degree of TCP precipitation and γ′ coarsening increased with increasing the exposure time, as shown in Fig. 6. Microstructural evolution both on the tensile pre-strained and the compressive pre-strained single crystal CMSX-4 showed similar behavior during thermal exposure at 950 °C.

Fig. 6 SEM micrographs of tensile pre-strained CMSX-4: (a) Pre-strained; (b) Thermally exposed for 5 h at 950 °C; (c) Exposed for 10 h at 950 °C

4 Conclusions

1) Compressive and tensile pre-strain at room temperature generated shear bands in single crystal superalloy CMSX-4. γ′ phase on the shear band preferentially grew during thermal exposure at 950 °C.

2) The growth of γ′ on the shear band brought about disappearance of the neighbouring γ which generated precipitation of TCP. TCP precipitation is attributed to the high concentration of forming elements in the preferentially grown γ′ on the shear band.

3) Pre-strain in the single crystal components may cause TCP precipitation during service and deteriorate properties of the alloy.

References

[1] MENG J, JIN T, SUN X, HU Z. Effect of surface recrystallization on the creep rupture properties of a nickel-base single crystal superalloy [J]. Materials Science and Engineering A, 2010, 527: 6119-6122.

[2] B?RGEL R, PORTELLA P D, PREUHS J. Recrystallization in single crystals of nickel base superalloys [C]//Proceedings of Superalloys, 2000. PA: TMS, 2000: 229-238.

[3] JO C Y, CHO H Y, KIM H M. Effect of recrystallisation on microstructural evolution and mechanical properties of single crystal nickel base superalloy CMSX-2: Part 1—Microstructural evolution during recrystallisation of single crystal [J]. Materials Science and Technology, 2003, 19(12): 1665-1670.

[4] ZHANG B, YAO C H, LU X, LIU C K, HU C Y, BAI M Y. Recrystallization of single crystal nickel-based superalloy [J]. Journal of Iron and Steel Research, 2009, 16(6): 75-79.

[5] XIONG J, LI J, LIU S. Surface recrystallization in nickel base single crystal superalloy DD6 [J]. Chinese Journal of Aeronautics, 2010, 23: 478-485.

[6] COX D C, REOBUCK B, RAE C M F, REED R C. Recrystallisation of single crystal superalloy CMSX-4 [J]. Materials Science and Technology, 2003, 19(4): 440-446.

[7] PAUL U, SAHM P R, GOLDSCHMIDT D. Inhomogeneities in single-crystal components [J]. Materials Science and Engineering A, 1993, 173: 49-54.

[8] BOND S D, MARTIN J W. Surface recrystallization in a single crystal nickel-based superalloy [J]. Journal of Materials Science, 1984, 19: 3867-3872.

[9] GOLDSCHMID T D, PAUL U, SAHM P R. Porosity clusters and recrystallization in single-crystal components superalloys [C]//Proceedings of Superalloys, 1992. PA: TMS, 1992: 155-164.

[10] PORTER A, RALPH B. The recrystallization of nickel-base superalloys [J]. Journal of Materials Science, 1981, 16: 707-713.

[11] WINBERG L, DAHL?N M. Recrystallization in a powder metallurgy nickel-base superalloy [J]. Journal of Materials Science, 1978, 13: 2365-2372.

[12] WANG L, XIE G, ZHANG J, LOU L H. On the role of carbides during the recrystallization of a directionally solidified nickel-base superalloy [J]. Scripta Materialia, 2006, 55(5): 457-460.

[13] XIE G, ZHANG J, LOU L H. Effect of heat treatment atmosphere on surface recrystallization of a directionally solidified Ni-base superalloy [J]. Scripta Materialia, 2008, 59: 858-861.

[14] CHOI B G, KIM I S, KIM D H, JO C Y. Temperature dependence of MC decomposition behavior in Ni-base superalloy GTD 111 [J]. Materials Science and Engineering A, 2008, 478(1-2): 329-335

[15] PORTER D A, EASTERLING K E. Phase transformations in metals and alloys [M]. London: Chapman & Hall, 1992.

[16] MOVERARE J J, JOHANSSON S, REED R C. Deformation and damage mechanisms during thermal-mechanical fatigue of a single-crystal superalloy [J]. Acta Materilia, 2009, 57: 2266-2276.

[17] CHENG K U. Precipitation behavior and role of μ phase in several Re-containing single crystal superalloys [D]. IMR, 2009.

热暴露下预应变对CMSX-4单晶高温合金的

显微组织演变的影响

B. G. CHOI, C. Y. JO, H. U. HONG, I. S. KIM, S. M. SEO, H. M. KIM

High Temperature Materials Group, Korea Institute of Materials Science,

797 Changwondaero, Changwon 641-010, Korea

摘 要:在室温下,对经完全热处理的第二代单晶高温合金CMSX-4实施压缩和拉伸预应变。压缩和拉伸预应变在单晶CMSX-4中产生了剪切带。单晶CMSX-4在950 °C下热暴露10 h, 沿剪切带产生了γ′粒子择优粗化。剪切带上的γ′粒子逐渐侵入γ通道。最后,γ通道沿着剪切带消失。TCP状粒子伴随着γ通道的消失而出现。然而,热暴露10 h的普通单晶CMSX-4没有产生TCP沉淀,也没有γ′粒子择优粗化。热暴露100 h的预应变CMSX-4沿剪切带产生了γ′粒子和TCP相粒子择优粗化,基体中也有γ′粒子粗化。

关键词:预应变;显微组织演变;高温合金;CMSX-4

(Edited by LI Xiang-qun)

Corresponding author: B.G. CHOI; Tel: +82-55-280-3321; E-mail: choibg@kims.re.kr

DOI: 10.1016/S1003-6326(11)60855-8