DOI:10.19476/j.ysxb.1004.0609.2017.07.09

700 ℃超超临界锅炉材料617B合金冷变形和退火过程中的组织演变

江 河,董建新,张麦仓,姚志浩

(北京科技大学 材料科学与工程学院,北京 100083)

摘 要:冷变形过程对617B合金管材的尺寸精度、组织和性能具有重要影响。通过对617B合金荒管进行不同变形量的冷轧实验,对其冷变形特性进行研究。对冷变形后的617B合金进行不同制度下的退火处理,对其退火过程中的组织演变规律进行研究,建立退火过程中的再结晶晶粒长大方程。结果表明:所构建的再结晶晶粒长大方程与实验数据值吻合度较好;617B合金退火过程中组织均匀性受退火温度影响最大;由于碳化物条带的存在,退火过程中易出现组织不均匀的现象,综合考虑晶粒尺寸和组织均匀性两个因素最终确定冷轧变形量为20%,中间退火制度为1140 ℃、10 min时得到的组织最为均匀。

关键词 镍基高温合金;退火;冷轧;静态再结晶

文章编号:1004-0609(2017)-07-1385-10 中图分类号:TG146.1 文献标志码:A

煤炭将在很长一段时间内作为一种主要的廉价发电燃料,但能源和环境问题的日益严峻使提高火电站发电效率的需求更加迫切[1]。现有的火电发电站的最高蒸汽温度为538 ℃,发展的先进超超临界电站的蒸汽温度可提高到620 ℃,正在研究中的下一代先进超超临界电站计划将燃煤效率提高到60%,蒸汽温度提高到760 ℃[2]。在超超临界条件下,材料需满足在750 ℃实验100000 h后持久强度不低于100 MPa,具有良好的耐烟气腐蚀能力,服役200000 h后烟气侧的腐蚀小于2 mm,此外合金还需要有较好的耐高温氧化能力、可加工性及焊接性[3]。传统的铁素体钢无法满足如此严苛的条件[4-5]。镍基高温合金因其良好的耐蚀能力和更高的蠕变和疲劳抗力,取代铁素体钢成为新一代超超临界电站的候选材料[4, 6]。

Inconel617合金是一种固溶强化型的镍基高温合金,由于其良好的抗氧化性能、力学性能和高温稳定性而被广泛用于高温环境[7]。617合金最早设计使用 温度为800 ℃以上,常被用于航空和地面用燃气涡轮机,冶金加工设施和电站结构件。617合金曾于20世纪70、80年代被美国和德国考虑用于HTGR计划中[8]。随着20世纪90年代超超临界蒸汽锅炉技术在欧洲和美国的兴起,超超临界用锅炉管材的研究受到人们的重视。617合金成为750 ℃锅炉构件的首选材料之一[9]。为满足超超临界电站用合金管材的需求,在617合金的基础上研发了改进型合金617B。617B合金在617合金基础上严格控制主要元素成分,并添加了B元素从而提高了合金的抗蠕变性能[10]。

虽然对617合金在组织稳定性[11]、力学性能[12-13]、热变形行为[14-15]、抗氧化性[16]和耐蚀性[17]方面已有较多研究,但针对其生产工艺国内外尚未见报道。617B合金管材生产中采用冷轧工艺,冷变形过程不仅决定了合金管材的尺寸精度,而且对合金最终的组织和性能起到决定性作用,所以研究合金冷变形行为具有重要意义[18-19]。高温合金的强度很高,在加工过程中对设备的载荷能力有较高要求,特别是具有强化相的高温合金在冷变形时还要考虑其塑性问题。本文作者通过617B合金荒管不同变形量的冷轧和中间退火实验,对617B合金的冷变形行为进行研究,得到了其静态再结晶晶粒长大方程。此外,将晶粒尺寸与组织均匀性相结合,得到617B合金冷轧变形量及中间退火制度的最佳匹配关系。

1 实验

本实验所用617B合金为真空感应熔炼(VIM)加保护气氛电渣重熔(ESR)的双联工艺冶炼后经过1210 ℃、48 h均匀化处理,进行开坯、热挤压后得到的荒管,其尺寸规格为d118 mm×22 mm,化学成分如表1所列。为研究一道次冷轧和中间退火制度对617B合金组织演变的影响,从荒管管壁切取规格为5 mm×20 mm×2000 mm的板条状试样,在四辊轧机上进行压下量为20%、30%、40%、50%的冷轧试验。冷轧后的试样切成小块,在箱式电阻炉中进行等温退火试验,退火温度为1140、1170、1200 ℃,保温时间为5、10、30、60、90 min,试样取出后进行水冷。

表1 617B合金电渣锭化学成分

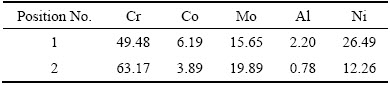

Table 1 Chemical compositions of alloy 617B ESR ingot (mass fraction, %)

通过光学显微镜、扫描电镜对冷轧及退火后的试样进行组织观察。试样用金相砂纸逐级打磨至2000号后用2.5 μm抛光膏进行机械抛光。扫描电镜(SEM)观察的浸蚀方法为在170 mL H3PO4+10 mL H2SO4+15 g CrO3混合溶液中电解侵蚀。金相观察的侵蚀方法为在10 g KMnO4+40 mL H2SO4+360 mL H2O的溶液中加热,煮沸30 min后用12%(质量分数)的草酸溶液进行清洗。晶粒尺寸采用截点法进行统计。

2 结果与分析

2.1 冷轧过程中的组织演变

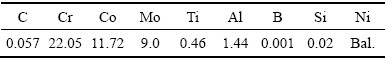

617B合金荒管组织如图1所示。由图1(a)可知,冷变形前的原始组织为等轴晶,且晶界和晶内均存在明显的碳化物析出。EDS能谱分析(见表2)表明晶界处碳化物和晶内碳化物条带的成分相近,且在电镜下均呈白色,已有研究表明[20-21],该析出相为富Cr的M23C6碳化物。荒管的晶粒尺寸并不均匀,碳化物的析出明显抑制了晶粒长大,碳化物条带出现的区域晶粒比较细小,平均尺寸在20~30 μm,而没有碳化物条带区域晶粒尺寸在60~70 μm。617合金由于碳化物存在导致晶粒尺寸不均匀的问题在其他研究中也有报道[20, 22]。

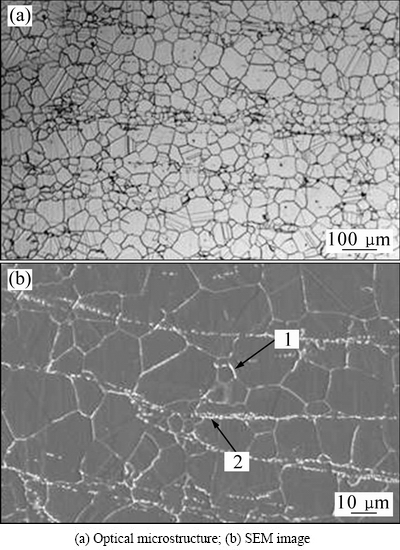

在617B合金管材的成型过程中需经过多道次冷轧,冷轧及中间退火实验对合金的组织和性能具有重要影响。冷轧和退火工艺的合理性将直接影响后续工艺的制定,以及最终成品管的质量。为研究冷轧过程对材料组织和性能的影响,对板条状试样进行不同压下量的冷轧试验,不同变形量下的轧后组织如图2所示。由图2可知,随着变形量的增大,垂直于轧向的横截面内原始晶粒逐渐被压扁,晶粒均匀的发生形变,随着变形量的增加晶粒变形程度逐渐增大。轧后的组织仍可观察到明显的碳化物条带存在,且晶粒尺寸并不均匀。

图1 617B合金冷变形前的初始组织

Fig. 1 Initial microstructures of alloy 617B before cold deformation

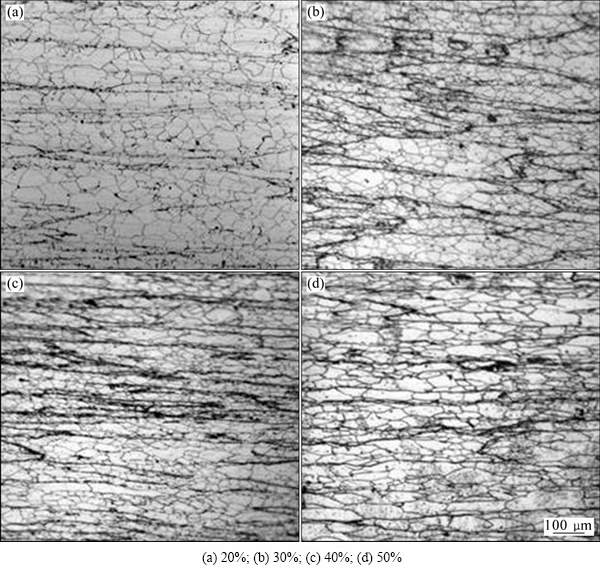

表2 617B合金碳化物成分

Table 2 Chemical compositions of carbides in alloy 617B (mass fraction, %)

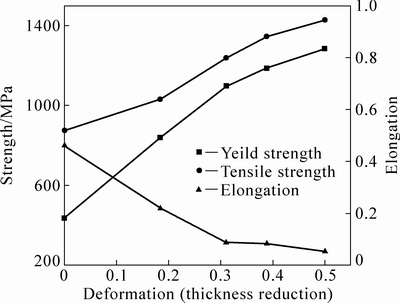

冷变形使显微组织发生变化的同时也对合金的力学性能产生影响,不同变形量冷轧后的板状室温拉伸结果如图3所示。由图3可知,随着变形量的增加,617B合金的抗拉强度和屈服强度逐渐增加,材料出现了明显的硬化;伸长率随着变形量的增加而降低,表明材料的塑性随着冷变形量的增加而降低。

图2 617B合金经不同变形量冷轧后的显微组织

Fig. 2 Microstructures of alloy 617B after cold rolling with different deformation degrees

图3 617B冷轧板材室温力学性能与变形量关系

Fig. 3 Relationship between mechanical properties and deformation degree of alloy 617B

2.2 退火工艺对组织的影响规律

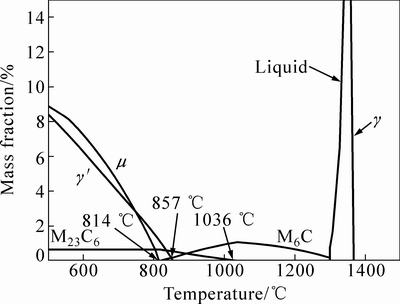

冷变形后会在合金中以位错堆积、形变孪晶等形式残留形变存储能,由以上分析可知冷变形后的合金因这些不稳定结构和能量状态的存在加工塑韧性下降,对合金的加工性能产生不利影响,因此需要采用退火再结晶来消除[23-25]。退火过程中以得到均匀的等轴晶为宜,而617B合金中存在较多的晶界碳化物,晶界碳化物的存在会在退火过程中导致组织不均匀,对合金性能产生不利影响。617B合金中的晶界碳化物主要为含Cr的M23C6型化合物,合金的退火温度应在M23C6型碳化物固溶温度以上,以使碳化物回溶,消除晶界碳化物在退火过程中对晶界迁移的阻碍作用,从而保证合金的静态再结晶过程均匀发生得到等轴晶组织。采用Thermo-calc软件计算的617B合金的热力学平衡相图如图4所示。由图4可知,M23C6型碳化物的回溶温度为1036 ℃,故实验中采用的最低退火温度为1040 ℃,以使M23C6型碳化物能够回溶。虽然提高退火温度有利于碳化物的回溶,但是退火温度过高会导致晶粒异常长大,因此退火温度不宜过高,实验中采用的退火温度为1140、1170、1200和1230 ℃。

图4 617B合金热力学平衡相图

Fig. 4 Thermodynamic equilibrium phase diagram of alloy 617B

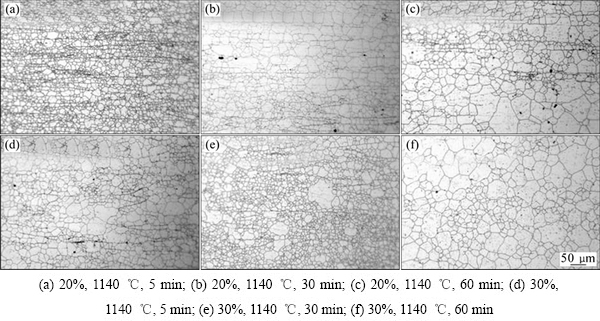

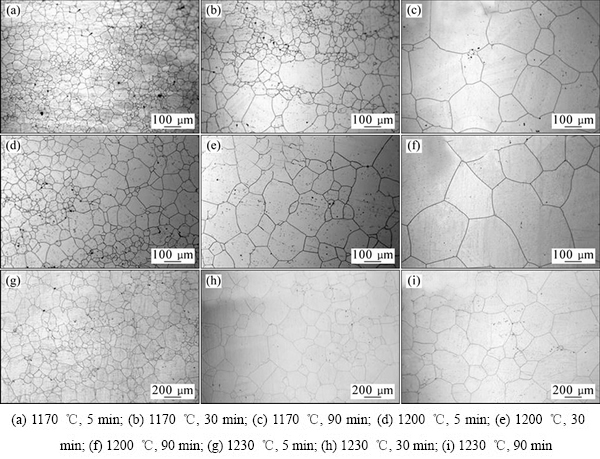

对冷轧后的617B合金进行不同制度下的中间退火试验,图5所示为冷轧20%和30%后的617B合金在1140 ℃退火不同时间后的组织。由图5可知,617B合金的再结晶趋势很大,保温5 min后静态再结晶已经基本完成,冷轧后拉长的晶粒被再结晶产生的等轴晶所取代。随着保温时间的延长,晶粒逐渐长大,不同变形量的合金退火过程中的组织演变趋势基本相同。退火过程中由于碳化物的不完全回溶,组织中仍存在碳化物条带,碳化物条带区域晶粒尺寸较小,合金退火后出现组织不均匀的现象。图6所示为617B合金变形量40%时不同退火温度保温不同时间的显微组织。由图6可知,随着退火温度的增加晶粒长大趋势增加,这是由于晶粒长大的主要驱动力是界面自由能的降低,晶界在界面自由能的驱动下发生迁移导致晶粒间的合并从而使晶粒长大。界面迁移需克服一定的位垒,是一个热激活的过程,温度升高为该过程提供了更多的能量。因此,温度对晶界迁移晶粒长大的影响显著[26]。当温度升高到1230 ℃时,晶粒尺寸剧烈增加晶粒尺寸过大不利于后续工艺中的组织控制,并会对成品管的质量带来影响,因此该温度不适宜作为退火温度。

2.3 退火再结晶晶粒长大动力学方程

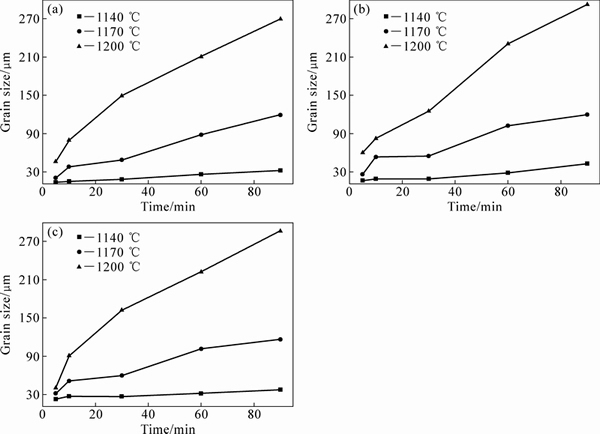

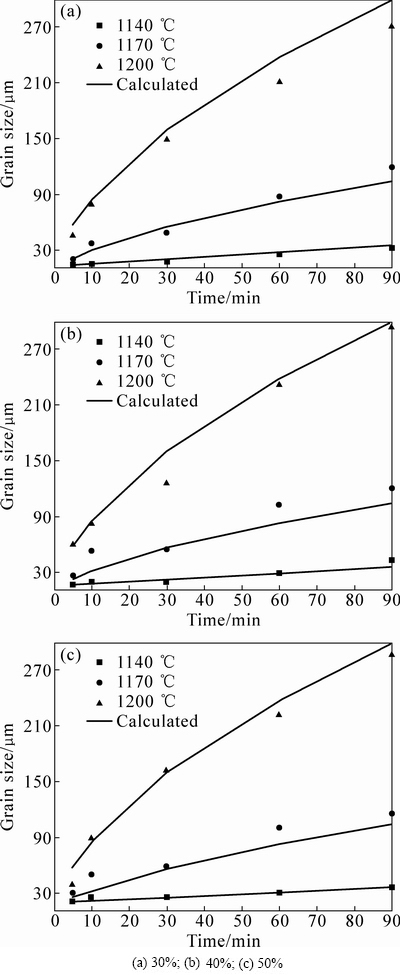

为直观反映晶粒尺寸变化与退火时间和退火温度的关系,617B合金不同变形量下退火保温过程中晶粒尺寸变化统计结果如图7所示。由图7可知,在退火处理开始阶段,晶粒尺寸迅速增加,在保温10~30 min后晶粒尺寸相对稳定,之后随着保温时间的延长晶粒尺寸继续增加。617B合金在退火过程中晶粒尺寸对退火温度十分敏感,随着退火温度的升高,晶粒迅速长大。这主要是因为实验中采用的退火温度在晶界碳化物的回溶温度以上,随着退火温度的升高晶界碳化物更易回溶,晶界钉扎减少,使晶粒迅速长大。

为对617B合金冷轧后退火过程中晶粒长大行为进行定性描述,对再结晶晶粒长大过程进行拟合。由上述分析可知,不同变形量的617B合金在退火过程中的再结晶规律类似,在短时间内迅速完成静态再结晶的形核过程,此后为晶粒长大过程。617B等镍基高温合金由于固溶了大量的固溶元素,层错能较低,再结晶的形核位置较多,因而在不同的变形量下刚好完成静态再结晶时的晶粒尺寸d0相差不大。因此,不同热处理制度下的晶粒尺寸主要受到加热温度、保温时间的影响。目前,较为常用的奥氏体晶粒长大模型为Sellars-Whiteman模型[27]:

(1)

(1)

以及Anelli模型:

(2)

(2)

图5 617B合金经20%和30%冷轧变形量、1140 ℃退火不同时间后的晶粒组织

Fig. 5 Microstructures of alloy 617B after cold rolling with deformation degrees of 20% and 30% and then being annealed at 1140 ℃ for different periods of time

图6 617B合金冷轧40%后在1170、1200和1230 ℃退火不同时间后的晶粒组织

Fig. 6 Microstructures of alloy 617B cold rolled with deformation degrees of 40% and then annealing at 1170, 1200 and 1230 ℃ for different periods of time

图7 保温时间对不同冷轧变形量的617B合金退火过程中晶粒尺寸的影响

Fig. 7 Effect of holding time during annealing on grain size of cold-rolled alloy with deformation degrees of 30% (a), 40% (b) and 50% (c)

Sellars-Whiteman模型中考虑了原始晶粒大小的影响,但未考虑晶粒长大速率随时间的变化,由以上分析可知,晶粒长大速率与时间相关,并不恒定。Anelli模型引入了时间指数m,但未考虑原始晶粒尺寸在晶粒长大模型中的作用,即当t为0时晶粒尺寸为0,这与实际情况不相符[28]。大多数学者将两种模型结合起来,在Sellars-Whiteman模型中引入时间指数m得到晶粒长大方程[29]:

(3)

(3)

式中:d为最终的晶粒尺寸;d0为完成再结晶时初始晶粒尺寸;t为保温时间;T为加热温度;Qg为晶粒长大的激活能;A、n和m为与材料有关的常数。利用 与1/T的线性关系,斜率的平均值即为

与1/T的线性关系,斜率的平均值即为 ;

; 与lnt的斜率的平均值即为m;A值可利用以上关系式进行计算。

与lnt的斜率的平均值即为m;A值可利用以上关系式进行计算。

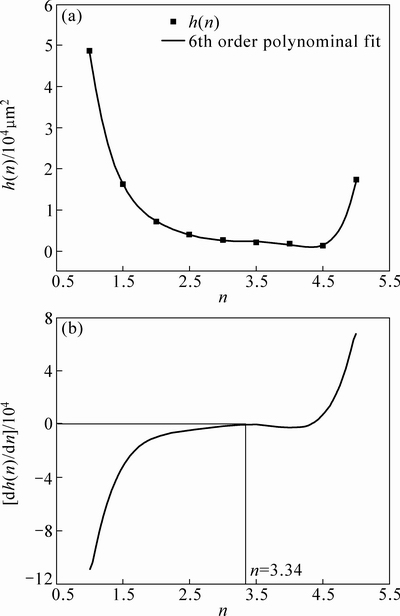

利用617B合金冷轧30%退火的平均晶粒尺寸数据,拟合推导出上述模型描述的晶粒长大方程,处理时保温5 min的晶粒尺寸作为原始晶粒尺寸值d0。事先设定n值,取n=1.0、1.5、2.0、2.5、3.0、3.5、4.0、4.5和5.0,通过试验数据线性回归确定Qg、m和A值。为准确确定n为何值时才是真正适合617B合金的晶粒长大方程,引入误差函数h(n),计算n取不同值时得到的理论晶粒尺寸d′与实际晶粒尺寸d差的平方和,即:

(4)

(4)

绘制h(n)-n散点图,误差函数最小时的n值即为晶粒长大方程的指数,拟合过程如图8所示,617B合金的晶粒长大方程的指数值n=3.34。将n值代入式(1),重新计算出最优解对应的长大激活能Qg=207.6 kJ/mol,长大时间指数m=1.916,A=1.41×1078,得到617B合金在不同热处理制度下的晶粒长大方程为

(5)

(5)

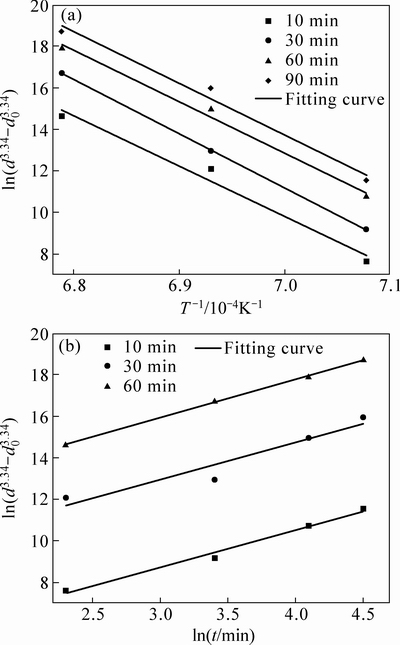

利用求得的n值对 和

和 两组线性关系进行拟合,计算结果如图9所示。图中的线性拟合结果近似平行,且拟合结果与实验值相近,表明617B合金的晶粒长大激活能值Q是唯一的,也就是说晶粒生长的机制不变,回归模型是准确有效的,可适用于描述617B合金冷轧后退火过程中晶粒的长大过程。

两组线性关系进行拟合,计算结果如图9所示。图中的线性拟合结果近似平行,且拟合结果与实验值相近,表明617B合金的晶粒长大激活能值Q是唯一的,也就是说晶粒生长的机制不变,回归模型是准确有效的,可适用于描述617B合金冷轧后退火过程中晶粒的长大过程。

为进一步验证617B合金晶粒长大模型的普遍适

用性,将不同变形量下保温5 min后的晶粒尺寸作为初始晶粒尺寸d0,代入式(3)得到晶粒长大动力学模型的预测值,将其与实验值进行比对,如图10所示。图10中散点为晶粒尺寸的实验值,曲线为理论计算值。由图10可知该模型的预测值与实验值吻合度较好,表明该模型具有普遍适用性。

图8 误差函数的多项式拟合和微分曲线

Fig. 8 Polynomial fitting curves (a) and differential curves of error function (b)

图9 退火温度及持续时间对617B合金晶粒尺寸变化的影响

Fig. 9 Effects of annealing temperature (a) and holding time (b) on variation of grain size for 617B alloy

图10 中间退火后晶粒尺寸的计算值(曲线)和实测值对比(散点)

Fig. 10 Relationship between grain size and annealing time for 617B alloy with different deformation degrees

2.4 退火过程的组织均匀性

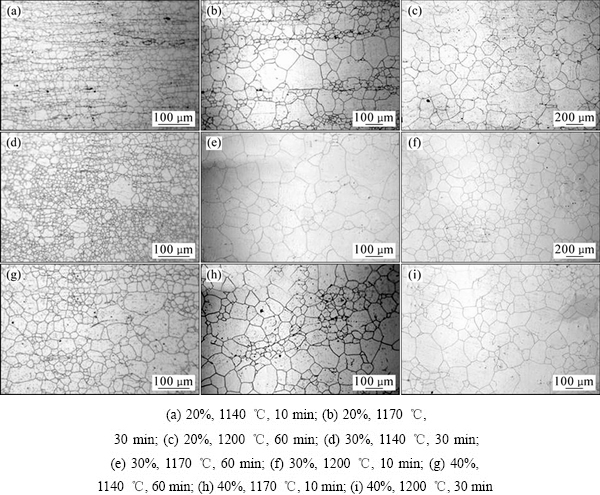

617B 合金由于晶界碳化物的存在,冷轧以及退火保温过程中晶粒尺寸不均匀的现象较为严重,而退火后组织的均匀性对合金的性能有重要影响。对于冷轧后退火态的617B合金管材影响其组织均匀性的因素主要有冷轧变形量、退火温度和保温时间,由于变量较多且相互间的交互关系较为复杂,为探究冷轧变形量与退火制度间的最佳组合关系,采用正交实验对合金的组织均匀性进行研究。对组织均匀性的影响因素每种取3个水平,其中轧制变形的3个水平分别为20%、30%、40%,退火温度的3个水平分别为1140、1170、1200 ℃,保温时间的3个水平是10、30、60 min。几种不同冷轧及退火制度处理后的617B合金组织如图11所示。由图11可知,保温时间对合金组织均匀性的影响较大,随着保温时间的延长,不同晶粒的长大速度差异较大,导致组织均匀性较差。此外,随着退火温度的升高和冷轧变形量的增加,组织均匀性均有所下降。因此需要合理选择冷轧和中间退火工艺参数,使其相机互匹配,保证组织的均匀性。通过比对可知,冷轧变形量为20%,退火温度为1140 ℃、保温时间为10 min时,组织均匀性最好。

结合以上分析可知,617B合金冷轧退火过程中发生了静态再结晶,其组织对冷变形量、退火温度、退火时间极为敏感;当考虑组织均匀性时,冷轧变形量和退火制度的最佳匹配关系为变形量为20%,退火制度为1140 ℃,10 min。

3 结论

1) 冷轧后的中间退火过程中,再结晶过程主要受到保温时间和退火温度的影响,随着保温时间的延长,再结晶过程逐渐完成,通过建立优化目标的误差函数确定了617B合金静态再结晶晶粒长大方程如下:

。

。

2) 基于正交试验设计结果对617B合金单道次冷轧及中间退火工艺进行了优化。冷轧变形量20%,在1140 ℃下保温10 min能获得最均匀的再结晶组织。

图11 不同冷轧及退火处理后的晶粒组织

Fig. 11 Grain microstructures after different cold rolling and annealing treatments

REFERENCES

[1] SARVER J, TANZOSH J. Steamside oxidation behaviour of candidate USC materials at temperatures between 650 and 800 ℃[J]. Energy Materials, 2007, 2(4): 227-234.

[2] HOLCOMB G R, COVINO B S Jr, BULLARD S D, CRAMER S D, ZIOMEK-MOROZ M, ALMAN D E, OCHS T. Ultra supercritical steamside oxidation[C]//Proceedings of the Advances in Materials Technology for Fossil Power Plants. Materials Park: ASM International, 2005.

[3] BAKER B A, GOLLIHUE R D. Optimization of INCONEL alloy 740 for advanced ultra supercritical boilers[C]// Proceedings of the advances in materials technology for Fossil Power Plants: Proceedings from the Sixth International Conference, Santa Fe, New Mexico: ASM International, 2004. 063.

alloy 740 for advanced ultra supercritical boilers[C]// Proceedings of the advances in materials technology for Fossil Power Plants: Proceedings from the Sixth International Conference, Santa Fe, New Mexico: ASM International, 2004. 063.

[4] BUGGE J, KJ R S, BLUM R. High-efficiency coal-fired power plants development and perspectives[J]. Energy, 2006, 31(10): 1437-1445.

[5] 林富生, 谢锡善, 赵双群, 董建新. 我国 700 ℃超超临界锅炉过热器管用高温合金选材探讨[J]. 动力工程学报, 2011, 31(12): 960-968.

LIN Fu-sheng, XIE Xi-shan, ZHAO Shuang-qun, DONG Jian-xin. Selection of superalloys for superheater tubes of domestic 700 ℃ A-USC boilers[J]. Journal of Chinese Society of Power Engineering, 2011, 31(12): 960-968.

[6] VISWANATHAN R, HENRY J, TANZOSH J, STANKO G, SHINGLEDECKER J, VITALIS B, PURGERT R. US program on materials technology for ultra-supercritical coal power plants[J]. Journal of Materials Engineering and Performance, 2005, 14(3): 281-292.

[7] HOSIER J C, TILLACK D J. Inconel alloy 617—A new high temperature alloy[J]. Metals Engineering Quarterly, 1972, 12(3): 51-55.

[8] 江 河, 董建新, 张麦仓, 姚志浩. 700 ℃超超临界用锅炉管材617合金研究进展[J]. 世界钢铁, 2014, 3: 26-39.

JIANG He, DONG Jian-xin, ZHANG Mai-cang, YAO Zhi-hao. A review of the study on alloy 617 for 700 ℃ ultra supercritical power plants[J]. World Iron & Steel, 2014, 3: 26-39.

[9] 王 珏, 董建新, 张麦仓, 谢锡善. 三种700 ℃以上超超临界电站用过热器管材[J]. 世界钢铁, 2011, 2: 26-35.

WANG Jue, DONG Jian-xin, ZHANG Mai-cang, XIE Xi-shan. Research on three candidate materials for superheater boiler tubes used in advanced ultra-supercritical power station[J]. World Iron & Steel, 2011, 2: 26-35.

[10] WER K L J, HUSEMANN R, BADER M. Development of nickel alloys based on alloy 617 for components in 700 C power plants[J]. Procedia Engineering, 2013, 55: 226-231.

[11] WU Q, SONG H, SWINDEMAN R W, SHINGLEDECKER JOHN P, VASUDEVAN VIJAY K. Microstructure of long-term aged IN617 Ni-base superalloy[J]. Metallurgical and Materials Transactions A, 2008, 39(11): 2569-2585.

[12] MO K, LOVICU G, TUNG H-M, CHEN Xiang, STUBBINS JAMES F. Microstructural evolution of alloy 617 and alloy 230: Following high temperature aging[C]//Proceedings of the ASME 2010 Pressure Vessels and Piping Conference, Bellevue, Washington, 2010. 25847.

[13] GUO Yan, ZHANG Zhou-bo, ZHONG Rong-can, HOU Shu-fang, WANG Bo-han. Microstructure and mechanical properties of alloy 617B[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(4): 1106-1113.

[14] JIANG He, DONG Jian-xin, ZHANG Mai-cang, YAO Zhi-hao. Hot deformation characteristics of Alloy 617B nickel-based superalloy: A study using processing map[J]. Journal of Alloys and Compounds, 2015, 647: 338-350.

[15] JIANG He, DONG Jian-xin, ZHANG Mai-cang, YAO Zhi-hao. Evolution of twins and substructures during low strain rate hot deformation and contribution to dynamic recrystallization in alloy 617B[J]. Materials Science and Engineering A, 2016, 649: 369-381.

[16] AKBARI-GARAKANI M, MEHDIZADEH M. Effect of long-term service exposure on microstructure and mechanical properties of Alloy 617[J]. Materials & Design, 2011, 32(5): 2695-2700.

[17] CHAPOVALOFF J, KACZOROWSKI D, GIRARDIN G. Parameters governing the reduction of oxide layers on Inconel 617 in impure VHTR He atmosphere[J]. Materials and corrosion, 2008, 59(7): 584-590.

[18] 冯昭伟, 米绪军, 王江波, 袁志山, 缪卫东, 周 瑾. 冷轧变形量及退火温度对Ni47Ti44Nb9板材织构和性能的影响[J]. 中国有色金属学报, 2013, 23(3): 756-764.

FENG Zhao-wei, MI Xu-jun, WANG Jiang-bo, YUAN Zhi-shan, MIAO Wei-dong, ZHOU Jin. Influence of cold rolling reduction and annealing temperature on texture and properties of Ni47Ti44Nb9 plate[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(3): 756-764.

[19] 汪 波, 易丹青, 陈宇强, 王 斌, 李泽英. 2E12铝合金在冷轧和退火过程中织构和显微组织的演变[J]. 中国有色金属学报, 2013, 23(11): 3064-3074.

WANG Bo, YI Dan-qing, CHEN Yu-qiang, WANG Bin, LI Ze-ying. Evolution of texture and microstructure of 2E12 aluminum alloy during cold rolling and annealing[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(11): 3064-3074.

[20] GARIBOLDI E, CABIBBO M, SPIGARELLI S, RIPAMONTI D. Investigation on precipitation phenomena of Ni-22Cr-12Co- 9Mo alloy aged and crept at high temperature[J]. International Journal of Pressure Vessels and Piping, 2008, 85(1): 63-71.

[21] CABIBBO M, GARIBOLDI E, SPIGARELLI S, RIPAMONTI D. Creep behavior of INCOLOY alloy 617[J]. Journal of Materials Science, 2008, 43(8): 2912-2921.

[22] 郭 岩, 周荣灿, 侯淑芳, 张红军. 617 合金 760 ℃ 时效组织结构及力学性能分析[J]. 中国电机工程学报, 2010, 26: 86-89.

GUO Yan, ZHOU Rong-can, HOU Shu-fang, ZHANG Hong-jun. Analysis of microstructure and mechanical properties of alloy 617 aged at 760 ℃[J]. Proceedings of the CSEE, 2010, 26: 86-89.

[23] 李一鸣, 任慧平, 金自力, 李德刚, 田荣彬. 低碳钢板冷轧退火组织和织构[J]. 材料热处理学报, 2010, 1: 74-79.

LI Yi-ming, REN Hui-ping, JIN Zi-li, LI De-gang, TIAN Rong-bin. Microstructure and texture of low carbon steel sheet during clod rolling and annealing[J]. Transactions of Materials and Heat Treatment, 2010, 31(1): 74-79.

[24] 孔学云, 王宝峰, 金自力, 任慧平, 张晓燕. 冷轧板再结晶退火中组织和织构演变的研究[J]. 材料热处理学报, 2007, 28(4): 97-101.

KONG Xue-yun, WANG Bao-feng, JIN Zi-li, REN Hui-ping, ZHANG Xiao-yan. Research on evolution of texture and microstructure of cold rolling steel sheet during annealing process[J]. Transactions of Materials and Heat Treatment, 2007, 28(4): 97-101.

[25] MA Feng-cang, LIU Ping, LI Wei, FENG Wei-jun, WANG Li. Effect of annealing and solid solution on microstructure and property of Fe-Mn-C TWIP steel[J]. Transactions of Materials and Heat Treatment, 2010, 9: 64-67.

[26] 丰 涵, 宋志刚, 郑文杰, 陈 斌, 季祥民. 固溶处理对 Inconel 690 合金组织和力学性能的影响[J]. 钢铁研究学报, 2009, 21(3): 46-50.

FENG Han, SONG Zhi-gang, ZHENG Wen-jie, CHEN Bin, JI Xiang-min. Effect of Solution Treatment on Microstructure and Mechanical Property of Inconel 690[J]. Journal of Iron and Steel Research, 2009, 21(3): 46-50.

[27] SELLARS C, WHITEMAN J. Recrystallization and grain growth in hot rolling[J]. Metal Science, 1979, 13(3/4): 187-194.

[28] ANELLI E. Application of mathematical modelling to hot rolling and controlled cooling of wire rods and bars[J]. ISIJ International, 1992, 32(3): 440-449.

[29] 陈礼清, 隋凤利, 刘相华. Inconel718 合金方坯粗轧加热过程晶粒长大模型[J]. 金属学报, 2009, 45(10): 1242-1248.

CHEN Li-qing, SUI Feng-li, LIU Xiang-hua. Grain growth model of Inconel 718 alloy forged slad in reheating process prior to rough rolling[J]. Acta Metallurgica Sinica, 2009, 45(10): 1242-1248.

Microstructure evolution of alloy 617B for 700 ℃ ultra-supercritical boilers during cold deformation and annealing treatment

JIANG He, DONG Jian-xin, ZHANG Mai-cang, YAO Zhi-hao

(School of Material Science and Engineering, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: Cold deformation has an important effect on the dimensional accuracy, microstructure and mechanical properties of alloy 617B pipes. The cold deformation characteristic of alloy 617B tube was investigated by single-pass cold rolling tests of different deformation degrees. The cold rolled alloy 617B was annealed under different conditions. The microstructure evolution mechanism was investigated, and the equation of recrystallized grain growth during annealing was established. The results shows that the grain size of alloy 617B tends to be uneven as a result of carbide strips. The size of recrystallized grain is mainly controlled by annealing temperature and the grain size predicted by the proposed grain model agrees well with the experimental results. The grain size is mostly uniform when the annealing treatment is (1140 ℃, 10 min) with the cold rolling reduction of 20%.

Key words: nickel-base superalloy; annealing; cold rolling; static recrystallization

Foundation item: Project (2012AA03A501) supported by the National High-tech Research and Development Program of China

Received date: 2016-06-28; Accepted date: 2016-10-15

Corresponding author: JIANG He; Tel: +86-10-62332884; E-mail: jianghe17@sina.cn

(编辑 龙怀中)

基金项目:国家高技术研究发展计划资助项目(2012AA03A501)

收稿日期:2016-06-28;修订日期:2016-10-15

通信作者:江 河,讲师,博士;电话:010-62332884;E-mail:jianghe17@sina.cn