ZK31+0.3Yb镁合金的热力模拟

刘志义, 叶呈武, 张 坤, 郑青春

(中南大学 材料科学与工程学院, 湖南 长沙, 410083)

摘要: 通过热压缩变形实验, 利用光学显微镜观察, 对ZK31+0.3Yb镁合金变形过程的流变应力和组织演变进行研究。 研究结果表明: 663 K/0.1 s-1是最佳的变形条件, 在此条件下, 合金的流变应力低, 动态再结晶充分激发, 合金的塑性好; 当变形温度降至623 K和573 K时, 动态再结晶不能充分激发, 合金变形的流变应力明显提高, 尤其是573 K变形时流变应力达到185 MPa; 而变形温度提高到723 K时, 晶界处形成楔形裂纹, 合金的塑性差; 在663 K时变形, 尽管应变速率降低至0.001 s-1, 合金的动态再结晶充分激发, 流变应力下降, 但变形的进程被减缓; 当变速率提高到1.000 s-1时, 晶粒间的协调变形不能发挥作用, 合金的塑性最差。

关键词: 镁合金; 热力模拟; 变形温度; 应变速率; 动态再结晶

中图分类号:TG111.7 文献标识码:A 文章编号: 1672-7207(2005)06-0933-05

Thermal mechanical simulation of ZK31+0.3Yb magnesium alloy

LIU Zhi-yi, YE Cheng-wu, ZHANG Kun, ZHENG Qing-chun

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The flow stress and microstructure evolution of ZK31+0.3Yb magnesium alloy were studied through hot compression deformation experiment and optical microscope observation. The results show that the suitable deformation condition is 663 K/0.1 s-1, which results in low flow stress and that the good ductility of the alloy is obtained due to the activation of dynamic recrystallization(DRX) of the alloy. When the temperature is decreased to 573 K and 623 K, the flow stress increases obviously due to the inhibited of the DRX, especially, the flow stress increases to 185 MPa when the temperature decreases to 573 K. The wedge cracking initiates at the grain boundary when the temperature increases to 723 K, which causes the poor ductility of the alloy. Although strain rate is decreased to 0.001 s-1, which causes the low stress due to DRX activated sufficiently, the deformation process is slowed down. Increasing the strain rate to 1.000 s-1 causes the poorest ductility due to the fracture of compatible deformation between grains.

Key words: magnesium alloy; thermal mechanical simulation; deformation temperature; strain rate; dynamic recrystallization

镁的资源丰富, 镁合金密度低, 比强度、 比钢度大, 是一种很有发展潜力的材料, 但其晶格对称性低, 塑性变形性能差, 大量镁合金只能以压铸件的形式使用, 生产效率低, 使用成本高, 因此, 开发高性能的变形镁合金具有非常重要的意义。

许多研究者对镁或镁合金的塑性变形过程进行了研究[1-8], 确定了镁合金变形过程的特点: 随材料的原始状态不同, 镁合金的变形机理发生改变。这一点与铝合金和其他合金材料不同。 各种合金元素因对镁合金层错能的改变值不同, 对变形机制也将产生各种不同的影响[3, 4]; 镁合金变形时, 晶粒的变形不均匀, 因而, 晶粒间和协调变形作用对镁合金的塑性变形过程意义重大[5, 6]。 此外, 镁合金的滑移有明显的方向性, 基面滑移系相对其他滑移系来说容易激发, 因此, 原始的织构对塑性变形有影响[7, 8]。

在此, 作者以铸态ZK31+0.3Yb镁合金为原料, 研究不同变形温度和应变速率对合金变形的变形应力和组织的影响。

1 实 验

本实验所用材料为Mg-3.0%Zn-0.7%Zr-0.3%Yb(质量分数)(简称为ZK31+0.3Yb镁合金), 铸锭在673 K均匀化24 h, 并沿浇注方向从铸锭上切取长条, 热力模拟标准试样尺寸(直径×长)为8 mm×10 mm, 试样两端面车0.1 mm深凹槽加石墨润滑。

热压缩试验在Gleeble1500热务模拟机上进行, 应变速率[AKε·]为0.100 s-1时变形温度分别为573, 623, 663和723 K, 应变量ε为5%, 10%, 20%, 30%, 50%和70%(对应真应变分别为0.05, 0.11, 0.22, 0.36, 0.69和1.20)。 为研究不同应变速率对变形的影响, 在663 K时进行应变速率为0.001 s-1和1.000 s-1的实验。 热压缩完成后, 试样在夹头上迅速以水冷却至室温。

所有变形过的试样沿压缩方向从中剖开, 机械抛光并化学侵蚀后在Poly-met金相显微镜上进行组织观察, 所用金相侵蚀液为5 g苦味酸+5 mL冰醋酸+100 mL乙醇+10 mL水。

2 结果与讨论

2.1 变形温度的影响

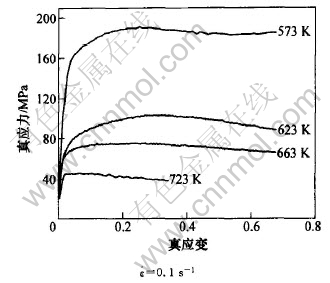

图1所示为ZK31+0.3Yb镁合金热压缩实验的真应力-真应变曲线。 可见, 在所有的变形温度下, 在变形的早期, 流变应力先迅速增加, 到达峰值后, 逐渐下降; 变形温度低(573 K), 应力峰值(σp)高, 对应的应变峰值(εp)大; 变形温度提高(623 K), εp仍很高, 但σp已明显下降; 高温(663 K, 723 K)变形时, 流变应力(σs)在经受很小的应变(εs)后, 即进入稳定阶段(见表1)。

众所周知, 镁合金变形时滑移系的开动与变形温度有关, 573 K变形时, 峰值应力185 MPa明显高于其他温度的流变抗力, 其值约为623 K变形时流变抗力的2倍。 可见, 这2个温度的变形机制不同, 这和文献[2]和[3]的报道结果一致。

图 1 不同变形温度下ZK31+0.3Yb镁合金的真应力—真应变曲线

Fig. 1 True stress-true strain curves of ZK31+0.3Yb magnesium alloy at various temperatures when ε=0.1 s-1

表 1 不同变形条件下ZK31+0.3Yb镁合金的稳态(峰值)应力及对应的稳态(峰值)应变

Table 1 Steady (peak) stress and steady (peak) strain of ZK31+0.3Yb magnesium alloy under various deformation conditions

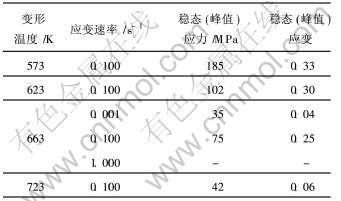

图2所示为ZK31+0.3Yb镁合金在663 K/0.1 s-1变形、 组织的演变过程。 可见, 在变形早期(图2(a)), 组织中最主要的特征是孪晶, 随应变量的增加(30%), 在晶界附近出现一些细小的动态再结晶(DRX)晶粒, 同时还出现了另一些比DRX晶粒大, 而比原始晶粒细小的晶粒[9](如图2(b)中箭头所示); 随变形量的进一步增加(图2(c)), 原始晶粒被拉长, DRX晶粒不断增多, 直到出现最高的变形量为止(图2(d)); 组织中主要以DRX晶粒为主, 但仍残余部分原始粗大晶粒。 由于新产生的DRX晶粒间的取向差小, 在变形过程中, 这些晶粒并不会长大, 因而各变形程度下的DRX晶粒尺寸相似[10, 11]。

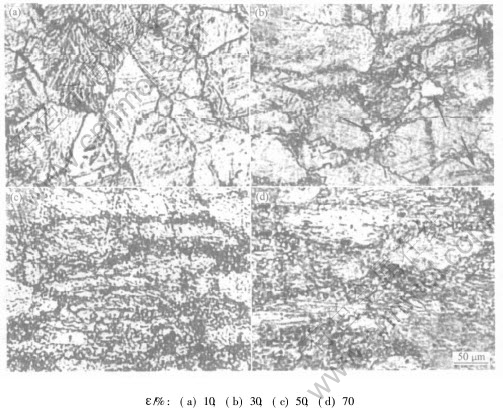

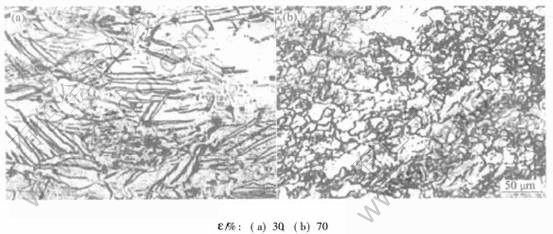

变形温度下降至623 K时, 峰值流变应力提高27 MPa, 在整个变形过程中, 流变应力均比663 K变形时高20 MPa左右, 主要是由于在623 K变形过程中, DRX没有充分激发, 因为DRX虽然能在很宽的温度范围内形核, 但只能在高于某一温度的条件下才能长大[4, 12]。 图3所示为ZK31+0.3Yb镁合金573 K 和623 K应变量(ε)为70%时的组织, 与图2(d)相比, DRX体积分数明显减少。

变形温度提高到723 K(尽管流变应力进一步下降, 但在晶界处观察到楔形裂纹(如图4中箭头所示)。 应变量为10%时(图4(a)), 这种楔形裂纹只在部分的晶界处可见; 当应变量达到30%时(图4(b)), 裂纹最多; 当应变量为70%时(图4(c)), 合金中全部为DRX组织, 位于原始晶界处的楔形裂纹消失。 其原因是: 在723 K变形时, 变形温度已经很高, 变形潜热的释放又进一步提高了变形温度, 晶界的强度进一步降低, 而晶界又是应力最集中的区域, 因而产生裂纹释放应力集中[13]; 当变形量较大时, 由于大量DRX的激发, 新晶粒在晶界处形核长大, 消耗了细小的裂纹, 因而观察到的组织主要是DRX新晶粒[14]。 J.A.del Valle等[7, 15]在实验中发现, 镁合金大变形量的轧制时, 反而有更好的塑性, 可能就与这种现象有关。

图 2 ZK31+0.3Yb镁合金于663 K变形的组织演变

Fig. 2 Microstructure evolution of ZK31+0.3Yb magnesium alloy deformation at 663 K

图 3 ε=70%时ZK31+0.3Yb镁合金于573 K和623 K变形的组织

Fig. 3 Microstructure of ZK31+0.3Yb magnesium alloy deformation at 573 K and 623 K when ε=70%

图 4 ZK31+0.3Yb镁合金723K变形的组织演变

Fig. 4 Microstructure of ZK31+0.3Yb magnesium alloy deformation at 723 K

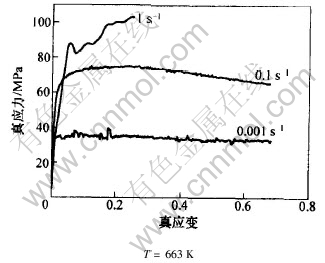

2.2 应变速率的影响

应变速率对流变应力的影响与温度对流变应力的影响相反, 随应变速率的提高, 流变应力迅速提高。 在低应变速率(0.001 s-1)时, σs和εs均小; 应变速率提高(0.100 s-1)时, σs和εs均提高(见表1), 当应变速率进一步提高至1.000 s-1时, 在变形的早期试样即发生了破裂, 流变应力随应变增加而快速增加, 直至试样破裂(见图5)。

图 5 不同应变速率下ZK31+0.3Yb镁合金的真应力—真应变曲线

Fig. 5 True stress-true strain curves of ZK31+0.3Yb magnesium alloy at various strain rates when T=663 K

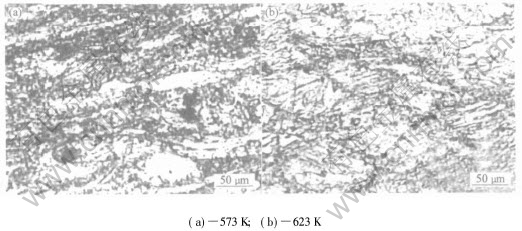

应变速率的下降, 不但能使试样顺利实现变形。 由表1可知, 流变应力随应变速率的下降而下降, 应变速率较小有利于合金变形过程的进行。 应变速率较高时, 变形只在有限的晶粒内进行。 如图6所示, 部分晶粒内发生了明显的孪生, 而另一些晶粒则几乎没有变形。 经分析认为, 应变速率高, 晶粒间的协调变形不易进行, 因而应变应力高, 合金的塑性差。

图 6 ε=10%和ε=1.000 s-1时ZK31+0.3Yb镁合金于663 K变形的组织

Fig. 6 Microstructure of ZK31+0.3Yb magnesium alloy at 663 K when ε=10% and ε=1.000 s-1

应变速率下降后, 虽然流变应力下降, 变形后组织中的DRX体积分数提高(图7(b)), 但变形的进程减慢, 如图7(a)所示; 当变形温度为663 K, 应变速率为0.001 s-1时, 即使变形量达到30%, 组织中仍没有明显的DRX。 O.Sivakesavam等[1]认为, 在压缩变形过程中, 应变速率的下降到0.100 s-1以下, 纯镁在晶界处产生楔形裂纹。 可见,应变速率的下降对塑性的提高产生不利的影响。

图 7 ε=0.001 s-1时ZK31+0.3Yb镁合金于663 K变形的组织

Fig. 7 Microstructures of ZK31+0.3Yb magnesium alloy deformation at 663 K when ε=0.001 s-1

3 结 论

a. 在变形温度663 K, 应变速率为0.100 s-1时进行塑性变形, 变形早期孪生大范围发生; 在变形的中后期, 动态再结晶充分激发, 塑性变形的流变应力低, 合金塑性好, 是ZK31+0.3Yb镁合金最佳的变形条件。

b. 低于663 K时的变形, 动态再结晶难以充分激发, 流变应力高, 合金的塑性不好; 当变形温度提高至723 K时, 又由于晶界楔形裂纹形成, 合金的塑性大大降低。

c. 在温度为663 K, 应变速率为0.001 s-1时, 虽然流变应力低, 动态再结晶易于充分激发, 但变形进程缓慢; 而应变速率提高到1.000 s-1时, 晶粒间不能协调变形, 合金的塑性最差。

参考文献:

[1]Sivakesavam O, Rao I S, Praad Y V. Processing map for hot working of as cast magnesium[J]. Mater Sci and Tech, 1993, 19: 805-810.

[2]Ion S E, Humphreys F J. Dynamic recrystallization and the development of microstructure during the high temperature deformation of magnesium[J]. Acta Mater, 1982, 30: 1909-1919.

[3]Galiyev A, Sitdikov O, Kaibyshev R. Deformation behavior and controlling mechanism for plastic flow of magnesium and magnesium alloy[J]. Mater Trans, 2003, 44: 426-435.

[4]Myshlyaev M M, McQueen H J, Mwembela A, et al. Twining, dynamic recovery and recrystallization in hot worked Mg-Al-Zn alloy[J]. Mater Sci Eng A, 2002, 337: 121-133.

[5]Koike J, Kobayashi T, Mukai T, et al. The activity of non-basal slip systems and dynamic recovery at room temperature in fine-gained AZ31B magnesium[J]. Acta Mater, 2003, 51: 2055-2065.

[6]Myers M A, Vhringer O, Lubarda V A. The onset of twining in metals: a constitutive description[J]. Acta Mater, 2001, 49: 4025-4039.

[7]del Valle J A, Pérez-Prado M T, Ruano O A. Texture evolution during large-strain hot rolling of the MgAZ61 alloy[J]. Mater Sci Eng A, 2003, 355: 68-78.

[8]Charghouri M A, Weatherly G C, Embury J D, et al. Study of mechanical properties of Mg-7.7%Al by neutron diffraction[J]. Phil Mag, 1998, 76A: 1671-1695.

[9]YE Cheng-wu, LIU Zhi-yi, ZHANG Kun, et al. Twinning during hot compression deformation of ZK31+0.3Yb magnesium alloy[J]. Transaction of Nonferrous Metals Society of China, 2005, 15(4): 884-888.

[10]Yang X Y, Miura H, Sakai T. Dynamic evolution of new grains in magnesium alloy AZ31 during hot deformation[J]. Mater Trans, 2003, 44: 197-203.

[11]Watanabe H, Tsutsui H, Mukai T, et al. Grain size control of commercial wrought Mg-Al-Zn alloys utilizing dynamic recrystallization[J]. Mater Trans, 2001, 42: 1200-1205.

[12]Humphreys F J, Hatherly M. Recrystallization and related annealing phenomena[M]. Oxfords: Pergamon Press, 1995. 19-38.

[13]Yoo M H. Slip twinning and fracture in hexagonal close-packed metals[J]. Metal Trans, 1981, 12A: 409-418.

[14]Doherty R D, Hughes D A, Humphreys F J, et al. Current issues in recrystallization: a review[J]. Mater Sci and Eng, 1997, 238A: 219-274.

[15]Chang T C, Wang J Y, Ming C. Grain refining of magnesium alloy AZ31 by rolling[J]. Mater Proc Tech, 2003, 140: 588-591.

收稿日期:2005-01-29

作者简介: 刘志义(1962-), 男, 湖南绥宁人, 教授, 从事镁合金变形与强韧化研究

论文联系人: 刘志义, 男, 教授; 电话: 0731-8836927(O); E-mail: Liuzhiyi@mail.csu.edu.cn