文章编号:1004-0609(2013)05-1189-06

Al-2%Cu二元合金微观组织模拟中液相扩散系数的计算

卜晓兵1,李落星1, 2,张立强1, 2,朱必武1, 2,徐 戎1, 2,王水平1

(1. 湖南大学 汽车车身先进设计制造国家重点实验室,长沙 410082;

2. 湖南大学 机械与运载工程学院,长沙 410082)

摘 要:采用改进的Miedema模型和Eyring模型,对Al-2%Cu合金的液相扩散系数进行理论计算,建立了二元合金液相扩散系数的理论计算模型,解决实验难以测量液相扩散系数导致数据匮乏的难题。在Eyring模型中,引入液态合金黏度—时间的变化曲线,替代原模型中的溶剂黏度数值,以进一步提高计算结果的准确性。在微观组织模拟中,基于常规恒定液相扩散系数模拟结果的柱状晶比例为20.1%,而基于本研究计算所得的液相扩散系数曲线模拟结果的柱状晶比例为64.8%,更接近实验测得的柱状晶比例58.1%,很好地验证了液相扩散系数理论计算模型的可行性和准确性。

关键词:Al-Cu合金;Miedema模型;Eyring模型;扩散系数;微观组织

中图分类号:TG292 文献标志码:A

Calculation of liquid phase diffusion coefficient in microstructure simulation of Al-2%Cu binary alloy

BU Xiao-bing1, LI Luo-xing1, 2, ZHANG Li-qiang1,2, ZHU Bi-wu1,2, XU Rong1,2, WANG Shui-ping1

(1. State Key Laboratory of Advanced Design and Manufacturing for Vehicle Body, Hunan University, Changsha 410082, China;

2. College of Mechanical and Vehicle Engineering, Hunan University, Changsha 410082, China)

Abstract: The liquid phase diffusion coefficient of Al-2%Cu alloy was calculated with the modified Miedema model and Eyring model, to further improve the accuracy. The mathematical model of liquid phase diffusion coefficient in binary alloy was established to resolve the lack of liquid phase diffusion coefficient data that are difficult to measure in the experiment. Instead of the solvent viscosity value, the viscosity—temperature curve of liquid alloy was introduced into the Eyring model to increase the accuracy of calculation. In the microstructure simulation, the simulated proportion of columnar grains based on the normal constant liquid phase diffusion coefficient is 20.1%; while the proportion of columnar grains based on the calculated liquid phase diffusion coefficient with the developed model is 64.8%, which is much closer to the experimental result of 58.1%, indicating that the mathematical model of liquid phase diffusion coefficient is feasible and accurate.

Key words: Al-Cu alloy; Miedema model; Eyring model; diffusion coefficient; microstructure

目前,微观组织研究发展缓慢的重要原因是缺少模拟必需的物性参数,而这些参数往往是影响微观组织模拟准确性的关键因素,如液相扩散系数等。在以往的微观组织模拟[1-6]中,通常假设液相扩散系数是与温度、合金成分无关的常数,这种简化处理在一定程度上严重影响了定量描述凝固组织结构的准确性。

由于液体分子间作用力的影响,所以液体分子不像固体有固定的晶格,难以用数学手段准确描述。并且,液体分子堆积密度较高,结构非常复杂,平均距离远比气体分子间平均距离小,但并非像固体那样有规律地排列,分子间总处在较强相互作用的范围内,所以有关液液传质及扩散方面的测量和理论研究远比气体及固体的困难。因此,延今为止,还没有完整的理论模型对其进行较为准确的描述和计算。同时,实验方法测量液体的扩散系数也存在很大的困难和局限性。

计算合金液相扩散系数前,应计算溶液中各成分的活度因子及相互作用系数。PORTER[7]、LUPIS等[8]对此进行了很多工作,虽然这些模型的表达式物理意义明确,但均难以对实验结果进行预测。MIEDEMA等[9]通过合金元素组元的摩尔体积V、电负性γ′和电子密度nws等基本性质,可以对二元合金的生成热进行计算。国内陈星秋等[10]、汤振雷等[11]、孙顺平等[12]、吴春峰等[13]通过Miedema模型计算了稀熔融金属的活度因子和活度相互作用系数,与实验结果吻合较好。但Miedema模型的自扩散系数数据缺乏,常采用固定的自扩散系数数值代替,会影响到液相扩散系数计算的准确性。

Eyring提出的绝对速率理论是具有较大影响的液体结构模型理论,采用该理论描述液相扩散系数具有独特的优越性[14]。Eyring模型中的待定系数可通过理论计算或者实验数据拟合得到[15-16]。虽然,采用Eyring模型可直接计算液相扩散系数,但未考虑合金成分之间的相互作用对扩散系数的影响,只能视为合金中组元成分的自扩散系数,不能反映液态合金的扩散行为。

为此,本文作者提出一种较为准确计算液相扩散系数的理论模型。通过对Miedema模型和Eyring模型加以改进,引入合金黏度—时间变化曲线,计算凝固过程中二元合金的液相扩散系数,探讨液相扩散系数对微观组织模拟的影响。

1 Miedema模型和二元合金液相扩散系数

Wigner-Seitz模型认为纯金属存在Wigner-Seitz元胞,每个元胞含有一个带正电的原子核和该原子的价电子,在元胞边界处,位能和电子密度处于最低值,据此计算纯金属的结合能。Miedema模型为改进的Wigner-Seitz模型,即将Wigner-Seitz理论从纯金属推广到二元合金[9]。该模型有两个假设:一是纯金属i和j形成有序金属间化合物时,合金由两种金属的元胞组成;二是两种纯金属形成合金时,其合金化效应被认为是元胞从纯金属到合金时其边界条件引起。

当纯金属i和j形成混合物时,由于i与j的电子密度nws存在电子密度差,因此i和j结合时需要调整电子浓度,使元胞边界的电子密度最低。Miedema认为元胞边界处存在的电子密度差对合金生成热ΔHij有正贡献,这就是著名的合金尺寸化效应。另外,电负性也对合金生成热ΔHij有影响。合金化时,组元i和j存在电负性差,会使其在接触边缘处发生电子转移,导致自由能降低,合金整体能量变低,两组元的电负性差对合金生成焓产生负贡献。

1.1 二元合金的生成热

Miedema模型中,二元i-j合金的生成热ΔHij可由式(1)[9]计算得到

(1)

(1)

(2)

(2)

(3)

(3)

式中:xi与xj分别为组元i和j的摩尔分数;(nws)i与(nws)j分别为组元i和j的电子密度;Vi与Vj分别为组元i和j的摩尔体积;p为Miedema模型常数,如果合金组元为两种过渡金属,则p=14.1;如果合金组元是两种非过渡金属,则p=10.6;如果合金组元中一种为过渡金属,另一种为非过渡金属,则p=12.3;ui与uj分别为组元i和j的电负性;q为与组元的电子分布有关的常数;r是与多价非过渡金属电子和过渡金属电子之间形成的杂化有关的常数;p/q为常数值,其值为9.4;r/p只对非过渡金属和过渡金属有意义,其数值是非过渡金属和过渡金属r/p数值的乘积,在本研究中,r/p的取值为5.7;φ为Miedema模型中的电负性参数;常数b对液相合金取值为0.73;T为温度,Tmi与Tmj分别为纯组元i和j的熔点。

1.2 二元合金的活度因子

在i和j组成的二元合金中,组元i的偏摩尔过剩自由能 与其活度因子γi的关系为

与其活度因子γi的关系为

(4)

(4)

组元i的偏摩尔过剩自由能 与i-j二元合金摩尔过剩自由能

与i-j二元合金摩尔过剩自由能 的关系为

的关系为

(5)

(5)

二元系i-j中,过剩自由能 与过剩熵

与过剩熵 和合金生成热ΔHij的关系为

和合金生成热ΔHij的关系为

(6)

(6)

(7)

(7)

联立式(1)~(7),可得到组元i的活度因子γi随成分摩尔分数 的变化关系:

的变化关系:

(8)

(8)

1.3 相互作用系数和二元合金液相扩散系数

在一定温度下,二元合金的相互作用系数 和偏摩尔过剩自由能

和偏摩尔过剩自由能 的关系如下:

的关系如下:

(9)

(9)

由式(1)~(5)及式(9)得:

(10)

(10)

二元合金的热力学因子gi可表示为

(11)

(11)

热力学因子gi与扩散系数Di之间的关系为

(12)

(12)

由于组元i在j中浓度极稀, 应为组元i在j中的自扩散系数,联立式(11)和(12)得到:

应为组元i在j中的自扩散系数,联立式(11)和(12)得到:

(13)

(13)

2 Eyring模型及液相自扩散系数

计算液相扩散系数时,常遇到Miedema模型中自扩散系数数据不全的问题。Eyring模型可以很好地解决这个问题。

虽然,采用Eyring模型可以直接计算液相扩散系数,但此模型没有考虑溶质与溶剂分子之间的相互作用系数以及溶质分子对溶剂活度因子的影响,计算的液相扩散系数只能作为自扩散系数。因此,可用Eyring模型计算式(12)和(13)中的自扩散系数 。

。

根据Eyring提出的决定速率理论,对于二元体系,有

(14)

(14)

(15)

(15)

(16)

(16)

式中: 为溶质i在溶剂j中的无限稀释扩散系数,即自扩散系数;k为波尔兹曼常数;mj为溶剂的黏度;λ1j、λ2j和λ3j为3个坐标方向分子间距离;Vi和Vj分别是溶质和溶剂的摩尔体积;N为阿伏伽德罗常数;Em, j和ED, ij分别是黏度活化能和扩散激活能;ξi是描述以i分子为中心的周围分子数的几何参数;

为溶质i在溶剂j中的无限稀释扩散系数,即自扩散系数;k为波尔兹曼常数;mj为溶剂的黏度;λ1j、λ2j和λ3j为3个坐标方向分子间距离;Vi和Vj分别是溶质和溶剂的摩尔体积;N为阿伏伽德罗常数;Em, j和ED, ij分别是黏度活化能和扩散激活能;ξi是描述以i分子为中心的周围分子数的几何参数; 是扩散处于活化态分子的配分函数;Fij是处于平衡态分子的配分函数;

是扩散处于活化态分子的配分函数;Fij是处于平衡态分子的配分函数; 和Fjj分别是黏度处于活化态和平衡态分子的配分函数。

和Fjj分别是黏度处于活化态和平衡态分子的配分函数。

假设转动配分函数、振动配分函数对平衡态和活化态是相同的,只考虑配分函数,可得到式(17):

(17)

(17)

Mi和Mj分别为组元i和j的相对分子质量。根据Eyring模型理论和式(17)的假设[17],可得到Em, j-ED, ij的估算式

(18)

(18)

由式(14) ~ (18)可得到:

(19)

(19)

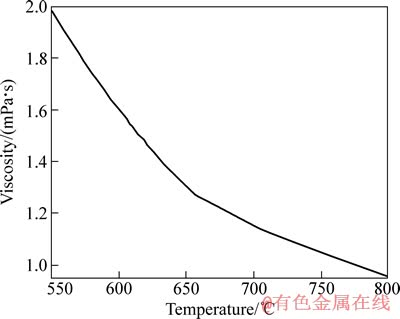

此外,当用Eyring模型计算自扩散系数时,使用的是溶剂的黏度值,而在实际液相扩散过程中,溶质的加入会影响溶液的黏度,计算时应采用图1所示的合金溶液的黏度变化曲线,以提高Eyring模型计算的准确性。

图1 合金溶液黏度随温度的变化

Fig. 1 Variation of viscosity with temperature for alloy solution

3 实验方案

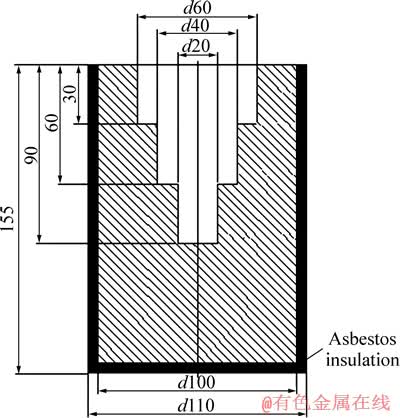

模具和铸件的尺寸见图2。铸件材料为Al-2%Cu合金。为了获得更好的微观组织形貌,模具外侧用石棉布包裹,浇注温度为740 ℃,模具温度为170 ℃。

图2 实验铸型形状及尺寸

Fig. 2 Shape and dimensions of experimental casting mold (Unit: mm)

对直径为40 mm的铸件进行粗磨、细磨、抛光后,采用氢氟酸腐蚀5 s,观察其晶粒组织。

铸件的微观组织采用元胞自动机模拟。元胞自动机是一种在空间、状态都离散,时间及空间上都是局部的网格动力学模型,是一种简单、直观的方法。该方法以凝固动力学和形核生长动力学为依据,考虑了形核位置和取向的随机性,可以模拟等轴晶与柱状晶之间的竞争生长、柱状晶向等轴晶转变等过程,在凝固组织模拟中得到广泛的应用。

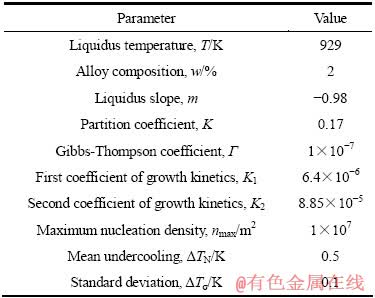

通过元胞自动机模型,将模拟得到的微观组织结果与实验结果进行对比分析,模拟过程所用参数见表1。

表1 材料性能和微观组织模型参数

Table 1 Material properties and model parameters used in microstructure simulations

4 结果和讨论

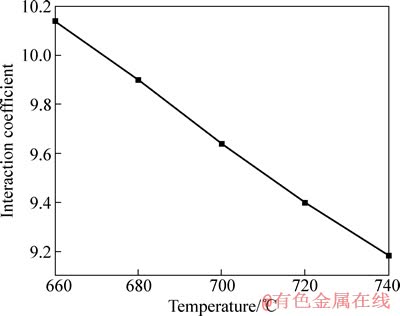

计算活度因子和液相扩散系数时,必须考虑合金成分的相互作用系数 。因为在微观组织模拟时,晶粒的形核和长大会受到不同温度下合金成分相互作用的影响。相互作用系数

。因为在微观组织模拟时,晶粒的形核和长大会受到不同温度下合金成分相互作用的影响。相互作用系数 随温度变化曲线如图3所示,由改进的Miedema模型计算得到。从图3中可看出,液相二元合金的相互作用系数

随温度变化曲线如图3所示,由改进的Miedema模型计算得到。从图3中可看出,液相二元合金的相互作用系数 随着温度的升高而下降。

随着温度的升高而下降。

图4中采用Eyring模型计算的自扩散系数,没有考虑合金成分的相互作用系数 ,需代入Miedema模型改进,获得图4中改进后的液相扩散系数曲线。

,需代入Miedema模型改进,获得图4中改进后的液相扩散系数曲线。

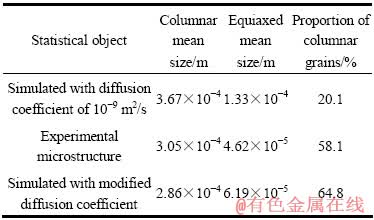

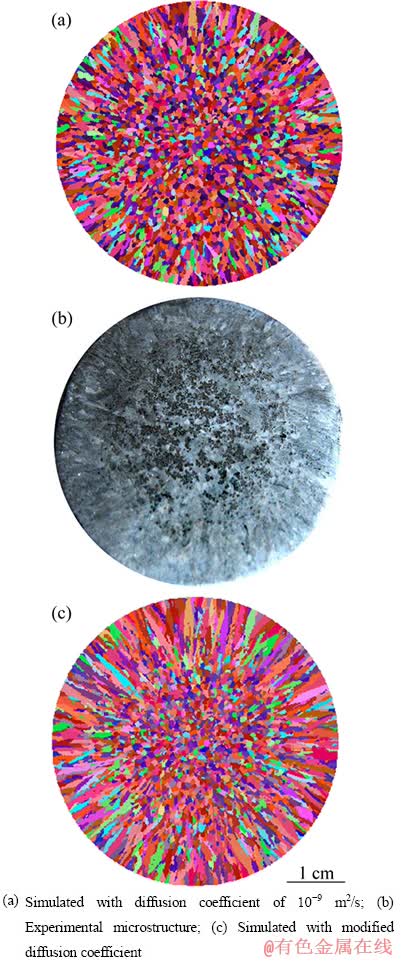

换热曲线采用ZHANG等[18]的反传热计算方法,计算宏观温度场,再将计算得到的液相扩散系数曲线代入微观组织的模拟计算中,得到更优化的模拟结果。图5(a)~(c)所示分别为采用常规恒定液相扩散系数(10-9m/s2)的微观组织模拟结果、实验组织形貌和基于计算的液相扩散系数的微观组织模拟结果。

由图5和表2可以看出,采用常规恒定液相扩散系数时,虽然出现柱状晶向等轴晶的转变,但柱状晶和等轴晶的晶粒大小与实验组织结果存在很大差别,尤其是柱状晶所占的比例差别很大。而基于计算的液相扩散系数模拟的微观组织结果,在柱状晶、等轴晶的晶粒大小以及柱状晶所占的比例方面,都与实验组织的很相似,能够比较真实地预测合金在凝固过程中晶粒形成的过程。微观组织模拟的结果也验证了液相扩散系数理论计算模型的准确性。

图3 合金成分相互作用系数随温度的变化

Fig. 3 Variation of interaction coefficient of alloy compositions with temperature

图4 合金溶液自扩散系数和液相扩散系数随温度的变化

Fig. 4 Variation of self-diffusion coefficient and diffusion coefficient of alloy solution with temperature

表2 直径为40 mm铸件微观组织统计结果

Table 2 Statistical simulated results of casting specimen with diameter of 40 mm

图5 直径为40 mm铸件凝固组织的模拟结果和实验结果

Fig. 5 Simulated and experimental results of solidification structures of casting specimen with diameter of 40 mm

5 结论

1) 采用改进的Miedema模型和Eyring模型,计算了模拟过程中普遍认为与合金成分、温度无关的液相扩散系数,得到了液相扩散系数随温度的变化曲线,为进一步研究液相扩散问题提供了理论依据。

2) 与常规将液相扩散系数设置为常数的模拟结果相比,采用本研究中计算得到的液相扩散系数曲线进行微观模拟能够更准确地反映Al-2%Cu合金等轴晶和柱状晶的分布位置、比例和晶粒大小,提高微观组织模拟的精度。

REFERENCES

[1] 刘永刚, 陈 军, 潘 治, 孙国雄, 仇春荔. Al-4.5%Cu合金凝固过程显微组织的数值模拟[J]. 中国有色金属学报, 2002, 12 (6): 1130-1135.

LIU Yong-gang, CHEN Jun, PAN Zhi, SUN Guo-xiong, QIU Chun-li. Microstructure simulation of solidification process of Al-4.5%Cu binary alloy[J]. The Chinese Journal of Nonferrous Metals, 2002, 12 (6) :1130-1135.

[2] 李 强, 李殿中, 钱百年. Al-7%Si凝固过程组织演变的元胞自动机方法模拟[J]. 材料工程, 2004(7): 35-39.

LI Qiang, LI Dian-zhong, QIAN Bai-nian. Modeling microstructure evolution of Al-7%Si during solidification process by cellular automaton method[J]. Journal of Materials Engineering, 2004(7): 35-39.

[3] 丁恒敏, 刘瑞祥, 陈立亮, 刘晶峰. 用Cellular Automation 模型方法模拟二元合金多晶粒枝晶生长[J]. 特种铸造及有色金, 2005, 25(6): 337-339.

DING Heng-min, LIU Rui-xiang, CHEN Li-liang, LIU Jing-feng. Simulation of treeing in binary alloys with cellular automation[J]. Special Casting and Nonferrous Alloys, 2005, 25(6): 337-339.

[4] 陈光友, 倪红卫, 张 华, 詹玮婷, 成日金, 刘吉刚. Al-Si合金凝固组织的数值模拟及预测[J]. 铸造技术, 2009, 30(1): 48-52.

CHEN Guang-you, NI Hong-wei, ZHANG Hua, ZHAN Wei-ting, CHEN Ri-jin, LIU Ji-gang. Numerical simulation and prediction of solidification structure of Al-Si alloy[J]. Foundry Technology, 2009, 30(1): 48-52.

[5] ZHU M F, HONG C P. A modified cellular automation model for the simulation of dendritic growth in solidification of alloys[J]. ISIJ International, 2001, 41(5): 436-445.

[6] VANDYOUSSEFI M, GREER A L. Application of cellular automation-finite element model to the grain refinement of directionally solidified Al-4.15wt% Mg alloys[J]. Acta Materialia, 2002, 50(7): 1693-1705.

[7] PORTER A W. On the vapour-pressures of mixtures[J]. Transactions of the Faraday Society, 1920, 16: 336-345.

[8] LUPIS C H P, ELLLIOTT J F. Prediction of enthalpy and entropy interaction coefficients by the “central atoms” theory[J]. Acta Metallurgica, 1967, 15(2): 265-276.

[9] MIEDEMA A R, de CHATEL P F, de BOER F R. Cohesion in alloys-fundamentals of a semi-empirical method[J]. Physica, 1980, 100B: 1-28.

[10] 陈星秋, 丁学勇, 刘 新, 郑海燕. 二元合金熔体组元活度计算式的改进[J]. 金属学报, 2000, 36(5): 492-496.

CHEN Xing-qiu, DING Xue-yong, LIU Xin, ZHENG Hai-yan. Improvement of calculation formula for activity of component in binary alloys systems[J]. Acta Metallurgica Sinica, 2000, 36(5): 492-496.

[11] 汤振雷, 王 为. 计算合金系统热力学性质的Miedema模型的发展[J]. 材料导报, 2008, 22(3): 115-118.

TANG Zhen-lei, WANG Wei. Review of Miedema model for calculating thermodynamic properties of alloys system[J]. Materials Review, 2008, 22(3): 115-118.

[12] 孙顺平, 易丹青, 臧 冰. 基于Miedema模型和Toop模型的Al-Si-Er合金热力学参数计算[J]. 稀有金属材料与工程, 2010, 39(11): 1974-1978.

SUN Shun-ping, YI Dan-qing, ZANG Bing. Calculation of thermodynamic parameters of Al-Si-Er alloy based on Miedema model and Toop model[J]. Rare Metal Materials and Engineering, 2010, 39(11): 1974-1978.

[13] 吴春峰, 李慧改, 郑少波, 杨存波. 二元合金热力学模 型—Miedema模型[J]. 上海金属, 2011, 33(4): 1-5.

WU Chun-feng, LI Hui-gai, ZHENG Shao-qiu, YANG Cun-bo. Thermodynamic model of the binary alloys—Miedema model[J]. Shanghai Metals, 2011, 33(4): 1-5.

[14] SIDDIQ M A, LUCAS K. Correlations for prediction of diffusion in liquids[J]. Canadian Journal of Chemical Engineering, 1986, 64(5): 839-843.

[15] 钱仁渊, 范益群, 史美仁, 时 钧. 用改进的Eyring方程推算无限稀扩散系数[J]. 南京化工大学学报, 1995, 17(4): 34-39.

QIAN Ren-yuan, FAN Yi-qun, SHI Mei-ren, SHI Jun. A modified Eyring’s equation for prediction of infinite dilution diffusion coefficient[J]. Journal of Nanjing University of Chemical Technology, 1995, 17(4): 34-39.

[16] 房 升. 基于Eyring反应速率理论的溶液黏度模型[J]. 化学进展, 2010, 22(3): 309-314.

FANG Sheng. Viscosity model for mixtures based on Eyring’s absolute reaction theory[J]. Progress Chemistry, 2010, 22(3): 309-314.

[17] GAINER J L, METZNER A B. Diffusion in liquids-theoretical analysis and experimental verification[J]. American Institute Chemical Engineers Symposium Series, 1965(6): 74-82.

[18] ZHANG Li-qiang, LI Luo-xing, JU Hui, ZHU Bi-wu. Inverse identification of interfacial heat transfer coefficient between the casting and metal mold using neural network[J]. Energy Conversion and Management, 2010, 51(10): 1898-1904.

(编辑 陈卫萍)

基金项目:国家“十二五”科技支撑计划项目(2011BAG03B02);国家自然科学基金面上项目(51075132);湖南大学汽车车身先进设计与制造国家重点实验室自主课题资助项目(61075005)

收稿日期:2012-05-06;修订日期:2012-11-26

通信作者:李落星,教授,博士;电话:0731-88821571;E-mail:llxly2000@163.com