DOI: 10.11817/j.issn.1672-7207.2018.11.005

超声塑化对聚合物熔融指数的影响

蒋炳炎,邹洋,刘弢,张英平,吴旺青

(中南大学 高性能复杂制造国家重点实验室,湖南 长沙,410083)

摘要:为量化研究超声塑化对聚合物流动性能的影响,研制超声塑化熔融指数检测装置,以PMMA(聚甲基丙烯酸甲酯)、PP(聚丙烯)、PA66(聚酰胺66)为研究对象,得到超声塑化工艺参数及超声振动外场对聚合物熔融指数的影响规律。研究结果表明:超声塑化能够永久增强聚合物流动性能,增大超声振幅、塑化压力和塑化时间可提高聚合物熔融指数;超声塑化对PMMA,PP和PA66流动性能影响程度不同,聚合物熔融指数增大率从大至小依次为PMMA,PP和PA66;低强度超声振动外场能够小幅度提高聚合物熔融指数,由此产生的流动性能改变可恢复。

关键词:超声塑化;聚合物;熔融指数;超声振动外场

中图分类号:TQ320.66 文献标志码:A 文章编号:1672-7207(2018)11-2670-07

Effect of ultrasonic plasticization on melt mass-flow rate of polymers

JIANG Bingyan, ZOU Yang, LIU Tao, ZHANG Yingping, WU Wangqing

(State Key Laboratory of High Performance Complex Manufacturing, Central South University, Changsha 410083, China)

Abstract: To quantitatively research the effect of ultrasound plasticization parameters on polymer flow properties, an ultrasound melt mass-flow rate(MFR) detection device was established to obtain the MFR of the polymethyl methacrylate(PMMA), polypropylene(PP) and nylon66(PA66) under different process parameters and ultrasound field conditions. The results show that ultrasonic plasticization can permanently enhance the flow properties of polymers. Increasing ultrasonic amplitude, and plasticizing pressure and time can increase melt index of the polymer. The sensitivity of different kinds of polymers to ultrasound plasticization is different, and the growth rate of MFR from high to low is PMMA, PP and PA66. Under the influence of low-intensity ultrasound vibration field, the flowability of polymer melt increases slightly and changes reversibly.

Key words: ultrasound plasticization; polymer; melt mass flow rate; ultrasonic vibration field

微纳制造技术正成为世界关注的焦点。微注射成型因具有低生产成本、高成型精度和易于自动化生产等优点而成为微纳制造关键技术之一[1-2]。常规微注射成型机多采用螺杆塑化方式,存在流道过大、单次塑化量过多等缺点,材料浪费严重,对大批量注射成型的负面影响不容忽视[3-4]。超声塑化是MICHAELI等[5]提出的新型微注射成型方法,具有原材料消耗少、成型时间短、不易热降解等优点,可以解决很多常规注塑方式存在的问题[6-7]。超声塑化时,工具头的高频振动使聚合物熔体出现超声空化[8-9]和诱导声流[9]现象,对聚合物的微观组织、形态演变及流动性能产生一定影响。为了获得最佳充填效果与制件质量,有必要研究超声塑化工艺参数对聚合物熔体流动性能的影响规律。LI等[10]通过实验发现超声振动频率、功率及作用时间对聚合物熔点、熔体黏度、相对分子质量等有显著影响;SACRIST N等[11-13]研究了超声塑化对聚乳酸(PLA)、聚酰胺(PA)、聚苯砜(PPSV)、超高分子量聚乙烯(UHMWPE)熔融塑化均匀性的影响,发现超声振幅及塑化压力是影响均匀性的关键参数。LEE等[14-15]研究了超声波振动辅助充填,发现合适的模具振型、振动频率、超声振幅能有效改善充填效果;SATO等[16-18]通过实验研究了辅助超声振动外场对注射/挤出成型工艺的影响,发现超声振动能有效克服充填中的困难、提高聚合物制件成型质量及力学性能。现有研究集中于超声波对聚合物流动性能或充填过程影响因素的定性分析,未量化超声塑化工艺参数对聚合物流动性能的影响规律。为此,自主研制超声塑化熔融指数(melt flow rate, MFR)测试装置,研究超声塑化工艺参数(超声振幅、塑化压力、塑化时间)及超声振动外场对PMMA,PP和PA66这3种不同类型典型聚合物熔融指数的影响,以便为制定超声塑化成型工艺参数、利用超声振动调控聚合物流动性能提供参考。

N等[11-13]研究了超声塑化对聚乳酸(PLA)、聚酰胺(PA)、聚苯砜(PPSV)、超高分子量聚乙烯(UHMWPE)熔融塑化均匀性的影响,发现超声振幅及塑化压力是影响均匀性的关键参数。LEE等[14-15]研究了超声波振动辅助充填,发现合适的模具振型、振动频率、超声振幅能有效改善充填效果;SATO等[16-18]通过实验研究了辅助超声振动外场对注射/挤出成型工艺的影响,发现超声振动能有效克服充填中的困难、提高聚合物制件成型质量及力学性能。现有研究集中于超声波对聚合物流动性能或充填过程影响因素的定性分析,未量化超声塑化工艺参数对聚合物流动性能的影响规律。为此,自主研制超声塑化熔融指数(melt flow rate, MFR)测试装置,研究超声塑化工艺参数(超声振幅、塑化压力、塑化时间)及超声振动外场对PMMA,PP和PA66这3种不同类型典型聚合物熔融指数的影响,以便为制定超声塑化成型工艺参数、利用超声振动调控聚合物流动性能提供参考。

1 熔融指数测试实验

1.1 实验平台

使用超声塑化实验平台[19]制备超声塑化试样,平台参数如表1所示。微塑件成型质量属于毫克级,塑化量取500 mg。超声振幅通过电源电压调节,调节范围为10~30 μm。

表1 超声塑化实验平台参数

Table 1 Parameters of ultrasonic plasticizing experiment platform

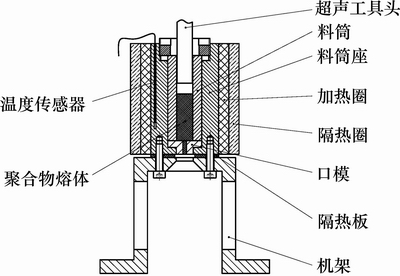

参照国际标准ISO1133-1—2011“塑料—热塑性塑料熔体质量流动速率和熔体体积流动速率的测定”,自行研制超声塑化熔融指数测试装置,如图1所示。使用电阻丝陶瓷加热圈加热料筒,功率为350 W。使用Omega公司5TC-TT-K-40-36型热电偶测量料筒座温度,精度为±1.5 ℃。使用Omega公司CN7523型温度控制器控制料筒座温度。超声工具头外表面、料筒内表面、口模表面粗糙度Ra均低于0.25 μm,以提高实验精度。超声工具头工作长度大于料筒长度,外径(0.075 mm)略小于料筒内径,距工具头端面25,45,50和55 mm处划有刻度,用于观察实验过程工具头相对位移。

图1 超声塑化熔融指数测试装置结构

Fig. 1 Structure of ultrasound MFR detection device

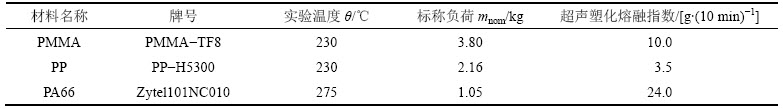

1.2 实验材料

PMMA(无定型)、PP(半结晶型)和 PA66(结晶型)是3种不同类型典型聚合物,将其作为超声塑化聚合物熔融指数测试实验材料,主要性能参数如表2所示,标准熔融指数测试条件如表3所示。

表2 实验材料性能参数

Table 2 Performance parameters of experimental materials

表3 实验材料标准熔融指数(MFR)测试条件

Table 3 Test conditions for standard MFR of experimental materials

1.3 实验方案

超声塑化对聚合物熔体流动性能的影响主要分为2部分:超声塑化引起聚合物相对分子质量及链段结构的变化,永久改变流动性能;超声振动外场引起熔体振动,产生剪切搅拌作用,降低熔体黏度,暂时改变流动性能。

为此,分别研究超声塑化工艺参数和超声振动外场对聚合物流动性能的影响。

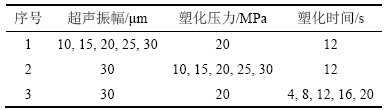

1.3.1 超声塑化熔融指数测试方案

使用超声塑化实验平台制备超声塑化试样,使用超声塑化熔融指数测试装置检测试样,研究材料类型、超声振幅、塑化压力、塑化时间对聚合物熔融指数的影响规律,试样制备方案如表4所示。

表4 超声塑化试样制备方案

Table 4 Preparation schemes of ultrasonic plasticized sample

1) 超声塑化试样的制备。连通超声电源,称取500 mg聚合物颗粒投入塑化腔,调节工具头塑化压力至20 MPa,塑化时间设为12 s,逐次调节超声振幅至10,15,20,25和30 μm,进行超声塑化处理,待冷却固化后取出,每组参数制取12个试样;称取500 mg聚合物颗粒投入塑化腔,调节超声振幅至30 μm,塑化时间设为12 s,逐次调节工具头塑化压力至10,15,20,25和30 MPa,进行超声塑化处理,待冷却固化后取出;称取500 mg聚合物颗粒投入塑化腔,调节超声振幅至30 μm,工具头塑化压力至20 MPa,逐次调节塑化时间至4,8,12,16和20 s,进行超声塑化处理,待冷却固化后取出。每组参数制备12个试样,均分为3份,测量每份试样熔融指数,结果取平均值。

2) 试样熔融指数测量。断开超声电源 (工具头不振动),开启加热圈,将料筒座温度升至实验温度(如表3所示),保温15 min以上。将上述制备试样投入料筒,保温4 min。将标称负荷的超声工具头插入料筒,直到挤出没有气泡的细条,用刮刀切断挤出物并丢弃。当工具头下标线降至料筒顶面时,开始用秒表计时,同时用刮刀切断挤出物并丢弃。以10 s为时间间隔切断挤出物,当工具头上标线达到料筒顶面时停止切割。丢弃有肉眼可见气泡的切段,冷却后将保留下的切段逐一称质量(精确至1 mg),计算平均质量。聚合物熔融指数RMF计算式为

(1)

(1)

式中:θ为实验温度(℃);mnom为标称负荷(kg);m为切段的平均质量(g);tref为参比时间取为10 min;t为切段的时间间隔(s)。

1.3.2 超声振动外场熔融指数测试方案

使用超声塑化熔融指数测试装置,研究材料类型、超声振幅对超声振动外场作用下聚合物熔融指数的影响规律。连通超声电源,开启加热圈,将料筒座温度升至实验温度,保温15 min以上。称取500 mg聚合物颗粒投入料筒,保温4 min。将标称负荷的超声工具头插入料筒,直到挤出没有气泡的细条,用刮刀切断挤出物并丢弃。开启超声工具头,当工具头下标线达到料筒顶面时,开始用秒表计时,同时用刮刀切断挤出物并丢弃。以10 s为时间间隔切断挤出物,当工具头上标线达到料筒顶面时停止切割,逐次调节超声振幅至10,15,20,25和30 μm,测量超声振动外场作用下聚合物熔融指数。在实验后半段关闭超声电源,工具头停止振动,恢复到标准熔融指数测量步骤,测量去除超声振动外场后的聚合物熔融指数。

2 实验结果与分析

验证超声塑化熔融指数测试装置的精度。在超声塑化熔融指数测试装置上测量聚合物的熔融指数,结果如表5所示。原料的熔融指数实验测试值与标准值偏差在5%以内,考虑原料本身批次不同带来的差异、实验装置精度差异、实验环境差异以及实验过程误差后,结果在可接受范围内,将实验值作为标准进行对比分析。

表5 不同聚合物材料熔融指数(MFR)实验值与标准值对比

Table 5 Comparison of experimental values and standard values of melting index of different polymer materials

2.1 超声塑化对熔融指数的影响

2.1.1 超声振幅对熔融指数的影响

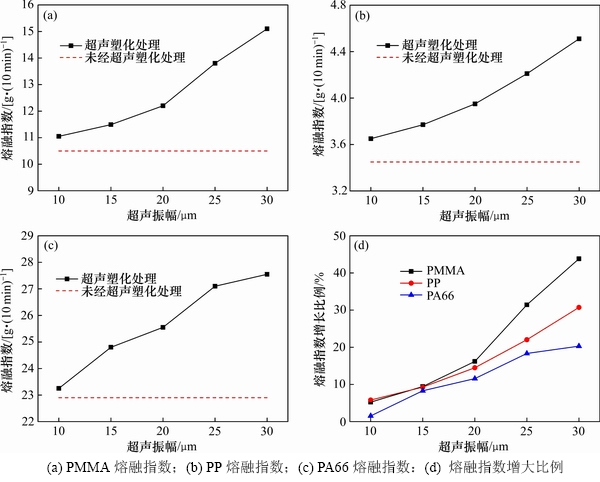

在塑化压力为20 MPa、塑化时间为12 s工艺条件下,超声振幅对PMMA,PP和PA66熔融指数的影响如图2所示。从图2可见:与未经过超声塑化处理相比,聚合物流动性能增强,熔融指数随超声振幅的增大近似呈正比例增大;聚合物属于大分子链段结构,熔融指数与聚合物相对分子质量及分布有关,相对分子质量越小,熔融指数越大。推测超声塑化改变了聚合物分子结构,超声振动影响聚合物相对分子质量及链段结构,聚合物分子链断裂,聚合物相对分子质量降低,分子链取向性增强,并且这种改变程度随着超声振幅的增加而增加。超声振幅越大,对聚合物分子链段结构造成的影响越剧烈,熔体流动性能越强。聚合物流动性能的改变在冷却固化后得以保留,材料改性引起的流动性改变不可逆转。超声振幅对不同聚合物熔融指数的影响不同,如图2(d)所示。当超声振幅为10 μm时,PMMA,PP和PA66熔融指数分别增大5%,6%和2%;当超声振幅为30 μm时,PMMA,PP和PA66熔融指数分别增大44%,31%和20%;当超声振幅从10 μm增大至30 μm时,PMMA,PP和PA66熔融指数分别增大39%,25%和18%。可见在塑化压力为20 MPa、塑化时间为12 s条件下,超声振幅对聚合物熔融指数影响从大至小依次为PMMA,PP和PA66。实验证明:相同超声塑化工艺对不同聚合物流动性能的影响程度不同。

2.1.2 塑化压力对熔融指数的影响

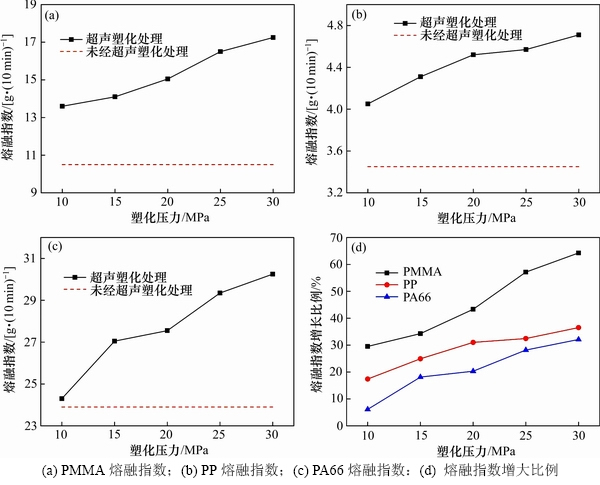

在超声振幅为30 μm、塑化时间为12 s工艺条件下,塑化压力对PMMA,PP和PA66熔融指数影响如图3所示。从图3可见:聚合物熔融指数随塑化压力增大近似呈正比例增大。S NCHEZ-S

NCHEZ-S NCHEZ等[14]的研究显示塑化压力越大,聚合物塑化程度越高,对材料相对分子质量及其分布影响越剧烈,材料流动性能明显改变,这与本实验结果一致。 塑化压力对不同聚合物熔融指数影响不同,如图3(d)所示。当塑化压力为10 MPa时,PMMA,PP和PA66熔融指数分别增大30%,17%和6%;当塑化压力30 MPa时,PMMA,PP和PA66熔融指数分别增大64%,37%和32%;当塑化压力从10 MPa增至30 MPa时,PMMA,PP和PA66熔融指数分别增大34%,20%和26%。可见:在超声振幅为30 μm、塑化时间为12 s条件下,塑化压力对PMMA融熔指数影响依然最大;此外,PA66熔融指数的增幅比PP的大。推测其原因是:当塑化压力为10 MPa时,PP熔融指数已明显增大,提高塑化压力对流动性能的提升较小,而PA66熔融指数增幅较小,所以,提高塑化压力对流动性能的提升较大。若要通过超声塑化提高PA66流动性能,塑化压力应大于10 MPa。

NCHEZ等[14]的研究显示塑化压力越大,聚合物塑化程度越高,对材料相对分子质量及其分布影响越剧烈,材料流动性能明显改变,这与本实验结果一致。 塑化压力对不同聚合物熔融指数影响不同,如图3(d)所示。当塑化压力为10 MPa时,PMMA,PP和PA66熔融指数分别增大30%,17%和6%;当塑化压力30 MPa时,PMMA,PP和PA66熔融指数分别增大64%,37%和32%;当塑化压力从10 MPa增至30 MPa时,PMMA,PP和PA66熔融指数分别增大34%,20%和26%。可见:在超声振幅为30 μm、塑化时间为12 s条件下,塑化压力对PMMA融熔指数影响依然最大;此外,PA66熔融指数的增幅比PP的大。推测其原因是:当塑化压力为10 MPa时,PP熔融指数已明显增大,提高塑化压力对流动性能的提升较小,而PA66熔融指数增幅较小,所以,提高塑化压力对流动性能的提升较大。若要通过超声塑化提高PA66流动性能,塑化压力应大于10 MPa。

图2 超声振幅对聚合物熔融指数的影响

Fig. 2 Effect of ultrasonic amplitude on MFR of polymers

图3 塑化压力对聚合物熔融指数的影响

Fig. 3 Effect of plasticizing pressure on MFR of polymers

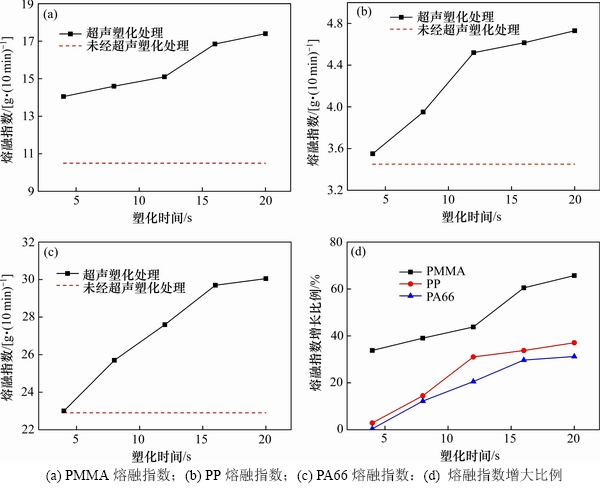

2.1.3 塑化时间对熔融指数的影响

在超声振幅为30 μm、塑化压力为20 MPa工艺条件下,塑化时间对PMMA,PP和PA66熔融指数影响如图4所示。从图4可见:聚合物熔融指数随超声塑化时间的增大近似呈正比例增大。这说明塑化时间越长,聚合物改性越明显,相对分子质量越低,聚合物熔融指数越大。塑化时间对不同聚合物熔融指数影响不同,如图4(d)所示。从图4(d)可见:当塑化时间4 s时,PMMA,PP和PA66熔融指数分别增大34%,3%和0.5%;当塑化时间为20 s时,PMMA,PP和PA66熔融指数分别增大66%,37%和31%;当塑化时间由4 s增至20 s时,PMMA,PP和PA66熔融指数分别增大30.0%,34.0%和31.5%,熔融指数从大至小的聚合物依次为PP,PA66和PMMA。推测其原因是当塑化时间为4 s时,PMMA熔融指数提升已较明显,此时,PP和PA66熔融指数提升较小,延长塑化时间可明显提高PP和PA66熔融指数。根据超声塑化工艺参数对聚合物的影响规律可推断,超声塑化对熔融指数影响程度从大至小的聚合物依次为PMMA,PP和PA66。

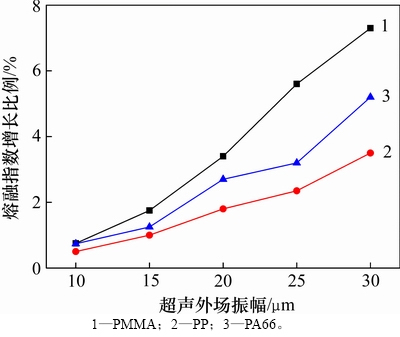

2.2 超声振动外场振幅对熔融指数的影响

超声振动外场振幅对聚合物熔融指数的影响如图5所示。从图5可见:PMMA,PP和PA66的熔融指数随超声振动外场振幅的增大近似呈正比例增大,说明超声振动外场振幅对聚合物熔体产生了一定的剪切搅拌作用,导致熔体黏度下降;PMMA,PP和PA66熔融指数分别增大7.3%,5.2%和3.5%。与超声塑化相比,超声振动外场振幅对聚合物熔融指数影响较小,可能与施加压力有关;PMMA,PP和PA66标称负荷分别为3.80,2.16和1.05 kg,换算成压强,PMMA,PP和PA66的标称负荷分别为0.48,0.28和0.13 MPa。标称负荷较小可能是熔融指数变化较小所致。在实验后半段停止超声工具头振动,聚合物熔融指数逐渐恢复至标准值,说明在较低强度超声振动外场作用下,超声振动对聚合物分子结构的影响较小,熔体流动性能改变可恢复。

图4 塑化时间对聚合物熔融指数的影响

Fig. 4 Effect of plasticizing time on MFR of polymers

图5 超声振动外场对聚合物熔融指数的影响

Fig. 5 Effect of ultrasonic vibration field on MFR of polymer

3 结论

1) 超声塑化后聚合物流动性能发生永久改变,推测超声振动改变了分子结构,流动性能改变在熔体冷却固化后保留,增大超声振幅、塑化压力和塑化时间近似正比增大聚合物熔融指数。

2) 超声塑化对不同种类聚合物流动性能的影响不同,塑化后聚合物熔融指数增幅从大到小依次为PMMA,PP和PA66。在超声振幅为30 μm、塑化压力为20 MPa、塑化时间为20 s的工艺条件下,PMMA,PP和PA66熔融指数分别增大66%,37%和31%。

3) 超声振动外场能够提高聚合物熔体流动性能,且流动性能的改变可恢复。当超声振幅为30 μm时,PMMA,PP和PA66熔融指数分别增大7.3%,5.2%和3.5%。

参考文献:

[1] ZHANG Nan, CHU Jingsong, BYRNE C J, et al. Replication of micro/nano-scale features by micro-injection molding with a bulk metallic glass mold insert[J]. Journal of Micromechanics & Microengineering,2012, 22(6): 065019.

[2] CHEN Z,TURNG L S. A review of current developments in process and quality control for injection molding[J]. Advances in Polymer Technology, 2010, 24(3): 165-182.

[3] MICHAELI W, KAMPS T, HOPMANN C. Manufacturing of polymer micro parts by ultrasound plasticization and direct injection[J]. Microsystem Technologies, 2011, 17(2): 243-249.

[4] 贾云龙, 蒋炳炎, 彭华建, 等. 微注射成型超声塑化中黏弹性生热效应[J]. 中南大学学报(自然科学版), 2016, 47(9): 2976-2983.

JIA Yunlong, JIANG Bingyan, PENG Huajian, et al. Viscoelastic heating effect in ultrasonic plasticization for micro injection molding[J]. Journal of Central South University(Science and Technology), 2016, 47(9): 2976-2983.

[5] MICHAELI W, SPENNEMANN A, G RTNER R. New plastification concepts for micro injection molding[J]. Microsystem Technologies, 2002, 8(1): 55-57.

RTNER R. New plastification concepts for micro injection molding[J]. Microsystem Technologies, 2002, 8(1): 55-57.

[6] JIANG Bingyan, HU Jianliang, LI Jun, et al. Ultrasonic plastification speed of polymer and its influencing factors[J]. Journal of Central South University, 2012, 19(2): 380-383.

[7] 刘小超. 聚合物超声塑化过程中声场及温度场分布研究[D]. 长沙: 中南大学机电工程学院, 2013: 1-5.

LIU Xiaochao. Research on the acoustic and temperature field distribution of polymer ultrasonic plasticizing process[D]. Changsha: Central South University. School of Mechanical and Electrical Engineering, 2013: 1-5

[8] PESHKOVSKY S L, FRIDMAN M L. Acoustic cavitation and its effect on flow in polymers and filled systems[J]. Polymer Composites, 1983, 4(2): 126-134.

[9] NEPPIRAS E A. Acoustic cavitation[J]. Physics Reports(Review Section of Physics Letters), 1980, 61(3): 159-251.

[10] LI Jiang, GUO Shaoyun, LI Xiaonan. Degradation kinetics of polystyrene and EPDM melts under ultrasonic irradiation[J]. Polymer Degradation & Stability, 2005, 89(1): 6-14.

[11] SACRIST N M, PLANT

N M, PLANT X, MORELL M, et al. Effects of ultrasonic vibration on the micro-molding processing of polylactide[J]. Ultrasonics Sonochemistry, 2014, 21(1): 376-386.

X, MORELL M, et al. Effects of ultrasonic vibration on the micro-molding processing of polylactide[J]. Ultrasonics Sonochemistry, 2014, 21(1): 376-386.

[12] GRABALOSA J, FERRER I,  A, et al. Influence of processing conditions on manufacturing polyamide parts by ultrasonic molding[J]. Materials & Design, 2016, 98: 20-30.

A, et al. Influence of processing conditions on manufacturing polyamide parts by ultrasonic molding[J]. Materials & Design, 2016, 98: 20-30.

[13] S NCHEZ-S

NCHEZ-S NCHEZ X, HERN

NCHEZ X, HERN NDEZ-AVILA M, ELIZALDE L E, et al. Micro injection molding processing of UHMWPE using ultrasonic vibration energy[J]. Materials & Design, 2017, 132: 1-12.

NDEZ-AVILA M, ELIZALDE L E, et al. Micro injection molding processing of UHMWPE using ultrasonic vibration energy[J]. Materials & Design, 2017, 132: 1-12.

[14] LEE J, KIM N. Prediction of charging rate in ultrasonic vibration of injection molding[J]. Journal of Materials Processing Technology, 2008, 201(1/2/3): 710-715.

[15] CHEN Y, LI H.Effect of ultrasound on the viscoelasticity and rheology of polystyrene extruded through a slit die[J]. Journal of Applied Polymer Science, 2006, 100(4): 2907-2911.

[16] SATO A, SAKAGUCHI H, ITO H, et al. Evaluation of replication properties on molded surface by ultrasonic injection molding system[J]. Plastics Rubber & Composites, 2013, 39(7): 315-320.

[17] 于同敏, 包成, 黄晓超. 超声技术在聚合物成型加工中的应用研究进展[J]. 高分子材料科学与工程, 2012, 28(11): 173-177.

YU Tongmin, BAO Cheng, HUANG Xiaochao. Application evolution of ultrasonic technology in polymers processing[J]. Polymer Materials Science and Engineering, 2012, 28(11): 173-177.

[18] 仇中军, 郑辉, 房丰洲, 等. 纵向超声波辅助微注塑方法[J]. 纳米技术与精密工程, 2012, 10(2): 170-176.

QIU Zhongjun, ZHENG Hui, FANG Fengzhou, et al. Longitudinal ultrasound-assisted micro-injection moulding method[J]. Nanotechnology and Precision Engineering, 2012, 10(2): 170-176.

[19] 吴旺青. 聚合物超声熔融塑化技术与测试装备研究[D]. 长沙: 中南大学机电工程学院, 2008: 28-29.

WU Wangqing. Research on the technology of ultrasonic melting and the testing technology of polymer[D]. Changsha: Central South University. School of Mechanical and Electrical Engineering, 2008: 28-29.

(编辑 陈灿华)

收稿日期:2017-12-13;修回日期:2018-01-28

基金项目(Foundation item):国家自然科学基金资助项目(51575540);中南大学研究生创新项目(2018zzts458) (Project(51575540) supported by the National Natural Science Foundation of China; Project(2018zzts458) supported by the Graduate Innovation Project of Central South University)

通信作者:蒋炳炎,博士,教授,从事微注射成型理论和应用研究;E-mail: jby@csu.edu.cn