文章编号:1004-0609(2013)S1-s0368-06

基于CAE技术的TB5钛合金V形波纹管结构优化设计

邱晓星,王英浩,唐 斌,程 亮,寇宏超,李金山

(西北工业大学 凝固技术国家重点实验室,西安 710072)

摘 要:采用线弹性有限元方法对TB5钛合金V形波纹管在轴向均布载荷作用下变形过程与应力分布进行了模拟分析,总结了不同结构参数对波纹管结构刚度与应力分布的影响规律,并据此对TB5钛合金V形波纹管结构设计进行了优化。分析结果表明:波纹管结构刚度随波纹管V形夹角、内径增大而增大,随波数增多而降低;波纹管径向应力分布随壁厚、V形夹角增大而趋于均匀,而波高增大导致径向应力分布均匀性降低;结构优化波纹管(波数为10,内径为80 mm)结构刚度为1 127.22 N/mm,在1 MPa均布载荷作用下,波峰外表面应力值为220.37 MPa,波谷处内侧为278.54 MPa。

关键词:TB5钛合金;线弹性有限元方法;V形波纹管;优化设计;数值模拟

中图分类号:TG47 文献标志码:A

Structural optimization of V-shaped TB5 titanium alloy metal bellow based on CAE technology

QIU Xiao-xing, WANG Ying-hao, TANG Bin, CHENG Liang, KOU Hong-chao, LI Jin-shan

(State Key Laboratory of Solidification Processing, Northwestern Polytechnical University, Xi’an 710072, China)

Abstract: Deformation process and stress distribution of TB5 titanium alloy bellow under evenly-distributed axial load was discussed via linear elasticity finite element method. The influences of structural parameters (inner diameter, thickness, V-shaped angle, wave number, wave height) on the stiffness and the stress distribution of the V-shaped bellow were summarized. The results show that the increase of thickness and V-shaped angle can homogenize the stress distribution while wave height has the opposite impact. The stiffness of the metal bellow rises when V-shaped angle and thickness go up and decreases as wave number increases. A group of optimized parameters are obtained according to the results under the condition that the wave number is 10 and the inner diameter is 80 mm. The stiffness of the optimized structure is 1 127.22 N/mm. The stress at the outer surface of the peak is 220.37 MPa while 278.54 MPa at the inner surface of the trough when an evenly-distributed axial pressure (1 MPa) is loaded.

Key words: TB5 titanium alloy; linear elasticity finite element method; V-shaped metal bellow; optimization design; numerical simulation

TB5是一种新型的亚稳β钛合金,具有比强度高、耐腐蚀性强、弹性模量小、铸造及冷成形性能优异等特点,因而在飞行器中常用于制造托架、紧固件、压缩空气管道等零件[1]。

波纹管是一种母线呈波浪形的回转薄壁壳体,具有较大的柔性和很高的抗疲劳性能[2-4]。而钛合金V形波纹管是一种航空航天中应用广泛的管路补偿器件,具有稳定性好、刚度可调、位移补偿量大、减振降噪能力强等特点。但由于其结构参数较多,设计过程复杂,成形过程更涉及扩散连接、应力松弛成形以及抗疲劳表面处理等技术,因而有必要对其进行研究。

近年来,随着计算机技术的快速发展,有限元方法的使用日益广泛[5-9]。通过使用有限元分析软件对波纹管的载荷-应力响应问题进行模拟,其计算结果与实验数据得到了较好的吻合[2-3, 10-11]。同时,根据其模拟结果可以预测波纹管可能的失效位置及其失效形式,对于工程实际有较好的指导意义。

作者采用线弹性有限元方法研究TB5钛合金V形波纹管在轴向均布载荷作用下的变形过程,得到V形波纹管结构参数对其结构刚度与应力分布的影响规律,并对V形波纹管结构参数进行优化。

1 有限元模型建立

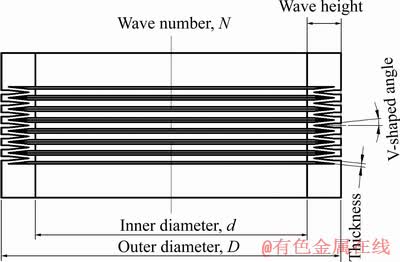

本文中考虑的波纹管的结构参数为内径、波纹管壁厚、V形夹角、波数和波高,如图1所示。

图1 V形波纹管的结构参数

Fig. 1 Structural parameters of V-shaped metal bellow

采用线弹性模型,材料为TB5钛合金,其弹性模量为110 GPa,泊松比为0.3。载荷形式是位于波纹管上表面的1 MPa均布载荷,通过模拟波纹管在载荷作用下轴向的位移变形,查看其沿波纹管径向的应力分布情况,并根据其轴向位移可以测出其刚度。网格划分采用中性轴算法,单元类型为8节点六面体线性减缩积分单元。

2 V形波纹管结构参数变化对其应力分布的影响

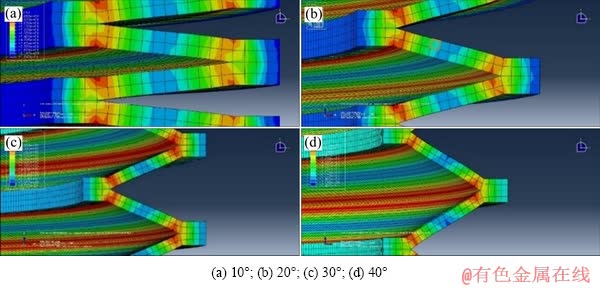

V形波纹管径向应力分布随V形夹角的变化如图2所示。当V形夹角从10°增大至40°时,V形波纹管径向的应力分布逐渐趋于均匀,波峰外壁处的应力集中现象逐渐消失,而在内壁处产生了应力集中。其变化原因是随着波纹管V形夹角的增大,在波高不变的情况下,波纹管的管壁部分径向长度增大,承受的载荷也相应增大,使得在波峰和波谷处的应力集中现象得到缓解;同时,由于波纹管管壁径向长度增大,管壁的柔度也相应增大,在轴向载荷作用下,波纹管管壁发生屈曲变形,因而,在波峰处应力集中的位置由外壁转移至了内壁。

图2 V形夹角对V形波纹管应力分布的影响

Fig. 2 Influence of V-shaped angle on stress distribution of metal bellow

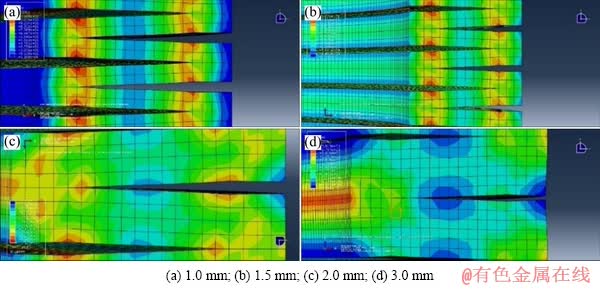

V形波纹管的径向应力分布随壁厚的变化如图3所示。壁厚增大在一定程度上使得波纹管径向应力分布变得均匀。在壁厚由1.0 mm增大至1.5 mm时,V形波纹管应力分布变得更为均匀;继续增加壁厚,波纹管的应力分布均匀性变化不大,但应力集中位置由波峰处外壁和波谷处内壁逐渐转移至波纹管的连接处;当波纹管的壁厚达到3.0 mm时,波纹管的应力集中部位位于波纹管的连接处正中,且为拉应力。增大壁厚使得波纹管波谷中部和管壁部分强度相接近,应力分布变得均匀,但当壁厚增大至焊缝宽度以上时,承载后,由于管壁强度、刚度较高,波谷中部则为相对薄弱位置,刚度较小,因而波谷内壁中部处变形量相对较大,应力集中变得明显。

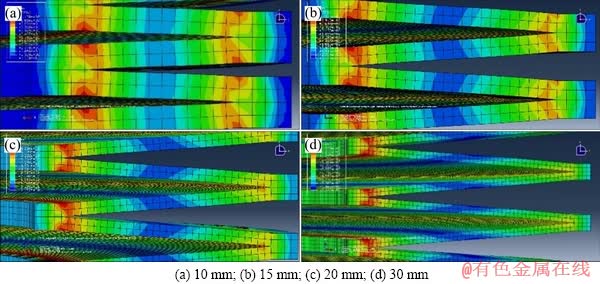

波高对波纹管应力分布的影响如图4所示。波高的增大使得波纹管在波谷处应力集中变得更加严重,波峰处的应力集中程度则逐渐减小。当波高为10 mm左右时,径向应力分布相对较为均匀。随着波高的增大,波纹管径向应力分布变得不均匀,当波高增至30 mm时,波谷处的最大应力达到1 370 MPa,超过了材料本身的屈服强度。因此,波高过大使得波纹管易在波谷处发生失效。产生这一现象的原因在于波高增大一方面使得波纹管的表面积增大,在承受均布载荷时合力增大;另一方面,在相同的力的作用下,波纹管波谷波峰处的力矩加大;因而,两种作用相互叠加,波纹管在波峰和波谷处的应力增大。同时,波纹管在承受轴向均布载荷时,其合力方向与波纹管的轴线存在一定的偏角,使得波纹管波峰处和波谷处变形程度不同,因而,波纹管在波谷处产生拉应力,在波峰处产生压应力。波峰处的压应力和轴向变形产生的拉应力相互抵消,使得波峰处的应力集中程度减小;波谷处的拉应力和轴向变形的拉应力相互叠加,使得波谷处的应力集中更为严重。

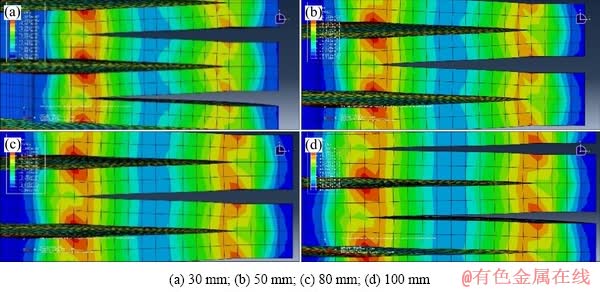

在波高值不变的情况下,波纹管的应力分布随波纹管内径的变化如图5所示。当内径为30 mm时,波纹管的应力集中位于波谷处;随着波纹管内径的增大,波纹管波峰处的应力集中开始变得显著。当波纹管的内径变为100 mm时,波峰和波谷处的应力集中相对较为接近,但波谷内壁的应力集中始终大于波峰外壁的。其原因为:在均布载荷作用下,V形波纹管的受力和轴线存在偏差,内径较小时,波纹管波谷处轴向刚度较小,因而变形量增大,波谷处应力集中也就较为明显;当波纹管的内径增大时,轴向刚度增大,变形量减小,应力值也就相应减小,分布也较为均匀。

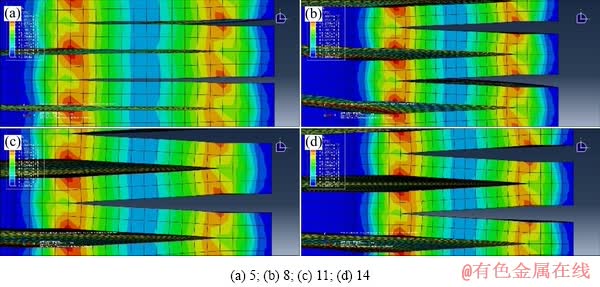

波数变化对波纹管应力分布的影响如图6所示。可以看到,波数对应力分布无明显影响。

图3 壁厚对V形波纹管应力分布的影响

Fig. 3 Influence of thickness on stress distribution of V-shaped metal bellow

图4 波高对V形波纹管应力分布的影响

Fig. 4 Influence of wave height on stress distribution of V-shaped metal bellow

图5 波高不变时波纹管内径对其应力分布的影响

Fig. 5 Influence of inner diameter on stress distribution of metal bellow

图6 波纹管波数对其应力分布的影响

Fig. 6 Influence of wave number on stress distribution of metal bellow

3 V形波纹管结构参数变化对其刚度的影响

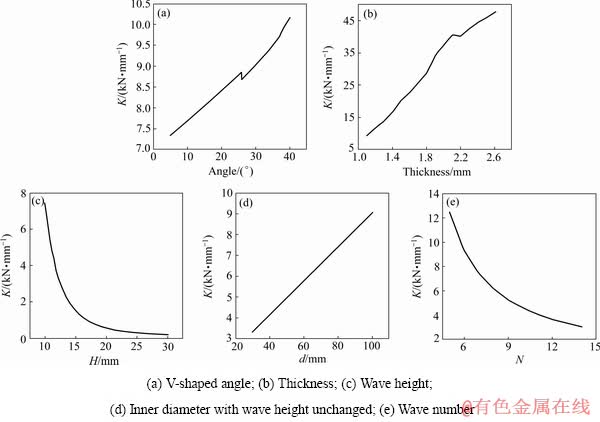

V形波纹管刚度随V形夹角变化如图7(a)所示。可以看到,当角度小于25.9°时,刚度和角度呈现高度线性关系。但在26°时,刚度发生突变,随后,刚度随着V形夹角的增大继续增大,但是,线性程度下降。这是由于在角度增大之后,随着波纹管管壁承受轴向载荷增大,载荷方向和轴线之间并不重合,波纹管管壁受力发生失稳,在承受相同的载荷条件下管壁发生屈曲变形,变形量增大,使得刚度首次发生突变。进一步增大V形夹角至37°时,波纹管的径向屈曲变形更为严重,刚度再一次发生突变。变形失稳对于波纹管十分不利,应当尽量避免V形夹角的大小处于波纹管失稳的范围内。

V形波纹管的刚度和其壁厚之间的关系如图7(b)所示。由图可知,壁厚增大使得波纹管的刚度也相应增大,柔度下降。因为在相同的载荷下,厚度增大使得波纹管的截面面积和截面二次极矩增大,该处的应力相应减小,变形量降低。与此同时,在相同载荷条件下,最大应力减小,同时,总体轴向位移量也相对减小,刚度增大。

波高对波纹管刚度的影响如图7(c)所示。可以看到,刚度和波高呈指数关系。当波高增大时,在相同的载荷条件下,连接处的力矩将相应增大,该处表面的拉应力也将增大,根据Hooke定律,变形量相应上升,总体刚度相应减小。但当波高在20 mm左右时,V形波纹管刚度随波高下降变得较为平缓。但是,波高增大使得波纹管连接处应力集中变得严重,容易产生裂纹,因此,实际设计时波高不宜过大。

图7 V形波纹管结构参数和其刚度之间关系

Fig. 7 Influence of structural parameters on stiffness of V-shaped metal bellow

波高不变,单独改变波纹管的内径,波纹管的刚度随内径变化如图7(d)所示。由图可知,在波高不变时,V形波纹管刚度随内径增大呈线性增大趋势。其原因在于,波高、V形夹角、波数不变,则波纹管的截面形状和面积都不发生变化。设波纹管的截面积为S,将其等效为无限小截面的组合,则每一个截面的刚度为一个定值k0。波纹管的整体刚度可以表示为

(1)

(1)

式中:h为V形波纹管的波高,mm,此处设定为一个定值;d为V形波纹管的内径,mm。可以看出,V形波纹管在固定波高时,波纹管的刚度和内径呈线性关系。但在实际应用中,波纹管的内径增大可能会发生变形上的改变,因此需要进行一些修正。

波数对波纹管刚度的影响如图7(e)所示。由于波纹管承受的载荷和波纹管的轴线存在一定的偏差,波纹管的变形存在着一定的失稳现象,故在相同的载荷下,刚度和波数之间不是严格的反比关系。当波数为5左右时,波纹管刚度随波数下降十分明显;而当波数大于10,波纹管的刚度随波数增大下降并不明显。但总体而言,波纹管的刚度随波数增大而下降。实际设计中,波纹管的波数不宜过大,否则波纹管变形量过大,易发生变形失稳。

4 结论

1) 通过模拟不同结构参数的V形波纹管在受轴向均布载荷时的变形行为,得到管壁径向应力的分布规律。研究结果表明:壁厚、V形夹角增大使得波纹管管壁径向的应力分布更为均匀。波高增大使得波纹管管壁径向的应力分布更为不均匀;当固定波高为一个定值时,随着波纹管内径的增大,波峰、波谷两处应力集中现象逐渐接近。波纹管波数变化对波纹管径向应力分布几乎无影响。

2) 分析了不同截面尺寸参数的V形波纹管的刚度,得出刚度随截面尺寸参数之间的变化规律。结果表明,V形夹角、壁厚增大对波纹管刚度的影响规律不同,但总体趋势都是随其增大而增大。波高增大使得波纹管的刚度呈指数下降。在固定波高不变时,波纹管的刚度随内径、外径增大呈现线性增大的特征,而波数增大使得波纹管的刚度下降,但二者不是严格的反比关系。

3) 根据以上结果,得到一组优化的内径为80 mm,波数为10的V形波纹管结构参数:V形夹角5°,壁厚1.5 mm,波高20 mm,内径80 mm,外径120 mm。经ABAQUS模拟可得,其刚度为1 127.22 N/mm,承载1 MPa时波峰外表面应力为220.37 MPa,波谷处内侧应力为278.54 MPa,二者较为接近,应力分布相对均匀。

REFERENCES

[1] 王洪涛. TB5钛合金高温变形行为与微观组织演变研究[D]. 沈阳: 东北大学, 2011.

WANG Hong-tao. Study on high temperature deformation behavior and evolution of the microstructure of TB5 titanium alloy[D]. Shenyang: Northeastern University, 2011.

[2] 陈 晔, 李永生, 顾伯勤, 刘艳江, 段 玫, 常 谦. 用ANSYS软件对U形波纹管的有限元分析[J]. 压力容器, 2000, 17(3): 34-36.

CHEN Ye, LI Yong-sheng, GU Bo-qin, LIU Yan-jiang, DUAN Mei, CHANG Qian. The finite element analysis to the U-shape bellows by the ANSYS program[J]. Pressure Vessel Technology, 2000, 17(3): 34-36.

[3] 李永生, 李建国. 波形膨胀节实用技术——设计、制造与应用[M]. 北京: 化学工业出版社, 2000: 1-70.

LI Yong-sheng, LI Jian-guo. Bellows expansion joint and practical technology—Design, manufacture and application[M]. Beijing: Chemical Industry Press, 2000: 1-70.

[4] 王 斌, 许 沂, 雷 鹍. 钛合金叠形波纹管的设计和制造[J]. 航空制造技术, 2011, 16: 60-65.

WANG Bin, XU Yi, LEI Kun. Design and manufacturing of TA15 titanium alloy V-shaped bellows[J]. Aeronautical Manufacturing Technology, 2011, 16: 60-65.

[5] SEKULSKI Z. Multi-objective topology and size optimization of high-speed vehicle-passenger catamaran structure by genetic algorithm[J]. Marine Structures, 2010, 23(4): 405-433.

[6] KIM H, QUERIN O M, STEVEN G P. On the development of structural optimization and its relevance in engineering design[J]. Design Studies, 2002, 23(1): 85-102.

[7] 张清卫. 基于ANSYS的钢框架结构优化设计研究与软件开发[D]. 天津: 天津大学, 2004: 1-27.

ZHANG Qing-wei. Study on structure optimal design and software development for steel frame based on ANSYS[D]. Tianjin: Tianjin University, 2004: 1-27.

[8] 王勖成. 有限单元法[M]. 北京: 清华大学出版社, 2003: 1-13.

WANG Xu-cheng. Finite element method[M]. Beijing: Tsinghua University Press, 2003: 1-13.

[9] 庄 茁, 由小川, 廖剑辉. 基于ABAQUS的有限元分析和应用[M]. 北京: 清华大学出版社, 2009: 3-47.

ZHUANG Zhuo, YOU Xiao-chuan, LIAO Jian-hui. Finite element method analysis and application based on ABAQUS[M]. Beijing: Tsinghua University Press, 2009: 3-47.

[10] 于 颖, 李永生, 於孝春, 胡 毅, 陈立苏. 波纹管的结构优化设计[J]. 压力容器, 2005, 22(12): 22-24.

YU Ying, LI Yong-sheng, YU Xiao-chun, HU Yi, CHEN Li-su. The structure optimization design of bellow[J]. Pressure Vessel Technology, 2005, 22(12): 22-24.

[11] 石亦平, 周玉蓉. ABAQUS有限元分析实例详解[M]. 北京: 机械工业出版社, 2006: 1-63.

SHI Yi-ping, ZHOU Yu-rong. ABAQUS finite element method example explanation[M]. Beijing: China Machine Press, 2006: 1-63.

[12] 曹金凤, 王旭春, 孔 亮. Python语言在Abaqus中的应用[M]. 北京: 机械工业出版社, 2011: 13-200.

CAO Jin-feng, WANG Xu-chun, KONG Liang. The application of Python in Abaqus[M]. Beijing: China Machine Press, 2011: 13-200.

[13] HEDAND M H. Python基础教程[M]. 北京: 人民邮电出版社, 2010: 1-160.

HEDAND M H. Beginning Python from novice to professional[M]. Beijing: Posts & Telecom Press, 2010: 1-160.

[14] 2008 GB/T 12777—2008. 金属波纹管膨胀节通用技术条件[S].

2008 GB/T 12777—2008. General specification for metal bellows expansion joints[S].

(编辑 杨 兵)

基金项目:凝固技术国家重点实验室自主课题资助项目(62-TP-2011)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:唐 斌,讲师,博士;电话:13991965416;E-mail: toby@nwpu.edu.cn