Effects of yttrium addition on microstructure and mechanical properties of as-extruded AZ31 magnesium alloys

PAN Fu-sheng(潘复生)1, CHEN Mei-bao(陈美宝)1, 2, WANG Jing-feng(王敬丰)1,

PENG Jian(彭 建)1, TANG Ai-tao(汤爱涛)1

1. National Engineering Research Center for Magnesium Alloys, Chongqing University, Chongqing 400044, China;

2. School of Safety Engineering, Chongqing University of Science and Technology, Chongqing 400042, China

Received 12 June 2008; accepted 5 September 2008

Abstract: The effects of yttrium addition on microstructure and mechanical properties of as-extruded AZ31 magnesium alloys were investigated by OM, XRD and SEM. The results show that the addition of yttrium results in the formation of a new phase, Al2Y. When the addition of yttrium is higher than 1.48%-2.91% (mass fraction), another new phase, Al3Y5Mn7, forms, and the amount of β-Mg17Al12 phase in the AZ31 alloy decreases sharply. The tensile test at room temperature indicates that the yield strength of as-extruded AZ31 alloys improves with the addition of yttrium, but the elongation decreases, which is possibly related to the formation of coarse blocky compounds containing yttrium and the grain coarsening in the alloys.

Key words: magnesium alloys; yttrium; microstructure; mechanical properties

1 Introduction

Magnesium alloys are becoming important light mass structural materials owing to their low specific density [1-2]. Recently, there has been significant increase in the usage of magnesium alloy for automobile, aerospace components, computer, mobile phones, etc[3]. However, commercial applications of magnesium alloys to important structural parts are limited because of poor tensile properties.

To meet the demands of more applications, magnesium alloys with high strength and excellent room temperature properties must be developed. Improvement in microstructure and properties of the alloys can be achieved by the addition of minor alloying element, and rare earths(RE) are important alloying elements to magnesium alloys which may improve casting characteristics, high temperature and ambient temperature properties. Recently it was reported that Y, La or Ce can improve the mechanical properties of magnesium alloys. LUO et a1[4] studied the strengthening effects of rare earth additions on wrought Mg-Zn-Zr-RE alloys. ZHANG et a1[5] studied the effects of yttrium on microstructure and mechanical properties of hot-extruded Mg-Zn-Y-Zr alloys. FANG et a1[6] studied the effect of yttrium on microstructures and mechanical properties of hot rolled AZ61 wrought magnesium alloy. ZHOU et al[7-8] reported that Nd, La and Ce have effects on both microstructures and mechanical properties of cast AZ61 alloy. LI et a1[9] reported the effects of Y on the microstructure and properties of cast AZ91 alloy.

However, investigation on the effects of Y addition on the microstructure and mechanical properties of AZ31 magnesium alloy are very limited. In the present work, yttrium was added to AZ31 magnesium alloy. The effects of Y on both microstructure and mechanical properties were investigated.

2 Experimental

2.1 Materials

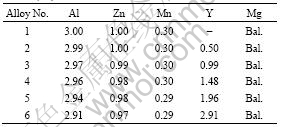

Raw materials used in the experiments were high- purity magnesium (>99.9%), zinc (>99.9%), the Mg-19.6% Y master alloy and the Al-9.8% Mn master alloy. The additions of yttrium were 0, 0.50%, 0.99%, 1.48%, 1.96% and 2.91% (mass fraction). The chemical compositions of the test alloys are listed in Table 1.

Table 1 Chemical composition of experimental alloys (mass fraction, %)

2.2 Experimental procedure

The casting experiment was carried out with the semi-continuous caster. The molten metal was poured into a columniform cast aluminum alloy mould with internal diameter of 92 mm and cooled rapidly by water.

The melt was protected from oxidation by a mixture of CO2 with 0.3% SF6 (volume fraction) during the melting and pouring stage. Before extrusion, the cast ingots were homogenized at 420 ℃ for 15 h. Then, these ingots were heated at 400 ℃ for 1.5 h, followed by direct extrusion from 80 mm down to l6 mm in diameter.

Tensile tests were performed on WE-10 materials test machine at a constant speed of 1 mm/min at room temperature. The microstructure was investigated with a Nikon Epithet metallographic microscope, a TESCAN VEGA Ⅱ LMU scanning electron microscope, and a Rigaku D/max-3C X-ray diffractometer.

3 Results

3.1 Effect of Y on microstructures of as-extruded AZ31 alloys

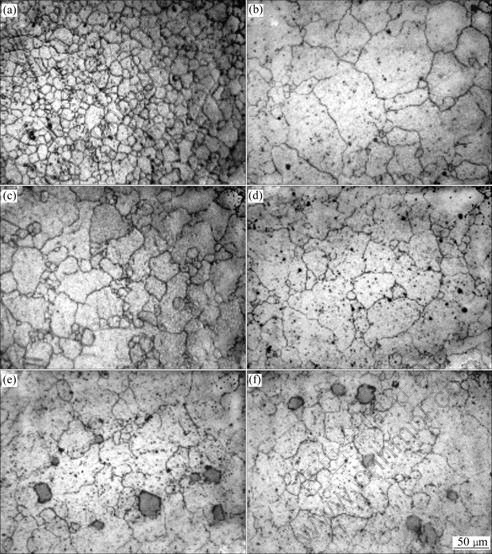

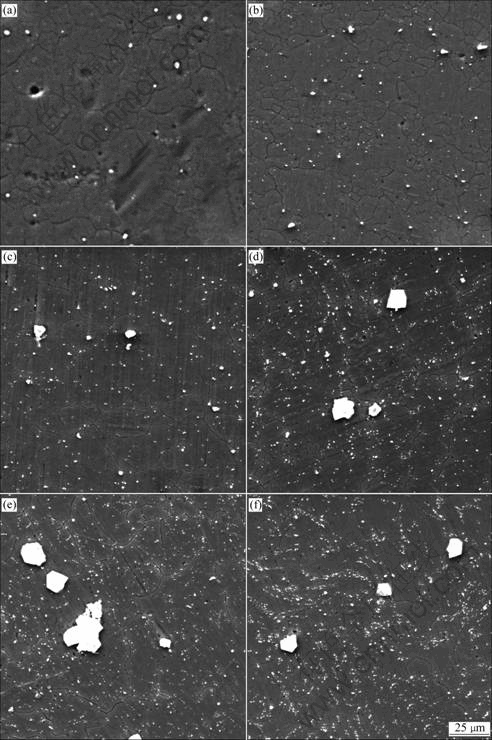

Fig.1 and Fig.2 show the optical micrographs and SEM images of the extruded AZ31 alloys. It can be seen from Fig.1 and Fig.2 that the grain coarsening with the Y addition can be observed, and the β-Mg17Al12 phases distribute mainly at the grain boundaries. The result shows that there are more coarse primary phases in Y-containing AZ31 alloys. These coarse compounds were found to be blocky in shape and 2-7 μm in size, and were proved to be Al-Y compounds by EDS (Fig.3). When the content of yttrium addition rose, the amount of coarse blocky compounds increased obviously while the amount of β-Mg17Al12 phases decreased.

Fig.1 Microstructures of as-extruded alloys: (a) Alloy 1; (b) Alloy 2; (c) Alloy 3; (d) Alloy 4; (e) Alloy 5; (f) Alloy 6

Fig.2 SEM images of extruded alloys: (a) Alloy 1; (b) Alloy 2; (c) Alloy 3; (d) Alloy 4; (e) Alloy 5; (f) Alloy 6

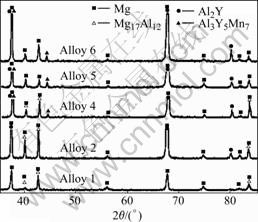

The X-ray diffraction (XRD) patterns taken from the as-extruded alloys are shown in Fig.4 from which the Y-containing phases were verified as Al2Y and Al3Y5Mn7. Three different phases of α-Mg, β-Mg17Al12 and A12Y were identified in the microstructure of AZ31- 0, 0.50% and 0.99%Y. While 1.5%, 2.0% and 3% Y was added to the AZ31 alloy, four different phases of α-Mg, β-Mg17Al12, A12Y and Al3Y5Mn7 were identified.

Fig.3 EDS pattern of Alloy 4

Fig.4 XRD patterns of extruded alloys

3.2 Effect of Y on mechanical properties of as- extruded AZ31 alloys

The results of the tensile tests of the as-extruded alloys at room temperature are shown in Fig.5. The experimental results show that the tensile strength of the extruded AZ31 alloys was changed slightly with the addition of yttrium. On the other hand, with the addition of Y, the yield strength of the AZ31 alloys was improved and the elongation was declined. Fig.5 shows that the AZ31 alloy with the addition of 0.50%Y has the best yield strength of 209 MPa.

Fig.5 Relationships between mechanical properties and Y content in alloys

The SEM images of the fracture of the as-extruded alloys are shown in Fig.6. The fracture surface of AZ31 alloy exhibited hybrid tough fracture of tear ridge and dimple, and dimple was tiny, deep and uniform in size. The fracture of AZ31 alloy was thought to be a quasi- cleavage fracture. But with the addition of yttrium, the fracture of AZ31-Y alloys exhibited more brittle fracture models with tear ridge and cleavage step. In addition, some educts can be seen in alloy 4, alloy 5 and alloy 6. With the increase of Y content, more educts are separated out and some of the educts are broken during the extrusion process.

4 Discussion

Y and Mg have same hexagonal close-packed(HCP) crystal structure with similar lattice parameters, and they have similar atom radii[11]. According to the principle of “size and structure matching”, Y can act as heterogeneous nucleation for α-Mg phase to restrain the growth of grain. As a result, Y should have good effect on grain refinement[12]. But the grain refinement of Y addition on the AZ31 alloy can not be found in the present work, because there are little separate Y phases in the AZ31-Y alloys. According to the binary alloy phase diagram of Mg-Y, Mg and Y can form the compound of Mg24Y5, in which the Y content is about 40%. According to the ternary alloy phase diagram of Mg-Al-Y, Al and Y can form compounds of Al2Y and Al3Y, in which the Y content is about 27% and 32% respectively[13]. In the present work, the A12Y compound with cubic structure was identified, but any binary compounds of Mg-Y and ternary compounds of Mg-Al-Y were not observed. Obviously, during the solidification process, the A12Y phase is hard to act as nucleating core due to different crystal structure. Because the crystallizing temperature of A12Y (980℃)[13] is much higher than the eutectic reaction temperature of L→α-Mg+Mg17Al12 (451 ℃), Al2Y will form first and concentrates at the front edge of α-Mg phase[14]. According to Fig.4, the AZ31 alloys with yttrium addition of high content contain a new phase of Al3Y5Mn7 when the content of Y is higher than 1.5%. After homogenization treatment, more Mg17Al12 phases are dissolved in α-Mg matrix due to the combination of A1 and Y. As a result, the amount of the Mg17Al12 phase decreases sharply.

Fig.6 SEM images of fracture of extruded alloys: (a) Alloy 1; (b) Alloy 2; (c) Alloy 3; (d) Alloy 4; (e) Alloy 5; (f) Alloy 6

The experimental results in Fig.5 show that the yield strength of AZ31 increases apparently but the elongation declines when 0.5% Y is added into the AZ31 alloy. The mechanism that yttrium improves the yield strength of AZ31 remains unknown. The possible reasons that yttrium decreases the elongation is related to the formation of many coarse blocky compounds containing yttrium and the increase of grain size in the AZ31-Y alloys [15]. The large amount of A12Y phase with large-size dimension occurring in the AZ31-Y alloys may increase the viscosity of alloy melt, decrease the flowability, and destroy boundary combination strength. The coarse brittle intermetallic phase particles have been found to have important influence on the micro-cracks formation and the flaws propagation.

5 Conclusions

1) The addition of yttrium has important influence on the microstructure of AZ31 alloy. The grain size in the as-extruded AZ31 alloy increases by the addition of yttrium.

2) A lot of coarse blocky Y-containing phases are found in the AZ31-Y alloy, which is verified as Al2Y. When more yttrium is added to the AZ31 alloy, another type of Y-containing phase, Al3Y5Mn7, appears in the as-extruded alloys

3) The yield strength of as-extruded AZ31 alloys increases with the addition of yttrium, but the elongation decreases, which is possibly related to the formation of coarse blocky compounds containing yttrium and the grain coarsening in the alloys.

References

[1] ZHOU Hong, LI Wei, WANG Ming-xing, ZHAO Yu. Study on ignition proof AZ91D magnesium alloy chips with cerium addition [J]. Journal of Rare Earths, 2005, 23(4): 466.

[2] WANG R M, ELIEZER A, GUTMAN E M. An investigation on the microstructure of an AM50 magnesium alloy [J]. Materials Science and Engineering A, 2003, 355(1/2): 201.

[3] AGHION E, BRONFIN B, ELIEZER D. The role of the magnesium industry in protecting the environment [J]. Journal of Materials Processing Technology, 2001, 117(3): 381-385.

[4] LUO Z P, SONG D Y, ZHANG S Q. Strengthening effects of rare earths on wrought Mg-Zn-Zr-RE alloys [J]. J Alloys Comp, 1995, 230(2): 109-114.

[5] ZHANG Y, ZENG Xiao-qin, LIU Liu-fa, LU Chen, ZHOU Han-tao, LI Qiang, ZHU Yan-ping. Effects of yttrium on microstructure and mechanical properties of hot-extruded Mg-Zn-Y-Zr alloys [J]. Materials Science and Engineering A, 2004, 373(1/2): 320-327.

[6] FANG Xi-ya, YI Dan-qing WANG Bin, LUO Wen-hai, GU Wei. Effect of yttrium on microstructures and mechanical properties of hot rolled AZ61 wrought magnesium alloy [J]. Transactions of Nonferrous Metals Society of China, 2006, 16(5): 1053-1058.

[7] ZHOU Hai-tao, ZENG Xiao-qin, DING Wen-jiang, MA Chun-jiang, ZHU Yan-ping. Effect of La and Nd on microstructures and mechanical properties of AZ61 wrought magnesium alloy [J]. Transactions of Nonferrous Metals Society of China, 2004, 14(1): 67-70.

[8] ZHOU Hai-tao, ZENG Xiao-qin, LIU Wen-fa,DING Wen-jiang, ZHU Yan-ping. Effect of Ce on microstructures and mechanical properties of AZ61 wrought magnesium [J]. The Chinese Journal of Nonferrous Metals, 2004, 14(1): 99-104. (in Chinese)

[9] LI Jin-feng, GENG Hao-ran, YANG Zhong-xi, WANG Ying-zi, CUI Feng, SUN Chun-jing. Effects of Y on microstructure and mechanical properties of AZ91 magnesium alloy [J]. Foundry, 2005, 54(1): 53-56. (in Chinese)

[10] ZENG Xiao-qin, DING Wen-jiang, YAO Zheng-yi, PENG Li-min, LU Chen. The microstructure and mechanical properties of Mg-Zn-Al alloys [J]. Journal of Shanghai Jiao Tong University, 2005, 39(1): 46-51. (in Chinese)

[11] HUANG Xiao-feng, WANG Qu-dong, ZENG Xiao-qin, YUAN Guang-yin, ZHU Yan-ping, DING Wei-jiang. Influence of rare earth on mechanical properties and high temperature creep properties of AM50 magnesium alloy [J]. Journal of the Chinese Rare Earth Society, 2004, 22(4): 493-496. (in Chinese)

[12] WANG Ming-xing, ZHOU Hong, WANG Li. Effect of yttrium and cerium addition on Microstructure and mechanical properties of AM50 magnesium alloy [J]. Journal of Rare Earths, 2007, 25(2): 233-237.

[13] LIU Chu-ming, ZHU Xiu-rong, ZHOU Hai-tao. Phase diagrams for magnesium alloys [M]. Changsha: Central South University Press, 2006. (in Chinese)

[14] SITDIKOV O, KAIBYSHEV R. Dynamic recrystallization in pure magnesium [J]. Mata Trans, 2001, 42(9): 1928-1937.

[15] ZHANG Shi-chang, WEI Bo-kang, CHEN Wei-chen. Effect of yttrium and mischmetal on fluidity and solidification structures of AZ91 magnesium alloy [J]. Foundry, 2004, 53(2): 118-121. (in Chinese)

(Edited by CHEN Ai-hua)

Foundation item: Project(50725413) supported by the National Natural Science Fundation of China; Project(2007CB613704) supported by the National Basic Research Program of China

Corresponding author: PAN Fu-sheng; Tel: +86-23-65112635; E-mail: fspan@cqu.edu.cn