文章编号:1004-0609(2010)S1-s0348-04

基于ABAQUS二次开发TC4线性摩擦焊过程的数值模拟

陈 亮,李文亚,马铁军,李京龙

(西北工业大学 摩擦焊接陕西省重点实验室,西安 710072)

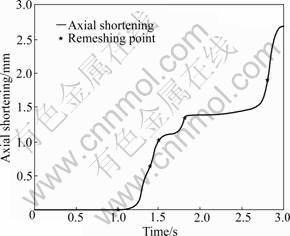

摘 要:基于ABAQUS/Standard模块,建立TC4线性摩擦焊接过程的二维有限元模型,采用网格重划分与映射技术来处理网格畸变问题,分析线性摩擦焊接接头温度场的演变和轴向缩短量的变化。结果表明:网格重划分与映射技术能较好地解决网格畸变带来的计算不收敛。焊接过程的前0.1 s内,焊接界面温度迅速升高至1 000 ℃以上,之后接头温度渐趋均匀,接头塑性金属开始被挤出形成飞边,轴向缩短量明显增加;摩擦停止时刻(3 s),单边轴向缩短量达到最大值,约为2.7 mm。

关键词:TC4钛合金;线性摩擦焊;数值模拟;网格重划分

中图分类号:TG 40 文献标志码:A

Numerical simulation of secondary development TC4 titanium alloy based on ABAQUS software during linear friction welding

CHEN Liang, LI Wen-ya, MA Tie-jun, LI Jing-long

(Shaanxi Key Laboratory of Friction Welding Technology,

Northwestern Polytechnical University, Xi’an 710072, China)

Abstract: A two-dimensional numerical model of linear friction welding (LFW) of TC4 titanium alloy was established based on the ABAQUS/Standard software. The remesh and map solution techniques in ABAQUS were employed to cope with the element distortion. The temperature evolution and the change of axial shortening during LFW were examined. The results show that the remesh and map solution techniques can well solve the element distortion, which usually results in an abnormal termination of the calculation. The temperature at the joint interface can reach quickly more than 1 000 ℃ within 0.1 s. After that, the temperature tends to be uniform across the interface and the axial shortening begins to increase obviously accompanying the formation of flash. At the end of friction (3 s), the maximum unilateral axial shortening is about 2.7 mm.

Key words: TC4 titanium alloy; linear friction welding; numerical simulation; remesh

线性摩擦焊接(Linear friction welding, LFW)是一种优质、高效、节能与环保的固相焊接方法,是解决先进航空发动机整体叶盘设计与制造的关键技术,特别是解决异质、空心、宽弦叶盘制造的唯一可能的连接技术。与传统的焊接方法相比,线性摩擦焊除了具有摩擦焊接高可靠性、低成本、焊缝锻造组织、少缺陷的优点外,对于非圆形构件,如方形、多边形截面试样,线性摩擦焊接能克服焊件形状对惯性摩擦焊、连续驱动摩擦焊的限制[1]。焊接过程中大的塑性变形与强烈的热力耦合作用给接头温度场、界面金属粘塑性流动状况的测量与表征带来很大困难,有限元模拟辅助试验研究已成为揭示LFW过程温度场和接头金属流动状况的重要手段。

早期,VAIRIS和FORST[2]模拟线性摩擦焊接TC4初始阶段的温升情况,计算中考虑材料非线性和边界条件的影响,同时考虑飞边挤出阶段钛合金氧化放热反应对摩擦焊接过程热分布的影响,模拟结果采用盲孔法热电偶测温进行验证。杜随更等[3]采用基于ANSYS的三维模型,结合接头线性运动特性,推导出摩擦界面每个振动循环单位面积上热流密度,对其积分取均值作为热输入,计算单晶DD3高温合金和粉末冶金Renē95高温合金的温度场与应力应变场。TAO等[4]和陶军等[5]采用DEFORM软件,利用热力耦合方法计算线性摩擦焊接TC4接头温度场、变形和应力分布,并结合试验,验证焊接过程中界面温度和接头轴向缩短量,基于计算结果,提出了控制接头缺陷的方法。最近,本课题组[6]基于ABAQUS软件的显式模块(Explicit),在计算中采用综合考虑应变、应变率强化与温度软化的Johnson-Cook材料本构,且将熔焊领域中的力学熔点引入计算中,研究不同工艺参数下接头温度场和轴向缩短量变化。但计算过程中,强烈的热-机械耦合和大的应变、应变率使得计算过程容易异常终止。因此,本文作者在以前工作的基础上,尝试采用ABAQUS隐式模块(Standard)中的映射与网格重划分技术来处理线性摩擦焊接过程中的网格畸变问题,研究整个焊接过程的温度场与轴向缩短量的变化。

1 有限元计算模型与映射技术

1.1 计算模型

根据焊接过程中接头变形的对称性,以单个接头施加刚性壁面,其模型如图1所示,TC4合金二维模型尺寸长40 mm、宽17 mm。采用四边形网格及梯度网格划分,离焊接界面8 mm处,网格尺寸为1 mm,其余部分网格大小为2 mm。单元类型为线性、缩减积分、热-位移耦合的CPE4RT单元。刚性壁面沿X向振动,试样仅允许沿Y向位移。焊接参数如下:压强100 MPa、振幅3.5 mm、频率35 Hz、摩擦时间3 s,3~60 s时间内给定试件换热系数为1 000 W/(m2·K),用来模拟由于夹具造成的焊接过程的急剧降温阶段。

计算中热源模型处理为基于塑性变形生热的用户自定义热流本构,给定的界面摩擦因数只是用于界面的剪切流动。材料模型是基于Johnson-Cook材料本构(J-C模型)及相关参数[6]离散化后输入的塑性模型,J-C本构中,材料屈服应力 综合考虑应变、应变率硬化与温度软化效应,适用于描述金属材料从低应变率到高应变率下的动态行为。力学熔点初步定为1 100 ℃。材料的热物性与以前计算模型中所用一致[6]。

综合考虑应变、应变率硬化与温度软化效应,适用于描述金属材料从低应变率到高应变率下的动态行为。力学熔点初步定为1 100 ℃。材料的热物性与以前计算模型中所用一致[6]。

(1)

(1)

式中:A、B、n、C、m为材料常数; 是等效塑性应变;

是等效塑性应变; 是等效塑性应变率;

是等效塑性应变率; 是参考应变率;

是参考应变率; 是无量纲温度。

是无量纲温度。

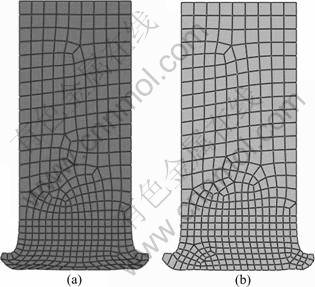

图1 有限元计算模型与网格划分

Fig.1 Numerical model and meshing

1.2 网格重划分与映射技术

对于大变形与强烈热-力耦合的数值模拟问题,ABAQUS/Explicit模块下常用的预防畸变方法一般为:任意拉格朗日欧拉法(Arbitrary Lagrangian- Eulerian, ALE),但ALE网格自适应技术仅适用于显式算法,而且不能完全解决畸变问题。根据ABAQUS用户手册,本研究基于ABAQUS/Standard模块下的网格重划分与映射技术(Remesh and map solution)来处理焊接过程中的网格畸变问题。当计算中网格畸变过大时,终止计算,取出网格畸变部件并重新划分网格,如图2所示,然后完成模型的装配与再次加载,同时将上一次计算终了时刻的数据作为本次计算的初始条件,映射到重划分模型中,提交任务计算。本研究中整个焊接过程共使用6次网格重划分与映射技术。

2 结果与讨论

2.1 接头温度场

图3所示为计算获得的焊接过程中不同时刻接头温度场。由图3可以看出,在焊接过程开始的0.1 s内,界面温度可骤升至1 100 ℃左右,但高温区域仅分布于界面中心区域。由于时间短,界面热量来不及向轴向与横向传导,因此在接头上存在较大的温度梯度(见图3(a));在1 s时,整个界面温度均超过1 000 ℃,但最高温度变化不大,约为1 080 ℃。接头高温区域进一步沿轴向扩大,超过900 ℃金属层厚度约0.8 mm(见图3(b));随后,高温金属层厚度基本稳定在0.8mm左右,接头温度场分布渐趋稳定,此现象一方面是摩擦界面生热不断生成高温粘塑性金属,另一方面是由于热量随高温金属被挤出形成飞边,而使产热与耗热平衡(见图3(c));3 s时,试件停止振动,冷却过程开始(见图3(d))。

图2 重划分前(a)与后(b)网格

Fig.2 Models before (a) and after (b) remesh

图3 不同时刻接头的温度场

Fig.3 Temperature field at different times during friction process: (a) 0.1 s; (b) 1.0 s; (c) 2.0 s; (d) 3.0 s

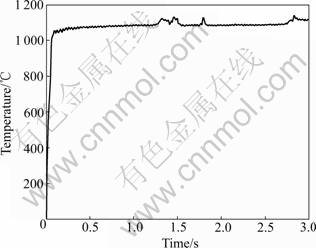

摩擦过程中界面中心点温度变化如图4所示。由图4可以看出,界面中心温度在0.1 s时间内迅速升高至1 100 ℃,然后至整个摩擦过程的完成变化不大,维持在平台温度1 080 ℃左右,这可辅助解释在线性摩擦焊中,当焊接过程进行到一定程度时,接头温度场达到准平衡状态的原因。

图4 摩擦过程中界面中心点的温度变化

Fig.4 Temperature varition of interface center during friction process

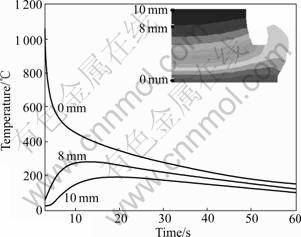

3~60 s过程为降温过程,此过程主要为接头温度场的均匀化,同时试件和夹具间的热传导将大部分热量从界面导走。图5所示为试件停止振动后接头中心轴线距焊缝0、8、10 mm处降温过程温度变化。由图5可以看出,焊缝中心点处温度在试样停止振动后,迅速下降,7 s内就可冷却到500 ℃左右。离焊缝界面8 mm处,温度由于热传导作用先升高至10 s时290 ℃左右,再缓慢下降至60 s时的120 ℃左右。离焊接界面10 mm处,温度变化趋势与8 mm点处相似,在60 s时,接头温度场基本均匀化。以上结果均与以前计算结果[6]相当。

2.2 轴向缩短量

图6所示为接头轴向缩短量变化曲线。从图6可以看出,在0~1 s时间内,接头轴向缩短量不明显,结合接头温度场分布云(见图3(a)与(b)),此阶段接头温度场分布不均匀,接头金属抵抗界面摩擦剪切应力能力相对较高。同时,小体积的高温区域使得高温金属不足以被挤出形成飞边。1 s后,接头高温区域分布渐趋均匀,整个接头温度场达到准平衡状态,高温金属开始被挤出;1.2 s后,接头呈现出明显的轴向缩短;3 s时,试样停止振动,缩短量达到最大约2.7 mm。在实际焊接过程中,在接头温度场达到均匀化后,轴向缩短量与时间呈近线性关系,本文作者以前基于显式算法也获得如此结论[6],而图6中表现出明显的非线性,分析认为这是因为网格重划分与映射技术导致网格在一定程度上的不连续,同时接头应力和应变场在映射过程中也会造成一定的偏差,但隐式算法下总的轴向缩短量与显式算法的吻合较好[6]。后续工作将通过修改映射设置来解决隐式算法下轴向缩短量的明显非线性。

图5 降温过程离焊缝不同位置处温度变化

Fig.5 Temperature changes at different positions of interface during cooling

图6 接头轴向缩短量的变化

Fig.6 Change of unilateral axial shortening with friction time

3 结论

1) 基于ABAQUS/Standard模块,结合网格重划分与映射技术研究线性摩擦焊接TC4钛合金过程中的温度场演变与轴向缩短量变化。

2) 基于ABAQUS二次开发的网格重划分与映射技术能较好地处理焊接过程中的网格畸变现象。焊接过程的0.1 s内,焊接界面温度迅速升高至1 100 ℃左右,随后接头界面温度渐趋均匀;1.2 s后,接头塑性金属被挤出形成飞边,轴向缩短量明显增加;3 s停止摩擦时,单边接头轴向缩短量约2.7 mm;随后的冷却过程,60 s内接头温度场快速均匀化。

REFERENCES

[1] 刘 军. 摩擦焊在美国的应用与发展[J]. 焊接技术, 1995(4): 46-47.

LIU Jun. Research and application of Friction welding technology in America [J]. Welding Technology, 1995(4): 46-47.

[2] VAIRIS A, FROST M. Modelling the linear friction welding of titanium blocks [J]. Materials Science and Engineering A, 2000, 292(1): 8-17.

[3] 杜随更, 王 庆, 傅 莉. 线性摩擦焊接过程三维热力耦合有限元分析[J]. 西北工业大学学报, 2002, 20(2): 180-183.

DU Sui-geng, WANG Qing, FU Li. On exploring linear friction welding of blade to disk of Aeroengine Rotor [J]. Journal of Northwestern Polytechnical University, 2002, 20(2): 180-183.

[4] TAO J, ZHANG T C, LIU P T, LI J, MANG Y. Numerical computation of a linear friction welding process [J]. Materials Science Forum, 2008, 575/578: 811-815.

[5] 陶 军, 孙成彬, 张田仓. 钛合金线性摩擦焊接头缺陷形成机理分析[J]. 航空制造技术, 2009(10): 139-142.

TAO Jun, SUN Cheng-bin, ZHANG Tian-cang. Study on the formation mechanism of welding defects in linear friction weld of titanium alloys [J]. Aeronautical Manufacturing Technology, 2009(10): 139-142.

[6] LI W Y, MA T J, LI J L. Numerical simulation of linear friction welding of titanium alloy: Effects of processing parameters[J]. Material and Design, 2010, 31(3): 1497-1507.

(编辑 李艳红)

基金项目:教育部留学回国人员科研启动基金资助项目(N9YK0003);教育部新世纪优秀人才计划资助项目(NECT-08-0463);教育部博士点新教师基金资助项目

通信作者:李文亚,副教授,博士; 电话:029-88495226;E-mail:liwy@nwpu.edu.cn