文章编号:1004-0609(2011)06-1229-06

镁合金铸轧凝固层焊合点控制及工艺优化

翁文凭1, 2,邓 康1,任忠鸣1,陈 琦2,迟之东2,赵奇特2

(1. 上海大学 材料科学与工程学院,上海 200072;

2. 苏州有色金属研究院有限公司 材料工艺研究所,苏州 215026)

摘 要:结合镁合金铸轧工艺特点,分析镁合金板坯铸轧过程中凝固层焊合点位置与板坯缺陷的影响规律;针对板坯厚度、铸轧区长度及铸轧速度等关键参数,简化凝壳径向生长及凝固前沿周向转动过程,确定铸轧速度匹配范围,建立凝固层焊合点位置控制模型,并通过工艺试验对控制模型进行验证。结果表明:通过理论模型确定工艺匹配范围,可稳定并优化镁合金铸轧工艺,大幅度降低铸轧板坯宏观缺陷,获得表面光洁、质量良好的镁合金铸轧板坯。

关键词:镁合金;双辊铸轧;凝固层焊合点;控制模型;工艺优化

中图分类号:TG146.2 文献标志码:A

Kiss-point of solidification layer position control and process optimization for magnesium alloys twin-roll casting

WENG Wen-ping1, 2, DENG Kang1, REN Zhong-ming1, CHEN Qi2, CHI Zhi-dong2, ZHAO Qi-te2

(1. School of Materials Science and Engineering, Shanghai University, Shanghai 200072, China;

2. Department of Materials Science and Technology, Suzhou Nonferrous Metals Research Institute,

Suzhou 215026, China)

Abstract: The effect of kiss-point position of solidification layer of twin-roll casting on macro-defects of magnesium alloys strip was analyzed through experiments and theoretical derivation. A kiss-point model which considers the strip thickness, set-back length and roll speed was established to optimize the process and enhance the surface quality of magnesium alloys strip. The results show that the model of kiss-point of solidification layer effectively stabilizes and optimizes the twin-roll casting processing, and the defect-free magnesium alloys strip is obtained by twin-roll casting.

Key words: magnesium alloys; twin-roll casting; kiss-point of solidification layer; model; process optimization

镁及镁合金为密排六方(HCP)晶体结构,其变形加工相对困难,传统工艺在制备厚度小于10 mm的镁合金薄板时,存在工序复杂、成材率低等缺点[1-2]。板带双辊铸轧工艺集凝固和变形于一体,具有投资少、流程短、成本低等优点,是镁合金薄板带制备技术发展的主流趋势[3-5]。目前,双辊铸轧技术在钢铁、铝带坯加工行业获得广泛的应用,镁合金铸轧技术集中在前期设备研制及工艺开发阶段[6-7],国内外学者也对镁合金铸轧板坯物相组成、组织特征以及后续热温轧制板带组织性能进行了一些研究[8-15],但针对镁合金铸轧板坯凝固前沿的基础研究较少。

镁合金结晶潜热小、热传导性能好,凝固过程中冷却速率大,导致镁合金铸轧工艺敏感,工艺参数匹配范围狭窄。凝固层前沿位置是铸轧工艺参数匹配情况的综合体现,铸轧工艺参数、凝固层焊合点位置及板坯宏观缺陷之间存在相互作用。在钢铁、铝铸轧领域,许多学者通过理论计算与工艺试验相结合的方法对凝固层焊合点位置开展了大量理论及工艺试验研 究[16-18],研究结果表明:铸轧区长度、铸轧速度及铸轧板坯厚度对铸轧凝固层焊合点位置起着重要作用,当铸轧区长度和板坯厚度等参数恒定时,铸轧速度显著影响凝固层焊合点位置。

根据铸轧工艺特点,本文作者针对镁合金铸轧板坯凝固前沿生长特征,建立凝固层焊合点位置控制模型,主要分析铸轧温度、冷却强度较稳定情况下,铸轧速度对凝固层焊合点位置的作用规律。通过工艺试验分析凝固层焊合点位置对板坯质量、工艺稳定性的影响规律。

1 镁合金铸轧板坯凝固过程及数理模型

1.1 镁合金铸轧板坯凝固过程

板带铸轧过程集中在狭小的铸轧区内,仅数秒钟就完成浇铸、凝固、轧制变形和出坯这一系列复杂的流变和物理化学过程[19]。铸轧带坯的凝壳从铸轧辊表面垂直向铸轧坯中心逐渐扩展,随着铸轧辊的不断旋转,热量从垂直于铸轧辊表面由冷却水连续带出,与液相线温度相一致的等温面便逐渐向熔体深处推移。对于具有一定结晶温度范围的镁合金,这个等温面相当于结晶的开始面,而等同于不平衡凝固固相线温度的等温面,则为结晶结束面,等温面与铸轧坯中心线的交点即为凝固层焊合点,也称为全凝固点。

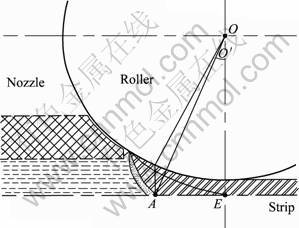

凝固层焊合点位置是双辊铸轧过程中需要控制的关键参数之一。它不仅对铸轧板坯表面质量和内部组织结构具有重要影响,而且还决定着铸轧过程能否连续进行。分析镁合金铸轧凝固前沿生长特征可知,凝固层焊合点位置必须满足两个位置极限:轧制变形咬入极限位置和辊缝中心线,其示意图如图1所示。图1中A点对应于轧制咬入极限位置时焊合点所处位置(咬入条件下对应焊合点位置),E点为辊缝中心线与板坯中心线的交点,即铸轧凝固层焊合点下限位置。

1.2 凝固层焊合点位置数理方程建立

根据镁合金铸轧板坯凝固前沿生长特点,可将凝壳生长过程简化为两个方向上的运动:熔体进入铸轧区与轧辊接触后,沿轧辊径向形成凝壳并不断沿径向长大,直到上下辊凝壳焊合,结束径向上的凝固生长过程,为径向凝壳生长过程;熔体进入铸轧区后,凝壳随轧辊在周向朝铸轧方向转动,该运动在到达凝固层焊合点后,即进入变形区,为凝壳周向移动。由于铸轧区仅仅数十毫米,远小于轧辊直径,因此将凝壳随轧辊的周向运动简化为水平运动,即周向运行位移简化为与水平分量相等。

图1 镁合金铸轧凝固层焊合点极限位置示意图

Fig.1 Schematic diagram of kiss-point position of solidification layer during twin-roll casting of magnesium alloy

据此,在铸轧区内针对凝壳生长建立如下坐标系:

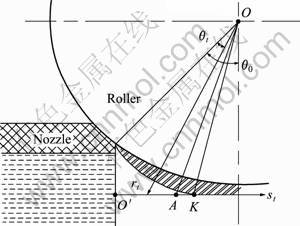

以轧辊中心为轴心,轧辊径向为坐标轴,凝壳生长方向为正方向,建立凝固层径向生长坐标系;以铸嘴出液端中心点为轴心,板坯中心线为坐标轴,板坯铸轧方向为正方向,建立凝壳水平运动坐标系。具体如图2所示。

图2 铸轧区凝固层坐标系建立

Fig.2 Coordinate system establishment for solidification layer

图2中θt为进入铸轧区熔体形成凝壳后在t时刻沿圆周方向的转动角;θ0为转动角的最大范围;rt为t时刻凝壳在径向坐标上的位置;st为t时刻凝壳在水平坐标上的位置;A点为凝固层焊合点咬入极限位置;K点为可能的凝固层焊合点位置。

在建立的坐标体系中,时间坐标以熔体进入铸轧区初始时刻为起点,两个方向的凝固前沿运动满足如下两个方程:

凝壳周向运动:

,0<st<L (1)

,0<st<L (1)

式中:v为铸轧线速度;t为熔体进入铸轧区经历凝固的时间;L为铸轧区长度。

凝壳径向生长:

(2)

(2)

式中:R为轧辊半径,在试验工况条件下为280 mm; 为凝壳在t时刻的生长厚度。

为凝壳在t时刻的生长厚度。

根据假设,铸轧区熔体仅沿垂直凝壳沿轧辊传热,凝壳径向生长满足平方根定理,则凝壳厚度满足

(3)

(3)

式中:k为凝固系数,为4.6 mm?s-1/2 [20]。

凝壳周向转动角度:

,0<

,0< <

< (4)

(4)

式中:ω为铸轧辊角速度; 参考文献[21]。

参考文献[21]。

凝固层运行至焊合点K时,存在如下几何关系:

(5)

(5)

式中:h1为辊缝厚度。

联立式(1)~(5),可对凝固层焊合点位置进行数理计算。

1.3 镁合金板坯铸轧凝固前沿控制模型

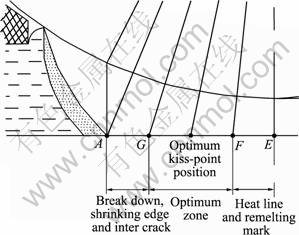

理想情况下,试验人员可通过大量炉次的试验,收集足够多的数据,并按试验结果绘制出凝固层焊合点位置不同区域实际图形,与板坯质量进行对应分析,从而绘制出凝固层焊合点优化区域。但该方法耗时长、投资大,为缩短研发周期,采用二分法将咬入极限位置至辊缝中心线位置等分为4个区域,假定当凝固层焊合点对应在中点位置时,对应最佳工艺,据此可认为靠近最佳工艺点左右两侧区域为工艺优化区域,如图3所示。

对图中铸轧变形区几何关系进行推导,可知

式中:LAE为凝固层焊合点位置范围;L为铸轧区长度。

而工艺优化区边界点F和G点对应的变形区长度分别为

图3 凝固层焊合点位置控制区域

Fig.3 Optimum zone of kiss-point of solidification layer

当板坯厚度和铸轧区长度一定时,铸轧速度需设置在如下范围,方可控制凝固层焊合点在工艺优化区域内。因此,建立凝固层焊合点控制模型如下:

(6)

(6)

2 试验方案的验证

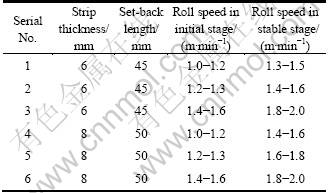

为验证凝固层焊合点控制模型的实际效果,设计工艺试验方案如表1所列。在板坯厚度、铸轧区长度固定的情况下,调整铸轧速度进行工艺试验,考察凝固层焊合点位置变化规律,并分析不同情况下铸轧板坯缺陷及宏观形貌。为排除偶然因素,每组试验进行两次重复试验。

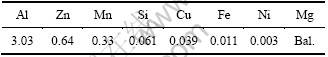

试验原料为商用AZ31合金锭,铸轧板坯化学成分检测结果如表2所列。试验主要设备包括d 560 mm×600 mm镁合金铸轧机、800 kg镁合金熔保炉以及辅助剪切、卷取等设备。试验流程为原材料及辅助工具准备—镁合金熔炼、静置—铸嘴装配—轧机启动及系统预热—参数设置与安全检查—熔体浇注—铸轧立板—稳定铸轧—铸轧板坯切头—铸轧板坯穿带—卷取—铸轧结束及清理。试验中熔保炉浇注温度控制在710~720 ℃范围内。

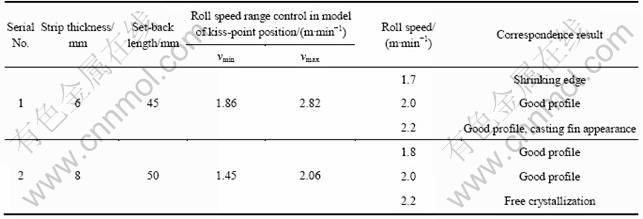

表1 镁合金铸轧试验方案

Table 1 Experimental parameters of magnesium alloys twin-roll casting

表2 镁合金铸轧板坯的化学成分

Table 2 Chemical composition of magnesium alloys strip obtained by twin-roll casting (mass fraction, %)

3 结果与分析

3.1 试验结果

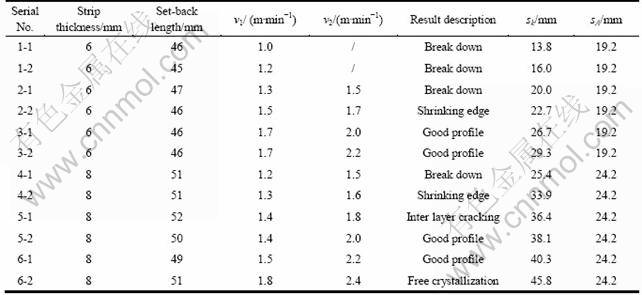

镁合金铸轧试验实际工艺参数记录及试验结果简述如表3所列。将试验方案中板坯厚度、铸轧区长度及铸轧速度等试验工况条件代入1.2节方程组,计算出不同试验方案下凝固层焊合点理论计算值sk,以及咬入极限值sA (sA=Rtanθ0)。理论计算忽略实际操作中铸轧区长度调整差异,均采用45和50 mm进行计算;仅立板阶段铸轧速度v1,尚未进入稳定阶段,因此稳定铸轧速度v2无法读取,凝固层焊合点sk速度按立板阶段速度计算。具体结果如表3所列。

3.2 讨论分析

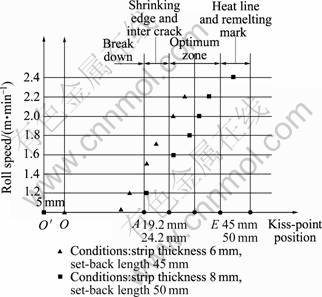

结合表4数理计算及试验结果,以铸嘴出液端为原点,板坯中心线为横坐标,铸轧速度为纵坐标,可绘制试验条件下凝固层焊合点位置与试验结果汇总图如图4所示。图4所示为不同铸轧速度、板坯厚度条件下铸轧板坯凝固层焊合点位置理论计算值,以及相应工况条件下板坯表面出现缺陷的情况。坐标原点O对应板坯厚度6 mm,铸轧长度45 mm的试验结果;坐标原点O′ 对应板坯厚度8 mm,铸轧区长度50 mm的试验结果;凝固层焊合点在铸轧区不同位置时对应铸轧板坯表面缺陷特征(标注在图上方)。从图4可以看出,当铸轧板坯厚度、铸轧区长度一定时,当铸轧速度越快,凝固层焊合点位置向辊缝中心线方向偏移,铸轧区中变形区长度逐渐缩小,此时铸轧板坯轧卡、冷凝块及横向裂纹缺陷逐渐消除,板坯表面质量逐步提高;当铸轧速度进一步提高时,板坯又会出现热带、孔洞、表面氧化及拉漏等缺陷。根据凝固层焊合点位置控制模型,针对前期试验工况,计算铸轧速度控制范围,其结果如表4所列。

上述分析表明,通过凝固层焊合点控制模型,固定板坯厚度与铸轧区长度后,可计算出铸轧速度理论匹配范围;根据理论匹配范围结果,控制速度在优化范围时,铸轧工艺稳定性及板坯质量均得到大幅度提高,验证理论计算模型,计算结果与实际试验基本吻合。表4中8 mm板坯,铸轧区长度50 mm时,设置铸轧速度为2.0 m/min条件下,其板坯的宏观照片如图5所示。

表3 试验结果及凝固层焊合点位置

Table 3 Experimental results and kiss-point position of solidification layer

表4 镁合金工艺优化计算结果

Table 4 Optimized parameters of magnesium alloys twin-roll casting though model

图4 不同工况下凝固层焊合点位置及板坯质量

Fig.4 Kiss-point position of solidification layer and strip quality under different conditions (O—Strip thickness 6 mm, setback length 45 mm; O′—Strip thickness 8 mm, setback length 50 mm; A—Kiss-point of griping condition of rolling; E—Kiss-point of roll nip)

图5 优化工艺下镁合金铸轧板坯

Fig.5 Magnesium alloys strip processed by optimized process parameters

4 结论

1) 镁合金铸轧过程中,凝固层焊合点位置是铸轧工艺参数匹配状况的综合体现,对铸轧板坯质量产生显著影响。当凝固层焊合点靠近咬入极限点时,板坯倾向出现轧卡、冷凝块、横向裂纹及缩边等缺陷;当凝固层焊合点靠近辊缝中心线时,铸轧板坯倾向出现热带、孔洞及拉漏缺陷。

2) 当铸轧区长度、板坯厚度一定时,铸轧速度应严格满足匹配条件,可控制凝固层焊合点位置位于优化区域。控制模型为

。

。

3) 建立理论模型主要针对镁合金铸轧板坯宏观缺陷考虑,而对于镁合金铸轧板坯的微观组织优化、成分偏析缺陷控制存在局限性。后期需通过大量炉次工艺试验,进行数据整理、归纳及总结,进一步对本研究模型进行优化,从而达到控制微观组织、全面提升板坯力学性能的目的。

REFERENCES

[1] ANDO S, TANAKA M, TONDA H. Pyramidal slip in magnesium alloy single crystals[J]. Materials Science Forum, 2003, 419/422: 87-92.

[2] 张青来, 卢 晨, 朱燕平, 丁文江, 贺继泓. 轧制方式对AZ31镁合金薄板组织和性能的影响[J]. 中国有色金属学报, 2004, 14(3): 391-396.

ZHANG Qing-lai, LIU Chen, ZHU Yan-ping, DING Wen-jiang, HE Ji-hong. Effect of rolling method on microstructure and properties of AZ31 magnesium alloy thin sheet[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(3): 391-396.

[3] LIANG D, COWLEY C B. The twin-roll strip casting of magnesium alloys[J]. Journal of the Minerals, Metal & Materials Society, 2004, 56(5): 26-28.

[4] PARK S S, LEE J G, PARK Y S, KIM N J. Fabrication of Mg alloy strips by strip casting[J]. Materials Science Forum, 2003, 419/422: 509-514.

[5] WATARI H, KOGA N, PAISARN R. Formability of magnesium alloy sheets manufactured by semi-solid roll strip casting[J]. Materials Science Forum, 2004, 449/452: 181-184.

[6] KAWALLA R, OSWAKD M, SCHMIDT C, ULLMANN M. New technology for the production of magnesium strips and sheets[J]. Metalurgija, 2008, 47(3): 195-198.

[7] 王广山, 邸洪双, 黄 锋. 立式双辊铸轧AZ31镁合金薄带试验研究[J]. 铸造, 2009, 58(4): 322-325.

WANG Guang-shan, DI Hong-shuang, HUANG Feng. Experimental study on vertical twin-roll casting of magnesium alloys strip[J]. Foundry, 2009, 58(4): 322-325.

[8] 娄花芬, 汪明朴, 唐 宁, 李 周, 郭明星, 雷 前. AZ31B镁合金的铸轧组织及其相关变形机制[J]. 中国有色金属学报, 2008, 18(9): 1584-1589.

LOU Hua-fen, WANG Ming-pu, TANG Ning, LI Zhou, GUO Ming-xing, LEI Qian. Microstructures of twin-roll cast AZ31B Mg alloy and its deformation mechanism[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(9): 1584-1589.

[9] 许光明, 王栋刚, 崔建忠. 热轧工艺对AZ61镁合金铸轧板显微组织的影响[J]. 特种铸造及有色合金, 2009, 29(2): 115-116.

XU Guang-ming, WANG Dong-gang, CUI Jian-zhong. Microstructure evolution of hot rolled AZ61 magnesium alloy strip[J]. Special Casting & Nonferrous Alloys, 2009, 29(2): 115-116.

[10] 赵 虎, 李培杰, 何良菊. AZ31镁合金铸轧和常规轧制板的变形组织及形变特征[J]. 中国有色金属学报, 2009, 19(11): 1887-1893.

ZHAO Hu, LI Pei-jie, HE Liang-ju. Deformation microstructure and characteristics of cast-rolling and normal rolling AZ31 magnesium alloy sheets[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(11): 1887-1893.

[11] 张 莹, 赵海波, 谢水生, 耿茂鹏, 郭洪民, 徐金华. AZ91D镁合金流变铸轧板材微观组织分析[J]. 兵器材料科学与工程, 2009, 32(4): 12-15.

ZHANG Ying, ZHAO Hai-bo, XIE Shui-sheng, GENG Mao-peng, GUO Hong-ming, XU Jin-hua. Analysis on microstructure of rheoroll-casting semi-solid AZ91D magnesium alloy[J]. Ordnance Material Science and Engineering, 2009, 32(4): 12-15.

[12] 唐 宁, 汪明朴, 娄花芬, 李 周, 郭明星, 雷 前. 双辊铸轧AZ31镁合金板坯的物相分析[J]. 中国有色金属学报, 2009, 19(3): 433-438.

TANG Ning, WANG Ming-pu, LOU Hua-fen, LI Zhou, GUO Ming-xing, LEI Qian. Phases analysis of twin-roll casting AZ31 Mg alloy plate blank[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(3): 433-438.

[13] 程尚栩, 杨湘杰, 郭洪民, 谢水生. 流变铸轧AZ91D镁合金半固态组织演变特点[J]. 特种铸造及有色合金, 2009, 29(11): 1016-1018.

CHENG Shang-xu, YANG Xiang-jie, GUO Hong-min, XIE Shui-sheng. Evolution of microstructural characteristics of rheo-rolling semi-solid AZ91D magnesium alloy[J]. Special Casting & Nonferrous Alloys, 2009, 29(11): 1016-1018.

[14] 王广山, 邸洪双, 黄 峰. 立式双辊铸轧镁合金薄带微观组织分析[J]. 特种铸造及有色合金, 2009, 29(9): 792-794.

WANG Guang-shan, DI Hong-shuang, HUANG Feng. Microstructure of vertical twin-rolling casting magnesium alloy[J]. Special Casting & Nonferrous Alloys, 2009, 29(9): 792-794.

[15] LIU Zhi-min, XING Shu-ming, BAO Pei-wei, LI Nan, YAO Shu-qing, ZHANG Mi-lan. Characteristics of hot tensile deformation and microstructure evolution of twin-roll cast AZ31B magnesium alloys[J]. Transactions of Nonferrous Metals Society of China, 2010, 20: 776-782.

[16] 张 璋. 超薄快速铸轧的凝固前沿计算及应用研究[D]. 长沙: 中南大学, 2004: 15-27.

ZHANG Zhang. Liquid-solid joint computing and application research of super-thin fast speed casting[D]. Changsha: Central South University, 2004: 15-27.

[17] 邱以清, 刘振宇, 刘相华, 王国栋. 双辊铸轧凝固层焊合点位置判别式的研究[J]. 东北大学学报: 自然科学版, 2007, 28(1): 60-62.

QIU Yi-qing, LIU Zhen-yu, LIU Xiang-hua, WANG Guo-dong. Study on discriminant for position of welding point of solidification layer during twin-roll casting[J]. Journal of Northeastern University: Natural Science, 2007, 28(1): 60-62.

[18] 彭成章, 宋 昕, 王文明, 胡忠举, 黄明辉. 铸轧速度对液态金属凝固行为的影响[J]. 湘潭矿业学院学报, 2003, 18(4): 35-37.

PENG Cheng-zhang, SONG Xin, WANG Wen-ming, HU Zhong-ju, HUANG Min-hui. Effect of casting speed on solidification behavior of liquid metal in twin-roller casting process[J]. Journal of Xiangtan Mineral Institute, 2003, 18(4): 35-37.

[19] SUN Bin-yu, YUAN Shi-jian, ZHANG Hong, DU Yan-ping, ZHANG Fang-ping. Establishment of mathematical moment model in twin casting rolling rolls[J]. Transactions of Nonferrous Metals Society of China, 2002, 12(5): 970-973.

[20] 陈平昌, 朱六妹, 李 赞. 材料成形原理[M]. 北京: 机械工业出版社, 2001: 50-51.

CHEN Ping-chang, ZHU Liu-mei, LI Zhan. Principle of materials processing[M]. Beijing: China Machine Press, 2001: 50-51.

[21] 曹鸿德. 塑性变形力学基础与轧制原理[M]. 北京: 机械工业出版社, 1981: 210-211.

CAO Hong-de. Rolling principles and fundamental mechanics of plastic deformation[M]. Beijing: China Machine Press,, 1981: 210-211.

(编辑 李艳红)

基金项目:江苏省自然科学基金资助项目(BK2010249);中色科技股份有限公司科技发展计划基金(2008YK02)

收稿日期:2010-06-03;修订日期:2010-11-20

通信作者:邓康,教授,博士;电话:021-56331102;E-mail: dengk2000@163.com