文章编号:1004-0609(2011)09-2099-06

溅射沉积铝合金基CrTiAlN涂层的

结构、力学以及摩擦学特性

石永敬1, 2, 潘复生1, 王维青1, 杨世才3, 龙思远1, 朱光俊2

(1. 重庆大学 材料科学与工程学院,重庆 400044;2. 重庆科技学院 冶金与材料工程学院,重庆 401331;

3. Teer Coatings Ltd., West Stone House, Berry Hill Industrial Estate, Droitwich, Worcestershire WR9 9AS, UK)

摘 要:采用反应非平衡磁控溅射技术制备出一系列LY12铝合金基CrTiAlN多层涂层,并通过X射线衍射仪、纳米压痕仪以及多功能摩擦磨损测试仪来研究CrTiAlN涂层的结构、力学以及摩擦学特性。结果表明:CrTiAlN涂层为以TiN0.9和CrN为主要组织取向的FCC结构,N2水平和衬底负偏压对涂层的力学特性和粘附强度有显著的影响。经过优化参数,在衬底偏压-55V和中N2水平条件下,CrTiAlN涂层的结合强度为10 N,显微硬度达到29.87 GPa。

关键词:CrTiAlN涂层;力学性能;结构特性;摩擦因数

中图分类号:TG 174.44 文献标志码:A

Structural, mechanical and tribological properties of CrTiAlN coatings on Al alloy deposited by sputtering

SHI Yong-jing1, 2, PAN Fu-sheng1, WANG Wei-qing1, YANG Shi-cai3, LONG Si-yuan1, ZHU Guang-jun2

(1. College of Materials Science and Engineering, Chongqing University, Chongqing 400044, China;

2. School of Metallurgical and Materials Engineering,

Chongqing University of Science and Technology, Chongqing 400050, China;

3. Teer Coatings Ltd., West Stone House, Berry Hill Industrial Estate, Droitwich, Worcestershire WR9 9AS, UK)

Abstract: A series of CrTiAlN multi-layer coatings on LY12 Al alloy substrates were prepared using unbalanced reactive magnetron sputtering system. The structural, mechanical and tribological properties of coatings were studied by X-ray diffractometry, microhardness tester and multi-functional ball-on-disc tester. The results show that the CrTiAlN coatings belong to FCC structure consisting of TiN0.9 and CrN, and the N2 level and negative bias voltage have a significant effect on CrTiAlN multi-layer coatings. The adhesion strength of optimized CrTiAlN coatings is 10 N at -55 V and medium N2 level, and its microhardness value is about 29.87 GPa.

Key words: CrTiAlN coatings; mechanical property; structural property; friction coefficient

铝合金是目前重要的轻合金结构材料之一,在汽车和航空航天等相关领域具有巨大的应用前景。为了改善铝合金表面的力学性能和减摩特性,许多的研究致力于铝合金的表面涂层处理技术,如喷涂、化学转化以及微弧氧化等[1-3]。基于磁控溅射技术在制备减磨和润滑等硬质涂层领域取得的巨大成功,溅射沉积铝合金基硬质防护涂层开始吸引一些国内外研究者的注意。DOM?NGUEZ-CRESPO等[4]采用脉冲溅射制备出Al-Ce合金薄膜,并表征出合金薄膜的结构和电化学腐蚀行为。FIGUEROA等[5]采用直流磁控溅射技术沉积出2024-T3、6061-T4以及7075-T6等铝合金基AlN涂层,临界载荷值在30~70 N之间,努氏硬度值约为735~951 HK,表面和断面形貌展示为密集的柱状晶结构。盐雾腐蚀测试证实AlNx涂层对铝合金具有优异的保护性能[6]。DIESSELBERG等[7]采用直流反应溅射制备出铝合金基TiN涂层,TiNx(x<1)涂层的耐蚀性能与N原子含量有关,TiNx涂层比比TiN涂层显示出更加优异的耐蚀性能。随着磁控溅射技术的发展,硬质防护涂层已从传统的二元向三元、四元多相多层结构转变,如在高速钢的减摩等领域获得广泛应用的TiAlN以及CrAlN涂层,力学性能和减摩性能与CrN、TiN涂层的相比有显著改善[8-9]。磁控溅射CrTiAlN涂层是以CrN为基础通过添加Ti和Al元素构成的多层复合涂层,具有优良的高温耐磨耐蚀性能[10-15]。为了改善铝合金的力学和减摩性能,本文作者采用非平衡磁控溅射技术制备出LY12铝合金基CrTiAlN硬质涂层。

1 实验

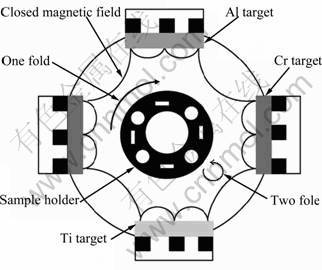

CrTiAlN涂层采用一个小型的闭合磁场非平衡磁控溅射离子镀膜机(UDP450)沉积,溅射金属气相源来自于4个尺寸规格为133 mm×330 mm的金属元素靶(摩尔分数为99.95%),相邻两个靶的磁极相反成90?布置,并相互构成一个闭合的磁场,如图1所示。衬底为LY12铝合金的成分(质量分数约为:Al 92%、Si 0.5%、Fe 0.5%、Cu 4.5%、Mg 1.8%)。CrTiAlN涂层在Ar+N2混合气氛条件下合成,N原子相对浓度和金属原子相对浓度通过靶功率和具有反馈控制的等离子体发射光谱监控,光谱强度监控靶为Cr靶,光谱强度采用OEM表示,OEM值的大小取决于真空腔内的N2浓度。涂层的调制周期通过样品架的转速和阴极靶的相对溅射功率来控制,样品架的转速为4 r/min。为了去除衬底表面的氧化物并保持平整,尺寸为d 30 mm×2 mm的铝合金衬底依次经过1200#碳化硅砂纸打磨和大约30 min的丙酮超声波清洗。在涂层沉积之前,真空腔的本底压力抽到4.1×10-4 Pa。Ar流速为25 mL/min,真空腔的溅射气压为0.3 Pa。涂层沉积的程序依次为:首先对衬底进行5 min的预溅射清洗,沉积大约100 nm厚的金属粘附层,然后输入N2,直到OEM值达到相应的设定值,4个阴极靶的溅射功率依次为:Cr-360W,Ti-945W,Cr-360W和Al-675W。

图1 CFUBMSIP系统内磁控靶和样品架分布示意图

Fig.1 Schematic diagram of various targets and sample holder in CFUBMSIP system

CrTiAlN涂层分别在不同的衬底偏压Vb(-40~-90 V)和OEM值(55%~75%)条件下合成。涂层的厚度采用POD-1球痕仪,所获总厚度值如表1所列。涂层的成分采用ESCALAB-250型X射线光电子能谱仪(XPS)分析,Al Kα源(1486.84 eV)辐射,大面积透镜扫描模式,扫描步长为0.1 eV。结合能的校订依次按照下面的步骤进行:Au4f7/2(84.0 eV),Ag3d5/2 (368.3 eV)和Cu2p3/2(932.7 eV)。涂层的晶体组织结构采用D/Max-2500型X射线衍射仪(XRD)分析,掠入射角度为2?,衍射靶为Cu Kα源,扫描步长为0.02?,扫描速度为6 (?)/min。截面形貌采用H-9000NAR型场发射透射电子显微镜(FETEM)。涂层的显微硬度和弹性模量采用带有维氏压头的Fischer scope H100型显微硬度仪测试,压入深度不超过涂层总厚度的10%。涂层的结合强度和摩擦因数采用多功能划痕-摩擦磨损测试仪(ST3001)检测,划痕测试在0~10的线性变载荷条件下进行。摩擦因数检测采用双向滑动模式,总滑动距离和滑动速度分别为4 mm和150 mm/min。

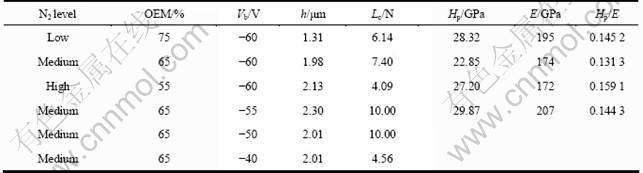

表1 CrTiAlN涂层的粘附强度、硬度和弹性模量

Table 1 Adhesion strength, hardness and elastic modulus of CrTiAlN coatings

2 结果与分析

在CrTiAlN多层涂层沉积过程中,CrN、TiN以及AlN的单层厚度和周期长度通过靶功率和样品架的转速来控制,样品架旋转一周完成一个周期的沉积。涂层沉积过程依次为金属支持层、过渡层以及化合物层。所测多层涂层的厚度约在1.3~2.3 μm之间,如表1所列,表中符号的意义分别如下:OEM为Cr靶表面光谱强度;Vb为衬底负偏压;h为涂层总厚度;Lc为涂层-衬底之间的粘附强度;Hp为涂层显微硬度;E为涂层弹性模量。CrTiAlN涂层样品分别在不同的N2水平和衬底偏压条件下合成,以下将分别讨论具有不同的N2水平和衬底偏压的CrTiAlN涂层的组织结构、显微硬度以及摩擦因数的变化。

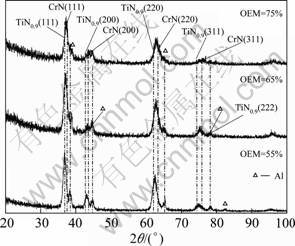

2.1 结构分析

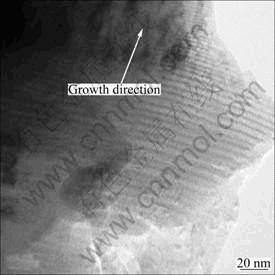

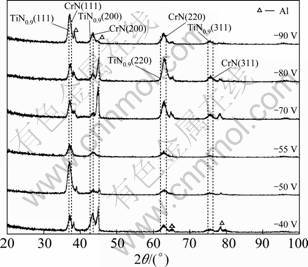

CrTiAlN涂层的周期结构为CrN/TiN/CrN/AlN,TEM截面如图2所示,图中箭头的方向表示涂层沉积方向。涂层的调制周期为2.0~5.0 nm。CrTiAlN涂层的组织结构采用掠入射XRD分析,将获得的XRD谱与粉末衍射图谱比对,图3和4分别展示出CrTiAlN涂层在不同的N2水平条件和不同的衬底偏压条件下的结构演化。结果表明:3种N2水平和6个衬底偏压涂层的组织结构显示为含TiN0.9和CrN的FCC结构(参考的粉末衍射卡片依次为TiN0.9—710299, CrN—762494,AlN—851327)。由图3可见,随着N2水平的增加,涂层的衍射峰位从低N2水平的CrN趋向于高N2水平的TiN0.9。文献[16]展示出3种N2水平条件下的原子浓度和化学组成,涂层结构的变化取决于N原子浓度和化学组成。由此可见,在同样的反应气氛条件下,CrN形成比TiN0.9容易。

在不同的偏压条件下,CrTiAlN涂层显示出FCC结构,涉及到(111)、(200)、(220)以及(311)4个取向,如图4所示。在Vb=-50 V时,涂层显示出强烈的(111)择优取向结构,随后(111)取向的强度逐渐降低,而(220)取向的强度逐渐增强;在Vb=-80 V时,涂层显示出(220)择优取向结构。这种取向的变化归因于轰击离子流的密度和轰击离子能,离子能和离子流密度的增加会极大地促进沉积原子的扩散,导致涂层的致密度和残余应力增加,因而涂层会出现取向结构。受残余应力的影响,(200)、(220)以及(311)峰出现漂移。对谱峰的半高宽分析表明,在不同的偏压条件下,半高宽值无变化,这意味着谱峰择优取向结构的演化对半高宽无影响。图3和4中没有密排六方结构的AlN出现,但并不表明多层涂层中没有密排六方结构的AlN形成,AlN峰很可能由于应力的原因出现漂移。

图2 CrTiAlN涂层的TEM截面形貌

Fig.2 TEM cross-section micrograph of CrTiAlN coatings at Vb=-55 V and OEM=65%

图3 CrTiAlN涂层的XRD图谱

Fig.3 XRD patterns of CrTiAlN coatings (Vb=-60 V)

图4 CrTiAlN涂层的XRD谱

Fig.4 XRD patterns of CrTiAlN coatings (OEM=65%)

2.2 粘附强度

CrTiAlN涂层同LY12铝合金的粘附强度采用多功能划痕-摩擦磨损测试仪检测,获得的粘附强度值(Lc)如图5和表1所示。结果表明,N2水平和偏压都会影响涂层与LY12的粘附强度。在Vb=-60 V和OEM=65%时,CrTiAlN涂层的Lc值达到10 N而不剥落;而在OEM=55%和OEM=75%时,CrTiAlN涂层均出现剥落失效,粘附强度Lc值分别为4.09和6.14 N。对OEM=65%的涂层分析表明,当Vb为-50~-55 V时,CrTiAlN涂层的Lc值在达到10 N而不失效剥落,小于或高于这个负偏压值,粘附强度Lc值均会减小。N2水平和衬底偏压对粘附强度的影响分别可以解释为涂层中原子浓度的变化[16-17]。

2.3 力学性能分析

硬度和弹性模量是评估硬质涂层力学性能的重要指标。表1显示沉积工艺参数对CrTiAlN涂层的硬度和弹性模量具有重要的影响。随着N2水平的增加,弹性模量逐渐减小,显微硬度在中N2水平和-60 V条件下最小。经过对工艺参数的优化,CrTiAlN涂层在中N2水平和-55 V偏压条件下的显微硬度达到29.87 GPa,弹性模量达到207 GPa。在相关的文献中,显微硬度Hp和弹性模量E的比值(Hp/E)也用来作为评估硬质涂层减磨和失效性能的重要指标[18]。从表1可以看出,N2水平对CrTiAlN涂层Hp/E的影响无明显规律,但偏压在-55 V时的Hp/E值要大于偏压在-60 V时的Hp/E值。综合来看,Hp/E在0.144~0.145附近有最好的力学性能。

图5 CrTiAlN涂层的划痕测试

Fig.5 Scratch test of CrTiAlN coatings: (a) OEM=75%, Vb=-60 V; (b) OEM=65%, Vb=-60 V; (c) OEM=55%, Vb=-60 V; (d) OEM=65%, Vb=-40 V; (e) OEM=65%, Vb=-50 V; (a) OEM=65%, Vb=-55 V;

2.4 摩擦学特性分析

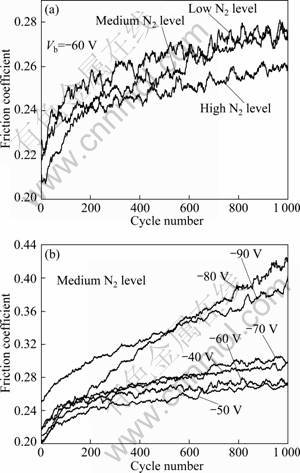

采用往复式摩擦磨损测试仪分析CrTiAlN涂层的摩擦学特性,获得的结果表示为摩擦因数—循环次数的函数关系,如图6所示。结果显示,摩擦因数随着循环次数的增加而增加,同时N2水平和衬底偏压对 涂层的摩擦因数具有重要的影响。图6(a)中3种N2水平的平均摩擦因数依次为0.246(OEM=55%)、0.256(OEM=65%)以及0.261(OEM=75%),说明N2水平越高摩擦因数就越小。图6(b)则展示出具有不同偏压CrTiAlN涂层的摩擦因数随循环次数的变化,平 均摩擦因数依次为0.272(-40 V)、0.251(-50 V)、0.261(-60 V)、0.273(-70 V)、0.326(-80 V)以及0.332(-90 V),这个结果表明偏压在-50 V时摩擦因数最小,而在-80 V时摩擦因数最大。N2水平和衬底偏压对摩擦因数的影响与涂层内氮化物离子键的浓度、涂层的致密度以及沉积结构等有关。

图6 CrTiAlN涂层的摩擦因数—循环次数曲线

Fig.6 Friction coefficient—cycle number curves of CrTiAlN multilayer coatings: (a) With different N2 level; (b) With different bias voltage

3 结论

1) 磁控溅射沉积CrTiAlN涂层为以TiN0.9和CrN为主要组织取向的FCC结构。在OEM=65%时,CrTiAlN涂层在偏压在-50 V和-90 V时为(111)取向,在-80 V时为(220)取向。

2) 在OEM=65%和衬底负偏压为-50~-55 V条件下,CrTiAlN涂层的结合强度临界值达到10 N,涂层的显微硬度值也达到29.87 N。

3) N2水平和衬底负偏压对CrTiAlN涂层的摩擦因数具有重要的影响,在衬底负偏压为-60 V时,OEM为55%时的CrTiAlN涂层的摩擦因数最小;在OEM=65%时,衬底负偏压为-50 V时CrTiAlN涂层的摩擦因数最小。

REFERENCES

[1] HA Y, SE H, SOO Y, YOUNG H, KYUNG H. Correlation between Al2O3 particles and interface of Al-Al2O3 coatings by cold spray [J]. Applied Surface Science, 2005, 252: 1891-1898.

[2] BALBYSHEV V, KING D, KHRAMOV A, KASTEN L, DONLEY M. Investigation of quaternary Al-based quasicrystal thin films for corrosion protection [J]. Thin Solid Films, 2004, 447/448: 558-563.

[3] WEI T, YAN F, TIAN J. Characterization and wear- and corrosion-resistance of microarc oxidation ceramic coatings on aluminum alloy [J]. Journal of Alloys and Compounds, 2005, 389: 169-176.

[4] DOM?NGUEZ-CRESPO M A, RODIL S E, TORRES-HUERTA A M, RAM?REZ-MENESES E, SU?REZ-VEL?ZQUEZ G. Structural and electrochemical performance of sputtered Al-Ce films on AA6061 aluminum alloy substrates [J]. Surface and Coatings Technology, 2009, 204(5): 571-579.

[5] FIGUEROA U, SALAS O, OSEGUERA J. Deposition of AlN on Al substrates by reactive magnetron sputtering [J]. Surface and Coatings Technology, 2005, 200(5/6): 1768-1776.

[6] SCH?FER H, STOCK H R. Improving the corrosion protection of aluminium alloys using reactive magnetron sputtering [J]. Corrosion Science, 2005, 47(4): 953-964.

[7] DIESSELBERG M, STOCK H R, MAYR P. Corrosion protection of magnetron sputtered TiN coatings deposited on high strength aluminium alloys [J]. Surface and Coatings Technology, 2004, 177/178(30): 399-403.

[8] KIM G, LEE S Y, HAHN J H. Properties of TiAlN coatings synthesized by closed-field unbalanced magnetron sputtering [J]. Surface and Coatings Technology, 2005, 193(1/3): 213-218.

[9] LIN J, MISHRA B, MOORE J J , SPROUL W D, REES J A. Effects of the substrate to chamber wall distance on the structure and properties of CrAlN films deposited by pulsed-closed field unbalanced magnetron sputtering (P-CFUBMS) [J]. Surface and Coatings Technology, 2007, 201(16/17): 6960-6969.

[10] YANG Q, ZHAO L, CAI F, YANG S, TEER D G. Wear, erosion and corrosion resistance of CrTiAlN coating deposited by magnetron sputtering [J]. Surface and Coatings Technology, 2008, 202, 3886-3892.

[11] COOKE K, YANG S, SELCUK C, KENNEDY A, TEER DG, BEALE D. Development of duplex nitrided and closed field unbalanced magnetron sputter ion plated CrTiAlN-based coatings for H13 aluminium extrusion dies [J]. Surface and Coatings Technology, 2004, 188/189: 697-702.

[12] ALBERDI A, MAR?N M, D?AZ B, S?NCHEZ O, GALINDO E R. Wear resistance of titanium-aluminium-chromium-nitride nanocomposite thin films [J]. Vacuum, 2007, 81(11/12): 1453-1456.

[13] TAM P, ZHOU Z, SHUM P, LI K. Structural, mechanical, and tribological studies of Cr-Ti-Al-N coating with different chemical compositions [J]. Thin Solid Films, 2008, 516(16): 5725-5731.

[14] ZHOU Z, TAM P, SHUM P, LI K. High temperature oxidation of CrTiAlN hard coatings prepared by unbalanced magnetron sputtering [J]. Thin Solid Films, 2009, 517: 5243-5247.

[15] BAI L, ZHU X, XIAO J, HE J. Study on thermal stability of CrTiAlN coating for dry drilling [J]. Surface and Coatings Technology, 2007, 201(9/11): 5257-5260.

[16] SHI Y J, LONG S Y, YANG S C, PAN F S. Structural and tribological properties of CrTiAlN coatings on Mg alloy by closed-field unbalanced magnetron sputtering ion plating [J]. Applied Surface Science, 2008, 254(22): 7342-7350.

[17] SHI Y J, LONG S Y, YANG S C, PAN F S. Deposition of nano-scaled CrTiAlN multilayer coatings with different negative bias voltage on Mg alloy by unbalanced magnetron sputtering [J]. Vacuum, 2010, 84: 962-968.

[18] LEYLAND A, MATTHEWS A. On the significance of the H/E ratio in wear control: A nanocomposite coating approach to optimised tribological behaviour [J]. Wear, 2000, 246: 1-11.

(编辑 何学锋)

基金项目:重庆市自然科学基金资助项目(CSTC, 2010BB4290)

收稿日期:2010-08-25;修订日期:2011-01-23

通信作者:石永敬,博士;电话:023-65023711;E-mail: yjshi001@yahoo.com.cn