多向锻造制备ZK60镁合金部分重熔组织演变和力学性能

来源期刊:中国有色金属学报(英文版)2012年第z2期

论文作者:陶健全 程远胜 黄少东 彭菲菲 杨文选 鲁美琪 张志明 金 鑫

文章页码:428 - 434

关键词:ZK60镁合金;半固态工艺;多向锻;力学性能;组织;

Key words:ZK60 Mg alloy; semi-solid processing; multi-axial forging; mechanical properties; microstructure

摘 要:为了提高ZK60镁合金的力学性能,采用多向锻造和部分重熔工艺;研究重熔温度和保温时间对ZK60镁合金半固态组织的影响;研究多向锻造和部分重熔工艺制备的ZK60镁合金构件在不同触变成形温度下的力学性能。结果表明:多向锻造加部分重熔工艺是一种制备半固态触变成形ZK60镁合金的有效方法。在部分重熔过程中,随着保温时间的延长和重熔温度的升高,晶粒长大。升高重熔温度,晶粒球化效果明显得到改善。当触变成形温度从560 °C升高至574 °C时,ZK60镁合金的力学性能明显提高。

Abstract: In order to improve the mechanical properties of ZK60 magnesium alloy components, the multi-axial forging (MAF) plus partial remelting route was used in this study. The effect of remelting temperature and holding time on microstructure of semi-solid ZK60 magnesium alloy was also studied. Furthermore, the tensile mechanical properties of ZK60 , magnesium alloy components produced by multi-axial forging plus partial remelting route were compared at different thixoforging temperatures. The results showed that the multi-axial forging followed by partial remelting is an effective route to produce semi-solid ZK60 magnesium alloy for thixoforming. During the partial remelting, with prolonging the holding time and increasing the remelting temperatures, the solid grain size increased. With the increase of remelting temperature, the degree of spheroidization tended to be improved. With increasing the thixoforming temperature from 560 °C to 574 °C, the tensile mechanical properties of ZK60 magnesium alloy were improved.

Trans. Nonferrous Met. Soc. China 22(2012) s428-s434

TAO Jian-quan1, CHENG Yuan-sheng2, HUANG Shao-dong1, PENG Fei-fei1, YANG Wen-xuan1, LU Mei-qi1, ZHANG Zhi-ming1, JIN Xin1

1. No.59 Institute of China Ordnance Industry, Chongqing 400039, China;

2. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China

Received 28 August 2012; accepted 25 October 2012

Abstract: In order to improve the mechanical properties of ZK60 magnesium alloy components, the multi-axial forging (MAF) plus partial remelting route was used in this study. The effect of remelting temperature and holding time on microstructure of semi-solid ZK60 magnesium alloy was also studied. Furthermore, the tensile mechanical properties of ZK60 magnesium alloy components produced by multi-axial forging plus partial remelting route were compared at different thixoforging temperatures. The results showed that the multi-axial forging followed by partial remelting is an effective route to produce semi-solid ZK60 magnesium alloy for thixoforming. During the partial remelting, with prolonging the holding time and increasing the remelting temperatures, the solid grain size increased. With the increase of remelting temperature, the degree of spheroidization tended to be improved. With increasing the thixoforming temperature from 560 °C to 574 °C, the tensile mechanical properties of ZK60 magnesium alloy were improved.

Key words: ZK60 Mg alloy; semi-solid processing; multi-axial forging; mechanical properties; microstructure

1 Introduction

Magnesium alloys have received much attention as important materials in aerospace, automobile and electronic industries due to their low density, high specific strength, good electromagnetic shielding characteristics and good machineability [1-3]. ZK60 is the most widely used commercial magnesium alloy. However, the use of ZK60 has been limited due to its poor mechanical properties [4-6].

Thixoforming is a semi-solid metal processing route, which involves forming of alloys in the semi-solid state to near net shaped components [7-9]. The thixoforming requires starting material which has been treated in such a way that when it is in the semi-solid state, the microstructure is spheroidal rather than dendritic [10-14]. Some routes, such as recrystallization and partial melting (RAP) [15], strain induced melt activation (SIMA) [16] and semi-solid thermal transformation (SSTT) [17], can achieve this requirement. The multi-axial forging (MAF), equal channel angular extrusion (ECAE) and compound extrusion belong to severe plastic deformation [18-21]. Among them, MAF is an effective route for RAP process in the thixoforming. The technique can produce ultrafine-grained materials with excellent mechanical properties and physical properties.

Although a number of authors have reported on the microstructure evolution and mechanical properties of magnesium alloys in the semi-solid state, there have been few reports on the microstructural evolution of semi-solid ZK60 magnesium alloy prepared by the multi-axial forging and partial remelting route [22,23].

The microstructure evolution of ZK60 magnesium alloy prepared by the multi-axial forging and partial remelting route is examined in the semi-solid state. Then, the effect of remelting temperatures and holding time on microstructure of the ZK60 alloy is investigated. Moreover, the mechanical properties of thixoforming ZK60 magnesium alloy are also presented.

2 Experimental

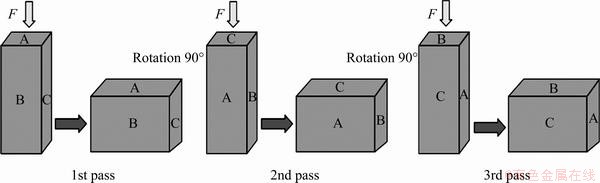

The alloy used in the present study was ZK60 magnesium alloy, with the measured composition (mass fraction, %) of 5.52 Zn, 0.36 Zr. Billets of 70 mm×70 mm×140 mm were cut from an as-cast ZK60 magnesium alloy bar. As shown in Fig. 1, the dimension ratio of 1:1:2 of the billets was kept during MAF, but the loading direction was turned by 90° from pass to pass. Subsequent work consisted of sequential deformation of billets along three orthogonal directions on a 800 hydraulic press. Billets were heated in an electrical resistance furnace at (380±5) °C for 1 h. Before MAF, the as-cast ZK60 alloy was heated to (380±5) °C. The processing speed was 15 mm/min. In total, three processing passes were used. Oil lubricant was used as lubricant during MAF. The MAF die configuration imposed the equivalent strain ee of 0.639 on billets during each pass according to the following equation [24]:

(1)

(1)

where h0 and h are the initial and final height of billets, respectively. Tensile samples were cut perpendicular to the axis of the last compression for the MAF-processed billet. Due to the 50% reduction in height per pass, e is approximately equal to 2.1 after three-pass MAF.

Investigation of microstructure evolution during partial remelting was done on MAF formed samples with a diameter of 8 mm and a length of 12 mm. Samples were heated into the semi-solid state in an electrical resistance furnace under a protective gas flow (argon atmosphere), isothermally held and quenched in water to room temperature. These samples were held at various temperatures between the solidus and liquidus of the ZK60 alloy for 5-90 min. For the thixoforging, slugs with 38 mm in diameter and 52 mm in length were cut from the MAF formed ingots. The slugs were rapidly induced at different time into the semi-solid region and then thixoformed into a die. The thixoforging temperatures were 560 °C and 574 °C. The applied pressure and dwelling time were 120 MPa and 60 s, respectively.

The mechanical properties were measured according to ASTM B557 on cylindrical samples with a reduced section of 6 mm and a gauge length of 50 mm using an Instron 5569 testing machine at a cross head speed of 1 mm/min. The microstructures of MAF- processed and partial remelting processed samples were observed using an Olympus metallographic microscope (OM). Samples for microscopic examination were cut parallel to the last compression direction of the MAF-processed billet. After mechanical polishing, samples were etched for 3 s using a solution of 100 mL ethanol, 6 g picric acid, 5 mL acetic acid and 10 mL water. The mean grain sizes were calculated using the linear intercept method.

3 Results and discussion

3.1 Microstructures of as-cast and multi-axial forging ZK60 magnesium alloy

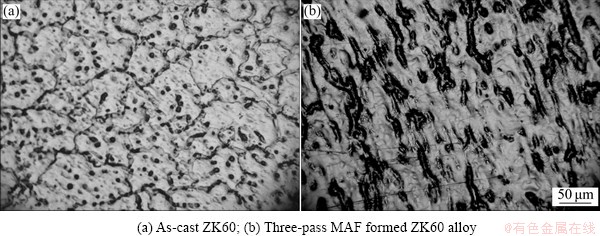

Figure 2 shows the optical microstructure of as-cast ZK60 alloy and three-pass MAF formed ZK60 alloy. As shown in Fig. 2(a), as-cast ZK60 alloy contained a significant volume fraction of some point-shaped or island-shaped Mg-Zn eutectic compounds at grain boundaries and within grains. Figure 2(b) shows the microstructure of three-pass MAF-formed ZK60 magnesium alloy. The microstructural features of the three-pass MAF formed ingot, were elongated and unrecrystallized grains and intermetallic particles were vertical in the compression direction.

3.2 Microstructure evolution with increasing holding temperature

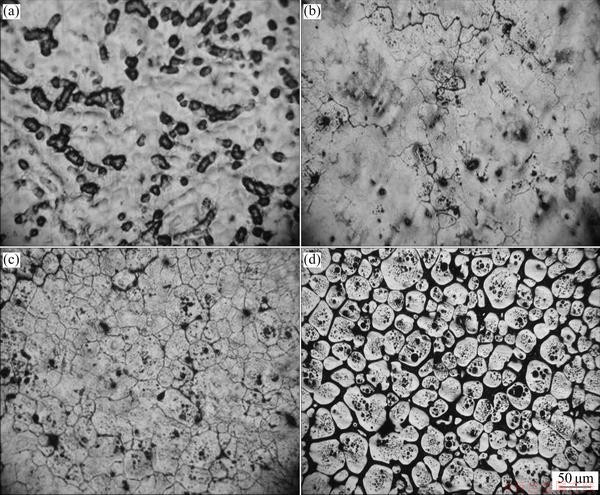

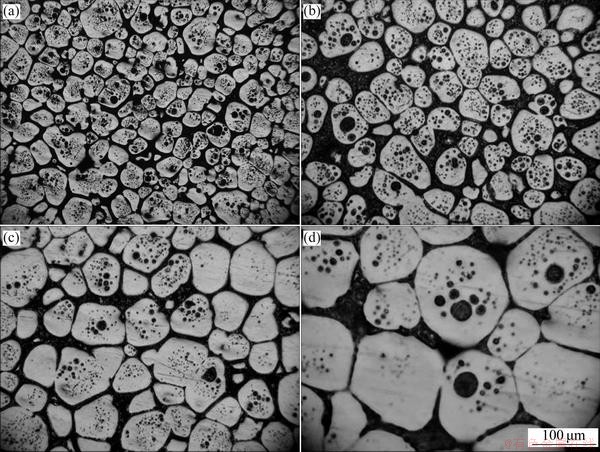

Figure 3 shows the microstructural evolution of the MAF ZK60 alloy during partial melting at different temperatures for 5 min. Following partial melting in each case, the microstructure consisted of near-globular solid grains with a liquid film. Furthermore, the grain boundary liquid film was thicker with increasing isothermal holding temperature. When the holding temperature was 540 °C, a large number of second phase particles distributed in the grain. With increasing the temperature, second phase particles gradually dissolved, and a small number of recrystallized grains occurred at the grain boundary. When the holding temperature was 560 °C, the microstructure of ZK60 alloy completely consisted of recrystallized grain and bits of liquid film at the grain boundary. With increasing the temperature to 574 °C, grain boundaries were gradually penetrated by liquid due to the dissolution of the last solidified phase of low melting temperature. The near-globular solid grains with a liquid film were obtained in the microstructure of ZK60 alloy during partial remelting.

Fig. 1 Schematic of multi-axial forging

Fig. 2 Microstructure of ZK60 alloy

Fig. 3 Microstructure evolution of MAF ZK60 alloy partially remelted at 540 °C (a), 550 °C (b), 560 °C (c) and 574 °C (d) for 5min

3.3 Microstructure evolution with increasing holding time

The three-pass MAF formed ingot during partial remelting can be classified as being consistent with the MAF route. Figure 4 shows the microstructural evolution of the MAF formed ZK60 alloy during partial remelting at 560 °C for 5 min, 20 min, 30 min and 90 min. When the alloy has been heated just above the solidus, grain boundaries were gradually penetrated by liquid due to the dissolution of the last solidified phase of low melting temperature. As soon as liquid phase has occurred at grain boundaries, grain spheroidization and coarsening were activated simultaneously (Fig. 4(a)). When the holding time was extended to 20 min, an examination of the microstructure revealed that polygonal grains had undergone a significant degree of spheroidization (Fig. 4(b)). With further prolonging the holding time, grain coarsening by coalescence resulted in the unification of adjacent grains (Figs. 4(c) and (d)). With increasing the holding time, the intragranular liquid droplets within solid grains coalesced to form some liquid pools, minimizing the solid-liquid interface and reducing the number of intragranular liquid droplets.

Fig. 4 Microstructure evolution of MAF formed ZK60 alloys partially remelted at 560 °C for 5 min (a), 20 min (b), 30 min(c) and 90 min (d)

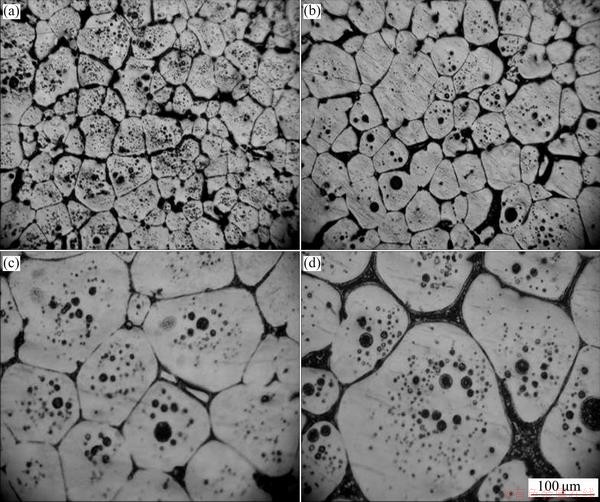

Figure 5 shows the microstructural evolution of the MAF formed ZK60 alloy during partial remelting at 574 °C for 5 min, 20 min, 30 min and 90 min. Recrystallization occurred entirely and fine almost perfectly globular recrystallized grains with a small amount of intragranular liquid droplets were distributed homogeneously (Fig. 5 (a)). With increasing the holding time, solid grains coarsened slightly. Significant grain coarsening had occurred and the solid grain boundary liquid film was thicker with prolonging the holding time.

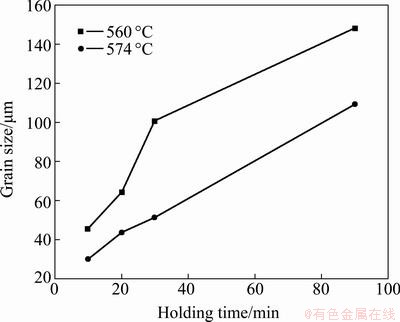

Figure 6 shows the grain size for MAF formed ZK60 alloys during partial remelting at 560 °C and 574 °C for different holding time. Grain size results show a continuous increase of the grain size with prolonging the holding time for MAF formed ZK60 alloys. At the low holding temperature, solidified phase was not completely dissolved, a small number of liquid film occurred at the grain boundary, solid grain grew up by the mergering adjacent grains. In the partial remelting of 574 °C, because of the dissolution of the last solidified phase of low melting temperature, grain boundaries were gradually penetrated by liquid. The growth of solid grain by the mergering route was blocked. Therefore, compared with the alloy during partial remelting at 560 °C, the alloy during partial remelting at 574 °C exhibited finer solid grains.

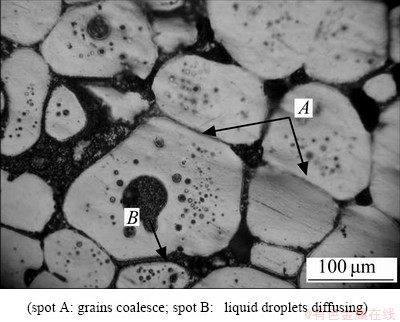

It is important to note that liquid droplets were present in the majority of grain cross-sections in all samples. Figure 7 shows the microstructure of MAF formed ZK60 alloys partially remelted at 560 °C for 90 min. The formation of liquid droplets inside grains can be attributed to chemical segregation and grain coalescence [25]. During the partial remelting, the second-phase compounds with low melting point were melted to a liquid. At higher temperatures, the formation of so-called “entrapped liquid” pools as a result of partial remelting [26]. On the other hand, some grains contact with each other because they are not penetrated by liquid during the partial remelting. With further prolonging the holding time, these grain boundaries are rewelded and therefore some new grains form with irregular shape (Fig. 4). During coalescencing, it is inevitable that some liquid is entrapped into the new formed grains. It is of interest to note that liquid droplets inside grains coalesce to become larger in size, as shown in Fig. 7 (spot A) [27-30]. To minimize the solid-liquid interface energy inside grains, liquid droplets diffuse through solid grains and then merge into some irregular liquid pools, as shown in Fig. 7 (spot B).

Fig. 5 Microstructure evolution of MAF formed ZK60 alloy partially remelted at 574 °C for 5 min (a), 20 min (b), 30 min (c) and 90 min (d)

Fig. 6 Grain size for formed MAF ZK60 alloy during partial remelting at 560 °C and 574 °C for different holding time

3.4 Mechanical properties of ZK60 alloy under different partial remelting temperatures

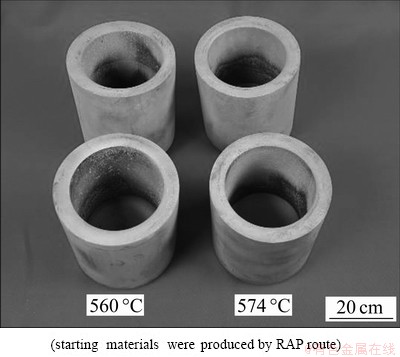

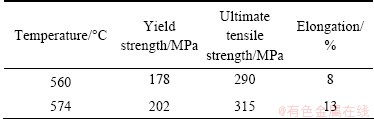

Figure 8 shows the photography of successfully thixoforged components with different thixoforming temperatures. The thickness of components was 4 mm. The starting materials were produced by the RAP route. As shown in Fig. 8, there was no problem in filling the die for the RAP alloy. The mechanical properties of ZK60 magnesium alloy under different partial remelting temperatures are shown in Table 1. In this study, the RAP route (three-pass multi-axial forging plus partial remelting) has been shown to produce ideal, fine semi-solid state structure, in which globular primary phase particles have a little amount of entrapped liquid. It is reasonable to expect relatively high mechanical properties shown in Table 1.

Fig. 7 Microstructure of MAF formed ZK60 alloy partially remelting at 560 °C for 90 min

The mechanical property testing results indicate that the increase of holing temperature improved the ultimate tensile strength (UTS), yield strength (YS) and elongation to fracture. It should be mentioned that the ultimate tensile strength for ZK60 thixoforged from starting material produced by the MAF route exhibited a stronger dependence on partial remelting temperature for 5 min. With increasing the thixoforming temperature from 560 °C to 574 °C, mechanical properties obviously improved, the ultimate tensile strength for the thixoformed MAF alloy increased from 290 MPa to 315 MPa, the yield strength increased from 178 MPa to 202 MPa, and the elongation to fracture increased from 8% to 13%. When the thixoforming temperature was 560 °C, the solid grain became larger in size due to the grain coalescing, as shown in Fig. 4. That will result in poor liquidity during thixoforming for MAF formed ZK60 alloy. Increasing the thixoforming temperature to 574 °C, almost perfectly globular grains obviously occurred in the microstructure. These were favorable for the thixoforming of ZK60 alloy.

Fig. 8 Photos of four successfully thixoforged components with different thixoforming temperatures

Table 1 Mechanical properties of ZK60 alloy thixoformed from MAF formed conditions after reheating for 5 min at different temperatures

4 Conclusions

1) Multi-axial forging followed by partial remelting is an effective route to produce semi-solid ZK60 magnesium alloy for thixoforming. During multi-axial forging, with increasing the equivalent strain, coarse grains are refined.

2) Prolonging the holding time resulted in grain coarsening in partial remelting. However, increasing the reheating temperature was favorable for obtaining the spheroidal semi-solid microstructure and decreasing the probability of calescence among solid grains.

3) The tensile mechanical properties of thixoformed ZK60 magnesium alloy components strongly depend on the microstructure. When the thixoforming temperature was 574 °C, good elongation to fracture (13%) was obtained for thixoformed ZK60 magnesium alloy, with a yield strength of 202 MPa and a tensile strength of 315 MPa.

References

[1] CHEN Q, SHU D Y, HU C K, ZHAO Z D, YUAN B G. Grain refinement in an as-cast AZ61 magnesium alloy processed by multi-axial forging under the multitemperature processing procedure [J]. Materials Science and Engineering A, 2012, 541: 98-104.

[2] ZHAO Z D, CHEN Q, HU C K, HUANG S H, WANG Y Q. Near-liquidus forging, partial remelting and thixoforging of an AZ91D+Y magnesium alloy [J]. Journal of Alloys and Compounds, 2009, 485: 627-636.

[3] CHEN Q, HUANG Z W, ZHAO Z D, HU C K. Thermal stabilities, elastic properties and electronic structures of B2-MgRE (RE=Sc, Y, La) by first-principles calculations [J]. Computational Materials Science, 2013, 67: 196-202.

[4] ZHAO Z D, CHEN Q, WANG Y B, SHU D Y. Microstructural evolution of an ECAE-formed ZK60-RE magnesium alloy in the semi-solid state [J]. Materials Science and Engineering A, 2009, 506: 8-15.

[5] CHEN Q, LUO S J, ZHAO Z D. Microstructural evolution of previously deformed AZ91D magnesium alloy during partial remelting [J]. Journal of Alloys and Compounds, 2009, 477: 726-731.

[6] ZHAO Z D, CHEN Q, CHAO H Y, HUANG S H. Microstructural evolution and tensile mechanical properties of thixoforged ZK60-Y magnesium alloys produced by two different routes [J]. Materials and Design, 2010, 31: 1906-1916.

[7] LIN H Q, WANG J G, WANG H Y, JIANG Q C. Effect of predeformation on the globular grains in AZ91D alloy during strain induced melt activation (SIMA) process [J]. Journal of Alloys and Compounds, 2007, 431: 141-147.

[8] CHEN Q, ZHAO Z D, ZHAO Z X, HU C K, SHU D Y. Microstructure development and thixoextrusion of magnesium alloy prepared by repetitive upsetting-extrusion [J]. Journal of Alloys and Compounds, 2011, 509: 7303-7315.

[9] LUO S J, CHEN Q, ZHAO Z D. Effects of processing parameters on the microstructure of ECAE-formed AZ91D magnesium alloy in the semi-solid state [J]. Journal of Alloys and Compounds, 2009, 477: 602-607.

[10] TZIMAS E, ZAVALIANGOS A. Evolution of near-equiaxed microstructure in the semisolid state [J]. Materials Science and Engineering A, 2000, 289 (1-2): 228-240.

[11] ATKINSON H V. Modelling the semisolid processing of metallic alloys [J]. Progress Materials Science, 2005, 50(3): 346-352.

[12] CHEN Q, YUAN B G, ZHAN G Z, SHU D Y, HU C K, ZHAO Z D, ZHAO Z X. Microstructural evolution during reheating and tensile mechanical properties of thixoforged AZ91D-RE magnesium alloy prepared by squeeze casting-solid extrusion [J]. Materials Science and Engineering A, 2012, 537: 25-38.

[13] ZHAO Z D, CHEN Q, TANG Z J, HU C K. Microstructural evolution and tensile mechanical properties of AM60B magnesium alloy prepared by the SIMA route [J]. Journal of Alloys and Compounds, 2010, 497: 402-411.

[14] ATKINSON H V, BURKE K, VANEETVELD G. Recrystallisation in the semi-solid state in 7075 aluminium alloy [J]. Materials Science and Engineering A, 2008, 490: 266-276.

[15] LUO S J, CHEN Q, ZHAO Z D. An investigation of microstructure evolution of RAP processed ZK60 magnesium alloy [J]. Materials Science and Engineering A, 2009, 501: 146-152.

[16] ZHAO Zu-de, CHEN Qiang, KANG Feng, SHU Da-yu. Microstructural evolution and tensile mechanical properties of thixoformed AZ91D magnesium alloy with the addition of yttrium [J]. Journal of Alloys and Compounds, 2009, 482: 455-467.

[17] ZHAO Zu-de, CHEN Qiang, TANG Ze-jun, WANG Yan-bin, NING Hai-qing. Microstructure evolution and mechanical properties of Al2O3sf/AZ91D magnesium matrix composites fabricated by squeeze casting[J]. Journal of Materials Science, 2010, 45: 3419-3425.

[18] CHEN Q, SHU D Y, ZHAO Z D, ZHAO Z X, WANG Y B, YUAN B G. Microstructure development and tensile mechanical properties of Mg-Zn-RE-Zr magnesium alloy [J]. Materials and Design, 2012, 40: 488-496.

[19] CHEN Q, ZHAO Z X, SHU D Y, ZHAO Z D. Microstructure and mechanical properties of AZ91D magnesium alloy prepared by compound extrusion [J]. Materials Science and Engineering A, 2011, 528: 3930-3934.

[20] ZHAO Z D, CHEN Q, HU C K, SHU D Y. Microstructure and mechanical properties of SPD-processed an as-cast AZ91D+Y magnesium alloy by equal channel angular extrusion and multi-axial forging [J]. Materials and Design, 2009, 30: 4557-4561.

[21] ZHAO Z D, CHEN Q, CHAO H Y, HU C K, HUANG S H. Influence of equal channel angular extrusion processing parameters on the microstructure and mechanical properties of Mg–Al–Y–Zn alloy [J]. Materials and Design, 2011, 32: 575-583

[22] ZHAO Z D, CHEN Q, WANG Y B, SHU D Y. Effect of predeformation on semi-solid microstructure of ZK60+RE magnesium alloy [J]. Transactions of Nonferrous Metals Society of China, 2009, 19: 535-539.

[23] ZHAO Z D, CHENG Y S, CHEN Q, WANG Y B, SHU D Y. Reheating and thixoforging of ZK60+RE alloy deformed by ECAE [J]. Transactions of Nonferrous Metals Society of China, 2010, 20: 178-182.

[24] HAGEN F, NORBERT H, HAJO D, KARL ULRICH K. Influence of processing route on the properties of magnesium alloys [J]. Solid State Phenomena, 2008, 141-143: 43-48.

[25] YANG M B, PAN F S, CHENG R J, SHEN J. Effects of holding temperature and time on semi-solid isothermal heat-treated microstructure of ZA84 magnesium alloy [J]. Transactions of Nonferrous Metals Society of China, 2008, 18: 566-572.

[26] CHEN Q, YUAN B G, ZHAN G Z, SHU D Y, HU C K, ZHAO Z D, ZHAO Z X. Microstructural evolution during reheating and tensile mechanical properties of thixoforged AZ91D-RE magnesium alloy prepared by squeeze casting-solid extrusion [J]. Materials Science and Engineering A, 2012, 537: 25-38.

[27] SU G H, CAO Z Y, LIU Y B,WANG Y H, ZHANG L,CHENG L R. Effects of semi-solid isothermal process parameters on microstructure of Mg-Gd alloy. [J] Transactions of Nonferrous Metals Society of China, 2010, 20(s2): s402-s406.

[28] HU Y, HE B L, YAN H. Rheological behavior of semi-solid Mg2Si/AM60 magnesium matrix composites at steady state. [J] Transactions of Nonferrous Metals Society of China, 2010, 20(s3): s883-s887.

[29] YANG M B, PAN F S, CHENG R J, SHEN J. Effects of holding temperature and time on semi-solid isothermal heat-treated microstructure of ZA84 magnesium alloy [J]. Transactions of Nonferrous Metals Society of China, 2008, 18(3): 566-572.

[30] KLEINER S, BEFFORT O, UGGOWITZER P J. Microstructure evolution during reheating of an extruded Mg-Al-Zn alloy into the semisolid state [J]. Scripta Materialia, 2004, 51: 405-410.

陶健全1,程远胜2,黄少东1,彭菲菲1,杨文选1,鲁美琪1,张志明1,金 鑫1

1. 中国兵器工业第五九研究所,重庆 400039;

2. 哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001

摘 要:为了提高ZK60镁合金的力学性能,采用多向锻造和部分重熔工艺;研究重熔温度和保温时间对ZK60镁合金半固态组织的影响;研究多向锻造和部分重熔工艺制备的ZK60镁合金构件在不同触变成形温度下的力学性能。结果表明:多向锻造加部分重熔工艺是一种制备半固态触变成形ZK60镁合金的有效方法。在部分重熔过程中,随着保温时间的延长和重熔温度的升高,晶粒长大。升高重熔温度,晶粒球化效果明显得到改善。当触变成形温度从560 °C升高至574 °C时,ZK60镁合金的力学性能明显提高。

关键词:ZK60镁合金;半固态工艺;多向锻;力学性能;组织;

(Edited by YANG Hua)

Foundation item: Project(51175018) supported by the National Natural Science Foundation of China; Project(HIT.NSRIF2010118) supported by the Fundamental Research Funds for the Central Universities, China

Corresponding author: TAO Jian-quan; Tel: +86-23-68792232; E-mail: jarryallen@163.com

DOI: 10.1016/S1003-6326(12)61742-7