DOI: 10.11817/j.ysxb.1004.0609.2020-39517

基于非圆形搅拌针下压的5A06/2219-T6回填式摩擦点焊接头组织与力学性能

李送斌,封小松,王 瑾,宋学成,崔 凡

(上海航天设备制造总厂有限公司,上海 200245)

摘 要:采用带非圆截面搅拌针的焊接工具对5A06与2219铝合金进行了搅拌针下压的回填式摩擦点焊试验,对焊点进行微观组织结构分析与力学性能测试。结果表明:在焊接过程中,特殊的材料流动使得上板与下板的材料在焊点内部呈层状混合,并在焊点中心下部形成了上板材料留存区域。焊点完全消除了传统套筒下压带来的焊点竖直界面弱连接及环沟槽现象,但更容易在焊点下部形成延伸至焊核内部的界面残留,随着下压量的增加,进一步演变为向下板弯曲的Hook特征。拉剪试验表明,焊点断裂载荷随下压量增大而增加,最大拉剪力为5.7 kN;断裂模式为由焊点底部Hook缺陷起裂,穿过焊核区扩展断裂。

关键词:回填式摩擦点焊;搅拌针下压;异种铝合金;显微组织;力学性能

文章编号:1004-0609(2020)-07-1552-07 中图分类号:TG453 文献标志码:A

回填式摩擦点焊(Refill friction spot welding,RFSSW)技术由德国HZG(原GKSS中心)于1996年发明,其最主要的优势是可获得无匙孔的焊点表面。由于该技术属于固相连接技术,避免了传统熔化点连接的诸多缺陷而受到广泛研究和关注[1-2]。按照焊接过程的不同,回填式摩擦点焊分套筒下压(Sleeve-plunge,SP)与搅拌针下压(Pin-Plunge,PP)两种焊接方式。相比于PP方式,SP方式可以获得更大的连接面积与更高的焊点接头断裂载荷[3]。因此,对摩擦点焊的研究多以套筒下压方式展开。

目前,套筒式回填搅拌摩擦点焊仍存在诸多的问题。首先,由于套筒几何形状等原因,导致焊点在径向方向的流动性较差,处于搅拌针下方的试板搭接界面受搅拌作用不足,焊点中心处易出现韧带粘连[4-6];其次,受焊接过程影响,材料在回填过程中出现不完全回填时,将导致焊点出现孔洞、侧面弱连接等缺陷,严重时甚至出现环形沟槽缺陷[7-10];此外,焊点Hook的几何形状影响同样强烈影响焊点的断裂模式,Hook的高度较大时将导致焊点力学性能较差[11-14]。这些问题的存在在一定程度上限制了这一工艺技术的应用[15]。但是,采用搅拌针下压的焊接方式,又面临了针受力过大、难以压入被焊材料的问题。

为克服SP焊接模式存在的问题,同时降低焊接过程中焊接工具的轴向负载,本文设计了非圆截面的搅拌针进行搅拌针下压的焊接试验。进一步地,为清楚地观察被焊材料的流动情况,被焊材料选择了5A06和2219异种铝合金,通过对焊点微观组织结构及力学性能的分析,探究这一新型的焊接工艺过程特性。

1 实验

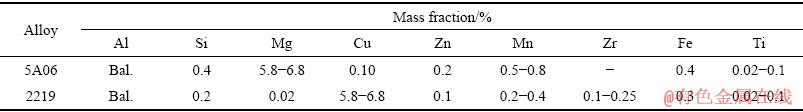

本实验中选用1.8 mm厚5A06铝合金作为上试板、5 mm厚2219-T6铝合金作为下试板进行搭接点焊,试板尺寸均为120 mm×40 mm,母材的化学成分如表1所列。RFSW实验在由德国HARMS WENDE公司制造的标准回填式摩擦点焊设备(型号RPA100)上进行,焊前使用机械打磨及化学清洗的方式除去表面氧化层和油污。

图1所示为焊接工具及相应的焊接过程示意图。由图1(a)可知,焊接工具的套筒直径为9 mm,搅拌针外径为5.2 mm,其中,搅拌针端面形状为直径5.2 mm圆与长轴5.5 mm短轴2.5 mm椭圆相交得到,轴向长度3 mm。针下压回填式摩擦点焊技术的基本过程与传统的摩擦点焊过程类似,可以分为摩擦预热、搅拌针下压搅拌、材料回填、点焊完成4个阶段,如图1(b)~(e)所示。所不同的是,在正式焊接前,搅拌针与套筒之间的间隙即“过渡槽”由待焊母材上板同种材料所填充,焊接结束时混合材料重新填满间隙,实现无材料缺失的焊接过程。焊接中使用的工艺参数为:焊接时间3 s,旋转速度2000 r/min,下压深度2.0、2.2、2.4和2.6 m。

表1 5A06和2219的化学成分

Table 1 Chemical compositions of 5A06 and 2219

图1 焊接工具及相应的焊接过程示意图

Fig. 1 Schematic diagram of welding tools and corresponding welding process

焊接完成后,沿垂直于焊点中心的方向截取并制备金相试样,分别使用金相显微镜与扫描电镜观察焊点接头宏观和微观组织形貌。在CSS-44100型万能试验机上进行拉剪试验,取3个同参数试样断裂载荷平均值为断裂载荷。

2 结果与讨论

2.1 横截面形貌与显微组织

图2所示为典型的焊点横截面组织形貌。由图2可知,焊点内部无明显的缺陷存在。与传统套筒下压所得到的焊点形貌不同,搅拌针下压情况下得到的焊点直径较小,在搭接界面处,焊点的直径仅稍大于搅拌针直径。同时,在微观组织形貌上与套筒下压存在较大的区别,在传统套下压方式下,材料的混合主要集中在套筒下方区域,焊点中心部位的搭接界面变形程度较小。而非圆截面搅拌针的下压对焊点中心部位的挤压作用较强,焊点中心部位的原始搭接界面不复存在,上下试板材料的混合较为充分,由组织形貌的不同,可以将整个焊点大致分为3个区域:上下试板材料以层状交叠方式相混合的焊核混合区(Ⅰ区);在焊点中下部留存呈椭球状的上试板材料残留区(Ⅱ区);当搅拌针回抽时,混合材料向下并流向中心聚拢的回填区(Ⅲ区),这几个区域并没有特别明显的分界面。

图2 典型焊点横截面组织形貌

Fig. 2 Cross-section morphology of typical welding spot (2.4 mm plunge depth)

焊核混合区以焊点中心轴呈中心对称分布,其与上下试板母材存在明显的界限,回填区内上下试板材料相互交叠呈层状分布,整体呈倒置的“凹”字形。由焊点中心至母材,焊核混合区内分层的材料先是与试板表面平行,至交界处混合区内材料向上弯曲,最终延伸至混合区与上试板母材交界处。而在混合区底部则存在由搭接界面延伸至搅拌区内部的上试板材料。

为了进一步分析焊点微观组织形貌,对焊点A、B、C、D典型区域(见图2)进行了扫描电镜分析。图3(a)所示为混合区A处的典型形貌。由图3(a)可知,混合区与上试板材料实现了无缺陷连接,消除了传统套筒下压方式带来的侧面弱连接问题。图3(b)所示为混合区B处的典型形貌。作为回填材料的最终结合位置,焊点中心并无明显缺陷,上下试板材料以相互交叠的层状方式回填至焊点,5A06与2219-T6实现了良好的冶金结合。图3(c)所示为留存区与聚拢区交界C区的典型形貌。作为留存在焊点中部的上试板材料,其与下试板材料的结合存在较明显的不连续界面残留,这表明此处的材料流动传质不够充分。图3(d)所示为混合区与下试板交界D区的典型形貌。从图3(d)可见,此处氧化膜残留有向焊核内部延伸的趋势,但该界面残留并未随层状材料延伸至焊核内部;随着向焊核内部的延伸,残留的上下试板界面由未连接状态转变为完全冶金结合状态。

从焊点的典型截面来看,基于非圆截面搅拌针下压的焊接模式,其特殊的材料流动使得传统的套筒下压焊接模式存在的焊点竖直界面环沟槽、弱连接缺陷得以避免。但是由于材料由外侧向中心回填的特殊流动方式,使得原始搭接界面容易向内延伸,得以残留在焊核内部,形成Hook的缺陷。Hook缺陷的存在破坏了接头的连续性,并降低了试板或接头的有效承载面积,焊点受拉剪作用力时裂纹易沿Hook扩展[16-17]。

为了获得这种缺陷的形成规律,对不同针下压深度的焊点形貌进行了观察,图4所示为搅拌针分别压入下试板0.2、0.4、0.6、0.8 mm的焊点横截面形貌。从图4可见,随下压深度的增加,Hook向下弯曲的角度逐渐增大。将该界面无明显氧化膜存在处设为尾端,测量其尾端相对于原始界面向焊核内延伸的高度d、宽度w。随着搅拌针下压量的增加,Hook的高度先增加后减小,而向焊核内部延伸的宽度则随下压量的增加而减少。

据分析,在其他参数不变的条件下,增加下压深度通常意味着增加焊接热输入,也带来对焊接区域更强的摩擦剪切作用,这有利于原始搭接界面氧化膜的破碎和弥散分布。因此,随着下压量的增加,首先造成的是Hook高度的增加,但继续增加下压量,材料流动增剧且温度升高,使得一部分氧化膜破碎消失,在继续增大下压深度的情况下Hook高度反而减小。Hook高度的增加减小了下板的有效承载厚度,使接头承载能力下降;但Hook角度的增大提升了剪切作用下裂纹沿Hook扩展的难度,提升了接头的力学性能。

图3 图2中焊点区内各区域微观形貌

Fig. 3 Microstructures of welding spot shown in Fig. 2

图4 不同下压深度对应的混合区底部形貌

Fig. 4 Bottom morphologies of mixed section at different plunge depths

因此,从实验结果来看,采用非圆截面搅拌针进行针下压回填式摩擦点焊,消除了传统套下压方式带来的侧面弱连接问题,上下试板在混合区内以相互交叠的层状形式相混合形成了具有良好冶金结合的焊核区域。但同样地,非圆截面搅拌针下压得到的焊点容易导致原始搭接界面残留进而形成Hook的情况,这将对焊点的承载能力产生显著影响。

2.2 力学性能分析

为评价不同参数下的焊点性能,并验证接头的微观组织结构分析,对不同工艺参数下的焊点力学性能进行了测试,并分析了焊点断裂模式。

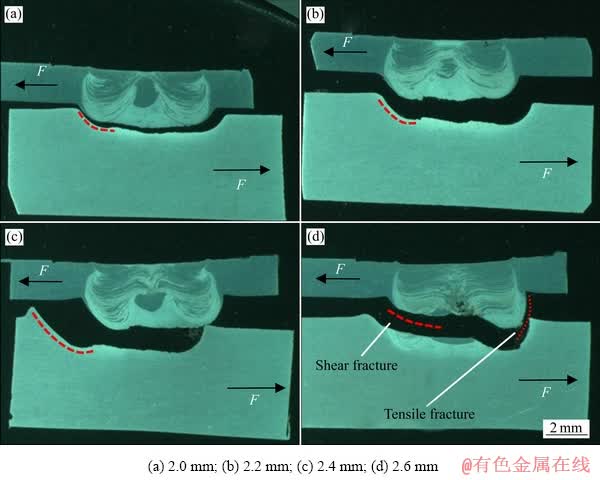

图5所示为搅拌针下压深度与断裂载荷之间的关系。图6(a)~(c)对应下压深度为2.0~2.4 mm 时焊点的破坏形式。由图6可见,焊点的断裂特征表现为焊核从下试板剥离。值得注意的是,断裂起始位置均为Hook尖端,之后沿残余上试板与下试板界面向下扩展,最终在焊点底部的热机影响区断裂,焊核从下试板剥离。裂纹在Hook特征处扩展时,断裂界面较为平滑,进一步表明焊核内部残余的上试板材料与下试板的混合程度较差,未能实现紧密的冶金结合;随下压深度的增加,尽管断裂模式未发生变化,但由图5中显示的数据可见,接头的断裂载荷随下压深度的增加而增加。由焊点的破坏形式可见,当下压深度增加时,上下试板的机械连接特征逐渐增强。在断裂模式一致的情况下,焊核区尺寸在高度方向的增大意味着焊点承载面积的增大,最终表现为焊点的断裂载荷随下压深度的增加而逐渐增大。

图5 搅拌针下压深度与断裂载荷之间的关系

Fig. 5 Relationship between tool plunge depth and failure load

图6 不同下压深度下焊点破坏形式

Fig. 6 Fracture modes of weld spot at different plunge depth

图6(d)所示为下压深度为2.6 mm时焊点破坏形式。焊核受剪切撕裂的同时部分焊核从下试板剥离。焊点受拉剪力作用,其起裂位置为Hook尖端,之后裂纹向焊核内部扩展,最终在焊核底部热机影响区断裂。这是由于下压深度的增加,Hook的延伸方向与拉剪力近似垂直,裂纹萌生之后无法沿Hook继续扩展,裂纹向焊核内部扩展。同时,随拉应力的增大上下试板在拉剪力方向发生位移,焊核与热机影响区受拉应力作用沿Hook发生剥离,最终导致焊点以剪切模式起裂,剥离模式终止,总体表现为焊核剪切撕裂的同时部分焊核从下试板剥离。由于断裂模式的变化,且由于混合区力学性能较好,焊点断裂载荷在下压深度为2.6 mm时达到最大值,其值为5.7 kN。

非圆截面搅拌针改变了上下试板的连接状态,并随之改变了上下试板的断裂模式。上下试板材料在混合区实现了较优的冶金结合,但仍旧未能解决Hook缺陷,但此方法为解决侧面弱连接提供了思路,并为通过改进搅拌针形状提升焊点力学性能提供了有效途径。

3 结论

1) 受搅拌针特殊形状及搅拌针下压的焊接方法影响,焊点的微观组织特征与传统套下压方式具有显著差别,焊核区内上下试板材料相互交叠后以分层方式实现混合并实现了良好的冶金结合,在焊点中心下部位置容易产生呈椭球状的上试板材料留存。

2) 基于非圆形搅拌针下压的回填式摩擦点焊方法消除了传统套下压方式固有的焊点竖直界面弱连接缺陷,但焊核区内上下试板的原始搭接界面残留容易形成Hook缺陷,其尺寸和形状受下压深度显著影响。

3) 下压深度与接头拉剪强度呈正相关,在下压深度为2.6 mm时,焊点抗拉剪载荷为5.7 kN,焊点的断裂模式均为由Hook起裂,穿过焊核区断裂。

REFERENCES

[1] OUYANG J, YARRAPAREDDY E, KOVACEVIC R. Microstructural evolution in the friction stir welded 6061 aluminum alloy (T6-temper condition) to copper[J]. Journal of Materials Processing Technology, 2006, 172(1): 110-122.

[2] CAM G, MISTIKOGLU S. Recent developments in friction stir welding of alloys[J]. Journal of Materials Engineering & Performance, 2014, 23(6): 1936-1953.

[3] AMANCIO-FILHO S T, CAMILLO A P C, BERGMANN L, DOS SANTOS J F, KURY S E, MACHADO N G A. Preliminary investigation of the microstructure and mechanical behavior of 2024 aluminum alloy friction spot weld[J]. Materials Transactions, 2011, 52(5): 985-991

[4] KUBIT A, BUCIOR M, WYDRZYNSKI D, TRZEPIECINSKI T, PYTEL M. Failure mechanisms of refill friction stir spot welded 7075-T6 aluminum alloy single-lap joints[J]. International Journal of Advanced Manufacturing Technology, 2018, 94(10): 4479-4497.

[5] ANDRZEJ K, DAWID W, TOMASZ T. Refill friction stir spot welding 7075-T6 aluminum alloy single-lap joints with polymer sealant interlayer[J]. Composite Structures, 2018: 201(10): 389-397.

[6] ZHOU L, LUO L Y, ZHANG T P, HE W X, HUANG Y X, FENG J C. Effect of rotation speed on microstructure and mechanical properties of refill friction stir spot welded 6061-T6 aluminum alloy[J]. International Journal of Advanced Manufacturing Technology, 2017(5/8): 1-9.

[7] SHEN Zhi-kang, YANG Xin-qi, ZHANG Zhao-hua, CUI Lei, LI Tie-long. Microstructure and failure mechanisms of refill friction stir spot welded 7075-T6 aluminum alloy joints[J]. Materials and Design, 2013, 44: 476-486.

[8] SHI Yao, YUE Yu-mei, ZHANG Li-guo, JI Shu-de, WANG Yue. Refill friction stir spot welding of 2198-T8 aluminum alloy[J]. Transactions of the Indian Institute of Metals, 2017, 71(1): 139-145.

[9] LI Zheng-wei, GAO Shuang-sheng, JI Shu-de, YUE Yu-mei, CHAI Peng. Effect of rotational speed on microstructure and mechanical properties of refill friction stir spot welded 2024 Al alloy[J]. Journal of Material Engineering and Performance, 2016, 25(4): 1673-1682.

[10] YUE Yu-mei, SHI Yao, JI Shu-de, WANG Yue, LI Zheng-wei. Effect of sleeve plunge depth on microstructure and mechanical properties of refill friction stir spot welding of 2198 aluminum alloy[J]. Journal of Materials Engineering and Performance, 2017, 26(10): 5064-5071

[11] CAO J Y, WANG M, KONG L, GUO L J. Hook formation and mechanical properties of friction spot welding in alloy 6061-T6[J]. Journal of Materials Processing Technology, 2016, 230: 254-262.

[12] BRZOSTEK R C, SUHUDDIN U, SANTOS J F D. Fatigue assessment of refill friction stir spot weld in AA2024-T3 similar joints[J]. Fatigue &Fracture of Engineering Materials and Structures, 2017, 41(1): 967-968.

[13] XU Zhi-wu, LI Zheng-wei, JI Shu-de, ZHANG Li-guo. Refill friction stir spot welding of 5083-O aluminum alloy[J]. Journal of Materials Science & Technology, 2018, 34(5): 144-451.

[14] ZHAO Y Q, LIU H J, CHEN S X, LIN Z, HOU J C. Effects of Sleeve plunge depth on microstructures and mechanical properties of friction spot welded alclad 7B04-T74 aluminum alloy[J]. Materials & Design, 2014, 62(10): 40-46.

[15] SHEN Z, DING Y, GOPKALO O, DIAK B, GERLICH A P. Effects of tool design on the microstructure and mechanical properties of refill friction stir spot welding of dissimilar Al alloys[J]. Journal of Materials Processing Technology, 2017, 252: 751-759.

[16] BUFFA G, FRATINI L, PIACENTINI M. On the influence of tool path in friction stir spot welding of aluminum alloys[J]. Journal of Materials Processing Technology, 2008, 208(1/3): 309-317.

[17] 申志康, 杨新岐, 张照华, 尹玉环. 铝合金回填式搅拌摩擦点焊组织及力学性能分析[J]. 焊接学报, 2013, 34(6): 73-76.

SHEN Zhi-kang, YANG Xin-qi, ZHANG Zhao-hua, YIN Yu-huan. Microstructure and mechanical properties of refill friction stir spot welding in aluminums [J]. Transaction of the China Welding Institution, 2013, 34(6): 73-76.

Microstructure and mechanical properties of 5A06/2219-T6 refill friction spot weld with non-circular pin-plunge mode

LI Song-bin, FENG Xiao-song, WANG Jin, SONG Xue-cheng, CUI Fan

(Shanghai Aerospace Equipments Manufacture Co., Ltd., Shanghai 200245, China)

Abstract: 5A06/2219 aluminum alloy was pin plunge refill friction spot welded using non-circular cross section pin, the microstructure and tensile property of the joint were discussed. The results show that the special materials flow in welding spot makes upper and lower plates materials mixed in a multi-layer structure, and forms a residual area of upper plate material. The welding spot eliminates the weak-bonding of vertical interface in traditional sleeve plunge refill friction spot welding, but causes upper plate material of original lap interface extending into interior of stir zone, and as the plunge depth increases, makes it a characteristic of Hook defects. The tensile-shear tests show that the fracturing load of welding spots increases with the increase of plunge depth and the maximum tensile shear is 5.7 kN. It can be concluded that the cracks start with Hook defects and propagate into stir zone.

Key words: refill friction spot welding; pin plunge; dissimilar aluminum alloys; microstructure; mechanical property

Foundation item: Project(2018YFB1105804) supported by the National Key Research and Development Program of China; Project(17110730400) supported by the Shanghai International Science and Technology Cooperation Program, China

Received date: 2019-05-20; Accepted date: 2019-10-08

Corresponding author: FENG Xiao-song; Tel: +86-21-24187196; E-mail: fxsupc@163.com

(编辑 龙怀中)

基金项目:国家重点研发计划资助项目(2018YFB1105804);上海市国际科技合作项目(17110730400)

收稿日期:2019-05-20;修订日期:2019-10-08

通信作者:封小松,研究员,博士;电话:021-24187196;E-mail:fxsupc@163.com