文章编号:1004-0609(2007)07-1047-06

振动和合金化对消失模铸造AZ91D组织与性能的影响

李继强,樊自田,王元庆,董选普

(华中科技大学 材料成型及模具技术国家重点实验室,武汉 430074)

摘 要:振动凝固和Ce-Sb复合微合金化都能明显细化消失模铸造AZ91D镁合金的铸态组织。经振动凝固的铸态组织特征与原始铸态的相差不大,复合微合金化后的细化效果更显著,且经Ce-Sb复合微合金化处理后在α-Mg基体上出现大量弥散分布的颗粒状CeSb相,在晶内和晶界分布着少量的Al11Ce3针状相。两种处理工艺都能使消失模AZ91D试样的抗拉强度和伸长率得到较大幅度提高,其中经Ce-Sb复合微合金化后的常温力学性能提高最大,两种方法都没有使消失模AZ91D试样的断裂方式发生明显改变,但Ce-Sb复合微合金化后的合金铸态断口具有明显的塑性变形特征。

关键词:AZ91D合金;消失模铸造;振动凝固;Ce-Sb合金化

中图分类号:TG 146.2 文献标识码:A

Effects of vibration and alloying on microstructure and properties of AZ91D magnesium alloy via lost foam casting

LI Ji-qiang, FAN Zi-tian, WANG Yuan-qing, DONG Xuan-pu

(State Key Laboratory of Material Processing and Die and Mould Technology,

Huazhong University of Science and Technology, Wuhan 430074, China)

Abstract:Vibration-freezing and adding 1.0%Ce-0.4%Sb can obviously refine the microstructure of lost foam cast AZ91D magnesium alloy. The characteristic of as-cast microstructure has a little difference from that of vibration-freezing. But the microstructure has smaller grain size after addition of microscale cerium and antimony. From SEM photographs of the samples after Sb-Ce alloying, it is found that a large number of granular CeSb phase distributes in the grain, and a little needle Al11Ce3 phase in both grain and boundary. Both the methods can improve the tensile strength and elongation of AZ91D alloy via LFC to a great extent. And the improved value is the largest by addition of Ce and Sb. Although they can’t change the fracture mode of AZ91D alloy, SEM fractographs of tensile fracture surface after Sb-Ce alloying have obvious plastic deformation.

Key words:AZ91D alloy; lost foam casting; vibration-freezing; Ce-Sb alloying

镁合金被认为是极具应用开发前景的商用轻质材料,具有比强度和比刚度高等优点。面对全球性的能源危机和环境污染等问题,镁合金作为汽车工业的一种轻量化材料备受关注。其中以Mg-Al系中的AZ91铸造合金应用最广,占铸造镁合金总量的90%以上[1-2]。但该合金由于结晶温度间隔宽、凝固收缩大、强度低等缺点一直限制了其应用范围的扩大[3]。

实现金属材料组织的微细化是提高力学性能的重要措施,晶粒越细,枝晶间距越小,材料的强度越 高[4]。对于消失模铸造,通过振动凝固来细化晶粒有其特殊的资源和工艺优势[5-6]。因为在砂型铸造过程中,如果对铸型施以机械振动,很容易把铸型振垮;而在金属型铸造过程中,由于其冷速过快,振动对结晶的影响作用基本不大;消失模铸造采用无黏接剂的

干砂造型,需要机械振动来紧实型砂,如果在液态金属凝固过程中利用消失模铸造中现成的紧实振动台,通过振动电机产生的机械振动,使镁液在动力学激励下生核,达到细化组织的目的,是一种操作简便、成本低廉、无环境污染的方法。此外在镁中加入合金元素,无论是固溶,还是形成金属间化合物,都可以提高其强度[7-10],但目前合金化的研究多集中在单个合金元素对性能的影响,对于两种或两种以上的合金元素对镁合金力学性能、铸造性能的影响还鲜有报道。

本文作者从细化AZ91D镁合金铸态组织,提高铸件强度出发,研究在消失模铸造条件下,机械振动对AZ91D镁合金力学性能、显微组织的影响及作用机理;同时按照“少量多元”的原则,在以往的研究基础上,对比锑和稀土铈复合微合金化对AZ91D镁合金铸态性能的影响,为在工业上的进一步扩大应用奠定理论基础。

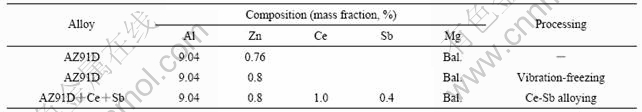

1 实验

原材料选用商用AZ91D镁合金、纯稀土元素Ce(纯度为99.9%)和纯Sb(纯度为99.99%),合金成分设计及改性工艺如表1所示。模型材料为可发性聚苯乙烯泡沫塑料(密度为0.02 g/cm3),模样经线切割机割制。将上好涂料的模组放入底抽式砂箱内,填入水洗石英砂,经三维振动紧实台振动紧实后盖上0.1 mm 厚的塑料薄膜等待浇注。

合金在实验室条件下置于电阻炉坩埚中熔炼,在熔炼过程中用覆盖剂覆盖,精炼后于740 ℃浇注成型。对于振动凝固试样一俟浇注完毕,立即按设定好的激振力进行振动,直至试样完全凝固;对于合金化试样,为防止Ce在熔炼过程中过量损失,精炼后再加入纯稀土元素,静止一段时间后立即浇注成形。浇注过程中真空度一直保持在0.02 MPa,完成后继续保持该真空度5 min。实验用试样系经多炉次浇注,各炉次实验操作严格按照上述步骤进行。

浇注后的合金化试样用等离子发射光谱仪(ICP)测定合金中铈和锑的含量,金相试样经粗磨、抛光后,用4%的硝酸酒精溶液浸蚀。使用Olympus:PMG-3金相显微镜观察铸态组织,采用X’Pert PRO X射线衍射仪进行物相鉴别,利用JXA-8800R型EPMA进行显微组织观察及元素分析。拉伸试样采用直径为8 mm的棒状标准拉伸试样,在Zwick-Roell材料实验机上进行常温拉伸测试,拉伸速率为1 mm/min,并在QUANTA 400型扫描电子显微镜观察断口形貌。

2 实验结果

2.1 铸态微观组织

由Mg-Al二元合金相图可知, AZ91合金的铸态组织由Al、Zn在Mg中的固溶体α-Mg及β-Mg17Al12组成[11]。显微组织观察表明,对于没有经过任何处理的AZ91镁合金消失模铸态组织是以玫瑰状的枝晶为基体,在其晶界处不连续分布着网状的β-Mg17Al12相(见图1(a));经机械振动过的AZ91消失模铸态组织,其基本特征和未处理的铸态组织相差不大,不同的只是玫瑰状的α-Mg枝晶晶粒比铸态的细(见图1(b));而经Ce-Sb微合金化后的AZ91消失模铸态组织中α-Mg枝晶变得更细,原先网状的β-Mg17Al12相变成断续、弥散分布的骨骼状,其数量亦减少(见图1(c),(d)),且该合金中出现了针状和颗粒状的新相(见图2)。

光谱分析表明,铈和锑加入到AZ91D后,约82%与合金元素形成新相熔于合金液中,其余的铈和锑在加入后由于氧化烧损和反应速度等原因,分别进入熔渣或沉入坩锅底部。图2所示为AZ91D-1.0%Ce- 0.4%Sb合金中的粒状化合物、针状化合物的二次电子图像和各元素的面扫描分析结果。由此可知针状相为Al-Ce化合物,而粒状相为Ce-Sb化合物。结合AZ91D及AZ91D-1.0%Ce-0.4%Sb合金的X射线衍谱的分析结果(图3),确定AZ91D-1.0%Ce-0.4%Sb合金组织中

表1 合金成分及改性工艺

Table 1 Chemical composition of alloys and modifying processing

图1 不同状态下消失模AZ91铸态光学显微组织

Fig.1 Microstructures of AZ91D via lost foam casting in different processing: (a) As-cast; (b) vibration-freezing; (c) Ce-Sb alloying; (d) Ce-Sb alloying

图2 AZ91D-1.0%Ce-0.4%Sb合金中的二次电子图像及各元素面分布

Fig.2 Secondary electron image and face scanning maps of AZ91D-1.0%Ce-0.4%Sb

存在的相为α-Mg基体、网状β-Mg17Al12、球状CeSb和针状Al11Ce3。其中组织中新出现的针状相,分布并不确定,有的位于晶粒内部,有的起始于一个晶粒内部,终止于另一个晶粒内部,横穿晶界,不过这种相数量较少;而新出现的颗粒状的新相,主要弥散分部于晶界和基体内部,且这种相在数量上相对于杆状相来说要多得多。

稀土元素具有活泼的化学性质。在AZ91D合金中加入金属Sb和Ce后,之所以会形成Ce-Sb相和Al-Ce相,而不形成Mg-Ce、Mg-Sb、Al-Sb等其它物相,这主要是由它们之间的电负性差值所决定 的[12-14]。元素间的电负性差值越大,则它们之间的结合力也就越大,就越容易形成金属间化合物。由表2可以明显看出,Sb-Ce之间的电负性差值最大(为0.8),然后是Sb-Mg、Al-Ce和Mg-Ce,因此,Sb-Ce优先化合为CeSb相。由于加入的Sb量小于稀土Ce的加入量,当Sb与Ce反应完全后,剩余的Ce将继续和Al反应,生成针状Al11Ce3相。

表2 各元素的电负性

Table 2 Electronegativity value of elements

图3 合金的X射线衍射谱

Fig.3 XRD patterns of as-cast AZ91D alloys: (a) AZ91D; (b) AZ91D-1.0%Ce-0.4%Sb

2.2 力学性能

不同处理状态下消失模AZ91D试样的室温力学性能如图4所示。可以看出,室温拉伸时,经0.4%Sb-1%Ce合金化后的消失模AZ91D试样的抗拉强度σb最高(182.23 MPa),与铸态相比(134.48 MPa),σb提高了36%,而经机械振动过的消失模AZ91D试样的抗拉强度(165.72 MPa)提升幅度为23%。两种改性方法对消失模AZ91D室温伸长率(δ)的影响与强度规律相似,即0.4%Sb-1%Ce合金化后的消失模AZ91D试样的伸长率δ最高(为2.53%),相比于铸态(1.78%)提高了42%,经机械振动过的消失模AZ91D试样的δ为2.24%,提高25%。

图4 不同处理状态下消失模AZ91D试样的室温力学性能

Fig.4 Mechanical properties of AZ91D alloy via lost foam casting in different processing

图5所示为不同状态下的消失模AZ91D试样的拉伸断口SEM照片。可以看出,铸态时拉伸断口存在较大的解理面(图5(a)所示),断裂方式是以解理为主的脆性断裂;经机械振动处理过的拉伸断口解理面相对于铸态的解理面要小,而且还出现少量的韧窝(图5(b)所示),表明拉伸过程中有塑性变形的特征,但总体而言其断裂方式仍然是以解理为主的脆性断裂。而经Sb-Ce复合微合金化处理后的拉伸断口中小的解理面仍然清晰可见,少量的韧窝和大的撕裂棱也同时出现,表明拉伸过程中也有塑性变形的特征,但和经机械振动处理过的拉伸断口一样,其断裂方式仍然是以解理为主的脆性断裂。

3 分析与讨论

3.1 机械振动和微合金化对铸态组织的影响机理

机械振动之所以能细化合金的组织,主要是因为

图5 不同处理状态下消失模AZ91D试样拉伸断口形貌

Fig.5 SEM photographs of AZ91D via lost foam casting in different processing: (a) As-cast; (b) Vibration-freezing; (c) Ce-Sb alloying

机械振动影响了合金的形核和长大这两个基本过程。在合金过冷期间,机械振动使熔体产生空化的作用,形成空穴,当空穴崩溃,流体充填其间时,流动的动量将会产生很高的压力,而这种压力的增加就会使合金的熔点温度提高。由Clausius-Clapeyron公式[15]:

(1)

(1)

式中 Tm为105 Pa压力下的熔点温度;?p为压力的改变值;?Tp为熔点温度的改变;?Hm为结晶潜热;V1为固态体积;V2为液态体积。

当压力增加时,其熔点温度也要增加。这就是说,在液体金属温度一定的情况下,由于振动提高了金属的熔点温度,即提高了液相线平均温度,从而提高了过冷度,这就势必造成自发形核核心数目的增多,使晶粒细化。此外,在枝晶生长过程中,机械振动对液体的扰动作用,使液体中枝晶之间发生碰撞、磨损,从而使枝晶破碎和增殖,形成了许多细小晶粒,这些作用都可以明显细化晶粒。

当在液态镁合金中加入合金元素后,形成CeSb相、α-Mg基体、β-Mg17Al12相。CeSb相的一个晶面与α-Mg的一个晶面错配度为0.09%,与β-Mg17Al12的晶面错配度为2%[16],根据非均匀形核理论,满足新相在固体上形核的条件(晶面错配度小于15%),所以CeSb相能够成为α-Mg及β-Mg17Al12相的异质形核核心,提高形核率,起到细化晶粒作用。

由于CeSb相和Al11Ce3相均为高熔点化合物[9, 17],在AZ91D镁合金凝固过程中会优先于其他相析出,随着温度的降低,在晶体长大过程中聚集在液-固界面前沿,在结晶界面前沿造成成分过冷,故可促进基体晶粒的均匀形核,从而细化晶粒。此外,CeSb相和Al11Ce3相这两种化合物都可以阻碍α-Mg晶粒长大,也有利于晶粒的进一步细化。

3.2 机械振动和合金化对消失模试样力学性能的影响

机械振动及合金化提高合金力学性能的原因主要在于二者使合金的晶粒得到明显的细化(如图1所示)。由细晶强化理论可知,晶粒越细,晶界面积越大,晶界对晶内位错的阻碍作用就越大,因此,迫使晶粒发生变形所需的外力就越大,即合金的强度就越高。根据Hall-Petch关系式和改进的Taylor理论可知,具有较少滑移系的六方结构金属的晶界对晶粒的滑移变形具有强烈的阻碍作用,因此晶粒细化将显著提高AZ91D合金的强度。

另一方面,Sb-Ce合金化后的消失模AZ91D试样的抗拉强度得到大幅提高,其原因除细化晶粒之外,由于生成Al11Ce3相,从而减少了β-Mg17Al12相的数量,使得沿晶界分布的网状β-Mg17Al12相变为断续、弥散分布的骨骼状,且分布更趋于均匀,有效强化了晶界,从而提高了合金的强度和塑性。再者由于在Sb-Ce合金化后的组织中出现了大量的颗粒状CeSb相,这种相弥散分布于α-Mg基体内部和晶界,形状圆整,应力难以在此集中,从而有效地阻碍了位错滑移。虽然组织中也出现了杆状相,应力极易在该相的尖端处集中,对力学性能的提高极为不利,但该相数量较少,而且Mg是一种密排六方结构,滑移系很少,当由针状相尖端处引起的应力集中所产生的裂纹在扩展的过程中,受到晶内粒状相的阻碍时,要想改变扩展方向较为困难,而且这种相是一种硬而脆的相,本身对裂纹的扩展就起阻碍作用。

4 结论

1) 机械振动和Ce-Sb复合微合金化均有细化消失模AZ91D铸态组织的作用,且复合微合金化效果要比机械振动好。

2) Sb、Ce的复合加入使消失模AZ91D铸态组织中出现了杆状的Al11Ce3和颗粒状的CeSb新相,各相在α–Mg晶粒内部和晶界均有分布,对基体均起强化作用。

3) 机械振动和Ce-Sb复合微合金化都能使消失模AZ91D的抗拉强度和延伸率得到大幅度提高。经机械振动过的抗拉强度提高23%,伸长率提高25%;而经0.4%Sb-1%Ce合金化的抗拉强度提高36%,伸长率提高42%。

4) 铸态、机械振动和Ce-Sb复合微合金化的消失模铸造AZ91D的断口的断裂方式都是以解理为主的脆性断裂,但复合微合金化后的断口出现了少量的韧窝和大的撕裂棱。

REFERENCES

[1] Kaneko T, Suzuki M. Automotive applications of magnesium alloys[J]. Materials Science Forum, 2003, 419/422: 67-72.

[2] Cao H, Wessen M. Effect of microstructure on mechanical properties of as cast Mg-Al alloy[J]. Mechanical and Materials Transaction A, 2004, A35: 309-319.

[3] TIAN Xue-feng, FAN Zi-tian, HUANG Nai-yu, WU He-bao, DONG Xuan-pu. Microstructure and mechanical properties of magnesium alloy prepared by lost foam casting[J]. Trans Nonferrous Met Soc China, 2005, 15(1): 7-13

[4] He S M, Zeng X Q, Peng L M. Microstructure and strengthening mechanism of high strength Mg-10Gd-2Y-0.5Zr alloy[J]. Journal of Alloys and Compounds, 2007, 427: 316-323.

[5] 王元庆, 樊自田, 李继强. 消失模铸造AZ91D振动凝固及半固态热处理组织的演变[J]. 特种铸造及有色合金, 2006, 26(8): 506-509.

WANG Yuan-qing, FAN Zi-tian, LI Ji-qiang. Evolution of microstructure of AZ91D magnesium alloy in lost foam casting under vibration and semi-solid heat treatment condition[J]. Special Casting & Nonferrous Alloys, 2006, 26(8): 506-509.

[6] 田学锋, 樊自田, 黄乃瑜. 机械振动对消失模铸造镁合金组织及力学性能的影响[J]. 中国有色金属学报, 2006, 16(11): 1838-1844.

TIAN Xue-feng, FAN Zi-tian, HUANG Nai-yu. Effect of mechanical vibration on microstructure and mechanical properties of lost foam casting magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(11): 1838-1844.

[7] 刘生发, 黄尚宇, 徐 萍. Ce对AZ91镁合金铸态组织细化的影响[J]. 金属学报, 2006, 42(4): 443-448.

LIU Sheng-fa, HUANG Shang-yu, XU Ping. Influence of cerium addition on as-cast microstructure refinement of AZ91 magnesium alloy[J]. Acta Metallurgica Sinica, 2006, 42(4): 443-448.

[8] 郭旭涛, 李培杰, 曾大本, 刘树勋. 混合稀土去除再生镁合金中的夹杂[J]. 中国有色金属学报, 2004, 14(8): 1295-1300.

GUO Xu-tao, LI Pei-jie, ZENG Da-ben, LIU Shu-xun. Inclusions decrease in recycling magnesium alloy with rare earths[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(8): 1295-1300.

[9] YUAN Guang-yin, SUN Yang-shan, DING Wen-jiang. Effects of Sb addition on the microstructure and mechanical properties of AZ91 magnesium alloy[J].Scripta Materialia,2000, 43: 1009- 1013.

[10] 郑伟超, 李双寿, 汤 彬, 曾大本. 混合稀土对AZ91D镁合金组织和力学性能的影响[J]. 金属学报, 2006, 42(8): 835-842.

ZHENG Wei-chao, LI Shuang-shou, TANG Bin, ZENG Da-ben. Effects of mischmetal on microstructure and mechanical properties of AZ91D magnesium alloy[J]. Acta Metallurgica Sinica, 2006, 42(8): 835-842.

[11] Nayeb-Hshemi A A, Clark J B. Phase diagrams of binary magnesium alloys[M]. Metals Park, Ohio: ASM International,1998.

[12] WU Guo-hua, FAN Yu, GAO Hong-tao, ZHAI Chun-quan, ZHU Yan-ping. The effect of Ca and rare earth elements on the microstructure, mechanical properties and corrosion behavior of AZ91D[J]. Mater Sci Eng A,2005, A408: 255-263.

[13] HUANG Zheng-hua, GUO Xue-feng, ZHANG Zhong-ming. Effects of Ce on damping capacity of AZ91D magnesium alloy[J]. Trans Nonferrous Met Soc China, 2004, 14(4): 311-315.

[14] DU Wen-wen, SUN Yang-shan, MIN Xue-gang. Microstructure and mechanical properties of Mg-Al based alloy with calcium and rare earth additions[J]. Mater Sci Eng A, 2003, A356: 1-7.

[15] Flemings M C. Solidification processing[M]. New York: McGraw-Hill Inc, 1974: 265-267.

[16] Michael M, Avedesian, Baker H. ASM speciality handbook magnesium and magnesium alloy[M]. Ohio: ASM International Materials Park, 1999.

[17] WANG Ying-xin, GUAN Shao-kang, ZENG Xiao-qin, et al. Effects of RE on the microstructure and mechanical properties of Mg-8Zn-4Al magnesium alloy[J].Mater Sci Eng A, 2006, A416: 109-118.

(袁赛前)

基金项目:国家自然科学基金资助项目(50275058); 国家高技术研究发展计划资助项目(2007AA03Z113)

收稿日期:2006-11-03;修订日期:2007-05-20

通讯作者:樊自田,教授;电话:027-87543876;E-mail: fanzt@mail.hust.edu.cn