文章编号:1004-0609(2016)-08-1577-11

新型Al-Mg-Sc-Zr和Al-Zn-Mg-Sc-Zr合金的研究进展

徐国富1, 2,彭小燕1,段雨露1,曹晓武1,邓 英1, 2,尹志民1, 2

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 中南大学 有色金属材料科学与工程教育部重点实验室,长沙 410083)

摘 要:在迄今为止的所有微合金化元素中,钪可最大程度提高铝合金综合性能。相比传统铝镁合金,新型Al-Mg-Sc-Zr合金抗拉强度提高60~130 MPa,屈服强度提高80~150 MPa,且可获得大于2000%高速超塑性。与传统铝锌镁合金相比,新型Al-Zn-Mg-Sc-Zr合金抗拉强度提高66~96 MPa,屈服强度提高36~98 MPa,钨极氩弧焊系数大于0.75,搅拌摩擦焊系数大于0.90,且可获得大于1500%高速超塑性。钪锆添加到铝合金中可形成Al3(Sc,Zr)粒子,该粒子可细化铸造组织、抑制再结晶发生和稳定细晶组织,产生显著的细晶强化、亚结构强化和析出强化,从而提高合金强度,实现优良的超塑性能。

关键词:铝合金;Al-Mg-Sc-Zr合金;Al-Zn-Mg-Sc-Zr合金; 微合金化;强化机制;超塑性

中图分类号:TG146.21 文献标志码:A

在迄今为止的所有微合金化元素中,钪(Sc)可最大程度提高铝合金综合性能[1-8]。用微量Sc (0.07%~0.35%,质量分数,下同)合金化的铝合金称为铝钪合金或含Sc的铝合金。与不含Sc的同类合金相比,铝钪合金强度高、塑韧性好、耐蚀性能和焊接性能优异,在船舶、航天工业、火箭导弹、核能等高新尖技术部门的应用前景十分广阔,受到国内外材料学界的广泛关注,是新一代轻质结构材料[9-14]。20世纪70年代以后,俄罗斯科学院巴依科夫冶金研究院和全俄轻合金研究院相继对Sc在铝合金中的存在形式和作用机制进行了系统地研究,已开发出4个系列17个牌号的工业含钪铝合金体系:1) 非热处理强化可焊A1-Mg-Sc系合金;2) 热处理强化高强度可焊A1-Zn- Mg-Sc系合金;3) 热处理强化高强可焊A1-Li-Sc系航空合金[1, 10]。所有开发的含钪铝合金的强度都比未添加钪时有明显的提高,且同时具有很好的焊接性 能[15-19]。含钪铝合金产品主要瞄准航天、航空、舰船的焊接荷重结构件以及碱性腐蚀介质环境用的铝合金管材、铁路油罐、高速列车关键结构件等。在国内,在国家自然科学基金、国家重大基础研究项目(973)、总装预研项目、国家高技术新材料项目(863)和科技部国际合作基金的资助下,学者们对含钪铝合金进行了比较深入的研究,并与相关企业合作,形成了具有自主知识产权的高性能铝钪合金板材、型材、锻件及其配用焊丝的制备技术,初步搭建了具有中国特色的铝钪合金研究开发应用平台,为铝钪合金在航天航空、舰船等领域的应用提供了材料和技术的支撑。锆的复合添加可有效降低昂贵钪的有效添加量。本文作者结合课题组多年经验,主要介绍新型中强可焊超塑Al-Mg-Sc-Zr和高强可焊超塑Al-Zn-Mg-Sc-Zr合金研究进展。

1 A1-Mg-Sc-Zr合金

Al-Mg合金是热处理不可强化型合金,具有优良的抗腐蚀性、较高的比强度、较好的塑性和可焊性,热导和电导性能也很出色。主要用来制作容器、部件、水管、装饰物品等。Al-Mg合金在铝制焊接结构中应用最广,在航空航天、车辆制造、电工电子等领域受到了青睐[20-21]。

在铝镁合金的基础上添加微量钪锆进行改性,开发出的新型铝镁钪合金延续了Al-Mg合金的优良性能,比如良好的焊接性能和抗腐蚀性能,同是也克服了其受热易软化的缺点,提高了合金强度。

Mg为Al-Mg-Mn合金的强化元素,当合金中Mg含量从0.01提高到0.06时,强度显著增加。尽管随着温度的降低,Mg在Al中的固溶度变化明显,但该系合金中基本不存在沉淀析出强化现象[22]。那是因为β相呈网状在晶界滑移带上析出,而且沉淀相不与母相共格,颗粒大,核心少,形核困难。冷变形处理后的制品,常温下长时间放置过程中,β相会以较慢的速度析出,从而使得合金因固溶强化效应减弱而强度减小。因此,对于传统Al-Mg合金而言,即使提高Mg含量来提高Al-Mg合金的力学性能,但其强度依然达不到高强度的要求。

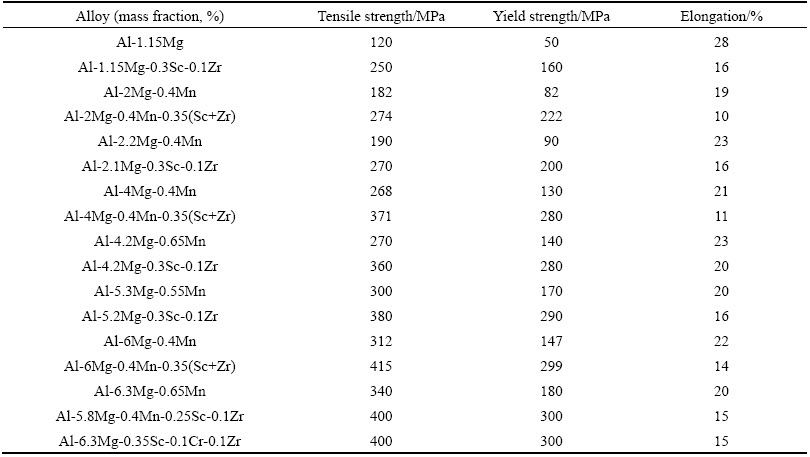

表1所列为新型Al-Mg-Sc-Zr合金和传统铝镁合金的力学性能比较[15, 23]。由表1可知,随镁含量的提高,铝镁合金整体强度提高,在传统铝镁合金基础上添加微量钪锆后,合金的抗拉强度可提高60~130 MPa,屈服强度可提高80~150 MPa,与此同时,合金仍然具有高伸长率。在轻质结构材料中,Al-Mg-Sc无疑是未来最具有竞争力的,在国防、航天航空、舰船等领域都大有作为。

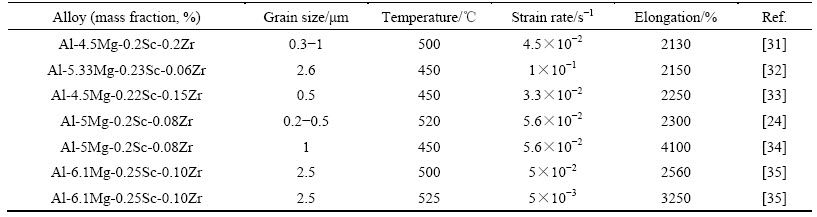

超塑成形是制造形状复杂铝合金构件的一种理想工艺。为满足工业制造需求,需实现高应变速率超塑成形 (应变速率≥1×10-2 s-1)。目前,用于研发高应变速率超塑铝合金的方法有两种:通过大塑性变形降低晶粒尺寸,如搅拌摩擦工艺、高压扭转、多轴锻造和叠轧;通过添加形成稳定粒子的微量元素,从而稳定热变形过程中的晶粒尺寸,如KAIBYSHEV等[24]和LEE等[25]通过添加钪锆获得高超塑Al-Mg合金。目前,Al-Mg系合金超塑研究已有较多报道[26-30]。新型Al-Mg-Sc-Zr合金具有超细晶粒结构,因此具有优良的超塑性能,如表2所列,易于实现工业生产和应用。用该种材料成型一些特殊部件应用于航天航空、舰船工业,具有很好的应用前景。

表1 传统铝镁合金及新型铝镁钪合金热加工态/退火态力学性能[15, 23]

Table 1 Mechanical properties of traditional Al-Mg alloy and new Al-Mg-Sc alloy subjected to hot working or annealing

表2 铝镁钪合金超塑性能[31-35]

Table 2 Superplasticities of Al-Mg-Sc alloy[31-35]

2 A1-Zn-Mg-Sc-Zr合金

Al-Zn-Mg合金属于时效可强化合金,具有强度高、加工性能好、焊接性能优良等特点,是目前许多军用和民用飞机,交通运输工具中不可缺少的重要结构材料。在中强可焊Al-Zn-Mg的基础上,俄罗斯全俄轻合金研究院与全俄复合材料研究院合作,用钪锆作为添加剂,开发了新型01970、01975和01981合金。钪锆添加在该类合金中形成细小弥散的Al3(Sc, Zr)粒子,从而显著改善合金的力学性能、焊接性能和抗应力腐蚀性能[36]。

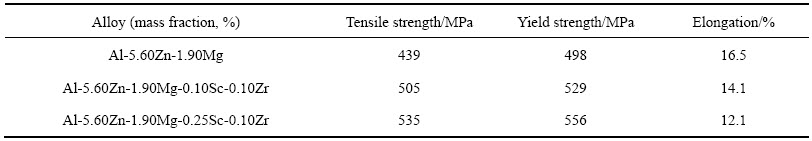

本文作者课题组在该类新材料的基础上,相继开发了Al-5.60Zn-1.90Mg-0.10Sc-0.10Zr和Al-5.60Zn-1.90Mg-0.25Sc-0.10Zr合金[37-38]。表3所列为未添加钪锆和添加不同钪锆的Al-Zn-Mg时效态合金力学性能。由表3可知,相比Al-5.60Zn-1.90Mg时效态合金,0.10%Sc+0.10%Zr添加使合金屈服强度和抗拉强度分别提高了66 MPa和31 MPa,0.25%Sc+ 0.10%添加使合金屈服强度和抗拉强度分别提高了96 MPa和58 MPa,与此同时,两种钪锆添加合金的伸长率均保持在12%以上的高水平。

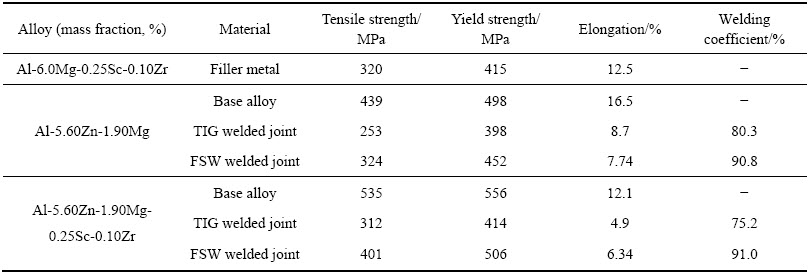

研制的新型铝锌镁钪合金为可焊合金,采用自行研制的Al-6.0Mg-0.25Sc-0.15Zr焊丝,对该类新材料进行了钨极氩弧焊(Tungsten inert gas welding, TIG)和搅拌摩擦焊(Friction stir welding, FSW),焊后性能见表4所列[39-40]。由表4可知,对比Al-Zn-Mg合金,Al-Zn-Mg-Sc-Zr 合金TIG接头的屈服强度和抗拉强度分别提高了59 MPa (23.3%)和16 MPa (4.0%),FSW接头相应值分别提高了 77 MPa (23.8%) 和 54 MPa (11.9%)。Al-Zn-Mg-Sc-Zr 合金FSW接头的抗拉强度、伸长率和焊接系数分别达到了506 MPa、6.34%和91.0%,其焊接性能甚至优于近期报道的超高强Al-Zn-Mg-Cu合金FSW焊件的[41]。

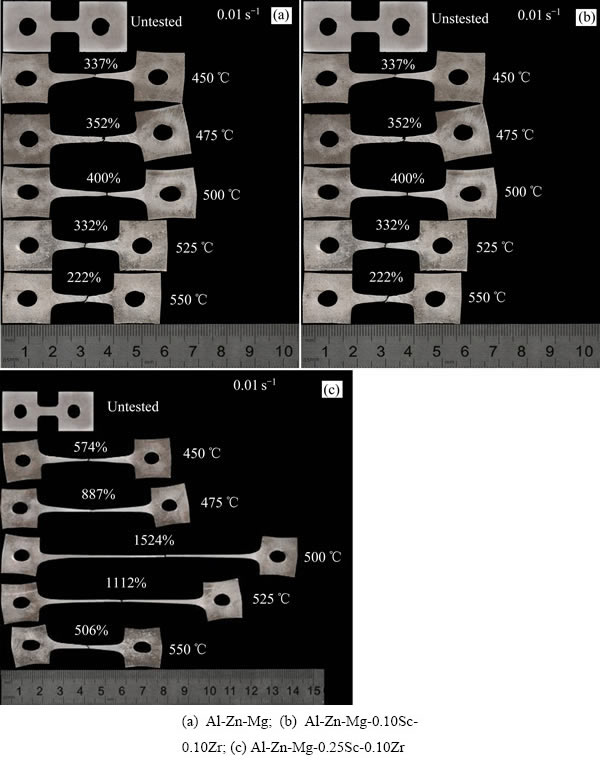

不像其他超塑铝合金需要实施复杂而苛刻的超塑预处理工艺,新型Al-Zn-Mg-Sc-Zr合金只需进行简单热力处理就可获得优良的超塑性能[42]。图1所示为传统Al-Zn-Mg和添加不同钪的Al-Zn-Mg合金板材在500 ℃和0.01 s-1下超塑拉伸形貌[43]。由图1可知,随钪含量的增加,合金断后伸长率提高,未添加钪锆的合金断裂时发生严重颈缩,但对于高应变速率超塑合金,平行段只发生均匀变形,无颈缩。

表3 研究合金时效态力学性能[37-38]

Table 3 Mechanical properties of Al-Zn-Mg alloy after ageing[37-38]

表 4 焊丝, 基材和接头力学性能[39-40]

Table 4 Mechanical properties of filler metal, base alloys and welded joints[39-40]

图1 500 ℃和0.01 s-1下铝锌镁合金的拉伸形貌

Fig. 1 Appearances of tensile specimens after maximum superplastic deformation at 500 ℃ and 0.01 s-1

3 钪锆微合金化机制

3.1 强化机制

钪锆强化铝合金及其焊接件主要包括细晶强化、亚结构强化及析出强化[37, 44]。

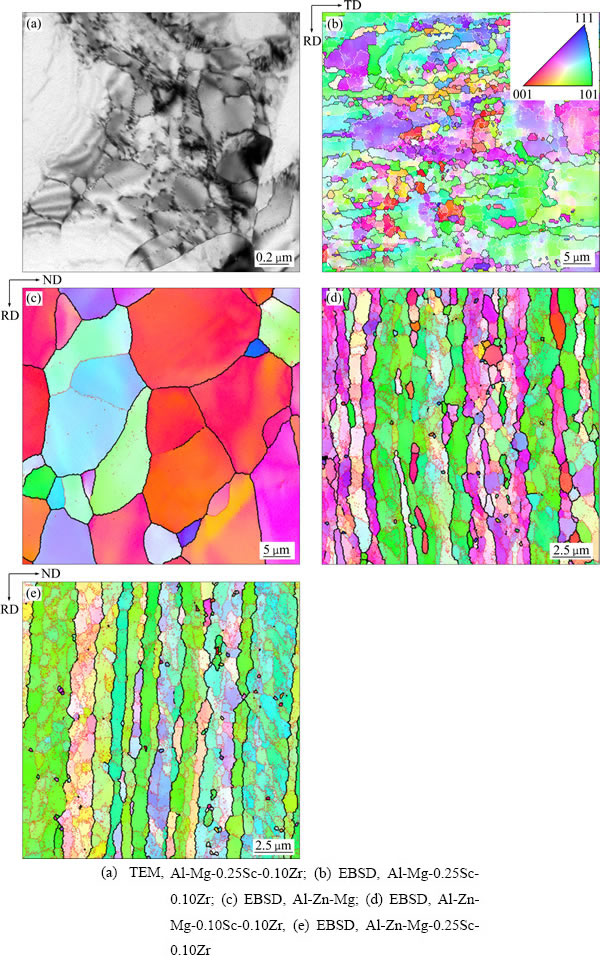

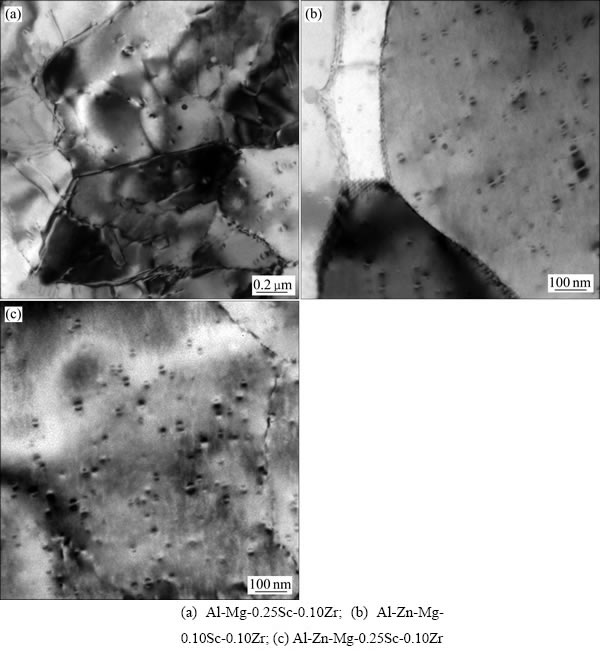

经退火后的Al-Mg-Sc-Zr合金板材和经固溶-时效处理后的铝锌镁合金如图2所示[35, 43]。与未添加钪锆铝合金相比,新型Al-Mg-Sc-Zr或Al-Zn-Mg-Sc-Zr合金的仍然保持非再结晶的微米级亚晶结构。对于Al-Zn-Mg时效态合金,晶界主要由15°~55°大角度晶界构成,其晶粒尺寸为8.26 μm,而对于Al-Zn-Mg- Sc-Zr固溶时效态合金晶界则主要以10°以内的亚晶界构成,其晶粒尺寸分别为1.36 μm和0.93 μm。由此可知,复合添加钪锆均可有效抑制Al-Zn-Mg合金在热处理过程中再结晶的发生,显著减小了合金晶粒尺 寸[45-47]。微量钪锆添加之所以能有效抑制再结晶的发生得益于形成的高密度细小弥散的与基体共格的二次Al3(Sc, Zr)粒子,该粒子在固溶处理过程中具有较高的热稳定性[48],能强烈钉轧位错及晶界,阻碍位错移动及晶界迁移(见图3)[43],从而有效抑制再结晶的发生,从而起到细晶强化和亚结构强化作用[49-52]。研究显示,Al3(Sc, Zr)与Al3Zr和 Al3Sc相比,高温下热稳定性更好[25]。由于这些共格的细小弥散分布Al3(Sc, Zr)粒子的存在,使Al-Mg-Sc-Zr合金晶粒高温热稳定性较好,利于提高超塑性。

对于不含钪锆的铝合金而言,其析出强化主要是指时效析出相对合金强度的影响。析出相强化包含奥罗万(Orowan)强化、化学强化、共格强化、模量强化、有序强化、派-纳力强化和堆垛层错强化。在实际过程中,往往以一种强化机制为主。

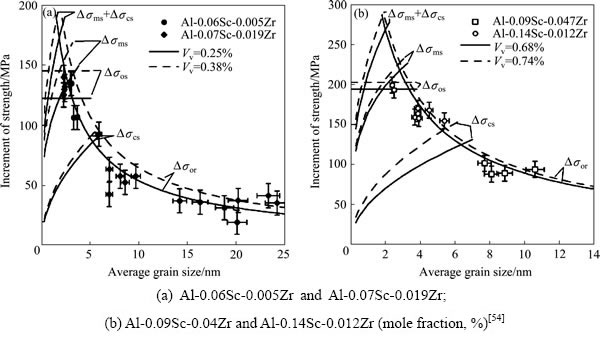

对于热处理不可强化铝镁合金,由于析出相粗大,析出强化较弱。对于可热处理可强化铝锌镁合金而言,在不同的时效时期,其主要强化机制不同。在欠时效或峰时效时期,时效相与基体共格且尺寸小,位错以切过方式同时效相发生交互作用。过时效后,析出相粗大,失去共格关系,位错则以绕过方式通过粒子,即奥罗万强化机制[53]。在钪锆添加的铝合金中,还需考虑Al3(Sc, Zr)粒子引起的析出强化。Al3(Sc, Zr)粒子尺寸变化时,析出强化机制也相应发生转变,如图4所示[54]。当Al3(Sc, Zr)粒子半径小于2 nm时,其强化机制主要为切过强化,由切过强化机制转变为奥罗万绕过机制Al3(Sc, Zr)粒子的转变尺寸为4~6 nm。

图2 退火态Al-Mg-Sc-Zr合金和时效态Al-Zn-Mg合金的显微组织

Fig. 2 Microstructures of annealed Al-Mg-Sc-Zr alloys and aged Al-Zn-Mg alloys

图3 成品态铝镁和铝锌镁合金板材中的Al3(Sc,Zr)粒子TEM像

Fig. 3 TEM images of Al3(Sc,Zr) particles in Al-Mg and Al-Zn-Mg alloys

图4 Al3(Sc, Zr)粒子尺寸与强化机制关系

Fig. 4 Relationship between size of Al3(Sc, Zr) and strengthening mechanism

3.2 超塑机制

要获取结构超塑性,晶粒尺寸需小于15 μm。钪锆复合添加到铝合金后主要以两种相形式存在:微米级的初生Al3(Sc, Zr)粒子和纳米级的次生Al3(Sc, Zr) 粒子。初生Al3(Sc, Zr) 粒子形成于铸造凝固过程,为晶粒形核提供潜在的形核位置。当未添加Zr时,Sc含量大于0.55%(质量分数,共晶点成分),可起到细化铸造组织作用,但存在0.10%Zr时,Sc含量只要大于0.18%就可起到细化晶粒效果[14, 37]。纳米级的次生Al3(Sc, Zr) 粒子形成于均匀化热处理过程中,且与基体完全共格[55],可有效抑制成品材料制备过程中再结晶的发生和晶粒长大,更多地保留亚结构,Sc含量越高,再结晶程度越低[44]。因此,钪锆添加到铝合金中可获得细小的超细亚晶组织,满足组织超塑要求。

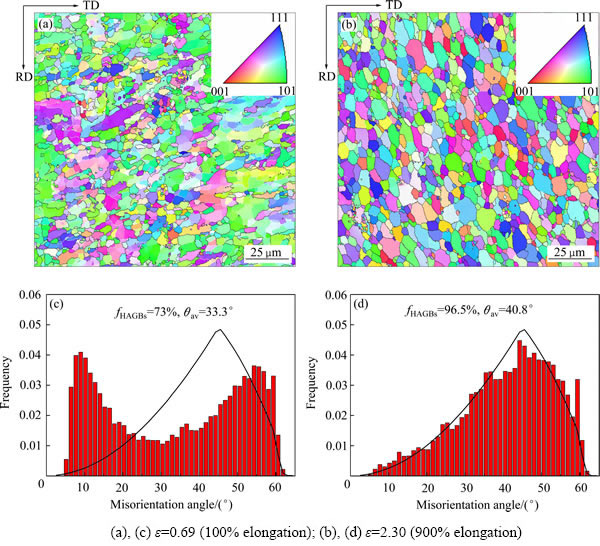

钪锆复合微合金化实现高应变速率超塑性,除了形成超细亚晶结构外,还可归因为稳定热变形过程中的晶粒尺寸。图5所示为Al-Mg-0.25Sc-0.10Zr合金在500 ℃ 和 5×10-2 s-1不同真应变下的显微组织[35]。由图5可知,经900%变形后,合金仍保持微米级晶粒尺寸。根据图5可知,随着变形的进行,发生了动态再结晶,显微组织转变为了再结晶组织。在超塑变形过程中,这种动态再结晶会导致小角度晶界逐渐转变为大角度晶界,如图5(a)和(b)所示。对这种持续再结晶的机制,在前人的报道中多有出现。当合金中含有大量的较粗大的(尺寸约为1 mm)、均匀分布的第二相粒子时,在变形很严重的区域就会出现持续再结晶。这些区域主要是指粗大沉淀相附近区域—粒子激化形核区(PSL)[56]。比如,超塑性Al-5%Ca-5%Zn合金中的Al3CaZn粒子[57]对晶粒的成核有很重要的作用。然而,Al-5%Ca-5%Zn和Al-6%Cu-0.4%Zr[58]合金在变形前的微观结构主要由大量的亚晶界组成。当有些合金不含粗大的第二相或者亚晶界,持续再结晶的机制包括转动或者转换,抑或两者都有。亚晶界转动,反过来会促进界面的滑移或者晶粒上特定滑移系的位错滑移,使亚晶界最终逐渐转化为大角度晶界。Al-Mg-0.25Sc-0.10Zr合金中没有粗大的第二相,因而动态再结晶机制主要是亚晶的变化。这个过程使小角度晶界转变为大角度晶界,利于晶界滑移和超塑变形的进行[24]。

图5 Al-Mg-0.25Sc-0.10Zr合金在500 ℃和5×10-2 s-1不同真应变下的显微组织

Fig. 5 Microstructures of Al-Mg-0.25Sc-0.10Zr alloy at 500 ℃ and 5×10-2 s-1, EBSD maps and boundary misorientation angle distributions after deforming to different strains

4 结论

1) 相比传统铝镁合金,新型Al-Mg-Sc-Zr合金抗拉强度提高60~130 MPa,屈服强度提高80~150 MPa,且可获得大于2000%高速超塑性。

2) 相比铝锌镁合金,新型Al-Zn-Mg-Sc-Zr合金抗拉强度提高66~96 MPa,屈服强度提高36~98 MPa,钨极氩弧焊系数大于0.75,搅拌摩擦焊系数大于0.90,且可获得大于1500%高速超塑性。

3) 钪锆添加到铝合金中可形成Al3(Sc,Zr) 粒子,该粒子可细化铸造组织,抑制再结晶发生,稳定晶粒尺寸,产生显著的细晶强化、亚结构强化和析出强化,提高合金强度,实现优良超塑性能。

REFERENCES

[1] ROYSET J, RYUM N. Scandium in aluminium alloys[J]. International Material Reviews, 2005, 50(l): 19-44.

[2] 林肇琦, 马宏声, 赵 刚. 铝-钪合金的发展概况(一)[J]. 轻金属, 1992(1): 54-58.

LIN Zhao-qi, MA Hong-sheng, ZHAO Gang. The development of Al-Sc alloy (Ⅰ)[J]. Light Metal, 1992(1): 54-58.

[3] 林肇琦, 马宏声, 赵刚.铝-钪合金的发展概况(二)[J]. 轻金属, 1992(2): 53-60.

LIN Zhao-qi, MA Hong-sheng, ZHAO Gang. The development of Al-Sc alloy (Ⅱ)[J]. Light Metal, 1992(2): 53-60.

[4] 戴晓元, 夏长清, 马 科, 刘 娟. Sc对Al-Zn-Mg-Cu-Zr合金铸态组织和力学性能的影响[J]. 中国有色金属学报, 2007, 17(8): 1324-1329.

DAI Xiao-yuan, XIA Chang-qing, MA Ke, LIU Juan. Effect of Sc on as-cast microstructures and mechanical properties of Al-Zn-Mg-Cu-Zr alloys[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(8): 1324-1329.

[5] 李文斌, 潘清林, 肖艳苹, 何运斌, 刘晓艳. 含钪Al-Zn-Cu-Mg-Zr合金的腐蚀行为和电化学阻抗谱特征[J]. 中南大学学报(自然科学版), 2011, 42(9): 2642-2650.

LI Wen-bin, PAN Qing-lin, XIAO Yan-ping, HE Yun-bin, LIU Xiao-yan. Corrosion behaviors and electrochemical impedance spectroscopy features of Al-Zn-Cu-Mg-Zr alloy containing Sc[J]. Journal of Central South University (Science and Technology), 2011, 42(9): 2642-2650.

[6] 肖代红, 巢 宏, 陈康华, 黄伯云. 微量Sc对AA7085铝合金组织与性能的影响[J]. 中国有色金属学报, 2008, 18(12): 2145-2150.

XIAO Dai-hong, CHAO Hong, CHEN Kang-hua, HUANG Bai-yun. Effect of minor Sc addition on microstructure and properties of AA7085 alloy[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(12): 2145-2150.

[7] 郭加林, 尹志民, 王 华, 何振波, 商宝川. 微量Sc和Zr对2524SZ合金薄板疲劳裂纹扩展特性的影响[J]. 中国有色金属学报, 2010, 20(5): 827-832.

GUO Jia-lin, YIN Zhi-min, WANG Hua, HE Zhen-bo, SHANG Bao-chuan. Effects of minor Sc and Zr on fatigue crack development characteristics of 2524SZ alloy sheet[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(5): 827-832.

[8] 陈 琴, 潘清林, 王 迎, 彭 虹, 张志野, 尹志民. 微量Sc和Zr对Al-Mg-Mn合金组织与力学性能的影响[J]. 中国有色金属学报, 2012, 22(6): 1555-1563.

CHEN Qin, PAN Qing-lin, WANG Ying, PENG Hong, ZAHNG Zhi-ye, YIN Zhi-min. Effects of minor scandium and zirconium on microstructure and mechanical properties of Al-Mg-Mn alloys[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(6): 1555-1563.

[9] ZHANG Wei, XING Yuan, JIA Zhi-hong, YANG Xiao-fang, LIU Qing, ZHU Chang-luo. Effect of minor Sc and Zr addition on microstructure and properties of ultra-high strength aluminum alloy[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(12): 3866-3871.

[10] FILATOV Y A, YELAGIN V I, ZAKHAROV V V. New Al-Mg-Sc alloys[J]. Materials Science and Engineering A, 2000, 280: 97-101.

[11] 叶 锐, 杨继东, 彭小燕, 徐国富, 尹志民. Al-Zn-Mg-Sc-Zr合金搅拌摩擦焊接接头的显微组织、力学性能及局部腐蚀性能[J]. 中国有色金属学报, 2015, 25(10): 2656-2665.

YE Rui, YANG Ji-dong, PENG Xiao-yan, XU Guo-fu, YIN Zhi-min. Microstructure, mechanical properties and localized corrosion property of friction stir welded joint of Al-Zn-Mg-Sc-Zr alloy[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(10): 2656-2665.

[12] 潘清林, 尹志民, 邹景霞, 陈显明, 张传福. 微量Sc在Al-Mg合金中的作用[J]. 金属学报, 2001, 37(7): 749-753.

PAN Qing-lin, YIN Zhi-min, ZOU Jing-xia, CHEN Xian-ming, ZHANG Chuan-fu. Effects of minor Sc addition on microstructure and tensile property of Al-Mg alloy[J]. Acta Metallurgica Sinica, 2001, 37(7): 749-753.

[13] KENDIG K L, MIRACLE D B. Strengthening mechanisms of an Al-Mg-Sc-Zr alloy[J]. Acta Materialia, 2002, 50: 4165-4175.

[14] 黄宏锋, 姜 锋, 刘兴涛, 周 江, 钟沐春, 韦莉莉. Al3(Sc,Zr)粒子与剪切带对Al-Mg-Sc-Zr合金再结晶及断裂行为的影响[J]. 中国有色金属学报, 2015, 25(5): 1117-1127.

HUANG Hong-feng, JIANG Feng, LIU Xing-tao, ZHOU Jiang, ZHONG Mu-chun, WEI Li-li. Effects of Al3(Sc, Zr) particles and shear bands on recrystallization and fracture behaviors of Al-Mg-Sc-Zr alloy[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(5): 1117-1127.

[15] 尹志民, 潘清林, 姜 锋, 李汉广. 钪和含钪合金[M]. 长沙: 中南大学出版社, 2007.

YIN Zhi-min, PAN Qing-lin, JIANG Feng, LI Han-guang. Scandium and its alloys[M]. Changsha: Central South University Press, 2007.

[16] HUANG Ji-wu, YIN Zhi-min, LEI Xue-feng. Microstructure and properties of 7A52 Al alloy welded joint[J]. Transactions of Nonferrous Metals Society of China, 2008, 18(4): 804-808.

[17] 陈苏里, 姜 锋, 尹志民, 雷学锋, 聂 波. 含钪和不含钪铝镁钪合金焊接接头的组织与性能[J]. 中国有色金属学报, 2006, 16(5): 836-840.

CHEN Su-li, JIANG Feng, YIN Zhi-min, LEI Xue-feng, NIE Bo. Microstructure and properties of Al-Mg-Sc alloy weld joints filled with Al-Mg-Zr and Al-Mg-Zr-Sc weld wires[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(5): 836-840.

[18] 杨福宝, 刘恩克, 徐 骏, 张志峰, 石力开. Sc、Zr 和Er 微合金化Al-5Mg 填充合金的焊接热裂敏感性[J]. 中国有色金属学报, 2010, 20(4): 620-627.

YANG Fu-bao, LIU En-ke, XU Jun, ZHANG Zhi-feng, SHI Li-kai. Hot-cracking susceptibility of (Sc, Zr, Er)-microalloyed Al-5Mg filler metals[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(4): 620-627.

[19] 陈继强, 尹志民, 何振波. 微量钪对Al-Zn-Mg-Zr热轧板搅拌摩擦焊接头组织与性能的影响[J]. 中国有色金属学报, 2010, 20(10): 1883-1888.

CHEN Ji-qiang, YIN Zhi-min, HE Zhen-bo. Effects of minor Sc on microstructure and mechanical properties of Al-Zn-Mg-Zr hot rolled plate[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(10): 1883-1888.

[20] 王祝堂, 田荣璋. 铝合金及其加工手册[M]. 长沙: 中南工业大学出版社, 1988.

WANG Zhu-tang, TIAN Rong-zhang. Aluminum alloy and its processing manual[M]. Changsha: Central South University of Technology Press, 1988.

[21] 邓至谦, 周善初. 金属材料及热处理[M]. 长沙: 中南工业大学出版社, 1989.

DENG Zhi-qian, ZHOU Shan-chu. Metal materials and heat treatment[M]. Changsha: Central South University of Technology Press, 1989.

[22] 《有色金属及其热处理》编写组. 有色金属及其热处理[M]. 北京: 国防工业出版社, 1981: 39.

Editorial committee of 《Non-ferrous metals and its heat treatment》. Non-ferrous metals and its heat treatment[M]. Beijing: National Defence Industry Press, 1981: 39.

[23] RYEN  , HOLMEDAL B, NES E. Characterisation and modelling of work Hardening in Al-Mg and Al-Mn alloys[J]. Materials Science Forum, 2002, 396/402: 1145-1150.

, HOLMEDAL B, NES E. Characterisation and modelling of work Hardening in Al-Mg and Al-Mn alloys[J]. Materials Science Forum, 2002, 396/402: 1145-1150.

[24] KAIBYSHEV R, AVTOKRATOVA E, APOLLONOV A, DAVIES R. High strain rate superplasticity in an Al-Mg-Sc-Zr alloy subjected to simple thermomechanical processing[J]. Scripta Materialia, 2006, 54: 2119-2124.

[25] LEE S, UTSUNOMIYA A, AKAMATSU H, NEISHI K, FURUKAWA M, HORITA Z, LANGDON TG. Influence of scandium and zirconium on grain stability and superplastic ductilities in ultrafine-grained Al-Mg alloys [J]. Acta Materialia, 2002, 50: 553-564.

[26] DUAN Yu-lu, XU Guo-fu, XIAO Dan, ZHOU Li-qi, DENG Ying, YIN Zhi-min. Excellent superplasticity and deformation mechanism of Al-Mg-Sc-Zr alloy processed via simple free forging[J]. Materials Science and Engineering A, 2015, 624: 124-131.

[27] 谢优华, 陆 政, 戴圣龙. Al-6Mg-0.2Sc铝合金高温力学行为研究[J]. 材料工程, 2007(3): 49-52.

XIE You-hua, LU Zheng, DAI Sheng-long. Mechanical behavior of A1-6Mg-0.2Sc aluminum alloys at elevated temperature[J]. Journal of Materials Engineering, 2007(3): 49-52.

[28] LIU F C, MA Z Y, ZHANG F C. High strain rate superplasticity in a Micro-grained Al-Mg-Sc alloy with predominant high angle grain boundaries[J]. Journal of Materials Science and Technology, 2012, 28: 1025-1030.

[29] 赵 俊, 黎文献, 肖于德. 含微量Zr的Al-6%Mg合金再结晶行为及其超塑性[J]. 轻合金加工技术, 2003, 31(8): 42-45.

ZHAO Jun, LI Wen-xian, XIAO Yu-de. Influence of zr on me recrystallization and superplasticity behavior of Al-6%Mg alloy[J]. Light Alloy Fabrication Technology, 2003, 31(8): 42-45.

[30] 张 超, 沙 玲, 芮玉龙. 铝-镁-钪合金超塑性胀形工艺有限元分析[J]. 机械工程材料, 2008, 32(2): 81-84.

ZHANG Chao, SHA Ling, RUI Yu-long. Superplastic bulging simulation of Al-Mg-Sc alloy[J]. Materials for Mechanical Engineering, 2008, 32(2): 81-84.

[31] TURBA K, M LEK P, CIESLAR M. Superplasticity in an Al-Mg-Zr-Sc alloy produced by equal-channel angular pressing[J]. Materials Science and Engineering A, 2007, 462: 91-94.

LEK P, CIESLAR M. Superplasticity in an Al-Mg-Zr-Sc alloy produced by equal-channel angular pressing[J]. Materials Science and Engineering A, 2007, 462: 91-94.

[32] LIU F C, MA Z Y. Achieving exceptionally high superplasticity at high strain rates in a micrograined Al-Mg-Sc alloy produced by friction stir processing[J]. Scripta Materialia, 2008, 59: 882-885.

[33] PEREVEZENTSEV V N, SHCHERBAN M Y, MURASHKIN M Y, VALIEV R Z. High-strain-rate superplasticity of nanocrystalline aluminum alloy 1570[J]. Technical Physics Letters, 2007, 33: 648-650.

[34] AVTOKRATOVA E, SITDIKOV O, MARKUSHEV M, MULYUKOV R. Extraordinary high-strain rate superplasticity of severely deformed Al-Mg-Sc-Zr alloy[J]. Materials Science and Engineering A, 2012, 538: 386-390.

[35] CAO Xiao-wu, XU Guo-fu, DUAN Yu-lu, YIN Zhi-min, LU Li-ying, WANG Ying-jun. Achieving high superplasticity of a new Al-Mg-Sc-Zr alloy sheet prepared by a simple thermal- mechanical process[J]. Materials Science and Engineering A, 2015, 647: 333-343.

[36] DENG Ying, PENG Bing, XU Guo-fu, PAN Qing-lin, YE Rui, WANG Ying-jun, LU Li-ying, YIN Zhi-min. Stress corrosion cracking of a high-strength friction-stir-welded joint of an Al-Zn-Mg-Zr alloy containing 0.25wt.%Sc[J]. Corrosion Science, 2015, 100: 57-72.

[37] DENG Ying, YIN Zhi-min, ZHAO Kai, DUAN Jia-qi, HE Zhen-bo. Effects of Sc and Zr microalloying additions on the microstructure and mechanical properties of new Al-Zn-Mg alloys[J]. Journal of Alloys and Compounds, 2012, 530: 71-80.

[38] DENG Ying, YIN Zhi-min, DUAN Jia-qi, ZHAO Kai, TANG Bei, HE Zhen-bo. Evolution of microstructure and properties in a new type 2 mm Al-Zn-Mg-Sc-Zr alloy sheet[J]. Journal of Alloys and Compounds, 2012, 517: 118-126.

[39] DENG Ying, PENG Bing, XU Guo-fu, PAN Qing-lin, YIN Zhi-min, YE Rui, WANG Ying-jun, LU Li-ying. Effects of Sc and Zr on mechanical property and microstructure of tungsten inert gas and friction stir welded aerospace high strength Al-Zn-Mg alloys [J]. Materials Science and Engineering A, 2015, 639: 500-513.

[40] LEI Xue-feng, DENG Ying, PENG Yong-yi, YIN Zhi-min, XU Guo-fu. Microstructure and properties of TIG/FSW welded joints of a new Al-Zn-Mg-Sc-Zr alloy[J]. Journal of Materials Engineering and Performance, 2013, 22: 2723-2729.

[41] ZHANG Fei, SU Xue-kuan, CHEN Zi-yong, NIE Zuo-ren. Effect of welding parameters on microstructure and mechanical properties of friction stir welded joints of a super high strength Al-Zn-Mg-Cu aluminum alloy[J]. Materials & Design, 2015, 67: 483-491.

[42] DUAN Yu-lu, XU Guo-fu, ZHOU Li-qi, XIAO Dan, DENG Ying, YIN Zhi-min, PENG Bing, PAN Qing-lin, WANG Ying-jun, LU Li-ying. Achieving high superplasticity of a traditional thermal–mechanical processed non-superplastic Al-Zn-Mg alloy sheet by low Sc additions[J]. Journal of Alloys and Compounds, 2015, 638: 364-373.

[43] 邓 英, 尹志民, 徐国富.铝锌镁系合金钪锆复合微合金化[M]. 长沙: 中南大学出版社, 2015: 88-144.

DENG Ying, YIN Zhi-min, XU Guo-fu. Sc and Zr microalloying in Al-Zn-Mg series alloys[M]. Changsha: Central South University Press, 2015: 88-144.

[44] DENG Ying, XU Guo-fu, YIN Zhi-min, LEI Xue-feng, HUANG Ji-wu. Effects of Sc and Zr microalloying additions on the recrystallization texture and mechanism of Al-Zn-Mg alloys[J]. Journal of Alloys and Compounds, 2013, 580: 412-426.

[45] 余 琨, 李松瑞, 黎文献, 肖于德. 微量Sc和Zr对2618铝合金再结晶行为的影响[J]. 中国有色金属学报, 1999, 9(4): 709-713.

YU Kun, LI Song-rui, LI Wen-xian, Xiao Yu-de. Effect of trace Sc and Zr on recrystallization behavior of 2618 alloy[J]. The Chinese Journal of Nonferrous Metals, 1999, 9(4): 709-713.

[46] 尹志民, 高拥政, 潘青林, 张永红, 尹松波. 微量Sc和Zr对Al-Mg合金铸态组织的晶粒细化作用[J]. 中国有色金属学报, 1997, 7(4): 75-78.

YIN Zhi-min, GAO Yong-zhen, PAN Qing-lin, ZHANG Yong-hong, YIN Song-bo. Effect of trace Sc and Zr on grain refinement of as-cast Al-Mg alloys[J]. The Chinese Journal of Nonferrous Metals, 1997, 7(4): 75-78.

[47] 张迎晖, 孝云祯, 马宏声. 微量元素Sc对工业纯铝再结晶的影响[J]. 中国有色金属学报, 1998, 8(1): 85-88.

ZHANG Ying-hui, XIAO Yun-zhen, MA Hong-sheng. Effect of trace Sc on recrystallization of industrial pure aluminum[J]. The Chinese Journal of Nonferrous Metals, 1998, 8(1): 85-88.

[48] 周 向, 尹志民, 段佳琦, 赵 凯, 何振波. Al-Zn-Mg-Sc-Zr合金板材制备过程中组织性能的演变[J]. 中南大学学报(自然科学版), 2011, 42(12): 3680-3685.

ZHOU Xiang, YIN Zhi-min, DUAN Jia-qi, ZHAO Kai, HE Zhen-bo. Microstructure and properties evolution of Al-Zn-Mg-Sc-Zr alloy sheet in different treat conditions during preparation process[J]. Journal of Central South University (Science and Technology), 2011, 42(12): 3680-3685.

[49] 戴晓元, 夏长清, 孙振起, 华熳煜, 吴 茵. Al-9.0Zn-2.5Mg- 1.2Cu-0.12Sc-0.15Zr合金的组织和性能[J]. 中国有色金属学报, 2007, 17(3): 396-402.

DAI Xiao-yuan, XIA Chang-qing, SUN Zhen-qi, HUA Man-yu, WU Yin. Microstructure and properties of Al-9.0Zn-2.5Mg- 1.2Cu-0.12Sc-0.15Zr alloy[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(3): 396-402.

[50] ZOU Liang, PAN Qing-lin, HE Yun-bin, WANG Chang-zhen, LIANG Wen-jie. Effect of minor Sc and Zr addition on microstructures and mechanical properties of Al-Zn-Mg-Cu alloys[J]. Transactions of Nonferrous Metals Society of China, 2007, 17(2): 340-345.

[51] HE Yong-dong, ZHANG Xin-ming, YOU Jiang-hai. Effect of minor Sc and Zr on microstructure and mechanical properties of Al-Zn-Mg-Cu alloy[J]. Transactions of Nonferrous Metals Society of China, 2006, 16(2): 1228-1235.

[52] 贺永东, 张新明, 陈健美, 唐建国, 微量Sc和Zr对7A55合金铸锭组织的细化机理[J]. 中南大学学报(自然科学版), 2005, 36(6): 919-923.

HE Yong-dong, ZHANG Xin-ming, CHEN Jian-mei, TANG Jian-guo. Refinement mechanism of trace Sc and Zr as-cast 7A55 alloys[J]. Journal of Central South University (Science and Technology), 2005, 36(6): 919-923.

[53] 刘 刚.含多尺度第二相时效铝合金力学性能的模型化与实验研究[D]. 西安: 西安交通大学, 2002.

LIU Gang. Modeling and experimental investigation into the mechanical properties of aged aluminum alloys containing multi-scaled second phase particles[D]. Xi’an: Xi’an Jiaotong University, 2002.

[54] SENKOV O N, SHAGIEV M R, SENKOVA S V, MIRACLE D B. Precipitation of Al3(Sc,Zr) particles in an Al-Zn-Mg-Cu-Sc-Zr alloy during conventional solution heat treatment and its effect on tensile properties[J]. Acta Materialia, 2008, 56(15): 3723-3738.

[55] 戴晓元, 夏长清, 彭小敏, 7×××铝合金退火过程中二次Al3(Sc, Zr)粒子的析出行为[J]. 中国有色金属学报, 2010, 20(3): 451-455.

DAI Xiao-yuan, XIA Chang-qing, PENG Xiao-min. Precipitation behavior of Al3(Sc, Zr) secondary particles in 7××× aluminum alloys during annealing [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(3): 451-455.

[56] HUMPHREYS F J. The nucleation of recrystallization at second phase particels in deformed aluminium[J]. Acta Metallurgica, 1977, 25: 1323-1344.

[57] P REZ-PRADO M T, MCNELLEY T R, GONZ

REZ-PRADO M T, MCNELLEY T R, GONZ LEZ- DONCELY G, RUANO O A.Texture analysis of the transition from slip to grain boundary sliding in a continuously recrystallized superplastic aluminum alloy[J]. Materials Science and Engineering A, 2003, 342: 216-230.

LEZ- DONCELY G, RUANO O A.Texture analysis of the transition from slip to grain boundary sliding in a continuously recrystallized superplastic aluminum alloy[J]. Materials Science and Engineering A, 2003, 342: 216-230.

[58] EDDAHBI M, RUANO O A, MCNELLEY T R. The evolution of grain boundary character during superplastic deformation of an Al-6 pct Cu-0.4 pct Zr alloy[J]. Metallurgical and Materials Transactions A, 2001, 32(5): 1093-1102.

Research advance on new Al-Mg-Sc-Zr and Al-Zn-Mg-Sc-Zr alloys

XU Guo-fu1, 2, PENG Xiao-yan1, DUAN Yu-lu1, DENG Ying1, 2, YIN Zhi-min1, 2

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Nonferrous Materials Science and Engineering, Ministry of Education,

Central South University, Changsha 410083, China)

Abstract: In all micro-alloying elements, scandium offers the greatest potential for improving the property of aluminum alloys. Sc and Zr can improve the tensile strength and yield strength by 60-130 MPa and 80-150 MPa, respectively. The new Al-Mg-Sc-Zr alloy exhibits high strain rate superplasticity with the elongation more than 2000%. Compared with the tensile strength and yield strength of conventional Al-Zn-Mg, the corresponding values are 66-96 MPa and 36-98 MPa higher, respectively. Moreover, the welding coefficients of tungsten inert gas and friction stir welded joints are 0.75 and 0.90, which are higher in the new Al-Zn-Mg-Sc-Zr alloy, respectively. Furthermore, excellent high-strain superplasticity with the elongation above 1500% can be obtained in the new Al-Zn-Mg-Sc-Zr alloy. The Al3(Sc, Zr) particles can refine casting structure, inhibit recrystallization and the stabilize fine grain structure, and thus cause significant grain refinement strengthening, substructure strengthening and precipitation strengthening, which leads to the improvement of strength and excellent superplasticity.

Key words: aluminum alloy; Al-Mg-Sc-Zr alloy; Al-Zn-Mg-Sc-Zr alloy; micro-alloying; strengthening mechanism; superplasticity

Foundation item: Project(51312010402) supported by General Armament Department, China

Received date: 2015-10-01; Accepted date: 2016-03-26

Corresponding author: XU Guo-fu; Tel: +86-731-88877217; Fax: +86-731-88877217; E-mail: csuxgf66@csu.edu.cn

(编辑 王 超)

基金项目:总装预研基金资助项目(51312010402)

收稿日期:2015-10-01;修订日期:2016-03-26

通信作者:徐国富,教授,博士;电话:0731-88877217;传真:0731-88877217;E-mail: csuxgf66@csu.edu.cn