文章编号:1004-0609(2008)09-1674-06

碳纳米管在与铜粉混合球磨过程中的形态演化

谷万里,盛文斌

(山东理工大学 机械工程学院)

摘 要:分别将直径小于2 nm的单壁碳纳米管(单壁管含量为50%),直径8~10 nm的多壁碳纳米管和直径80~100 nm的多壁碳纳米管与铜粉混合,并进行机械球磨,用SEM和TEM对球磨过程中碳纳米管的形态演变进行研究。结果表明:直径80~100nm的碳纳米管在受到机械冲击时以发生断裂为主,而在形态上依然保持碳管的基本结构;其断口有开口和封口两种结构,在开口处具有比较复杂的微观结构且存在大量的赘生管;直径小于10 nm的碳纳米管在机械球磨过程中则易形成球状的缠结、纳米碳颗粒和巴基葱;这种差异与不同直径的碳纳米管中不饱和化学键所占的比例有关。

关键词:碳纳米管;巴基葱;纳米复合材料;机械球磨

中图分类号:TG 146 文献标识码:A

Morphology transformation of carbon nanotubes mixed with

copper powder during mechanical ball milling process

GU Wan-li, SHENG Wen-bin

(School of Mechanical Engineering, Shandong University of Technology, Zibo 255049, China)

Abstract: Carbon nanotubes with diameters of <2 nm, 8?10 nm and 80?100 nm were mixed with copper powder and treated by mechanical ball milling process for different milling times. The morphology transformation of carbon nanotubes during ball milling process was observed by SEM and TEM, respectively. The results show that the carbon nanotubes with diameter of 80?100 nm are fractured and the characteristic structure of nanotube is kept under the mechanical ball milling process. The broken nanotubes were obtained and a lots of neoplasitc tubes are formed. Whereas for the nanotubes with diameters of 2 nm and 10 nm, the twists of carbon nanotubes, carbon nano-particles and carbon onions are formed during the ball milling process. The diversity of the nanotubes with deferent diameters is resulted from the difference of the relative ratio of the unsaturated chemical bond.

Key words: carbon nanotube; carbon onion; nanocomposite; mechanical ball milling

自从1991年碳纳米管被发现以来[1],这种材料所具有的高强度与高的电导率及热导率、低热膨胀系数等优良性能很快引起材料科学工作者的重视,并成为一个研究热点[2?3]。在对碳纳米管的制备工艺与性能方面进行研究的同时,利用碳纳米管的优良性能来制备复合材料的问题也很快引起了材料学界的重视。碳纳米管首先在增强树脂基复合材料方面取得很大进 展[4?5],但在制备金属基复合材料方面的应用,虽然也有一些研究报道[6?8],但同时也还面临着很大的困难,这其中的主要困难在于碳纳米管具有很大的比表面积和比表面能因而团聚现象严重,很难在金属基体中均匀分散。另一方面,碳纳米管的表面活性较低,与金属基体的润湿性差,这造成了其与金属基体之间的界面结合较差。因此,能否将碳纳米管均匀分散在金属中是制备复合材料的关键。为解决这一问题,一些研究者力于对碳纳米管的表层进行金属包覆[9?10]和表面改性后在溶液中制备碳纳米管/金属复合粉[11]。

机械球磨是一种传统的材料细化与均匀化技术,与上述材料制备方法相比,该方法的最大优势是工艺过程相对简单,适合于大规模生产,因此,成为制备金属基复合材料的重要方法。在对碳纳米管与金属混合粉进行机械球磨的过程中,不同的工艺条件、不同的混合体系都会使碳纳米管的表面活性与形态发生不同情况的改变;另一方面,不同种类的碳纳米管在相同的球磨条件下的形态演化也不尽相同,而目前关于这方面的研究报道还较少[12?14]。本文作者研究了不同直径的碳纳米管与铜粉混合后进行机械球磨过程中的形态演变,对其形态上的差异及其原因进行了分析。

1 实验

实验所用的碳纳米管为深圳纳米港公司提供的产品,第一种为单壁碳纳米管(单壁管含量为50%),直径小于2 nm,以下称为CNTs1;第二种为多壁碳纳米管,直径8~10 nm,以下称为CNTs2;第三种为多壁碳纳米管,直径80~100 nm,以下称为CNTs3。用南京大学仪器厂生产的QM?1SP4?CL型球磨机对上述3种碳纳米管首先进行30 min预球磨,预球磨后再与铜粉混合球磨,铜粉为市售普通纯铜粉,粒度小于50 μm。用玛瑙磨球和玛瑙球磨罐。碳纳米管在混合粉中的质量分数均为5%,转速均为300 r/min。

用飞利浦公司生产的FEI Siron200扫描电镜(SEM)和日本电子公司生产的JEM?2010透射电镜(TEM)对球磨至不同阶段碳纳米管的微观形貌及其转变规律进行研究。电镜样品的制备过程为:将球磨后的混合粉放在烧杯中,倒入适量蒸留水后用超声波分散20 min,分散后铜粉沉到杯底,碳纳米管则分散在溶液中,吸取一滴溶液滴在SEM样品台上晾干后进行SEM分析,用铜网在溶液中捞取样品进行TEM分析。

2 结果与讨论

2.1 实验结果

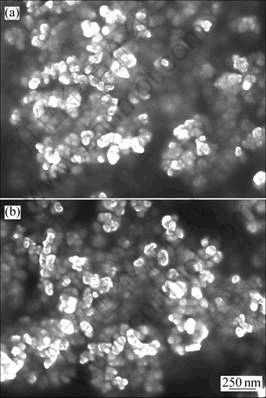

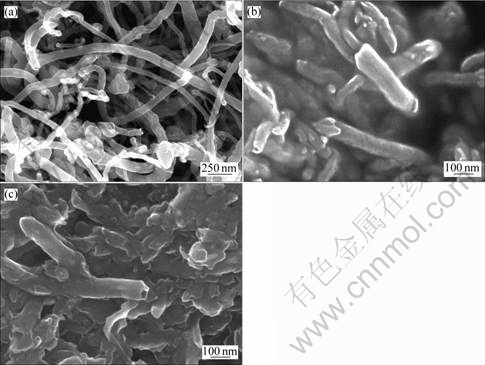

图1所示为分别与铜粉混合后球磨30 min后CNTs1和CNTs2的扫描电镜照片。图2所示为CNTs3球磨前及与铜粉混合后分别球磨30 min和60 min的扫描电镜照片。由图可知,球磨前的CNTs3是外表光滑的具有很大长径比的管状形貌。在经过30 min的球磨后,CNTs1和CNTs2均演化成直径约50 nm的球形,球的微观细节则难以在扫描电镜的分辨率下获得。而直径较大的CNTs3则是发生了折断,随着球磨时间的延长,其折断也更加严重,在折断处可以看到开口的碳管。

图1 CNTs1(a)和CNTs2(b)分别球磨30 min的SEM像

Fig.1 SEM morphologies of CNTs1 (a) and CNTs2 (b) ball milled for 30 min

图2 CNTs3球磨前(a)及分别球磨30 min(b)和60 min(c)的SEM像

Fig.2 SEM morphologies of original CNTs3(a) and ball milled for 30 (b) and 60 min (c)

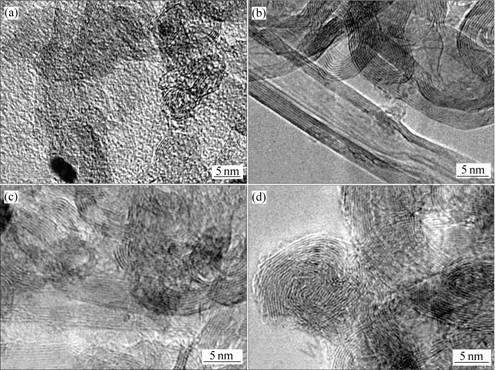

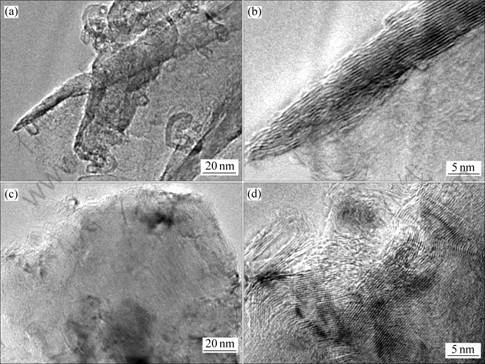

图3所示为球磨前的CNTs1和CNTs2及这两种碳管分别与铜粉混合球磨30 min的透射电镜照片。可以看出,球磨前的两种碳管尽管有不同程度的缠结,但仍然保持管状结构。球磨后碳纳米管的形态概括起来有两种类型:一种是碳纳米管进一步地缠结在一起,如图3(c)所示,碳纳米管依然保持碳纳米管的基本结构;另一种则是形成纳米颗粒结构,如图3(d)所示。

图3 球磨前的CNTs1和CNTs2和分别球磨30 min后的透射电镜照片

Fig.3 TEM morphologies of original CNTs1 and CNTs2((a), (b)) and ball milled for 30 min((c), (d))

将球磨时间延长到60 min时,碳纳米管的形态如图4所示。此时CNTs1的微观结构发生了比较明显的变化,出现较多的是如图4(a)所示的纳米颗粒。与图3中的情形相比,一方面是颗粒更加接近于球形,另一方面是颗粒内已经完全没有碳纳米管的结构特征。图4(a)所示的CNTs1的结构应属于一种原子的近程有序结构,而图4(b)中可以发现巴基葱的结构特征。相比之下,CNTs2还是以碳管形成的缠结结构为主。这一结果表明,碳纳米管的稳定性与其直径有关。在受到外力冲击的情况下,直径小的碳纳米管更容易演化为其它结构,从以上两图的演变过程来看,先形成的缠结应该是碳纳米管演变为其它结构的一种过度 状态。

图4 CNTs1和CNTs2分别球磨60 min后的透射电镜照片

Fig.4 TEM morphologies of CNTs1(a), (b) and CNTs2 (c), (d)ball milled for 60 min, respectively

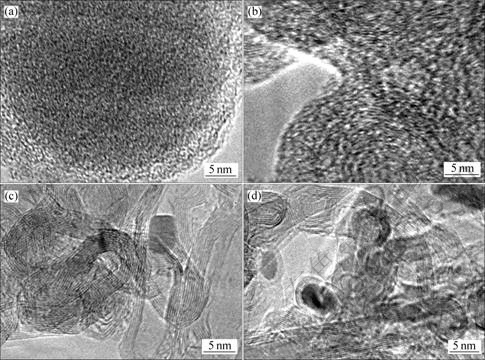

图5所示为CNTs3与铜粉混合球磨60 min后碳管断口处的透射电镜照片,其中图5(b)、(d)所示分别为(a)、(c)的高倍放大照片。从低倍的(a)、(c)可以看出,有开放式和封闭式两种断口,封闭的断口形貌相对比较简单,原子依然是层状排列,只是在不同区域的排列方向有些差别,各区域之间无明确的界面而是以一种渐变的方式来过度。相比之下,开放式断口处的形貌则比较复杂,一方面,在断口处有很多直径细小的赘生碳管;另一方面,断口处碳管壁的层数是逐渐减少的,而在端部形成尖状结构。在赘生管与母管的连接处附近的碳原子排列如图6所示。由图可知,连接处附近的碳原子基本保持层状排列结构,不同区域的排列方向有明显差异但也没有明显的分界线。

图5 CNTs3与铜粉混合球磨60 min的透射电镜照片

Fig.5 TEM morphologies of CNTs3 ball milled with copper powder for 60 min

图6 CNTs3中赘生管与母管交界处的透射电镜照片

Fig.6 TEM morphologies for boundaries between neoplasitc tube and mother-tube

2.2 讨论

文献[13]对碳纳米管在与铁粉混合球磨过程中的形态变化进行研究认为,在球磨过程中碳纳米管将逐渐转化为纳米颗粒与巴基葱。而从以上实验结果来看,这种转化过程还与碳纳米管的直径有直接关系,不同直径的碳纳米管在机械球磨过程中的结构稳定性存在比较大的差异。概括地讲,直径大的碳纳米管更易于保持管状结构。而直径较小的碳管则易于转化为其它形态。在这种形态转化过程中,碳管先是缠结在一起,然后转化为纳米颗粒和巴基葱结构。形成缠结可以理解为是进一步发生形态转变的过度状态,这对解释碳管直径与形态转变之间的关系是有帮助的,直径较小的碳管更容易形成缠结,而形成缠结后各个碳原子层之间有可能进行重新组合而形成其它结构。对于直径较大的碳管,由于形成缠结的机会小,因此,不易向其它形态转化,在机械球磨的程中则主要表现为 断裂。

从碳原子的化学键方面可以对上述实验现象给出进一步的解释。由于碳纳米管可以看成是由石墨片层卷曲后形成[15]。其同一层中的碳原子之间是以sp2杂化后的σ键相互结合,而层与层的碳原子之间则以π键相互结合。这种结构会使处于表层的碳原子有剩余的不饱和键存在,这种不饱和键的存在会使体系的能量升高,从而导致结构的稳定性下降。很显然,碳纳米管的层数越少,这种不饱和键所占的比例就越高,因此,结构的稳定性也就越差,也就越容易在球磨或其它情况下转变为其它结构。

图5中碳管壁的逐层断裂与其复杂的开口形态之间应该具有某种联系。从图5 (a)可以看出,其赘生管既生长在内部也生长在外部,对图6中的赘生管与母管连接处的研究表明,碳原子依然保持层状排列,但不同区域的排列方向有较大差异。由于这些赘生管只是在断口附近大量出现,因此,很可能是母管中断裂的碳原子层重新卷曲所形成。从图5(a)中可以看到,开口碳管的断裂处并不整齐,因此,在其端部会形成参差不齐的一些类似于图5(b)所示那样的多层片状结构,与前面的分析相类似,在这些断层边缘的碳原子也会由于sp2杂化中的部分电子不能形成化学键,使体系的能量处于较高的状态,而当这些破碎的碳原子层卷曲为管状结构时可以使不饱和键消失从而使体系的能量降低而处于稳定状态。

结合前面CNTs1和CNTs2的结构转变,可以看出,在机械球磨过程中,碳纳米管中的原子结合键被破坏,随后可以重新组合成多种结构;对于直径较大的碳管,其主体还可以保持为管状结构,但一些破损的碳原子层将发生卷曲,从而形成一些赘生管,而对于直径较小的碳纳米管,它们在球磨过程中将更易于缠结在一起,球磨的冲击使一些结合键断裂并重新组合,在不同条件下会形成纳米颗粒与巴基葱结构。

从这个意义上讲,在选择碳纳米管作为金属基体的增强体时应更多地考虑直径较大的碳纳米管,对这种碳纳米管进行适当的球磨可以形成开口,由于在开口处的原子排列的有序性较差及部分悬键的出现因而处于较高的能量状态,这有利于碳纳米管与基体结合,从而获得分散均匀且致密的复合材料。

3 结论

1) 在机械球磨过程中,碳纳米管的原子结合键可以发生断裂并重新组合从而使碳纳米管的形态发生变化。

2) 不同直径的碳纳米管的形态演化有较大差异,直径较小的碳纳米管将首先形成缠结,随后演变为纳米颗粒和巴基葱等结构,而直径较大的碳管主要是发生断裂,这种差异与不同直径的碳纳米管中不饱和键的相对含量有关。

3) 大直径碳纳米管的断口有封闭式与开放式两种类型,在开放式断口处将产生一些结构复杂的赘生管,这种结构特征与断裂处的不饱和化学键有关。

致谢:

本文受山东省中青年教师访问学者计划项目,特此致谢。

REFERENCES

[1] IIJIMA S. Helical microtubes of graphitic carbon[J]. Nature, 1991, 354: 56?58.

[2] SOLVETAT J P, BONARD J M, THOMSON N H. Mechanical properties of carbon nanotubes[J]. Appl Phys A, 1999, 69: 255?260.

[3] BERBER S, KWON Y K, TOMNEK D. Unusually high thermal conductivity of carbon nanotubes[J]. Phys Rev Lett, 2000, 84(20): 4613?4616.

[4] GONG X, LIU J, BASKARAN. Surfactant-assisted processing of carbon nanotube/polymer composites[J]. Chemistry of Materials, 2000, 12(4): 1049?1052.

[5] QIAN D, DICKEY E C, ANDREWS R. Load transfer and deformation mechanism in carbon polystyrene composites[J]. Appl Phys Lett, 2000, 76(20): 2868?2870.

[6] 丁志鹏, 张孝彬, 许国良, 何金孝, 涂江平, 陈卫祥. 碳纳米管/铝基复合材料的制备及摩擦性能研究[J]. 浙江大学学报: 工学版, 2005, 39(11): 1811?1815.

DING Zhi-peng, ZHANG Xiao-bin, XU Guo-liang, HE Jin-xiao, TU Jiang-ping, CHEN Wei-xiang. Fabrication and tribological properties of carbon nanotubes-aluminum composites[J]. Journal of Zhejiang University: Engineering Science, 2005, 39(11): 1811?1815.

[7] DONG S R, TU J P, ZHANG X B. An investigation of the sliding wear behavior of Cu matrix composite reinforced by carbon nanotubes[J]. Mater Sci Eng A, 2001, 313(1/2): 83?87.

[8] CHEN Xiao-hua, LI Wen-hua, CHEN Chuan-sheng, XU Long-shan, YANG Zhi, HU Jing. Preparation and properties of Cu matrix composite reinforced by carbon nanotubes[J]. Trans Nonferrous Met Soc China, 2005, 15(2): 314?318.

[9] 王浪云, 涂江平, 杨友志, 张孝彬, 陈卫祥, 卢焕明. 多壁纳米碳管/Cu基复合材料的摩擦磨损特性[J]. 中国有色金属学报, 2001, 11(3): 367?371.

WANG Lang-yun, TU Jiang-ping, YANG You-zhi, ZHANG Xiao-bin, CHEN Wei-xiang, LU Huan-ming. Friction and wear behavior of multi-walled carbon nanotube/Cu matrix composites[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(3): 367?371.

[10] 易国军, 陈小华, 蒋文忠, 张 刚, 陈传盛. 碳纳米管的表面改性与镍的包覆[J]. 中国有色金属学报, 2004, 14(3): 479?483.

YI Guo-jun, CHEN Xiao-hua, JIANG Wen-zhong, ZHANG Gang, CHEN Chuan-sheng. Surface modification and nickel coating of carbon nanotubes[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(3): 479?483.

[11] 许龙山, 陈小华, 陈传盛, 李文华, 杨 植. 碳纳米管?超细铜粉复合粉体的制备[J]. 无机材料学报, 2006, 21(2): 309?314.

XU Long-shan, CHEN Xiao-hua, CHEN Chuan-sheng, LI Wen-hua, YANG Zhi. Preparation of CNTs and superfine Cu compound powder[J]. Journal of Inorganic Materials, 2006, 21(2): 309?314.

[12] DISMA F, AYMARD L, DUPONT L. Effect of Mechanical grinding on the lithium intercalation process in graphites and soft carbon[J]. J Electrochem Sco, 1996, 143: 3959?3971.

[13] LI Y B, WEI B Q, LIANG J, YU Q, WU D H. Transformation of carbon nanotubes to nanoparticles by ball milling process[J]. Carbon, 1999, 37(3): 493?497.

[14] 刘 芙, 张孝彬, 涂江平, 程继鹏, 孔凡志, 孙沿林, 卢焕明, 陈长聘. 碳纳米管的球磨处理及其对储氢性能的影响[J]. 太阳能学报, 2003, 24(1): 116?120.

LIU Fu, ZHANG Xiao-bin, TU Jiang-ping, CHENG Ji-peng, KONG Fan-zhi, SUN Yan-lin, LU Huan-ming, CHEN Chang-pin. Ball milling process and its effects on hydrogen storage of carbon nanotubes[J]. Acta Engergiae Solaris Sinaca, 2003, 24(1): 116?120.

[15] IIJIMA S, ICHIHASHI T. Single-shell carbon nanotubes of 1nm diameter[J]. Nature, 1993, 363: 603?605.

收稿日期:2008-03-05;修订日期:2008-06-10

通讯作者:谷万里,教授,博士;电话:0523-2786499;E-mail: guwanli@sdut.edu.cn

(编辑 龙怀中)