文章编号:1004-0609(2011)06-1389-07

基于粘弹性理论异种材料的共烧结致密化

刘 攀,何 浩,李益民

(中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:基于加压烧结粘弹性流动理论,引入烧结速率不匹配造成的界面应力,并考虑界面应力分布情况,建立两种材料共烧结致密化模型,描述共烧结界面应力对共烧结致密化的影响。通过两种材料自由烧结数据,进行材料参数拟合;通过拟合得到的材料参数进行共烧结致密化模型模拟。结果表明:共烧结会使得试样中存在密度梯度,并且可能加大或者缩小界面处密度差异,对共烧结后界面结合强度造成影响。采用不同孔隙率的铜粉共烧结进行验证,实验测得共烧结试样密度梯度分布以及界面处密度差异变化和模型预测结果一致。

关键词:共烧结;致密化;烧结理论;密度梯度

中图分类号:TF121 文献标志码:A

Co-sintering densification of heterogeneous materials based on viscoelastic theory

LIU Pan, HE Hao, LI Yi-min

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: A model based on viscoelastic theory was established on co-sintering densification. The interface stress caused by mismatch densification rates was modeled and calculated. The interface stress distribution was considered in the model. The model was simulated with the parameters fitted by free sintering of different materials. The results show that the density gradient in co-sintering samples is caused by interface stress, the density difference at co-sintering interface may be enlarged or minimized, and thus has different effects on interface bonding strength. The experimental verification was conducted by using copper powder with different powder loadings. The density gradients and density discrepancy at interface measured in the experiment agree well with the model predictions.

Key words: co-sintering; densification; sintering theory; density gradient

粉末共注射技术是在传统粉末注射成形基础上发展起来的一项新的成形工艺,通过不同的方式把多种组分在模具内复合注射成形,整合各组分的优越性能,可以在一个生产步骤内获得功能性和形状复杂性相统一的成形坯,实现表层/芯层具有不同材料及功能的结构,例如梯度硬质合金刀具、齿轮、滤芯、内致密外多孔牙科种植体,再将成形坯中的粘结剂脱除,经烧结致密化得到最终产品[1]。

成形后的共烧结是共注射成形非常重要的一道工序,这一过程中两种粉末颗粒的聚集体变成晶粒的聚结体,从而获得具有所需物理、力学性能材料的组合。不同粉末由于其元素种类以及含量、粉末形貌和粒度,或者共注射过程中的粉末装载量不同,烧结收缩速率存在很大差异,因此,会在共烧结界面处产生不匹配应力,造成烧结开裂或者变形等缺陷。由于注射成形要加入大量的粘结剂,生坯密度较低,烧结过程中会出现比传统粉末冶金更大的收缩,因此更加大了共烧结产生缺陷的可能性。

国外研究者对多种材料共注射共烧结进行实验研究[2-3],对共烧结中界面应力造成的变形和开裂也进行了研究,LU等[4]对陶瓷低温共烧结的应力和变形进行了研究。SCHOENBERG等[5]用FEA粘弹性模块对不同密度BaTiO3的共烧结进行界面应力的计算和分布的模拟;两者通过不同方法测得共烧结材料自由烧结过程中的致密化速率,界面处采用平板受力分析,忽略轴向应力,进行共烧结界面应力分析与计算。在实际共烧结过程中,由于界面应力对界面两侧共烧结材料致密化的影响,共烧结中致密化速率和自由烧结过程中的致密化速率已经不同,所以共烧结界面应力不能根据自由烧结测定的致密化速率计算,且根据牛顿第一定律,界面处轴向力是确实存在的,因此,两者共烧结界面应力的计算结果正确性都有待验证。RAVI和GREEN[6]通过薄层梯度复合材料的共烧结研究界面应力和界面弯曲率之间的关系,通过界面处的弯曲率计算共烧结过程中的界面应力大小。RAVI只提供了一种计算共烧结界面应力的方法,并没有研究实际共烧结情况下界面应力对共烧结造成的影响,从工程应用的角度来讲,共烧结研究的重点是界面应力对共烧结变形、开裂以及界面结合强度的影响,而不是界面应力大小的计算,所以,该研究实际应用意义不大。目前国外的研究中,对异种材料共烧结中界面应力的产生,应力造成的密度分布、烧结变形和开裂的研究还远不成系统,有待深入研究。

本文作者首先建立基本的共烧结致密化模型,研究共烧结界面应力对两侧共烧结材料致密化行为的作用机理,建立不同孔隙率材料共烧结密度模型。

1 模型

在共烧结过程中,由于共烧结两种材料的致密化速率不同,共烧结界面两侧材料会对彼此施加应力,从而改变了其原本的致密化行为,使得共烧结过程中两种材料的致密化行为和自由烧结过程中的致密化行为存在差异。

本文作者采用加压烧结粘弹性流动理论,建立了共烧结致密化模型。模型假设认为烧结体为线性粘弹性体,加压烧结时存在的蠕变和致密化形变是烧结体作为粘弹性体对施加的外力和自身的烧结力的粘性和弹性的混合响应[7]。宏观上施加的外部应力导致的应变速率和不施加外力时的烧结收缩应变速率是可以线性迭加的[8]。因为高温下加压烧结,多孔体的致密化应变比它的弹性应变大得多,所以忽略弹性应变,则在加压烧结情况下,多孔体的应变速率方程如下[9]:

(1)

(1)

式中: 为线应变速率,包括受力方向上的致密化应变和剪切应变速率;

为线应变速率,包括受力方向上的致密化应变和剪切应变速率; 为自由烧结平均静水压力;

为自由烧结平均静水压力; 为剪切应力;

为剪切应力; 为加压烧结中额外施加的平均静水压力;Kp为体积黏度;Gp为剪切黏度。

为加压烧结中额外施加的平均静水压力;Kp为体积黏度;Gp为剪切黏度。

对于体积应变速率和致密化速率,则有

(2)

(2)

式中: 为体积应变速率;

为体积应变速率; 为体积变化相对值;其中

为体积变化相对值;其中 为致密化速率;

为致密化速率; 为相对密度;

为相对密度; 、

、 和

和 为3个方向上的线应变速率。

为3个方向上的线应变速率。

由式(1)可以得到加压烧结多孔体致密化速率方程:

(3)

(3)

式(1)和(3)中的自由烧结平均静水压力 ,数值上等于烧结力P0

,数值上等于烧结力P0

(4)

(4)

烧结力也叫烧结势,是一种表观应力,使材料发生与在实际应力作用下相同的应变速率的静水压 力[10]。

对于开孔阶段的粉末体,其烧结力为

(5)

(5)

式中: 为表面能;D为晶粒尺寸;

为表面能;D为晶粒尺寸; 为初始相对密度。

为初始相对密度。

式(1)和(3)中的体积黏度Kp可以表示为相对密度的函数,对于开孔阶段的粉末体,体积黏度Kp为

(6)

(6)

式中: 为材料参数,用来表示致密化过程中材料的扩散能力,可以表示为

为材料参数,用来表示致密化过程中材料的扩散能力,可以表示为

(7)

(7)

式中:R为摩尔气体常数;Qb为晶界扩散激活能; 为材料常量,可以通过实验数据拟合。

为材料常量,可以通过实验数据拟合。

本文作者采用简化的晶粒长大模型[11]:

(8)

(8)

式中:k和n为材料常量;D0为初始晶粒尺寸。

2 模型应力计算

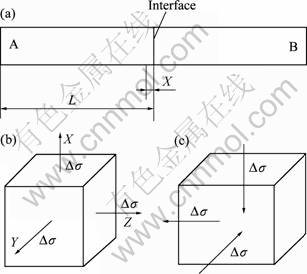

共烧结界面处受力分析如图1所示,图1(a)为共烧结试样示意图,共烧结试样两侧长度分别为L,A和B分别为共烧结两侧不同材料。共烧结界面A、B两侧无限靠近界面处的两微元的受力示意图如图1(b)和(c)所示。

图1 共烧结受力分析及应力分布示意图

Fig.1 Schematic diagram of stress analysis and stress distribution: (a) Co-sintering sample; (b) Material A; (c) Material B

受力方向分析:假设A组份收缩较B组份收缩快,所以在X和Y方向上,A对B为压应力,B对A为拉应力;在水平方向Z方向上,两端互相拉扯,A对B为拉应力,根据作用力与反作用力定律,B对A也为拉应力,如图1(b)和(c)所示。因为共烧结受力分析对象为界面处相邻两侧材料,所以采用A、B两侧无限靠近界面处的两微元进行受力分析。

受力大小分析:如图1(b)和(c)所示,两微元所受的三向力中,X和Y方向上受力情况相同,因此大小相同,设其大小为?σ,不包括方向性,并设压应力方向为负,则对于图1(b)和(c)中两微元中应力大小有σXX=σYY=?σ;Z方向上的受力与X、Y方向上受力不同,σZZ大小很难确定,为了计算方便,模型中假设Z方向上的应力大小和X、Y方向相同,则有σXX=σYY=σZZ=?σ。即A端受到大小相同的三向均匀拉应力,B端在X和Y方向上受到压应力,Z方向上受到拉应力。

假设界面应力?σ沿试样从界面处到试样末端呈三次方分布逐渐递减[12],即界面应力在界面处为最大值?σ,然后以三次方规律逐渐降低,在试样的末端,应力减小为零,公式如下:

(9)

(9)

式中:x为距离界面处的距离;L为共烧结试样界面到两端的距离.

异种材料的共烧结相当于沿共烧结材料A和B在L上有无数个存在外力条件下的微元的烧结,只是外加力不同,不同x处外加力为σx,所以共烧结的致密化模型就是沿L方向上外加力为σx的烧结,然后根据致密化方程推导出沿L方向上不同x处的烧结密度。

模型认为共烧结体为连续介质,只要烧结过程中不出现裂纹等宏观断裂缺陷,界面处即为连续的,所以界面上A、B相邻两侧的应变速率是相等的。由两侧的应变速率相等可以得到

(10)

(10)

对于左侧A端界面处微元,外加静水压力为

(11)

(11)

对于右侧B端界面处微元,外加静水压力为

(12)

(12)

对于左侧A端界面处微元,X方向剪切应力为 零;对于右侧B端界面处微元,X方向剪切应力为

(13)

(13)

将上述静水压力和剪切应力代入式(1),得到界面两侧X方向上的应变速率,根据式(10)的等式关系可以得到

(14)

(14)

烧结过程中,理论上G/K值是随烧结体密度变化而变化的,在烧结体的相对密度0.6~0.9这一区间,G/K值近似为常数[13],取剪切黏度与体积黏度之比G/K=0.6 [11],可得共烧结界面应力的表达式:

(15)

(15)

式(14)说明,界面应力的大小与两端自由烧结瞬时收缩速率差异呈正比,即两端材料的收缩速率差异越大,产生的界面应力越大,这与其他学者的研究及生产实践相符合。此外,界面应力的大小还与两端材料的体积黏度有关。

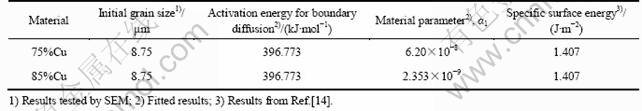

表1 共烧结模拟烧结参数表

Table 1 Sintering parameters for simulation of co-sintering

将界面应力?σ代入式(11)和(12)中,得到两侧微元外加平均静水压力σm;将σm、烧结静水压力σs和体积黏度Kp代入式(3)可以得到界面处两侧的致密化速率方程;将界面应力?σ代入式(9)得到共烧试样任何x处的应力σx,通过σx计算得出共烧结试样中各x点处的外加平均静水压力σm;将σm、烧结静水压力σs和体积黏度Kp代入式(3)就可以得到共烧结试样中任何一点x处的致密化速率方程,进而得到共烧结试样中的密度分布。

共烧结材料烧结参数见表1。

3 实验

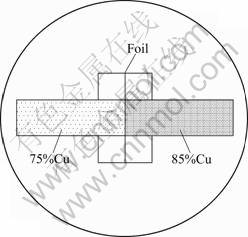

本实验采用传统的粉末冶金压制成形法制备烧结试样,粉末原料为水雾化纯铜粉,平均粒径为18.8 ?m。共烧结研究体系为粉末体积分数为75%和85%的纯铜粉,压制方法如图2所示。

图2 共烧结试样压制过程示意图

Fig.2 Schematic diagram of pressing procedure of sintering sample

压制方法为:首先在模具中卡片两侧装填相同体积的粉末料,然后取出卡片,压制,即得到共烧结试样,压制压力为300 MPa。在粉末中添加不同体积分数的石蜡来保证两侧具有不同的初始孔隙率,由于采用冷压进行共烧结试样压制,生坯中存在孔隙,实际两侧组份的生坯相对密度分别为0.73和0.81。试样为抗弯样,尺寸长为42 mm,宽为6 mm,厚为4 mm。热脱脂最高温度为700 ℃,升温速率为2 ℃/min,并在385 ℃保温60 min,保证热脱脂后收缩率小于0.2%。将热脱脂后的热膨胀试样机加工成尺寸为d 3 mm×20 mm的试样,进行热膨胀曲线的测定。

热脱脂试样在氩气气氛中进行烧结,保温温度分别为800 ℃和850 ℃,保温时间为0、10、20、30和60 min,升温速率为10 ℃/min,保温时间结束后将特定保温时间的试样进行油淬处理,保留烧结结束时的晶粒尺寸和密度。

采用排水法测量试样密度,然后进行晶粒度的测定和共烧结两侧孔隙率的对比。采用截点法进行晶粒度的测量,每组试样晶粒度的测量需测的晶粒数达到400以上。

4 实验结果与模拟

根据模型可以获得共烧试样在任意烧结温度和时间沿整个试样的密度分布曲线。将共烧结试样沿长度方向用线切割分成若干段,测量不同位置的密度,获得密度分布曲线,然后和理论计算曲线比较,验证模型是否与实验符合。

图3所示为800 ℃保温1 h和850 ℃保温30 min密度分布的理论计算曲线和实际测量的密度曲线(左侧为75%,右侧为85%)。由理论计算曲线可以看出,左侧为75%Cu端,横坐标为-1.0为试样末端,共烧应力为0,其密度为自由烧结的75%Cu的密度;横坐标为0为界面处,而横坐标为1.0为85%Cu试样末端,其密度为自由烧结的85%Cu的密度。从模拟计算的密度分布曲线中可以看出,对75%Cu端,密度从末端向界面处逐渐减小。在烧结过程中,界面应力抑制75%Cu端的烧结,使得其共烧密度比自由烧结的密度降低;而对85%Cu端,密度从末端向界面处逐渐增大。证明在共烧结过程中,界面应力促进了85%Cu端的烧结,使得其共烧密度比自由烧结的密度升高。而实验的结果曲线的趋势也证明了这一点,说明本文作者所建立的理论模型和共烧结的实际情况一致。虽然在数值上,计算的密度曲线和实验曲线并不完全吻合,但从误差值可以看出,曲线总的趋势应该不会发生变化。不吻合可能是由参数拟合的精度或实验测量造成的。

图3 共烧结试样密度分布

Fig.3 Relative density distribution of sintering specimens: (a) 800 ℃, 1 h; (b) 850 ℃, 30 min

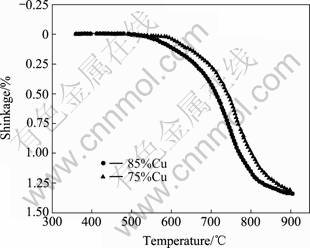

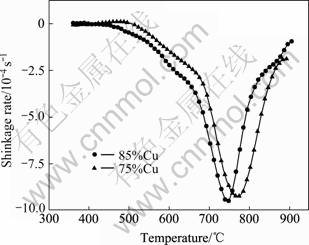

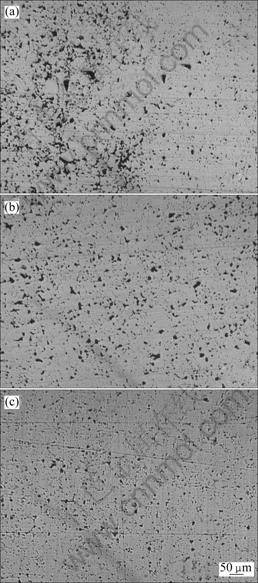

本实验中,两端材料相同但粉末装载量不同,因此,两端的致密化速率不同。致密化速率需要对热膨胀曲线分析获得(见图4),本研究对图4中的热膨胀曲线求导数可得致密化速率曲线,如图5所示。由图5可看出,热膨胀速率的曲线可以大致分为3段,在400 ℃前的一小段,热膨胀占主要作用,致密化尚未发生,故应变速率为0甚至为正,但对理论分析而言,此段无意义。在400 ℃到760 ℃段,对应于烧结的初始阶段, 85%Cu端的应变速率大于75%Cu端的致密化速率,这是由于在烧结的初始阶段,烧结的表面扩散机制占主导作用,75%Cu试样由于密度低,有些颗粒甚至尚未形成接触,颗粒之间的接触面积少于85%Cu端的,故原子完成表面扩散所需路径远,其致密化速率不及85%Cu试样的。对大于760 ℃段,可以看到75%Cu 和85%Cu试样的应变速率都降低,证明烧结致密化变慢,烧结驱动力逐渐耗尽 ,在此时85%Cu端的应变速率小于75%Cu端的。原因在于85%Cu端的致密化主要发生在第二阶段,在之后的烧结过程中,85%Cu致密化很慢,而75%Cu端由于初始密度低,在760 ℃之前致密化不完全,高于760 ℃后才开始快速致密化。因此,在本研究中烧结温度段,75%Cu端致密化速率大,85%Cu致密化速率小。因此,在共烧过程中,75%Cu端对85%Cu端施加压力,促进了 85%Cu端的致密化过程,同时,85%Cu端抑制了75%Cu端的致密化过程。图6所示为800 ℃保温1 h的共烧样界面和两端材料的金相照片。从图6可以看到,界面两端有明显的密度差异,85%Cu端孔隙率高,而75%Cu端孔隙率低。和远离界面的位置比较,85%Cu端界面处的孔隙率低于远离界面处的,而75%Cu端界面处的孔隙率高于远离界面处的。实验结果证明了理论模型,即对75%Cu端,密度从末端向界面处逐渐降低;而对85%Cu端,密度从末端向界面处逐渐增大。

图4 不同装载量铜粉的热膨胀曲线

Fig.4 Thermal expansion curves of Cu compacts with different powder loadings

图5 试样在不同温度的致密化速率曲线

Fig.5 Densification rate curves of specimens sintered at different temperatures

图6 800 ℃保温1 h的共烧样界面和两端的金相照片

Fig.6 Metallographs of interface and two sides for specimens sintered at 800 ℃ for 1 h: (a) Interface (left: 75%Cu, right: 85%Cu); (b) 75%Cu; (c) 85%Cu

从工程应用的角度分析,由于共烧结界面处75%Cu和85%Cu端的密度差比自由烧结时75%Cu和85%Cu的密度差增大,因此,烧结完成冷却时由于热膨胀系数不一致导致的残余应力越大,容易出现开裂,或者降低界面结合强度[15-16]。这个结论尤为重要,因为可以通过对共烧试样两端材料致密化速率的分析,获得共烧结过程中界面两侧的密度差的变化。前者是工程实践中应该避免的,因为容易导致缺陷,而后者是所希望发生的,因为会缓和界面应力,避免开裂,提高界面结合强度。

5 结论

1) 采用忽略弹性的粘性流动烧结理论,推导出不同孔隙率材料共烧结界面处的应力方程及两端材料的致密化方程,建立研究共烧结中界面应力影响两侧致密化行为的共烧结密度模型。

2) 异种材料共烧结过程中的界面应力和界面两侧材料的致密化速率差成正比,且和两侧共烧结材料的体积黏度有关。

3) 模拟结果显示,从共烧结试样末端到共烧结界面处存在密度梯度分布,并且共烧结界面两侧的密度差异相比自由烧结可能提高也可能降低。

4) 通过共烧结实验证明,模型拟合出的共烧结两侧密度梯度分布以及界面处密度差异变化与实验结果基本符合,说明用粘性流动理论模型研究异种材料共烧结的致密化行为是可行的。

REFERENCES

[1] ALCOCK J R, LOGAN P M, STEPHENSON D J. Metal Co-injection moulding[J]. Journal of Materials Science Letters, 1996, 15(23): 2033-2035.

[2] SIMCHI A. Densification and microstructural evolution during Co-sintering of Ni base superalloy powders[J]. Metallurgical and Materials Transaction, 2006, A37(8): 2549-2557.

[3] IMGRUND P, ROTA A, SIMCHI A. Micro injection moulding of 316L/17-4PH and 316L/Fe powders for fabrication of magnetic-nonmagnetic bimetals[J]. Journal of Materials Processing Technology, 2008, 200(1/3): 259-264.

[4] LU Guo-quan, SUTTERLIN R C, GYPTA T K. Effect of mismatched sintering kinetics on camber in a low-temperature cofired ceramic package[J]. Journal of the American Ceramic Society, 1993, 76(8): 1907-1914.

[5] SCHOENBERG S E, GREEN D J, SEGALL A E, MESSING G L, GRADER A S, HALLECK P M. Stresses and distortion due to green density gradients during densification[J]. Journal of the American Ceramic Society, 2006, 89(10): 3027-3033.

[6] RAVI D, GREEN D J. Sintering stresses and distortion produced by density differences in Bi-layer structures[J]. Journal of the European Ceramic Society, 2006, 26(1/2): 17-25.

[7] BORDIA R K, SCHERER G W. On constrained sintering (Ⅰ): Constitutive model for a sintering body[J]. Acta Metallurgica, 1988, 36(9): 2393-2397.

[8] MCMEEKING R M, KUHN L T. A diffusional creep law for powder compacts[J]. Acta Metallurgica et Materialia, 1992, 40(5): 961-969.

[9] KANTERS J, EISELE U, R?DEL J. Cosintering simulation and experimentation: Case study of nanocrystalline zirconia[J]. Journal of the American Ceramic Society, 2001, 84(12): 2757-2763.

[10] 黄伯云, 刘 咏, 贺跃辉. 基于连续体介质力学的粉末烧结理论[J]. 粉末冶金材料科学与工程, 1998, 3(4): 255-263.

HUANG Bai-yun, LIU Yong, HE Yue-hui. Powder metallurgy sintering theory based on continuous mechanics[J]. Materials Science and Engineering of Powder Metallurgy, 1998, 3(4): 255-263.

[11] KWON Y S, WU Y, SURI P. Simulation of the sintering densification and shrinkage behavior of powder-injection- molded 17-4PH stainless steel[J]. Metallurgical and Materials Transactions A, 2004, 35: 257-263.

[12] BORDIA R K, SCHERER G W. On constrained sintering (Ⅲ): Rigid inclusions[J]. Acta Metallurgica, 1988, 36(9): 2411-2416.

[13] SVOBODA J, RIEDEL H, ZIPSE H. Equilibrium pore surfaces, sintering stresses and constitutive equations for the intermediate and late stages of sintering (Ⅰ): Computation of equilibrium surfaces[J]. Acta Metallurgica et Materialia, 1994, 42(2): 445-452.

[14] 黄再兴, 郑泉水. 表面能对纳米颗粒的晶格收缩和固有频率的影响[J]. 力学学报, 1998, 30(2): 247-251.

HUANG Zai-xing, ZHENG Quan-shui. Effects of the surface energy on the lattice contraction and eigenfrequency of a nano-grain[J]. Acta Mechanica Sinica, 1998, 30(2): 247-251.

[15] 马 鑫, 冯吉才, 董占贵, 梁旭文. Al-Al2O3 结构件钎缝处的剪切应力分布与热膨胀匹配[J]. 中国有色金属学报, 2001, 11(5): 750-753.

MA Xin, FENG Ji-cai, DONG Zhan-gui, LIANG Xu-wen. Shear stress distribution in fillet of Al-Al2O3 soldering assembly and thermal expansion matching[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(5): 750-753.

[16] 熊柏青, 楚建新, 职任涛, 肖纪美, 陆建栋, 王连伟. 残余热应力对Si3N4/金属钎焊接头性能的影响[J]. 中国有色金属学报, 1998, 8(2): 210-213.

XIONG Bai-qing, CHU Jian-xin, ZHI Ren-tao, XIAO Ji-mei, LU Jian-dong, WANG Lian-wei. Effect of residual thermal stress on properties of Si3N4/metal brazing joints[J]. The Chinese Journal of Nonferrous Metals, 1998, 8(2): 210-213.

(编辑 李艳红)

基金项目:国家高技术研究发展计划资助项目(2007AA03Z114);国家自然科学基金资助项目(50721003)

收稿日期:2010-06-28 ;修订日期:2010-07-29

通信作者:何 浩,博士;电话:0731-88836113;E-mail: he_hao555@yahoo.com.cn