采用低温冷轧+时效工艺提高Al-Cu-Li合金的强度及塑性

来源期刊:中国有色金属学报(英文版)2017年第9期

论文作者:邓燕君 黄光杰 曹玲飞 吴晓东 黄利 夏明勇 刘庆

文章页码:1920 - 1927

关键词:Al-Cu-Li合金;低温冷轧;位错;T1相

Key words:Al-Cu-Li alloy; cryogenic rolling; dislocation; T1 precipitate

摘 要:为获得可提高Al-Cu-Li合金强度和塑性的加工工艺,比较如下两种工艺:固溶后的合金板材分别在低温(液氮温度)及室温下轧制变形(变形量达83%),随后在160 °C下进行人工时效。结果表明,在低温冷轧+时效工艺条件下得到的Al-Cu-Li合金具有更优的力学性能。在低温冷轧后由于动态回复的抑制会产生大量位错,这将促进T1相(Al2CuLi)在时效过程中的析出。时效过程析出的高密度T1相可有效钉扎位错,从而使合金的强度及塑性提高;相反,室温轧制+时效工艺得到的合金强度及塑性较低,这是由于低密度的T1相在晶内析出,而高密度的T1相在亚晶界处析出。

Abstract: To develop an improved approach in achieving an excellent combination of high strength and ductility, the solutionized Al-Cu-Li plates were subjected to rolling at cryogenic and room temperatures, respectively, to a reduction of 83%, followed by aging treatment at 160 °C. The results indicate that Al-Cu-Li alloys through cryogenic rolling followed by aging treatment possess better mechanical properties. Rolling at cryogenic temperature produces a high density of dislocations because of the suppression of dynamic recovery, which in turn promotes the precipitation of T1 (Al2CuLi) precipitates during aging. Such high density of T1 precipitates enable effective dislocation pinning, leading to an increase in strength and ductility. In contrast, room temperature rolled alloys after aging treatment exhibit lower strength and ductility due to low density of T1 precipitates in the grain interior and high density of T1 precipitates around subgrain boundaries.

Trans. Nonferrous Met. Soc. China 27(2017) 1920-1927

Yan-jun DENG, Guang-jie HUANG, Ling-fei CAO, Xiao-dong WU, Li HUANG, Ming-yong XIA, Qing LIU

College of Materials Science and Engineering, Chongqing University, Chongqing 400044, China

Received 24 April 2016; accepted 24 October 2016

Abstract: To develop an improved approach in achieving an excellent combination of high strength and ductility, the solutionized Al-Cu-Li plates were subjected to rolling at cryogenic and room temperatures, respectively, to a reduction of 83%, followed by aging treatment at 160 °C. The results indicate that Al-Cu-Li alloys through cryogenic rolling followed by aging treatment possess better mechanical properties. Rolling at cryogenic temperature produces a high density of dislocations because of the suppression of dynamic recovery, which in turn promotes the precipitation of T1 (Al2CuLi) precipitates during aging. Such high density of T1 precipitates enable effective dislocation pinning, leading to an increase in strength and ductility. In contrast, room temperature rolled alloys after aging treatment exhibit lower strength and ductility due to low density of T1 precipitates in the grain interior and high density of T1 precipitates around subgrain boundaries.

Key words: Al-Cu-Li alloy; cryogenic rolling; dislocation; T1 precipitate

1 Introduction

Al-Cu-Li alloys are extensively used for aerospace applications due to their high specific strength, good damage tolerance and excellent property stability [1]. An increased usage of Al-Cu-Li alloys depends on enhancing their mechanical properties such as strength and ductility further. For precipitation of hardenable alloys, recent results [2,3] have shown that a new processing route of severe plastic deformation (SPD) followed by aging treatment could significantly improve both strength and ductility. KIM et al [3] combined equal channel angular pressing (ECAP) in solid solution state with post-ECAP low-temperature aging of 2024 Al alloy and found that the yield strength was improved to ~630 MPa while a reasonable elongation to failure (~15%) was maintained. The SPD processes, such as ECAP, multiple compression, and high pressure torsion, have their own limitations for commercial application, for example, the requirement of a large load, the small size of the products, and the high labor and fuel expenses [4-6]. Recently, rolling at cryogenic temperature has been identified as one potential method to refine the grain microstructure in the bulk alloys, which could be as effective as the SPD processes [7-9].

A lot of investigations [7,8] have shown that cryogenic rolling at large strains followed by aging treatment could significantly improve both strength and ductility in Al and Cu alloys. For instance, by combining solid solutionizing, cryogenic rolling and aging treatment, the yield strength of 7075 Al alloy was improved to 615 MPa, with a good uniform elongation of 7.5% [2]. Generally, the significant improvement of strength through cryogenic rolling at large strains is attributed to the refinement of grain microstructure and the relatively high density of dislocations in the bulk alloys [8]. The aging treatment of cryogenic rolled alloys could significantly improve their strength and ductility due to the precipitation hardening and the occurrence of recovery and recrystallization, respectively [8,9]. However, HUANG et al [10] pointed out that another economic process of room temperature rolling at large strains followed by aging could also achieve a good combination of strength and ductility in Al-Cu-Mg alloys. This is due to the formation of high density of dislocations and nanosized S″precipitates. Then, an important question will be raised naturally: which process is better for Al-Cu-Li alloys to improve their mechanical properties through cryogenic or room temperature rolling followed by aging? Up to date, the related investigation is scarce in Al-Cu-Li alloys.

Therefore, the purpose of this work is to develop a procedure for significantly enhancing the strength and maintaining a reasonable ductility of age-hardened Al-Cu-Li alloys. The goals of the present work are: 1) to study the microstructure features and mechanical properties in cryogenic rolled (CR) and room temperature rolled (RTR) alloys; 2) to analyze the effect of rolling temperature on the evolution of mechanical properties, microstructure and precipitation behavior during aging.

2 Experimental

The Al-Cu-Li hot-rolled plates were provided by Southwest Aluminum (Group) Co., Ltd., China. The chemical composition of this material is 2.8% Cu, 1.4% Li, 0.3% Mn, 0.1% Zr and Al balance (mass fraction). The alloy plates were solution-treated and quenched, followed by cryogenic temperature rolling (CR) or room temperature rolling (RTR) to a total thickness reduction of 83%. In the case of rolling at cryogenic temperature, the solutionized plates were dipped in liquid nitrogen for 30 min before starting the first pass of cryogenic temperature rolling, and the plates were immersed in liquid nitrogen for 2 min before the next pass. To study the age hardening behavior, the CR and RTR samples were artificially aged at 160 °C for various time (1-84 h).

Mechanical properties were determined by room- temperature Vickers hardness and tensile tests. Hardness measurements were conducted under a load of 1 kg and a dwell time of 15 s, and the average hardness value was obtained from ten different measurements. Sheet tensile samples with a cross-section of 4 mm × 2 mm and a gauge length of 20 mm were prepared by electro- discharge machining. Tensile tests along the rolling direction of the samples were conducted on a tensile testing machine (SHIMADZU AG-X) at a strain rate of 10-4 s-1. The yield strength was determined with the 0.2% offset plastic strain method.

The microstructure features were characterized using an FEI TECNAI G2 F20 transmission electron microscope (TEM) with an operating voltage of 200 kV. The specimens for TEM investigations were cut parallel to the RD/ND plane (longitudinal section). And the TEM foils were prepared by mechanical grinding to a thickness of 60 μm and then thinning by a twin-jet electro polishing unit with a solution of 30% nitric acid and 70% methanol at -30 °C.

3 Results

3.1 Mechanical properties

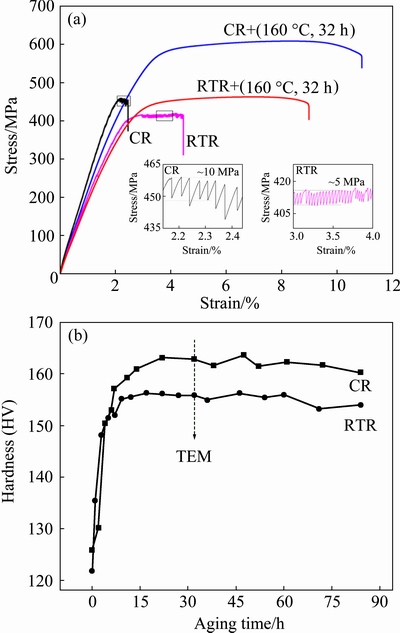

Figure 1(a) shows the engineering stress-strain curves of CR and RTR samples, and the corresponding yield strength, ultimate tensile strength, elongation-to- failure are presented in Table 1. For the CR sample, it shows higher yield strength (447 MPa) and ultimate tensile strength (455 MPa), but a lower elongation-to- failure (0.6%) as compared with the RTR sample. Additionally, the Portevin-Le Chatelier (PLC) phenomenon can be observed in the stress-strain curves, indicating that plastic flow instability appeared in both CR and RTR samples, which has been previously recognized by GANG et al [11]. The serrated flows of the curves of CR and RTR samples are magnified in Fig. 1(a), where the CR sample has higher strength and larger flow serration than RTR sample. The PLC phenomenon of CR and RTR samples may be due to the solute aging of mobile dislocations temporarily trapped at localized obstacles such as forest dislocations [12].

Fig. 1 Engineering stress-strain curves of CR, RTR, CR + peak-aged and RTR + peak-aged samples (Two small regions of the curves of CR and RTR samples are magnified to more clearly reveal the serrations) (a) and Vickers hardness of CR and RTR samples vs aging time (1-84 h) at 160 °C (To characterize the difference of microstructure features of peak-aged CR and RTR samples, CR and RTR samples aged at 160 °C for 32 h were examined using TEM) (b)

Table 1 Yield stress (YS), ultimate tensile strength (UTS), elongation-to-failure (EL) of CR, RTR, CR + peak-aged and RTR + peak-aged samples

Tensile tests were performed to further investigate the influence of rolling temperature on the mechanical properties of aged Al-Cu-Li alloys. The tensile specimens were severely rolled to 83% at cryogenic and room temperatures, respectively, and aged at 160 °C for 32 h, corresponding to the peak aging state. The yield strength and ultimate tensile strength of the aged CR sample are 575 and 608 MPa, respectively. Obviously, the aged RTR sample displays a substantially lower yield strength and ultimate tensile strength than the aged CR sample. At the same time, the aged CR sample exhibits a satisfactory elongation-to-failure of 8.2%. Moreover, PLC phenomenon disappears in both aged samples because of quite few solute atoms remaining in the matrix after precipitation process.

The Vickers hardness of the CR and RTR samples as a function of aging time is shown in Fig. 1(b). The hardness of CR and RTR samples after aging treatment behaves in a similar manner. The hardness values significantly increase with prolonging aging time, and reach the peak values of HV ~165 and HV ~150 at 22 h for CR and RTR samples, respectively. With a further increase in the aging time, the hardness values remain steady for both samples.

3.2 Microstructures of CR and RTR alloys

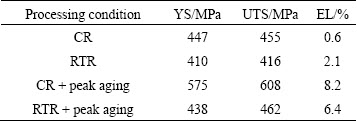

The microstructures of CR and RTR samples, as shown in Figs. 2(a) and (d), exhibit strongly elongated subgrains. Moreover, it is found that the size of subgrains is smaller, and the density of dislocations in the subgrains interior is much higher in CR sample [13]. In RTR sample, the structure of the low angle boundaries is in the form of a dislocation cell, as shown in Fig. 2(f) [14], and the better-defined subgrains with a much lower dislocation density. However, the microstructures of CR alloys consisting of high density of dislocations, dislocation-tangling zone, without the well-defined subgrains are observed in Fig. 2(c). Different micro- structure features between RTR and CR samples are due to the fact that recovery process was encouraged in RTR sample, but not in CR sample.

Fig. 2 TEM images with corresponding selected area diffraction (SAD) patterns oriented along <110> zone axis of cryogenic rolled sample (a-c) and room temperature rolled sample (d-f)

From the corresponding selected area diffraction (SAD) patterns, the diffraction spots of the {111} planes show angular spreading of 15° and 45° in CR and RTR alloys, respectively (see Figs. 2(b) and (e)). This indicates a significant increase in the averaged misorientation angle with the increasing rolling temperature [15]. It can be deduced that most of the volumes of CR sample may be subdivided by low angle cell boundaries, leading to a smaller averaged misorientation angle. Cell boundaries should be classified as incidental dislocation boundaries (IDBs) which are formed by trapping of glide dislocations [16]. However, in RTR sample, a significant fraction of large angle boundaries is present besides IDBs, such as subgrain boundaries, which are classified as geometrically necessary boundaries (GNBs) [17]. In a word, the ratios of IDBs/GNBs are different in both conditions, which may be due to different operative slip systems selected at different rolling temperatures [16].

3.3 Microstructures of aged CR and RTR alloys

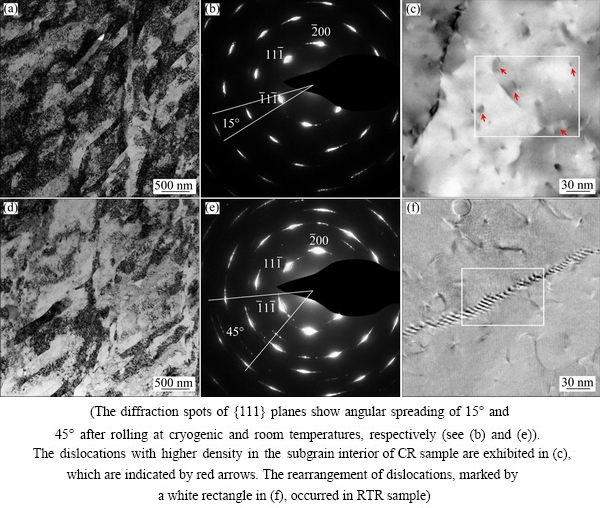

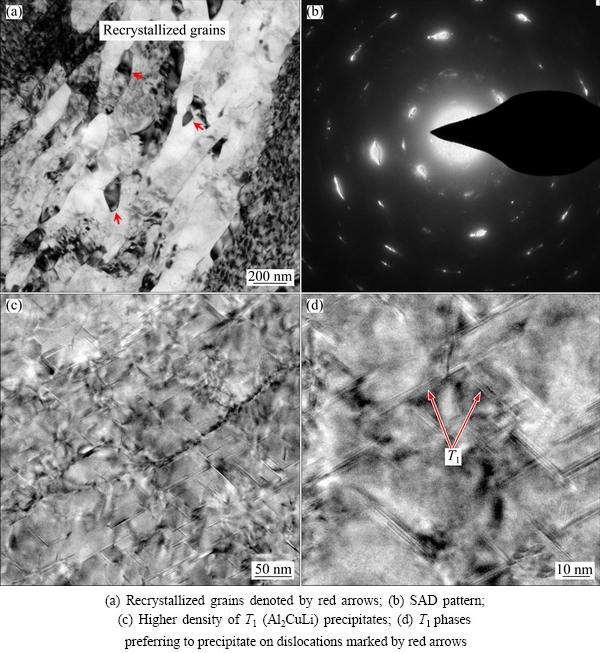

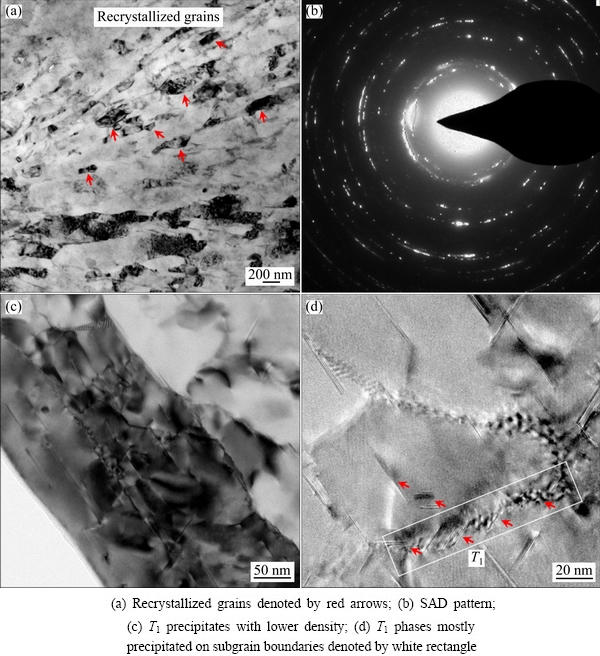

The TEM images of CR and RTR alloys after being aged at 160 °C for 32 h are shown in Figs. 3 and 4, respectively. The microstructures of both aged samples show a slight reduction of dislocation density as compared with the rolled samples. A few equiaxed grains with defined grain boundaries are observed in the aged CR samples (Fig. 3(a)). The corresponding SAD pattern in Fig. 3(b) reveals a polycrystalline structure. However, in comparison with the aged CR sample, more recrystallized grains with minimum residual dislocations are formed in the aged RTR sample (see Figs. 4(a) and (b)).

After being aged at 160 °C for 32 h (peak-aged), plate-like T1 precipitates are formed in both conditions, as shown in Figs. 3(c) and 4(c). The density of T1 precipitates in the aged CR samples is higher than that in the aged RTR samples (see Figs. 3(c) and 4(c)).

Fig. 3 TEM images with corresponding SAD patterns oriented along <110> zone axis of CR sample after aging treatment

Fig. 4 TEM images with corresponding SAD pattern oriented along <110> zone axis of RTR sample after aging treatment

Figures 3(d) and 4(d) present that the plate-like T1 phases prefer to precipitating on dislocations and subgrain boundaries in CR and RTR samples after being aged.

4 Discussion

4.1 Microstructural parameters and flow stress of rolled alloys

The engineering stress-strain curves in Fig. 1 show that the flow stress is improved as the rolling temperature decreases, and serrations appear on the tensile curves in both conditions. In large strain rolled Al-Cu-Li alloys, several important strengthening mechanisms are operative, including solid solution hardening, dislocation strengthening and boundary strengthening. The contributions of solid solution strengthening are similar for both conditions due to the same materials and heat treatment profile. Moreover, the larger dislocation density in CR sample indicates that the contribution from dislocation strengthening for the CR alloys is larger than that for the RTR alloys. But the contribution to flow stress of alloys at large strains is mainly from boundary strengthening, comparing to dislocation strengthening, which has been studied by HUGHES and HANSEN [17].

The contribution of boundary strengthening to flow stress is attributed to the GNBs and IDBs. The GNBs are strong barriers to slip, because the regions separated by the GNBs select different slip system combinations. Therefore, the strength contribution from the GNBs may be expressed by a Hall-Petch equation which defines the strength of the high angle grain boundary. On the contrary, the lower angle IDBs are assumed, to a certain extent, to be penetrable by mobile dislocations. For example, in-situ studies by high voltage electron microscopy have shown the dislocation passage through low angle boundaries [18]. So for the IDBs, it is practicable to account for the strength contribution from the total dislocation density of IDBs.

The contribution to flow stress of rolled Al-Cu-Li alloys from boundary strengthening can be expressed as [19]

(1)

(1)

/

/ (2)

(2)

where σGNB can be expressed as  , KHP is the slope of the straight line relating the flow stress of a polycrystalline material to the reciprocal square root of the grain size, and DGNB is the boundary spacing between parallel GNBs measured perpendicular to the boundaries. In the second contribution, σIDB can be expressed as

, KHP is the slope of the straight line relating the flow stress of a polycrystalline material to the reciprocal square root of the grain size, and DGNB is the boundary spacing between parallel GNBs measured perpendicular to the boundaries. In the second contribution, σIDB can be expressed as  , where M is the Taylor factor, α is a constant, b is the Burgers vector value, G is the shear modulus, θIDB is the misorientation angle across the IDBs and SV is the boundary area per unit volume.

, where M is the Taylor factor, α is a constant, b is the Burgers vector value, G is the shear modulus, θIDB is the misorientation angle across the IDBs and SV is the boundary area per unit volume.

The contribution of boundary strengthening (σGNB+σIDB) is significantly different with the change of rolling temperature. According to Eq. (2), the strength determining parameters of σGNB+σIDB are the boundary spacing (DGNB) and the boundary area per unit (SV) of IDBs. Due to the smaller boundary spacing (DGNB) in the CR sample, the contribution from σGNB in the CR sample is larger than that in the RTR sample. The larger fraction of low angle cell boundaries in the CR sample indicates that the boundary area per unit volume (SV) of IDBs is larger than that in the RTR sample. The contribution from σIDB for the CR sample is larger than that for the RTR sample. Some studies have shown that the contribution from the IDBs is almost twice that of the GNBs [17,19]. Therefore, in comparison with RTR sample, the higher yield stress is mainly due to the higher ratio of IDBs/GNBs, namely the larger fraction of low angle cell boundaries in CR sample.

4.2 Microstructure evolution of rolled alloys after aging treatment

The high yield stress of Al-Cu-Li alloys can be attributed to the precipitation of the T1 phases (Al2CuLi) [20]. Therefore, the evolution of the T1 phase is necessary to be examined by TEM. In both conditions, homogeneous precipitation of the T1 phase is almost absent in the matrix, but heterogeneous precipitation significantly occurs on structural defects (subgrain boundaries, dislocations) [7,21,22]. The subgrain boundaries and dislocations provide lower energy nucleation sites for the precipitation of T1 due to the higher drive force as compared with the matrix. It is known that abundant dislocations take place in the grain interior due to the suppression of dynamic recovery during rolling at the cryogenic temperature. Therefore, in the CR alloys after aging, the density of T1 phase is higher than that in the aged RTR alloys, which is attributed to the higher density of dislocations within the grains. Short-circuit diffusion paths for solutes [23,24] and solute atmospheres around dislocations introduced by the interaction between dislocations and solutes [25,26], all result in faster precipitation on dislocations introduced by deformation before aging [27].

The occurrence of recrystallization has been observed in both conditions. As compared with the CR sample after aging, the RTR sample shows a larger degree of recrystallization. Similar to precipitation, recrystallization during annealing (or aging) can also release strain energy introduced by deformation. As compared with precipitation, longer incubation time is needed for recrystallization, which is due to the larger required critical nucleation size and the higher activation energy of recrystallization. During the incubation of recrystallization, the nucleation and growth of precipitation on dislocations have occurred due to the diffusion mechanism and low activation energy. The strain energy is thus released at the beginning of the annealing process due to precipitation. The more strain energy is released in the CR sample after aging due to the more T1 phase precipitated as compared with that in the RTR sample. In both conditions, the remaining strain energy is used for recrystallization. Therefore, because of the lower strain energy remaining in CR sample after aging, the degree of recrystallization is lower than that in RTR sample after aging.

4.3 Mechanical properties of rolled alloys after aging

In the CR sample subjected to aging treatment, a significant increase in yield stress (29% increase), tensile strength (34% increase) and elongation (1800% increase) is observed. However, a less improvement in strengthening properties (YS (7%), UTS (11%) increase) and elongation (216% increase) is observed for the RTR sample after aging.

Since samples are both deformed to large strain, a heavy amount of dislocations and strain energy are stored in the samples. When these heavily deformed samples are subjected to aging treatment, recovery, recrystallization and precipitation occur simultaneously. The large enhancement of strength is attributed to precipitation hardening. And the effective enhancement of ductility in both conditions after aging is attributed to the following reasons: 1) the annihilation of dislocations during aging treatment due to recovery and recrystallization, which improves the capability of dislocation accumulation before saturation; 2) the precipitation of T1 phases (Al2CuLi). The high strain hardening capacity of Al-Cu-Li alloys with T1 phases is induced by the particular dislocation-precipitate interaction, i.e., T1 precipitate is sheared by single event on a given slip plane [28,29]. All these cause substantial elongation prior to failure (high ductility) of tensile sample in aged CR and RTR alloys.

The precipitation strengthening is the main contribution for the strength enhancement in both conditions after aging treatment. It is known that the main strengthening precipitate in Al-Cu-Li alloys is the T1 phase (Al2CuLi), which forms as semicoherent platelets along the {111}Al planes and exhibits a hexagonal structure [30]. The T1 precipitates act as strong obstacles to dislocation motion. As compared with the aged RTR sample, the strength of CR samples after aging is higher due to the larger density of T1 precipitates.

In the aged RTR sample, the elongation is lower than that of the CR samples after aging. This may be attributed to the high density of T1 precipitates at subgrain boundaries of aged RTR sample, which increases the strain concentration and decreases the adhesion between boundaries during tensile straining.

5 Conclusions

1) The strength and hardness of cryogenic rolled (CR) Al-Cu-Li alloys are higher than those of room temperature rolled (RTR) samples. Rolling at cryogenic temperature could cause a large number of dislocations and low-angle cell boundaries, thereby leading to the dislocation strengthening and boundary strengthening. Moreover, the strength effect of boundary strengthening is larger.

2) Upon aging of the CR Al-Cu-Li alloy, a good combination of high strength and ductility was achieved, attributing to the combined effects of precipitation hardening (T1 precipitates with high density were formed in the grain interior), recovery and partial recrystallization.

3) The RTR sample after aging has lower strength and ductility than the CR sample after aging. The TEM analysis reveals that this is attributed to a small quantity of T1 precipitates and the preferential distribution of T1 precipitates along the subgrain boundaries, which is prone to decrease the strength and ductility of aged RTR sample.

References

[1] DORIN T, DESCHAMPS A, GEUSER F D, SIGLI C. Quantification and modelling of the microstructure /strength relationship by tailoring the morphological parameters of the T1 phase in an Al-Cu-Li alloy [J]. Acta Materialia, 2014, 75: 134-146.

[2] SHANMUGASUNDARAM T, MURTY B S, SUBRAMANYA SARMA V. Development of ultrafine grained high strength Al-Cu alloy by cryorolling [J]. Scripta Materialia, 2006, 54(12): 2013-2017.

[3] KIM W J, CHUNG C S, MA D S, HONG S I, KIM H K. Optimization of strength and ductility of 2024 Al by equal channel angular pressing (ECAP) and post-ECAP aging [J]. Scripta Materialia, 2003, 49(4): 333-338.

[4] PANIGRAHI S K, JAYAGANTHAN R. Effect of rolling temperature on microstructure and mechanical properties of 6063 Al alloy [J]. Materials Science and Engineering A, 2008, 492(1-2): 300-305.

[5] WANG Yin-min, CHEN Ming-wei, ZHOU Feng-hua, MA En. High tensile ductility in a nanostructured metal [J]. Nature, 2002, 419(6910): 912-915.

[6] PANIGRAHI S K, JAYAGANTHAN R. A study on the mechanical properties of cryorolled Al-Mg-Si alloy [J]. Materials Science and Engineering A, 2008, 480(1-2): 299-305.

[7] HUANG Yuan-chun, YAN Xu-yu, QIU Tao. Microstructure and mechanical properties of cryo-rolled AA6061 Al alloy [J]. Transactions of Nonferrous Metals Society of China, 2016, 26(1): 12-18.

[8] PANIGRAHI S K, JAYAGANTHAN R, PANCHOLI V. Effect of plastic deformation conditions on microstructural characteristics and mechanical properties of Al 6063 alloy [J]. Materials & Design, 2009, 30(6): 1894-1901.

[9] PANIGRAHI S K, JAYAGANTHAN R. Effect of ageing on microstructure and mechanical properties of bulk, cryorolled, and room temperature rolled Al 7075 alloy [J]. Journal of Alloys and Compounds, 2011, 509(40): 9609-9616.

[10] HUANG Y J, CHEN Z G, ZHENG Z Q. A conventional thermo- mechanical process of Al-Cu-Mg alloy for increasing ductility while maintaining high strength [J]. Scripta Materialia, 2011, 64(5): 382-385.

[11] GANG U G, LEE S H, NAM W J. The evolution of microstructure and mechanical properties of a 5052 aluminium alloy by the application of cryogenic rolling and warm rolling [J]. Materials Transactions, 2009, 50(1): 82-86.

[12] OVRI H, LILLEODDEN E T. New insights into plastic instability in precipitation strengthened Al-Li alloys [J]. Acta Materialia, 2015, 89(1): 88-97.

[13] HU T, MA K, TOPPING T D, SCHOENUNG J M, LAVERNIA E J. Precipitation phenomena in an ultrafine-grained Al alloy [J]. Acta Materialia, 2013, 61(6): 2163-2178.

[14] DIXIT N, XIE K Y, HEMKER K J, RAMESH K T. Microstructural evolution of pure magnesium under high strain rate loading [J]. Acta Materialia, 2015, 87(1): 56-67.

[15] DALLA TORRE F, LAPOVOK R, SANDLIN J, THOMSON P F, DAVIES C H J, PERELOMA E V. Microstructures and properties of copper processed by equal channel angular extrusion for 1–16 passes [J]. Acta Materialia, 2004, 52(16): 4819-4832.

[16] KUHLMANN-WILSDORF D, HANSEN N. Geometrically necessary, incidental and subgrain boundaries [J]. Scripta Metallurgica et Materialia, 1991, 25(7): 1557-1562.

[17] HUGHES D A, HANSEN N. Microstructure and strength of nickel at large strains [J]. Acta Materialia, 2000, 48(11): 2985-3004.

[18] FUJITA H, TOYODA K, MORI T, TABATA T, ONO T, TAKEDA T. Dislocation behavior in the vicinity of grain boundaries in FCC metals and alloys [J]. Transactions of the Japan Institute of Metals, 1983, 24(4): 195-204.

[19] LIU Q, HUANG X, LLOYD D J, HANSEN N. Microstructure and strength of commercial purity aluminium (AA 1200) cold-rolled to large strains [J]. Acta Materialia, 2002, 50(15): 3789-3802.

[20] LI Jin-feng, LIU Ping-li, CHEN Yong-lai, ZHANG Xu-hu, ZHENG Zi-qiao. Microstructure and mechanical properties of Mg, Ag and Zn multi-microalloyed Al-(3.2-3.8)Cu-(1.0-1.4)Li alloys [J]. Transactions of Nonferrous Metals Society of China, 2015, 25(7): 2103-2112.

[21] RODGERS B I, PRANGNELL P B. Quantification of the influence of increased pre-stretching on microstructure-strength relationships in the Al-Cu-Li alloy AA2195 [J]. Acta Materialia, 2016, 108(15): 55-67.

[22] DECREUS B, DESCHAMPS A, DONNADIEU P, EHRSTRO M J C. On the role of microstructure in governing fracture behavior of an aluminum–copper–lithium alloy [J]. Materials Science and Engineering A, 2013, 586: 418-427.

[23] ARDELL A. On the coarsening of grain boundary precipitates [J]. Acta Metallurgica, 1972, 20(4): 601-609.

[24] HOYT J J, SPOONER S. The surface energy of metastable Al3Li precipitates from coarsening kinetics [J]. Acta Metallurgica et Materialia, 1991, 39(4): 689-693.

[25] HARPER S. Precipitation of carbon and nitrogen in cold-worked alpha-iron [J]. Physical Review, 1951, 83(4): 709-712.

[26] HAM F S. Stress-assisted precipitation on dislocations [J]. Journal of Applied Physics, 1959, 30(6): 915-926.

[27] GAO Chong, LUAN Yang, YU Jun-chuan, MA Yue. Effect of thermo-mechanical treatment process on microstructure and mechanical properties of 2A97 Al-Li alloy [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(7): 2196-2202.

[28] DESCHAMPS A, DECREUS B, DE GEUSER F, DORIN T, WEYLAND M. The influence of precipitation on plastic deformation of Al-Cu-Li alloys [J]. Acta Materialia, 2013, 61(11): 4010-4021.

[29] DORIN T, DE GEUSER F, LEFEBVRE W, SIGLI C, DESCHAMPS A. Strengthening mechanisms of T1 precipitates and their influence on the plasticity of an Al-Cu-Li alloy [J]. Materials Science and Engineering A, 2014, 605: 119-126.

[30] GABLE B M, ZHU A W, CSONTOS A A, STARKE E A Jr. The role of plastic deformation on the competitive microstructural evolution and mechanical properties of a novel Al-Li-Cu-X alloy [J]. Journal of Light Metals, 2001, 1(1): 1-14.

邓燕君,黄光杰,曹玲飞,吴晓东,黄 利,夏明勇,刘 庆

重庆大学 材料科学与工程学院,重庆 400044

摘 要:为获得可提高Al-Cu-Li合金强度和塑性的加工工艺,比较如下两种工艺:固溶后的合金板材分别在低温(液氮温度)及室温下轧制变形(变形量达83%),随后在160 °C下进行人工时效。结果表明,在低温冷轧+时效工艺条件下得到的Al-Cu-Li合金具有更优的力学性能。在低温冷轧后由于动态回复的抑制会产生大量位错,这将促进T1相(Al2CuLi)在时效过程中的析出。时效过程析出的高密度T1相可有效钉扎位错,从而使合金的强度及塑性提高;相反,室温轧制+时效工艺得到的合金强度及塑性较低,这是由于低密度的T1相在晶内析出,而高密度的T1相在亚晶界处析出。

关键词:Al-Cu-Li合金;低温冷轧;位错;T1相

(Edited by Wei-ping CHEN)

Foundation item: Projects (106112015CDJXZ138803, 106112015CDJXY130003) supported by the Fundamental Research Funds for the Central Universities, China; Project (51421001) supported by National Natural Science Foundation of China

Corresponding author: Xiao-dong WU; Tel: +86-23-65120787; E-mail: xiaodongwu@cqu.edu.cn

DOI: 10.1016/S1003-6326(17)60216-4