文章编号:1004-0609(2014)06-1578-07

柱塞式环模成型模具摩擦热数值分析

德雪红1, 2,俞国胜1,翟晓敏3

(1. 北京林业大学 工学院,北京 100083;

2. 内蒙古农业大学 机电工程学院,呼和浩特 010018;

3. 航天科工集团第六研究所,呼和浩特 010076)

摘 要:为研究柱塞啮合式生物质环模成型机摩擦特性,利用传热学原理及柱塞环模冷压成型特点,以42CrMo钢为凹模材料,建立成型机凹模摩擦热分析数学模型,并借助Solidworks及ANSYS软件对物料成型过程中凹模摩擦热进行温度场数值模拟试验及数据对比分析。结果表明:凹模温度随工作时间增加呈上升趋势,其耐磨衬套及保型筒内、外壁及凹模体外壁温度增加速度不同;凹模温度增速随凸模转速变化而变化,其内壁温度在凸模转速达240r/min时达最佳生物质物料木质素软化状态;通过调整模具材料、物料、生产率等相关因素,可有效缩短物料木质素达软化温度时间,提高物料成型质量。

关键词:柱塞式;生物质;成型;摩擦热;ANSYS软件

中图分类号:TK6;TH122;TP391.9;TG115.5+8;TG76 文献标志码:A

Numerical analysis of friction heat of plunger biomass ring briquetting mold

DE Xue-hong1, 2, YU Guo-sheng1, ZHAI Xiao-min3

(1. College of Mechanical Engineering, Beijing Forestry University, Beijing 100083, China;

2. College of Mechanical and Electrical Engineering,Inner Mongolia Agricultural University, Hohhot 010018, China;

3. Sixth Research Institute, Aerospace Science and Industry Group of China, Hohhot 010076, China)

Abstract: Heat transfer theory and characteristics of biomass ring briquetting mold under general condition were used to establish friction heat analysis model of the female die of ring briquetting mold. Numerical simulation experiment about friction heat formation process of the female die with material of 42CrMo was carried out by using of Solidworks and ANSYS software. The results show that the female die temperature of briquetting presents increasing trend with running time increasing. The temperature rising speeds are different from the internal and external surface and the shape holding tube of female die. The temperature of female die internal surface increases with rotating speed of punch increasing. The positive softening rate of lignin appears when the rotating speed of punch reaches 240 r/min. By adjusting the relevant factors of the mold material, structure, materials and production efficiency, etc., the time of reaching softening temperature point of lignin is shorten, and the material shaping quality is improved.

Key words: plunger; biomass; briquetting; friction heat; ANSYS software

生物质固化成型技术在当今大力倡导节能环保的时代越来越重要[1]。生物质物料被挤压成型过程分为冷压成型和热压成型,其中冷压成型因其具有节能环保等优点,越来越受重视。辊压式环模冷压成型机由于其产量高、能耗低、成型质量好等优点,成为未来生物质固化成型设备的主要发展方向[2-5],然而,该成型机的发展因其中的关键部件——环模的寿命低、成本高等因素受到严重制约。现今国内该成型机的研究还只是初步阶段,未有给环模设计制造提供有力理论设计依据。目前最新研发的柱塞式环模冷压成型机,吸取了现有环模成型机优点,且减少了其环模与压辊之间摩擦能耗损失,改良了压辊及环模,具有减少摩擦、节能、高效等优点。在成型理论研究领域中,当今学者对热压成型的研究较多,而对冷压成型方式,研究者只对普通螺旋压力成型机成型过程中型腔的摩擦热进行了理论分析[6-8],还没有学者对新型的柱塞式环模成型机摩擦热引起的温度进行理论研究。为此,本文作者对最新研发的柱塞式环模冷压成型机摩擦热引起的温度场进行了理论分析,为其设计制造提供有利的理论依据。

生物质物料在柱塞环模成型凹模内被挤压产生变形及位移,与凹模内壁接触产生摩擦,有部分能量转换为热能。摩擦生热对冷压成型有重要作用,即产生的热能可使物料和成型模具(凸模、凹模)温度升高,其中物料温度适度升高有助于提高其成型质量,这是因物料中所含木质素在适当温度下有软化、粘结和固化作用[5]。当温度在70~110 ℃时,木质素粘合力开始增加,200~300 ℃时木质素开始熔融,起粘合纤维素作用,此时用较小力便可使物料胶接成型,冷却固化后成型质量好。因此,对物料成型过程摩擦热分析在柱塞啮合式环模成型机设计中意义重大[9-12]。本文作者通过对物料在凹模成型过程的分析,用Solidworks建模,在ANSYS有限元环境下模拟凹模因摩擦热产生温度场,在柱塞凸模的较大挤压压力作用下,为使产生适当的摩擦热量使成型凹模温度尽可能长时间保持在70~110 ℃之间,确定出与之相适应的凸模转速,来保证获得较高的物料成型质量[13-15]。

1 柱塞式成型模具摩擦热分析

1.1 基本假设

生物质物料被挤压成型过程中一般会有压缩、滑移及保压3个阶段,其中压缩阶段主要发生在凹模入口处微小段距离。刚被填入凹模口处的松散物料在凸模压力下压强迅速提高,达峰值后再缓慢下降,由于此过程发生时间极短,可视为闭式压缩,此时物料主要发生弹性变形。在凸模继续作用下,在压力达峰值后物料与凹模有相对滑移过程,此时其相互摩擦力向动摩擦力转化,物料所受压强开始降低,开始进入滑移、保压阶段。而此时物料发生弹、塑性变形,由于其变形极微小可忽略其阻力,故此处可设凸模压力全用于克服物料与凹模间摩擦力。据上首先设物料在进入滑移和保压阶段已达最大密度,由于压缩是在凹模前端微小间距进行且较短时间内完成,为简化模型,假设物料在刚进入凹模腔即达最大密度,且均匀连续,忽略重力因素,认为物料与凹模筒壁间摩擦力等于成型凸模挤压力。

物料被挤压过程中的热量产生是复杂的过程。物料在凸模挤压下产生弹、塑性变形,且与凹模产生相对滑移,并可能伴随炭化等现象,很难对其进行精确分析。这里为简化热量来源,忽略物料的变形及理化性变化因素,设热能主要来自物料所受挤压力耗能及物料与凹模摩擦产生的部分散热量,即可使问题转化为无内部热源摩擦生热、导热问题。

1.2 各参数确定及物理意义

柱塞啮合式环模成型机挤压物料成型过程中,物料(成型后立即被挤出)、凸模(挤压物料后迅速与其脱离)受摩擦热影响相对较短,而成型凹模一直处于与物料的摩擦环境下,受摩擦热影响较大,故这里以成型凹模作为研究对象。设凹模内壁与物料间产生稳定热流密度为qw(W/m2),则成型凹模内壁热流密度qw可根据下式确定:

(1)

(1)

式中:α为热流分配系数;μ为摩擦系数; 为接触壁平均应力,Pa;v为当量滑移速度,m/s。

为接触壁平均应力,Pa;v为当量滑移速度,m/s。

上述重要参数物理意义如下:

1) 热流分配系数α:本文作者选择平均值相同条件的瞬时温升[16],得出进入成型凹模α:

(2)

(2)

式中:λ1、λ2分别为物料、凹模导热系数,W/(m·℃);u1、u2分别为物料、凹模相对滑动速度,m/s,此处u1=u2;K1、K2分别为物料、凹模传热系数,(其中K=λ/(ρc);c为比热,J/(kg·℃),ρ为密度,kg/m3;e为平均赫兹接触半宽,m。

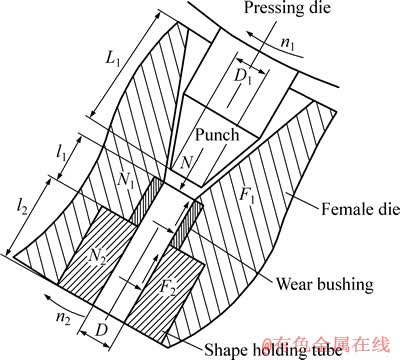

图1 生物质成型局部受力示意图

Fig. 1 Force schematic diagram of biomass briquetting

2) 成型凹模接触壁平均应力 :为提高凹模寿命,降低成本,成型凹模内嵌有耐磨衬套及保型筒,当物料在凹模内滑移时衬套及保型筒受力状态如图1所示(成型模具成型部位局剖示意图)。

:为提高凹模寿命,降低成本,成型凹模内嵌有耐磨衬套及保型筒,当物料在凹模内滑移时衬套及保型筒受力状态如图1所示(成型模具成型部位局剖示意图)。

图1中N为成型阶段平均应力,Pa;N1、N2分别为衬套内壁、保型筒内壁所受物料张力,Pa;D为凹模直径,m;l1、l2分别为衬套及保型筒长度,m;L1为凸模进入凹模长度,m。

假设物料是匀速推进的,则有

NπD2=πDl1μ1N1+πDl2μ2N2 (3)

式中:N1=N2= ;μ1、μ2分别为衬套、保型筒与物料间摩擦因数,取μ1=μ2。

;μ1、μ2分别为衬套、保型筒与物料间摩擦因数,取μ1=μ2。

3) 当量滑移速度v:由于生物质物料成型过程中成型机挤压物料是通过凸模及凹模作仿齿轮啮合运动实现的,且物料与凹模间发生的相对滑移是不连续的,但因凸模转速很高,为简化计算,可近似认为物料是连续滑移的,故将摩擦生热转化为一连续生热过程,并引入当量滑移速度v,据此,设物料进入凹模后即达最大密度ρ。则有:

(4)

(4)

式中:t为凸模啮合时间,s;ε为压缩比,ε=ρ1/ρ,ρ1为压缩前物料密度,kg/m3;n1为压模转速,r/s;Z1为压模上凸模每排个数。

2 有限元模拟

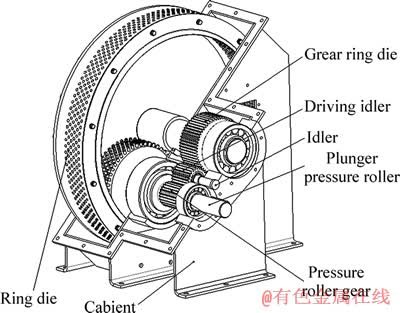

图2所示为本研究最新设计的柱塞啮合式环模成型机成型模具结构,其工作几何参数尺寸(如图1所示)如下:D=0.010 m,D1=0.010 m,l1=0.020 m,l2=0.035 m,L1=0.040 m,μ1=μ2=0.3,外形尺寸取环模凹模的1/100,这里衬套、保型筒及凹模体材料均选42CrMo,物料选木屑;设物料成型需最大压强120 MPa,推入阶段压强80 MPa,取平均推移压强为100 MPa。

图2 柱塞式成型模具结构示意图

Fig. 2 Structure sketch of plunger ring briquetting mold

2.1 模型建立及单元网格划分

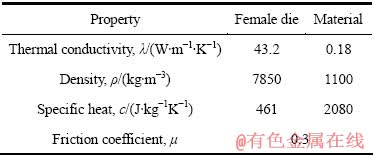

成型机模具成型部位由凸模和凹模组成,假设成型物料在凹模腔里均匀连续,因每一对凸、凹模啮合原理相同,故取环模凹模的1/100作为分析对象以建立三维几何模型。如表1所列[17-18],取80 ℃时材料特性作设计依据。

表1 80 ℃时材料特性

Table 1 Property of materials at 80 ℃

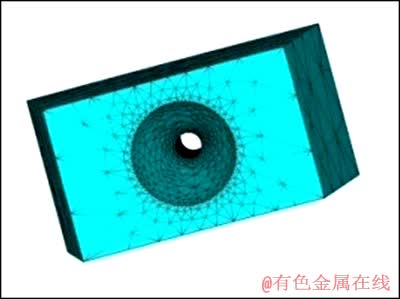

这里选用SOLID90二十节点六面体单元进行分析,该单元是三维八节点实体单元—SOLID70的高次形式,适用于三维稳态或瞬态热分析。其二十节点拥有一致温度形函数,适当温度协调形状,可很好适应模拟三维立体曲线边界。采用智能分网,实现自由划分网格。考虑到求解时对材料热物性参数取值、边界及初始条件等的处理,选取环模凹模1/100作为分析模型,并对实际加工中倒角、圆角等进行了简化。建立了如图3所示凹模摩擦热有限元分析模型。

图3 凹模摩擦热有限元分析模型

Fig. 3 Friction heat finite element analysis model of female die

2.2 导热微分方程及边界条件确定

本文作者选用三维非稳态无内热源导热模型建立柱塞啮合式生物质环模成型机凹模摩擦热温度场,其三维非稳态微分方程为

(5)

(5)

式中:T为温度,℃;τ为热传导时间,s。

凹模内壁因摩擦产生稳定热流,属第三类边界条件,由式(1)~(5)可求得热流密度qw。凹模向外散热主要是以同质金属及空气进行传导放热,金属导热系数一般43.2 W/(m2·℃);凹模与空气接触主要放热方式是辐射放热及对流换热,此处统一按放热考虑,属第二类边界条件,其放热系数通常3~15 W/(m2·℃),这里取经验值12 W/(m2·℃);设系统初始温度为25 ℃。

2.3 摩擦热产生分析

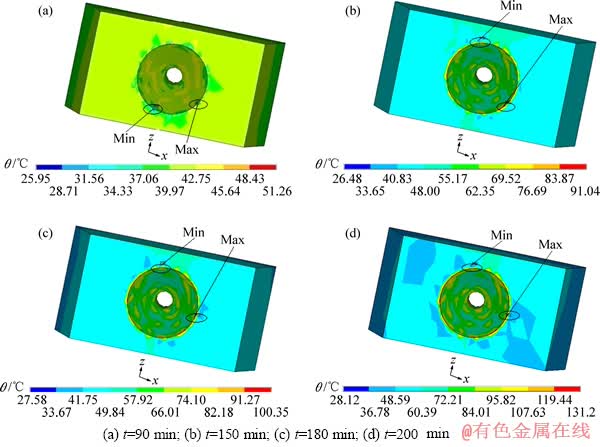

1) 图4所示为当凸模转速为160 r/min时凹模在90、150、180和200 min 4个时刻摩擦热温度场分布状态图。由图4可知,在任一时刻,成型凹模各部位温度随与发生摩擦表面距离的增大呈减小趋势。这主要是因当边界表面施加热流并使其在模型内部传递过程中,进入每一微元的能量,一部分满足该微元自身能量提高,导致其温度升高,另一部分向外传递,到模型的其他微元处,这符合能量守恒定律。还可看出,图4(a)~(d)中成型凹模温度是顺次逐渐升高的,即随工作时间延长凹模温度逐渐升高,这主要是因摩擦热不断产生,但散热速度相对慢的缘故。

图4 凹模不同工作时刻温度场图

Fig. 4 Temperature field chart of female die at four typical operating times

图5 衬套及保型筒内、外壁及凹模外壁温度随工作时间变化曲线

Fig. 5 Temperature change curves of internal (a), exterior (b) surface of bushing and shape holding tube and external surface (c) of female die

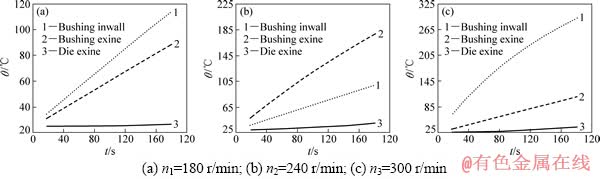

2) 图5所示为凹模中衬套及保型筒内壁、外壁及凹模外壁各处温度随工作时间变化规律。从图5(a)可看出,凹模衬套及保型筒内壁温度随工作时间变化规律,工作120 min(72×102 s)内,处于70 ℃以下,未达物料木质素软化点,在120~185 min(72×102~ 111×102 s)时间内温度保持在70~110 ℃之间,物料木质素保持在软化温度范围内,此时物料成型质量提高,但由于达到木质素软化温度用时较长(即120 min),使成型机工作初期相对较长时间内所获得物料成型质量差,这导致物料成型质量总体不好。

3) 图5还反映了凹模衬套内、外壁及凹模外壁随工作时间产生不同的温度变化曲线。从图5中的曲线可知,在同一时刻(如120×102 s),凹模衬套内壁(图5(a))、外壁(图5(b))及凹模外壁(图5(c))升高的温度幅度是不同的,这导致凹模不同部位形成温差并产生热应力,其中凹模衬套内壁和凹模外壁最高温差形成在144×102 s时刻,达138 ℃(即32~170 ℃),但这不足以产生热疲劳,可保证模具寿命。从图5(a)和(c)还知,衬套内壁及凹模外壁随工作时间加长,温度增长率是由小变大的,这主要是摩擦热量产生快而向外壁散热过程相对缓慢的缘故,这符合实际摩擦散热机理,模型建立符合实际。

3 确定凸模转速

3.1 模拟采样

环模成型机在不同凸模转速条件下,成型凹模所升高的温度是不同的,这里给凸模加载n1=180 r/min、n2=240 r/min、n3=300 r/min 3种不同转速,则取样60min、240min两个时刻凹模衬套、凹模体温度场分布状态分别如图6所示。

3.2 凸模转速确定

根据凹模温度场(见图6)及凹模内外壁温度变化曲线(见图7)综合分析可知:当凹模工作达60 min时,凹模内壁温度在凸模转速为n3=300 r/min状态时最先超过70 ℃、达106 ℃(见图6(e)),即使物料最先达木质素软化温度;当工作达240 min时,凹模温度也在300 r/min的状态下,最先上升到260 ℃,工作到300 min时,凹模温度接近300 ℃(图6(f)及图7(c)),这使温度升高过快,易出现物料的焦化现象,影响其成型质量。而在凸模转速n1=180 r/min时,凹模温度在工作150 min后才达70 ℃(图6(a)及图7(a)),在此期间物料成型质量均差,故物料整体成型质量相对差。当凸模转速n2=240 r/min时,凹模温度在成型机工作60~300 min时间内保持在70~175 ℃之间(见图6(c)、(d)和图7(b)),这使凹模内壁较长时间里均处在木质素软化温度范围内,使物料成型质量相对较好且稳定。综合上述比较可以确定,n2为最佳凸模转速。

图6 不同凸模转速下凹模不同工作时刻温度场图

Fig. 6 Temperature field chart of female die at two typical operating times in three punch rotating speeds

图7 不同凸模转速下凹模温度随工作时间的变化曲线

Fig. 7 Temperature history of female die at three rotating speeds of punch

4 结论

1) 柱塞啮合式成型机摩擦产生的热流密度qw与物料、模具材料、成型率等因素有关,适当选取可缩短物料中木质素达到软化温度所需时间,保证其成型质量。

2) 由物料与凹模之间产生的摩擦热使凹模各部位升高的温度不同,但因形成温差小,产生热应力较小,保证成型凹模寿命。

3) 本研究的柱塞啮合式生物质成型机在生产过程中,凹模温度随工作时间的增长及凸模转速增加呈逐渐上升趋势,当取凸模转速n2=240 r/min时,凹模内壁温度升高速度较为合理,有利于物料木质素软化,成型质量较高。

REFERENCES

[1] 欧阳双平, 侯书林, 赵立欣, 田宜水, 孟海波. 生物质固体成型燃料环模成型技术研究进展[J]. 可再生能源, 2011, 29(1): 14-18.

OU YANG Shuang-ping, HOU Shu-lin, ZHAO Li-xin, TIAN Yi-shui, MENG Hai-bo. The research progress in biomass annular mould forming for fuel technology[J]. Renewable Energy Resources, 2011, 29(1): 14-18.

[2] MANI S, TABI L G, SOKHANSANJ S. Effects of compressive force, particle size and moisture content on mechanical properties of biomass pellets from grasses[J]. Biomass and Bioenergy, 2006, 30(7): 648-654.

[3] 吴云玉. 基于生物质固体成型机理研究的环模疲劳寿命分析[D]. 济南: 山东大学, 2010: 1-84.

WU Yun-yu. Fatigue life study of loop die basic on biomass pelletizing mechanism[D]. Jinan: Shandong University, 2010: 1-84.

[4] KALIYAN N, MOREY R V. Natural binders and solid bridge type binding mechanisms in briquettes and pellets made from corn stover and switch grass[J]. Bioresearch Technology, 2010(101): 1082-1090.

[5] 杜红光, 董玉平, 王 慧, 郭飞强. 生物质冷压成型模具摩擦热分析[J]. 农业工程学报, 2011, 27(9): 58-62.

DU Hong-guang, DONG Yu-ping, WANG Hui, GUO Fei-qiang. Analysis of friction heat formed in biomass cold briquetting mold[J]. Transactions of the CSAE, 2011, 27(9): 58-62.

[6] 高明旺, 董玉平. 生物质热压成型温度场数值模拟[J]. 可再生能源, 2004(2): 23-25.

GAO Ming-wang, DONG Yu-ping. Numerical simulation of temperature field of biomass thermal compression[J]. Renewable Energy Resources, 2004(2): 23-25.

[7] DEVI L, PTASINSKI K J, JANSSEN F J J G, van PAASEN S V B, BERGMAN P C A, KIEL J H A. Catalytic decomposition of biomass tars: Use of dolomite and untreated olivine[J]. Renewable Energy, 2005, 30(4): 565-587.

[8] KALIYAN N, MOREY R V. Factors affecting strength and durability of densified biomass products[J]. Biomass and Bioenergy, 2009, 33: 337-359.

[9] 孙启新, 张仁俭, 董玉平. 基于ANSYS的秸秆类生物质冷成型仿真分析[J]. 农业机械学报, 2009, 40(12): 130-134.

SUN Qi-xin, ZHANG Ren-jian, DONG Yu-ping. Simulation analysis of compressing molding under general condition for straw biomass based on ANSYS[J]. Transactions of the Chinese Society for Agricultural Machinery, 2009, 40(12): 130-134.

[10] YUMAK H, UCAR T, SEYIDBEKIROGLU N. Briquetting soda weed (salsola tragus) to be used as a rural fuel source[J]. Biomass and Bioenergy, 2010, 34(5): 630-636.

[11] 刘圣勇, 杨国峰, 杨群发, 王 森, 华 磊, 王晓东. 螺杆挤压式生物质成型机优化设计与试验[J]. 农业机械学报, 2010, 41(7): 96-100.

LIU Sheng-yong, YANG Guo-feng, YANG Qun-fa, WANG Sen, HUA Lei, WANG Xiao-dong. Optimal design and experiment of screw briquetting biomass fuel machine[J]. Transactions of the Chinese Society of Agricultural Machinery, 2010, 41(7): 96-100.

[12] 霍丽丽, 田宜水, 孟海波, 赵立欣, 侯书林. 模辊式生物质颗粒燃料成型机性能试验[J]. 农业机械学报, 2010, 41(12): 121-125.

HUO Li-li, TIAN Yi-shui, MENG Hai-bo, ZHAO Li-xin, HOU Shu-lin. Parameters experiment of biomass pellet mill performance[J]. Transactions of the Chinese Society of Agricultural Machinery, 2010, 41(12): 121-125.

[13] SAEED MOAVENI. Finite element analysis: Theory and application with ANSYS[M]. New Jersey:Prentice Hall, 1999.

[14] KALIYAN N, MOREY R V. Factors affecting strength and durability of densified biomass products[J]. Biosystems Engineering, 2009, 33(3): 337-359.

[15] 汤爱君, 马海龙, 董玉平. 生物质挤压过程中的静水压应力[J]. 可再生能源, 2006(2): 28-31.

TANG Ai-jun, MA Hai-long, DONG Yu-ping. Hydrostatic pressure in biomass briquetting process[J]. Renewable Energy, 2006(2): 28-31.

[16] 温诗铸. 摩擦学原理[M]. 北京: 清华大学出版社, 1990: 296.

WEN Shi-zhu. Principles of tribology[M]. Beijing: Tsinghua University Press, 1990: 296.

[17] 易维明, 郭 超, 姚宝刚.生物质导热系数的测定方法[J]. 农业工程学报, 1996, 12(3): 38-41.

YI Wei-ming, GUO Chao, YAO Bao-gang. Measurement methods of heat conduct coefficient of biomass[J]. Transactions of the CSAE, 1996, 12(3): 38-41.

[18] 周美香. 木材径向导温系数的理论推导[J]. 干燥技术与设备, 2010, 8(6): 271-276.

ZHOU Mei-xiang. Theoretical derivation on wood thermal diffusivity in radial direction[J]. Drying Technology and Equipment, 2010, 8(6): 271-276.

(编辑 李艳红)

基金项目:国家“十二五”科技支撑计划课题(2012BAD30B0205)

收稿日期:2013-03-14;修订日期:2014-03-10

通信作者:俞国胜,教授,博士;电话:010-62338141;E-mail:sgyzh@bjfu.edu.cn