Portevin-Le Chatelier effect in Al-Zn-Mg-Cu-Zr aluminum alloy

CHEN Jun-zhou(陈军洲)1, 2, ZHEN Liang(甄良)1, FAN Li-wei(樊立伟)3,

YANG Shou-jie(杨守杰)2, DAI Sheng-long(戴圣龙)2, SHAO Wen-zhu(邵文柱)1

1. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China;

2. Beijing Institute of Aeronautical Materials, Beijing 100095, China;

3. Shenyang Aircraft Plants, Shenyang 110034, China

Received 13 August 2008; accepted 10 March 2009

Abstract: Portevin-Le Chatelier (PLC) effect in a severely cold-rolled Al-Zn-Mg-Cu-Zr aluminum alloy (AA7055 type) plate before and after annealing was investigated. The results show that the sample annealed at 300 ℃ undergoes PLC effect, whereas the PLC effect is not observed in the deformed sample or the samples annealed at 110 ℃ or 200 ℃. The main precipitates in the sample annealed at 300 ℃ are the coarsened η phases, while a mixture of small η′ phases and η phases dominates in the sample annealed at 200 ℃. In the deformed sample and sample annealed at 110 ℃, GP zone are the main precipitates. The different flow behaviors are ascribed to the type of precipitates as well as the dislocation density differences.

Key words: aluminum alloy; Portevin-Le Chatelier effect; precipitation; dislocation

1 Introduction

The properties of aluminum, chiefly high strength and light mass, make it ideal in many commercial uses. Its usage is limited, however, by a series of bands that form in rolling or deformation[1-2]. This phenomenon is referred to Portevin-Le Chatelier(PLC) effect, which is also known as serrated yielding[3-15]. The detailed mechanism is that, once a mobile dislocation has been impeded by obstacles, a solute-atom atmosphere can form around it and effectively pin it. With applied stress, the mobile dislocations then have to break away from the atmospheres and continue their motion. Therefore, the repetition of the interaction between the mobile dislocations and solute atom atmosphere leads to serrated yielding.

Although the effects of microstructure on the PLC effect have been investigated extensively in aluminum alloys, such as Al-Mg[11,13], Al-Cu[2, 15-16] and Al-Li systems[17-19], less attention is paid to Al-Zn-Mg-Cu- Zr aluminum alloy. THEVENET et al[8] once studied the PLC effect in one of the Al-Zn-Mg-Cu aluminum alloys, 7475 type, and concluded that above tageing=2 h and θageing=70 ℃ any PLC effect could not be observed. However, they only considered the influences of the precipitates on the PLC effect. In the present work, the effect of both initial dislocation density and type of precipitates on the serrated yielding in the AA 7055 Al alloy subjected to different ageing treatments is present. The reason of the PLC appearance in AA 7055 alloy subjected to deep ageing is explained.

2 Experimental

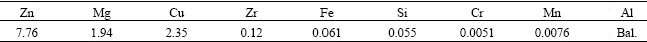

The aluminum alloy AA 7055 was used and its chemical composition is listed in Table 1.

Table 1 Chemical composition of AA 7055 aluminum alloy (mass fraction, %)

The alloy was firstly solid solution treated at 477 ℃ for 1 h and quenched into water at room temperature. Then, the alloy was cold rolled to about 0.4 mm-thick sheets (80% deformed). Samples of 15 mm in gauge length and 6 mm in width were cut from sheets in the rolling direction. Then, they were aged at various temperatures (110, 200, and 300 ℃) for 1 h and cooled in air. The ageing temperatures were chosen in terms of thermal analysis of the deformed sample. Immediately after heat treatment, tensile tests were carried out at a strain rate of 1.7×10-3 s-1 at room temperature using an Instron testing machine. It should be noted that the deformed samples for tensile test might be naturally aged.

Thermal analysis was performed in a differential scanning calorimeter(DSC). Polished alloy disks with a diameter of 5 mm were sealed in Al pans and heated in an Ar atmosphere from room temperature to 500 ℃ at a constant heating rate of 5 ℃/min.

To characterize the precipitates, X-ray diffractometer and transmission electron microscope were used. X-ray diffraction(XRD) measurements were performed using a Rigaku D/max-rB X-ray diffractometer with Cu Kα radiation. Scanning from 2θ= 10? to 100? was performed to record the XRD pattern. Transmission electron microscopy(TEM) observation was performed using a Philips Tecnai20 microscope operated at 200 kV.

3 Results

3.1 Thermal analysis

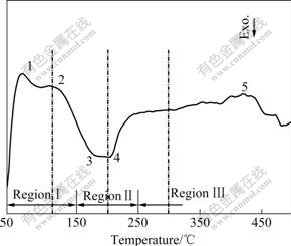

Fig.1 shows DSC curve from the 80%-deformed rolling sample with a heating rate of 5 ℃/min. An experimentally obtained baseline has been subtracted in order to identify the peaks. The curve has an endothermic reaction at lower temperatures (peak 2), exothermic reactions at intermediate temperatures including two overlapped peaks (peaks 3 and 4), and an endothermic reaction at higher temperatures (peak 5). It is worth noting that the peak 1 results from the system error by thermal instability at the beginning of the measurement. Therefore, the curve can be classified into three regions marked as Region Ⅰ, Region Ⅱ and Region Ⅲ, respectively. Comparison in the literature data indicates that the peak 2 is due to the dissolution of GP zone, the peak 5 is due to the dissolution of the equilibrium η phase, and the exothermic reactions in Region Ⅱ includes the formation of the metastable η′ phase, and the formation and coarsening of the η phase. According to the analysis of the DSC results, three temperatures (marked by dot-and-dash lines in Fig.1) are selected for subsequent annealing treatment to study the effect of the precipitates on PLC effect.

Fig.1 DSC curve from 80%-deformed rolling sample with heating rate of 5 ℃/min

3.2 Stress—strain curve

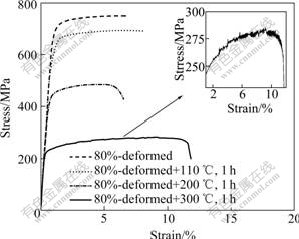

Fig.2 shows the stress—strain curves of samples under different conditions. The stress—strain curves can be classified into two groups according to their shapes. The first one shows a smooth curve for the deformed sample and the samples annealed at 110 ℃ and 200 ℃. The stress—strain curve of the second group shows that a serrated flow behavior, which is so-called the Portevin- Le Chatelier(PLC) effect, appears for the sample annealed at 300 ℃. The onset strain of serrations is about 2%. From Fig.2, it can be also seen that in group one, the deformed sample shows the highest strength due to a high dislocation density produced during the rolling deformation. The sample annealed at 110 ℃ has a little lower strength than that of the as-deformed one. The decrease of the strength may be the reason of the dissolution of small precipitates, such as GP zones. With increasing annealing temperature (annealed at 200 ℃), the strength is decreased significantly, suggesting the rearrangement of the dislocations (also called recovery) and the precipitation of large precipitates. The strength of the sample annealed at 300 ℃ is lower than that of any one in the group one, due to the complete recovery and coarsening of the precipitates at such high annealing temperature.

Fig.2 Stress—strain curves of samples under different conditions

3.3 Phase analysis

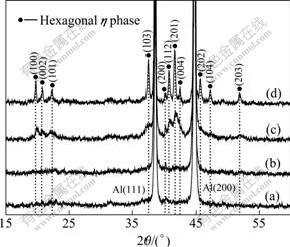

The XRD patterns of the samples before and after annealing are shown in Fig.3. In this figure, the diffraction diffraction plane indexes of the hexagonal η phase are also indicated. For the deformed sample before annealing, besides Al reflections, there appear some weak peaks at about 2θ=20? and 2θ=40?. These peaks deviate from the position of the hexagonal η phase. This deviation is contributed to the metastable hexagonal η′ phase, whose lattice parameters are a little larger than those of η phase[20-21]. ZHAO et al[22] has been reported that the broad peak at about 20? corresponds to the GP zones. Therefore, these weak peaks indicate that there exists a mixture of GP zones and η′ phase with a very small amount in the deformed sample.

Fig.3 XRD patterns of samples before and after annealing: (a) 80%-deformed; (b) 80%-deformed+110 ℃, 1 h; (c) 80%- deformed+200 ℃, 1 h; (d) 80%-deformed+300 ℃, 1 h

After annealing the deformed sample at 110 ℃ for 1 h, the GP zone peak at about 20? becomes weaker, indicating the dissolution of the GP zones. With increasing annealing temperature to 200 ℃, the η′ phase is formed. The intensities of η′ peaks between Al(111) and Al(200) increase significantly, suggesting the precipitation of a large amount of η′ phases during annealing. The small deviation of the peaks from those of η phase is still observed, indicating a mixture of η′ and η phases. For the sample annealed at 300 ℃ for 1 h, peaks of the precipitates turn sharper and move to the positions of η phase, suggesting all of the η′ phases are transformed into the η phases and η particles are coarsened, that is to say, the coarsened η phases dominate in the sample annealed at 300 ℃.

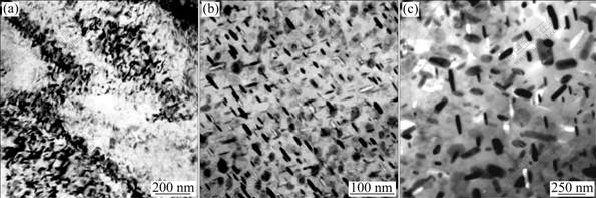

Fig.4 shows the TEM images of the samples annealed at 110, 200 and 300 ℃ for 1 h. It can be seen that the dislocation density inside grains is high when the sample is annealed at 110 ℃ for 1 h, as shown in Fig.4(a). At such low annealing temperature, only a few precipitates can be observed. When the sample is annealed at 200 ℃ for 1 h, a lager number of η′ needles with a length ranging from 3 nm to 15 nm can be observed, as shown in Fig.4(b). Some larger h needles with the length of 30 nm can be also seen in such condition. In Fig.4(c), h needles with the length of 40-80 nm and coarsened η particles larger than 100 nm can be observed after the sample is annealed at 300 ℃ for 1 h. The observations of precipitates by TEM agree well with the results from the XRD. Additionally, no high density dislocations inside grains are observed in the samples annealed at 200 and 300 ℃.

Fig.4 TEM images of samples annealed at 110 ℃(a), 200 ℃(b) and 300 ℃(c) for 1 h

4 Discussion

Results show that PLC effect appears concurrently with precipitation of coarsened η phase in this Al-Zn-Mg-Cu aluminum alloy only. According to the dislocation-solute atom interaction model, the reasons will be discussed.

It is well known that GP zones can delay the appearance of the PLC effect based on the interaction of their strain fields with alloying atoms or vacancies [8, 23]. Normally, the vacancies serve as channels for alloying atoms moving to mobile dislocations and forming an atmosphere, which favors the appearance of the PLC effect. When GP zones are present, however, they may trap vacancies as well as alloying atoms. The more the GP zones there are, the less alloying atoms will reach that destination. Therefore, PLC effect only becomes possible. Additionally, the metastable and partly coherent η′ phase can grow at a suitable temperature with vacancy cluster serving as nuclei. They are also capable of influencing the PLC effect, also by the way of binding vacancies[23]. In the present work, the precipitates in deformed sample and the samples annealed at 110 ℃ and 200 ℃ are mainly GP zones, η′ phases and the mixture of them, respectively. The GP zones and η′ phases delay the PLC effect by means of trapping vacancies. It may be the one reason for the absence of the PLC effect in these samples.

The other reason for the absence of the PLC effect may be the initial dislocation density. It is known that as the strain increases further during the tensile test, more dislocations are generated, and the interaction between the dislocations increases rapidly, resulting in more immobile dislocations and obstructing the movement of the mobile dislocations[13]. Therefore, in a material with much high initial dislocation density, once the mobile dislocations are pinned by the alloying atoms, they are more difficult to break away than those in a material without initial dislocation, resulting in the inhibition of PLC effect. This seems be the case of the deformed sample and the sample annealed at 110 ℃. For these samples, the initial dislocation density is much higher than that in the sample annealed at 300 ℃, as shown in Fig.4(a). With the strain increases during the uniaxial tensile test, the dislocation density increases further, leading to the decrease of the amount of the mobile dislocation. Additionally, the dislocations can also be obstructed by the small precipitates, GP zones and η′ phases, in these samples. According to the above discussion, it is believed that both the precipitates (including GP zones and η′ phases) and high dislocation density cause the absence of the PLC effect in the deformed sample and the samples annealed at 110 ℃ and 200 ℃.

For the sample annealed at 300 ℃ where the PLC effect has been observed, the dominate precipitates are stable η phase. Stable phases influence the PLC effect in a different way from the GP zones and η′ phases. The detailed mechanism remains unknown. But researchers [8, 23] have been pointed out that the stable phases interfere with PLC effect by affecting the type of serration and the stress drop size, but not influencing the onset strain, which indicates that there are no effective sinks for vacancies. On the other hand, after the sample is annealed at such high temperature, the initial dislocation density in the deformed sample reduces significantly and the stable phases coarsen to a large size. These all contribute to the movement of the mobile dislocations. Therefore, in terms of dislocation-solute atom interaction model, it is easy to understand the appearance of the PLC effect in sample annealed at 300 ℃. The small magnitude of stress drop in the stress—strain curve is contributed to the small amount of alloying atoms in the matrix due to the complete precipitation at such high annealing temperature.

5 Conclusions

1) In the AA 7055 aluminum alloy, the PLC effect appears in the samples annealed at 300 ℃ for 1 h after 80% cold rolling deformation, while no PLC effect is observed for the deformed sample and samples annealed at 110 ℃ and 200 ℃.

2) Different types of precipitates have different mechanisms to influence the PLC effect. GP zones and η′ phase can delay the PLC effect, whereas the PLC effect is promoted by the stable η phase.

3) High initial dislocation density can also impede the appearance of the PLC effect by means of obstructing the movement of the mobile dislocations.

References

[1] FRANKLIN S V, MERTENS F, MARDER M. Portevin-Le Chatelier effect [J]. Phys Rev E, 2000, 62(6B): 8195-8206.

[2] JIANG H F, ZHANG Q C, XU Y H, WU X P. Effect of aging on the serrated flow in Al-Cu alloys [J]. Acta Metall Sinica, 2006, 42(2): 139-142.

[3] COTTRELL A H. A note on the Portevin-Le Chatelier effect [J]. Phil Mag, 1953, 44: 829-832.

[4] SLEESWYK A W. Slow strain-hardening of ingot iron [J]. Acta Metall, 1958, 6: 598-603.

[5] WORTHINGTON P J, BRINDLEY B J. Serrated yielding in substitutional alloys [J]. Phil Mag, 1969, 19(162): 1175-1178.

[6] McCORMICK P G. A model for the Portevin-Le Chatelier effect in substitutional alloys [J]. Acta Metall, 1972, 20: 351-359.

[7] ONDERA R, ERA H, ISHIBASH T, SHIMIZU M. Effect of heat treatments on the Portevin-Le Chatelier effects in aluminum-silver alloys [J]. Acta Metall, 1983, 31(10): 1589-1593.

[8] THEVENET D, MLIHA-TOUATI M, ZEGHLOUL A. Effect of precipitation on the Portevin-Le Chatelier effect in an Al-Zn-Mg-Cu alloy [J]. Mater Sci Eng A, 1999, 266(1/2): 175-182.

[9] THEVENET D, MLIHA-TOUATI M, ZEGHLOUL A. Characteristics of the propagating deformation bands associated with the Portevin-Le Chatelier effect in an Al-Zn-Mg-Cu alloy [J]. Mater Sci Eng A, 2000, 291(1): 110-117.

[10] ABBADI M, HAHNER P, ZEGHLOUL A. On the characteristics of Portevin-Le Chatelier bands in aluminum alloy 5182 under stress-controlled and strain-controlled tensile testing [J]. Mater Sci Eng A, 2002, 337(1/2): 194-201.

[11] WEN W, MORRIS J G. An investigation of serrated yielding in 5000 series aluminum alloys [J]. Mater Sci Eng A, 2003, 354(1/2): 279-285.

[12] PENG K, CHEN W, QIAN K. Study on dynamic strain aging phenomenon of 3004 aluminum alloy [J]. Mater Sci Eng A, 2006, 415(1/2): 53-58.

[13] WEN W, MORRIS J G. The effect of cold rolling and annealing on the serrated yielding phenomenon of AA 5182 aluminum alloy [J]. Mater Sci Eng A, 2004, 373(1/2): 204-216.

[14] HALIM H, WILKINSON D S, NIEWCZAS M. The Portevin-Le Chatelier (PLC) effect and shear band formation in an AA 5754 alloy [J]. Acta Mater, 2007, 55(12): 4151-4160.

[15] JIANG H F, ZHANG Q C, WU X P, FAN J H. Spatiotemporal aspects of the Portevin-Le Chatelier effect in annealed and solution-treated aluminum alloys [J]. Scripta Mater, 2006, 54(12): 2041-2045.

[16] JIANG H F, ZHANG Q C, JIANG Z Y, CHEN Z J, WU X P. Investigation of kinematics of the Portevin-Le-Chatelier deformation bands with dynamic digital speckle pattern interferometry [J]. Chin Phys Lett, 2005, 22(1): 99-102.

[17] PINK E, BRUCKBAUER P, WEINHANDL H. Stress-drop rates in serrated flow of aluminum alloys [J]. Scripta Mater, 1998, 38(6): 945-95.

[18] PINK E, KUMAR S, TIAN B H. Serrated flow of aluminum alloys influenced by precipitates [J]. Mater Sci Eng A, 2000, 280(1): 17-24.

[19] SHEN Y Z, OH K H, LEE D N. The effect of texture on the Portevin-Le Chatelier effect in 2090 Al-Li alloy [J]. Scripta Mater, 2004, 51(4): 285-289.

[20] FERRAGUT R, SOMAZA A, TOLLEY A. Microstructural evolution of 7012 alloy during the early stages of artificial ageing [J]. Acta Mater, 1999, 47(17): 4355-4364.

[21] STILLER K, WARREN PJ, HANSEN V, ANGENETE J, GJ?NNES J. Investigation of precipitation in an Al-Zn-Mg alloy after two-step ageing treatment at 100 ℃ and 150 ℃ [J]. Mater Sci Eng A, 1999, 270(1): 55-63.

[22] ZHAO Y H, LIAO X Z, JIN Z, VALIEV R Z, ZHU Y T. Microstructures and mechanical properties of ultrafine grained 7075 Al alloy processed by ECAP and their evolutions during annealing [J]. Acta Mater, 2004, 52(15): 4589-4599.

[23] PINK E. Effect of precipitates on characteristics of serrated flow in AlZn5Mgl [J]. Acta Metall, 1989, 37(7): 1773-1781.

Foundation item: Project(2005CB23705) supported by the National Basic Research Program of China

Corresponding author: ZHEN Liang; Tel: +86-451-86412133; E-mail: lzhen@hit.edu.cn

DOI: 10.1016/S1003-6326(08)60408-2

(Edited by YANG Bing)