Numerical and experimental investigation on snow accumulation on bogies of high-speed trains

来源期刊:中南大学学报(英文版)2020年第4期

论文作者:高广军 张琰 王家斌

文章页码:1039 - 1053

Key words:high-speed train; snow issue; bogies; numerical simulation; experiment

Abstract: This paper reviews the current status of investigation on snow accumulation on the bogies of high-speed trains (HSTs) running in snowy region. First, the background of the snow issue occurring to the HST and the contra-measures for the snow issue proposed in the past decades are provided by reviewing previous studies. Next, the methodology for investigating the snow issue developed by High-Speed Train Research Center of Central South University is introduced, including the numerical simulation research platform and the experimental devices for two-phase flow wind tunnel tests. Then, effective anti-snow flow control schemes for guiding the underbody airflow and their impact on the motion and accretion of snow in the installation region of the bogies are presented. Finally, the remaining investigating challenge for the snow issue of HST and the future research with respect to the challenge are provided from an engineering application viewpoint.

Cite this article as: GAO Guang-jun, ZHANG Yan, WANG Jia-bin. Numerical and experimental investigation on snow

J. Cent. South Univ. (2020) 27: 1039-1053

DOI: https://doi.org/10.1007/s11771-020-4350-x

GAO Guang-jun(高广军)1, 2, 3, ZHANG Yan(张琰)1, 2, 3, WANG Jia-bin(王家斌)1, 2, 3

1. Key Laboratory of Traffic Safety on the Track of Ministry of Education, School of Traffic & Transportation Engineering, Central South University, Changsha 410075, China;

2. Joint International Research Laboratory of Key Technology for Rail Traffic Safety,Central South University, Changsha 410075, China;

3. National & Local Joint Engineering Research Center of Safety Technology for Rail Vehicle,Central South University, Changsha 410075, China

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2020

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2020

Abstract: This paper reviews the current status of investigation on snow accumulation on the bogies of high-speed trains (HSTs) running in snowy region. First, the background of the snow issue occurring to the HST and the contra-measures for the snow issue proposed in the past decades are provided by reviewing previous studies. Next, the methodology for investigating the snow issue developed by High-Speed Train Research Center of Central South University is introduced, including the numerical simulation research platform and the experimental devices for two-phase flow wind tunnel tests. Then, effective anti-snow flow control schemes for guiding the underbody airflow and their impact on the motion and accretion of snow in the installation region of the bogies are presented. Finally, the remaining investigating challenge for the snow issue of HST and the future research with respect to the challenge are provided from an engineering application viewpoint.

Key words: high-speed train; snow issue; bogies; numerical simulation; experiment

Cite this article as: GAO Guang-jun, ZHANG Yan, WANG Jia-bin. Numerical and experimental investigation on snow

accumulation on bogies of high-speed trains [J]. Journal of Central South University, 2020, 27(4): 1039-1053. DOI: https://doi.org/10.1007/s11771-020-4350-x.

1 Introduction

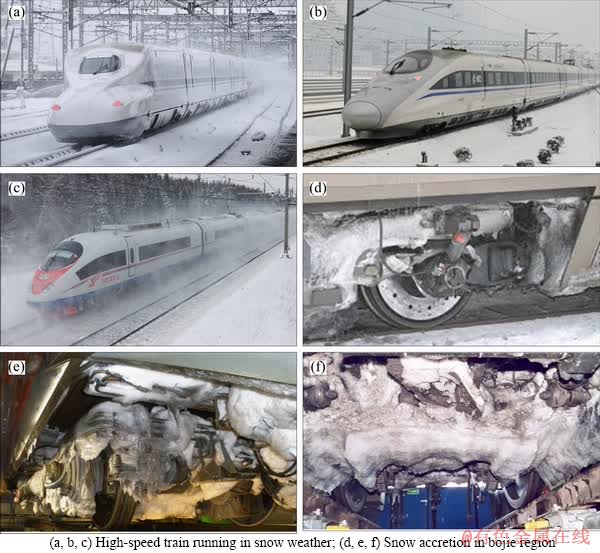

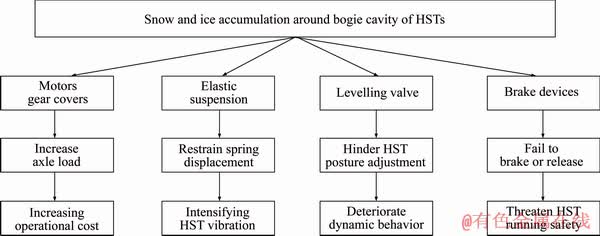

During the last two decades, high-speed trains (HSTs) in several countries have become one of the most popular means of transportation owing to the high capacity and efficiency in different operation environment around the world. At the same time, more and more railways, including both common- speed rail way (CSR) and high-speed railway (HSR) have been built in the regions where snowy weather is common. Examples of such railways include the Qinhuangdao-Shenyang HSR, Harbin-Dalian HSR and Lanzhou-Urumqi HSR in China, Trans-Siberian CSR in Russia, Kyushu and Akita Shinkansen in Japan, Helsinki-Tampere HSR in Finland and Frankfurt-Cologne HSR in Germany. HSTs running on these railway lines during winter will be subjected to a serious snow accumulation on the bogie cavities [1], as presented in Figure 1. This large amount of snow packing on the key components of bogies always contributes to serious problems, as illustrated in Figure 2, such as increasing the axle load [2], intensifying the HST vibration [3], deteriorating HST dynamic performance [4], failing to brake processing [5],and thus resulting in higher operational costs [6], lower railway transportation efficiency [7], worse passenger comfort [4] and dangerous running environment [8, 9].

Figure 1 Operational environment of HSTs in cold and snowy regions and snow accretion in bogie cavities:

Figure 2 Consequences of snow and ice issue of bogies

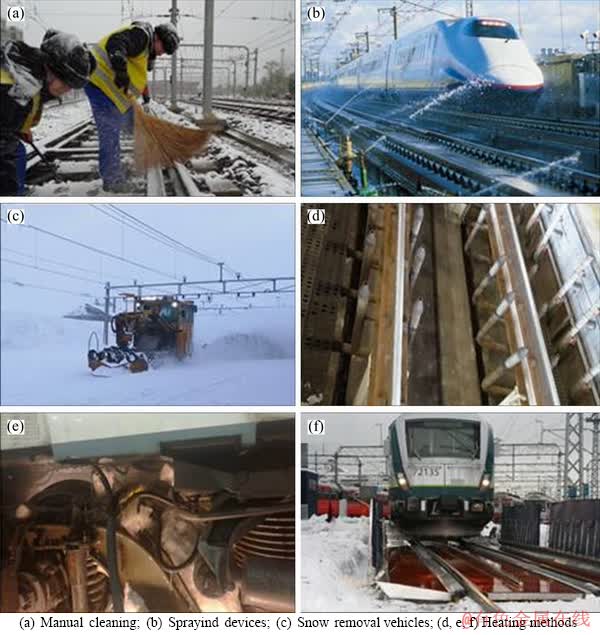

To solve this issue, several snow-resistance technologies have been developed in the past decades. All the anti-snow methods used currently are proposed according to three basic principles: reducing snow accumulating on the subgrade(the first group), melting snow and ice accretion in the cavity(the second group) and optimizing the bogie structures of HSTs(the third group). The examples belonging to the first group are manual cleaning in China, spraying devices in Japan [10] and snow removal vehicles [11], as presented in Figures 3(a)- (c). Additionally, the anti-snow brushers and fences are also installed along the railway lines in Sweden and Norway [11], so as to prevent the drifting snow from moving into the subgrade region [6]. Other Northern European railway companies have established several heating methods to melt the snow and ice from the bogie surfaces, as presented in Figures 3(d)-(f). For example, the hot air is released beneath the HSTs to heat the snow and ice on the bogie surface in Stockholm Vehicle Depot [11]. The hot water is used to melt the snow and ice on the bogies automatically in Helsinki Vehicle Depot [11]. Besides, the propylene glycol is adopted for improving the efficiency of snow- elimination process for HSTs in Russia [12]. Additionally, some foreign railway companies adjust the vehicle structures to optimize the snow- resistance behaviour of HSTs. Some examples of the third group are optimizing the suspension system of HSTs [13], improving the design of air conditions and cooling system [14], changing the contacting shape of the adjacent structures [4], adding anti-snow coating on the bogie surfaces [4], installing the snow plough at the head of vehicle [15].

Figure 3 Current solutions for snow and ice issue of bogies:

The contra-measures belonging to the first group have a very low efficiency to remove the accumulating snow from the subgrade and require the installation of the equipment along the HSRs. China has many long-distance HSR in the cold and snowy regions, these snow-removing solutions would be rather inefficient and costly. Besides, these snow-removing methods fail to totally clean the snow accretion from the HSRs, and serious snow issue still happens to the HSTs which have a long running time. The contra-measures for vehicle depot (belonging to the second group) have a great effect on reducing the utilization of HSTs, thereby significantly lowing the railway transportation efficiency in the winter. Furthermore, the snow-melting solutions of the second group cannot prevent the snow packing on the bogies when HSTs running on the HSR, leading to a dangerous operating environment. Additionally, the optimization of the vehicle structures (third group) has a limited effect on improving the anti-snow behaviour of HSTs, while these optimizing methods require a lot of manpower and resources.

Therefore, the snow issue of bogies needs an alternative solution which could prevent the formation of the dangerous operating environment. Such a method in snow-accretion prevention or the optimized designation of bogies can only be proposed with the increasing knowledge in the underlying flow physics responsible for the snow accumulation. This paper introduces the achievement on the snow issue of HSTs obtained by High-Speed Train Research Center of Central South University in the last decade, including the research methodology for snow issue of HSTs and the proposed effective anti-snow solutions for HSTs.

This structure of the present study is arranged as follows: in Section 2, the numerical algorithm and experimental devices for the snow issue of HSTs are provided. Section 3 introduces the proposed effective anti-snow solutions for HSTs. Finally, summaries are given in the last section.

2 Methodology

2.1 Numerical methodology

The snow flowing into bogie installation regions due to the underbody slipstream of HST is a typical snow-drifting phenomenon [16], thus, computational fluid dynamic (CFD) simulation method can be used to explore the snow issue [17-21]. At present, the research methods on the two-phase flow consist of Euler-Euler (E-E) and Euler-Lagrange (E-L) approaches. In the E-E method, both of two phases are treated mathematically as interpenetrating continua [22]. Since the volume of a phase cannot be occupied by other phases, the concept of phasic volume fraction is introduced. These volume fractions are assumed to be continuous functions of space and time and the sum is equal to one [22]. Therefore, based on this, the E-E approach is not the first choice for the wind-snow flow, as those snow particles should be treated as a dispersed phase. As to the E-L approach, the fluid phase is treated as a continuum by solving the Navier-Stokes equations, while the dispersed phase is solved by tracking a great amount of particles. A fundamental assumption made in this model is that the second dispersed phase occupies a low volume fraction, e.g., <10% [22]. According to the previous work, it shows that the volume fraction of snow particles in bogie regions is much lower than 10%. Thus, the discrete phase model (DPM) in ANSYS Fluent following the E-L method is used to calculate the snow particles’ trajectories [23, 24]. This model is proven to present sufficient accuracy on simulating the movement characteristics (velocity and displacement, etc.) of the solid particle phase in a continuous gaseous flow field whose volume fraction is less than 10% [25], as well as in others numerical studies [26-36].

2.1.1 Turbulence model and HST geometry

The underbody flow beneath the HST is extremely turbulent and complex, thus, the selection of turbulence model has a very important effect on the prediction accuracy of the strong shear flow around the bogie cavities. We conducted the two-phase flow numerical simulation using DES and DPM, URANS and DPM [11]. Although URANS has certain limitation on predicting the complex flow field, the numerical results of particles’ motion and snow accumulation on the bogies of URANS are similar to those obtained using DES, and URANS has slightly more snow accumulation than DES. The computational costs of DES and URANS were also counted to provide the guidance to the engineering application. Compared with DES and DPM, URANS and DPM significantly reduces the simulation time by approximately 35%, based on the same geometry model, mesh resolution and calculation converge criterion [11]. Thus, URANS and DPM can be treated as a nice recommendation to investigate the snow issue around the bogie region, for the combining consideration of numerical accuracy and computational costs. Additionally, considering the computational costs and simulation time when using a three-grouped HST model, it is much better that HST model employed in the numerical simulation made up of head car and a 1/3 length of the second car is applied to perform further local optimization of the bogie cavity shape [11].

2.1.2 Physical parameter selection of snow particles

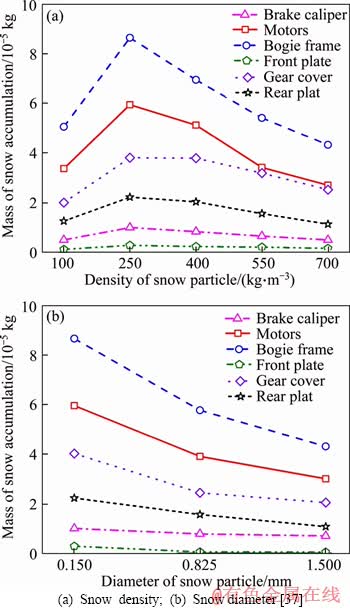

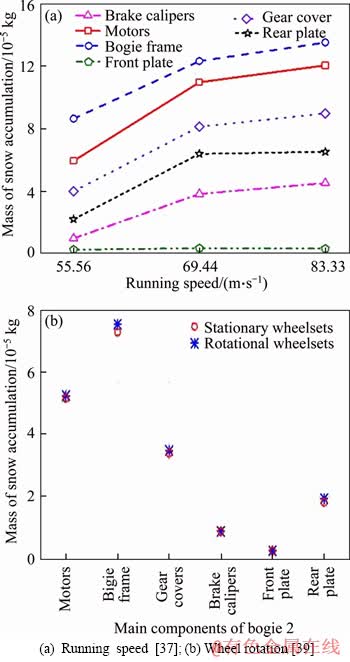

For the significant influence of snow physical parameters on the movement characteristics within cavity, effects of particle’s density (ρp) and diameter (dp) on the predicting results were investigated [37]. As presented in Figure 4(a), for 100 kg/m3≤ ρp≤ 250 kg/m3, the accumulating mass of snow increases obviously with the increasing value of snow density. This is because very light snow particles closely move with the air streamlines and flow round the bogie structures [38]. As the snow density exceeds 250 kg/m3, particles’ weight increases obviously with larger value of snow density, which causes a lower moving range of high-speed wind-snow flow in the cavities, thereby resulting in less snow accumulation mass of bogies [37]. This also indicates that increasing the value of density of snow particles can be treated as an effective anti-snow solution for the snow issue of the HSTs, which has also been confirmed by THOMAS [10]. The snow particle diameter was also found to play a key role in the numerical prediction of snow motion and final accretion. As illustrated by Figure 4(b), the accretion mass on the primary parts decreases obviously with increasing particle diameter. This is due to the weight of single particle grows cubically as a function of the diameter, which results in a much lower flowing range of snow particles beneath the bogie [38].

2.1.3 Boundary condition

The boundary condition setups have a great effect on the numerical predicting of the particles’ trajectories and accretion distribution around the bogie cavity. The effects of running speed and rotating wheels on the particles’ motion were also studied [37]. As reported by Figure 5(a), the snow accumulation on the bogie surface increases obviously when the operating speed of HST increases from 200 to 250 km/h. As the running speed exceeds 250 km/h, the running speed of HSTs has less effect on the snow accumulation on the bogie. The snow accumulation on the bogie surface at the running speed of 250 km/h is close to that at 300 km/h, and is much more than that at 200 km/h. As the speed of HSTs exceeds 250 km/h, the effect of running speed on the snow accumulation on the bogies can be neglected. The influence of the rotating wheels on the numerical results of snow accumulation was found only in the upper part of the bogie [39]. The rotational wheels drive more snow flow to the upper cavity, especially in the vicinity of the rear plates. The snow accumulation in the cavity was observed to decrease by about 3.2% when the rotational condition was adopted, as shown in Figure 5(b). This also indicates a necessary use of rotational wheels in the numerical investigations on the snow issue, in order to provide accurate prediction on the particles’ trajectories in the bogie cavities of the HSTs.

Figure 4 Effects of snow physical parameters on accretion mass on bogie:

Figure 5 Effects of boundary conditions of HST on accumulating mass on bogie:

2.2 Wind tunnel test

2.2.1 Continuous phase wind tunnel test

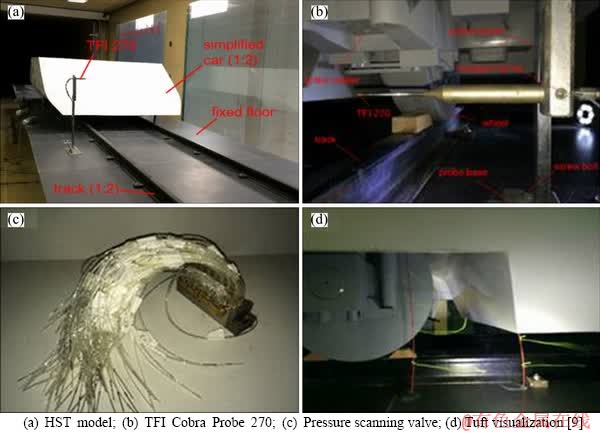

To study the underbody fluid characteristics in the installation region of bogies(continuous phase), a simplified HST having a power bogie with the large scale of 0.5 was measured in the high-speed test section of the wind tunnel at the National Engineering Laboratory for High Speed Railway Construction [9, 11, 40-42]. The size of the testing part is 15 m (length)×3 m (width)×3 m (height). In the continuous phase wind tunnel test, the velocity profile, surface pressure and air streamlines were measured using TFI Cobra Probe 270, pressure scanning valve, light and non-electrostatic silks, respectively, as shown in Figure 6. To ensure the reliability of the experimental results of the underbody flow, a wood board was adopted to lower the thickness of boundary layers. A pair of tracks with the same scaling factor (0.5) were installed on the fixed board. Additionally, several five-hole probes were installed on a probe holder with different height from the fixed board, in order to obtain the velocity profile distribution in the bogie cavity, which can be used for further algorithm validation of CFD method.

2.2.2 Two-phase flow wind tunnel test

To investigate the movement characteristics of snow around bogie cavity, two-phase flow experimental devices was independently developed by High-Speed Train Research Center of Central South University [9, 11, 41, 42], as shown in Figure 7(a). This special experimental platform consists of high-speed testing part of the wind tunnel, particle emission devices upstream test section, recovery devices downstream the test section. A fixed board was installed in order to reduce the thickness of boundary layers and improve the accuracy of measurement and the 1:4 scale tracks were installed on the fixed board. A simplified transparent bogie and HST body model with a scale of 1:4 was installed on the tracks, as shown in Figure 7(b). Sawdust was used to replace snow particles, and it was filtered using two screen meshes. The diameters of the sawdust particles are mainly in the range of 0.25-1.2 mm, and the average density of sawdust was 250 kg/m3 [37]. The sawdust was released through the particle emission device, as shown in Figure 7(a). The liquid honey was adopted to simulate the adhesion of the particles on the bogie surfaces. The high-speed camera was used to observe the trajectories of the sawdust particles.

Figure 6 Wind tunnel test for flow field in bogie cavity:

Figure 7 Two-phase flow wind tunnel test for particles’ trajectories in bogie cavity:

3 Anti-snow solution for HSTs

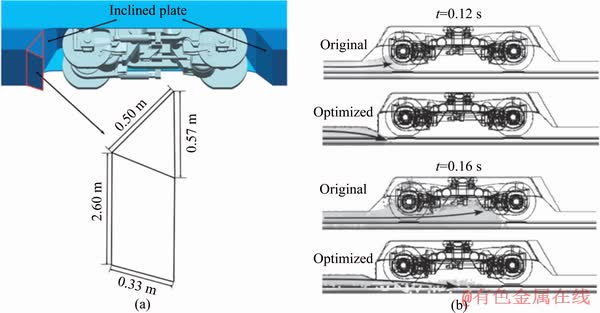

3.1 Adaptive deflecting devices

To solve the snow issue occurring to the HST, the adaptive deflecting devices were designed [42], which consists of controlling unit, air cylinder and deflecting plates. The configuration and installation of the adaptive deflecting devices are presented in Figure 8(a). Figure 8(b) shows the influence of the adaptive deflecting devices on the movement characteristics of snow particles around the bogie region at the simulation time of 0.12 s and 0.16 s. The snow particles are forced to move downwards at the entrance of the bogie cavity, avoiding directly impacting on the windward surface of the bogie. The adaptive deflecting devices are also found to significantly eliminate the fierce impingement on the rear part of the bogies caused by the upward motion of massive snow particles at the middle region of the bogie cavity. The optimization of the trajectories of snow particles at the front and middle region of the bogie cavity contributes to a 50.58% snow reduction on the bogie, indicating the effectiveness of the adaptive deflecting devices for the snow issue of HSTs.

3.2 Deflectors

The deflectors were used to optimize the trajectories of snow particles beneath the HST, and thereby achieving some snow reduction and improving the anti-snow performance of the HST. Considering the available underbody space of the HST, two types of deflectors with the deflecting angles of 2.58° and 5.14° were proposed [40], as depicted in Figure 9(a). The deflectors were installed at the upstream and downstream sides of the bogie cavity because the two-direction operation of HST on the HSRs. The deflectors were found to have a great positive effect on changing the movement characteristics in the bogie cavity. The deflectors obviously lower the particles’ flowing range in the vertical direction and thus alleviate the impinging flow of a great number of air streamlines and massive snow particles. Moreover, the deflector that having 5.14° deflecting angle presents a better contra-snow ability than the deflector with 2.58° inclining angle. Compared with the original HST, the installation of deflectors with 5.14° deflecting angle is found to decrease the snow accretion on the bogie by 49.34%, which is of great meaning to ensure the operational quality of HST during the winter.

Figure 8 Configuration of adaptive deflecting devices and its effect on snow particles’ trajectories [42]

Figure 9 Configuration of deflectors and their influence on movement characteristics of snow particles in bogie cavity [40]

3.3 Diversion slot

For a combining consideration of both anti-snow performance and energy consumption of HST during the winter, the diversion slots were proposed [43-45]. The diversion slots were also installed at the upstream and downstream sides of the bogie cavity. As presented in Figure 10. The diversion slots effectively alter the underbody flow characteristics and force more high-speed air streamlines to flow round the bogie structures, thereby alleviate the impact of snow on the windward surface of the bogie. Furthermore, the diversion slots were also found to significantly reduce the concentration level of snow near the primary heat-producing element of the bogie, such as the motors, gear covers and brake calipers, which is helpful to decrease the ice formation on the bogies. Compared with original HST, the application of the diversion slots can achieve approximately 50%, without any increase of frontal area and resistance force of the HST.

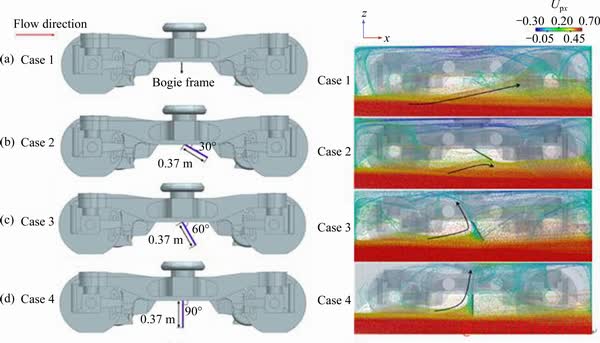

3.4 Hanging deflector

Previous study has proven that the upward motion of great number of snow particles at the middle part of bogie cavity contributes to massive snow accumulation on the rear windward surface of bogie. Thus, the deflectors hanging on the beam of the bogie were designed [46], as presented in Figure 11. Figure 11(b) shows the particles’ motion feature in the bogie region, and the presented results show that the installing angles of the hanging deflector have a great effect on the particles motion. The deflector installed at 30° prevents a number of snow particles from moving up along the rear plate of cavity. The deflector installed at 60° has a relatively better performance than the deflector at 30°, which causes most of the particles passing through bogie region underneath the frame. Besides, the deflector installed at 90° resulting in a significant reduction of snow particles distribution in the rear region while an increasing snow distribution at the front bogie region. Moreover, the deflector installed at 60° has the best anti-snow performance by showing a 62.46% snow reduction, especially for decreasing the snow accretion on the rear surface of bogie.

4 Accumulation of drifting snow around railway constructions

The snow accumulation on the railway lines has a great effect on the operating efficiency and safety of trains in the winter, as presented in Figure 12, which is mainly caused by the snow drifting phenomenon [47]. Snow blown by incoming airflow and its final accumulation distribution can be treated as a typical two-phase flow phenomenon. The snow accumulation around the cube [48-50], the roof [51-54] and the snow fence [55, 56] and has been studied using the two-phase flow method. With the rapid development of computer technology in the past decades, the CFD simulation for the snow drifting becomes more common [57-65].

Figure 10 Configuration of diversion slots and their influence on snow accumulation on bogie [43]

Figure 11 Installation of hanging deflectors and their influence on movement characteristics of snow particles in cavity [46]

Figure 12 Heavy snow accumulation on railway line and surrounding constructions

For the investigation of snow accumulation around the railway constructions, we also built the numerical methodology and conducted a great number of numerical simulations. In order to improve the predicting accuracy of snow movement, the influence of configuration of deposited snow on the flow field needs to be considered. Thus, we proposed the adaptive mesh method coupling with discrete phase model to simulate the process of snow drifting and depositing. The heat exchange between snow and wall and normal of element were considered to compute the deposited snow thickness and the direction of thickness increased, respectively.

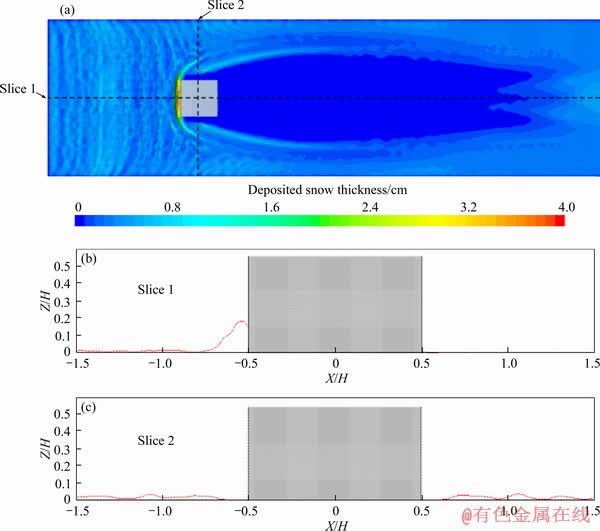

Figure 13 presents the numerical results of snow accumulation around a generic cube based on our numerical method. The height of cube was defined as H and the origin of coordinates was set as cube’s center. The distribution characteristic of snow accumulation shown in Figure 13(a) is similar to that reported by BEYERS et al [48], indicating a well predicting accuracy of the proposed numerical method. The deposited snow thickness at the slice 1(center line of cube: Y/H=0) and slice 1(center line of cube: X/H=0) are presented in Figures 13(b) and (c). The difference on deposited snow thickness between two numerical works is mainly caused by the different boundary condition and the account of computational time. Thus, the two-phase flow wind tunnel test will be carried out to further validate the numerical accuracy of the proposed method. Then, the proposed numerical method will be employed for the related investigation on the optimization of the anti-snow performance of railway constructions.

Figure 13 Deposited snow thickness around cube

5 Future work

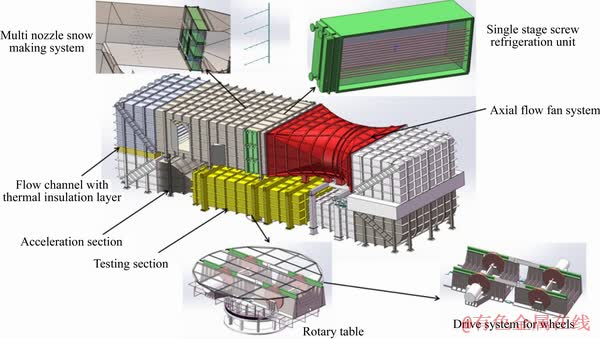

In our previous studies, the heat radiated from the main heat-producing components was considered to provide a more accurate numerical results of flow field in the bogie cavity, ensuring a good predicting accuracy of snow particles’ trajectories. However, the phase-changing process among snow, water and ice happened on the surfaces of these components was not simulated. The trajectory of sprayed water induced by rotating wheels and high-speed underbody flow has a great effect on the ice formation in the cavity, while this was not analyzed in previous studies. To overcome this challenge, a low-temperature wind-snow experimental platform will be built in the next research stage, as shown in Figure 14.

This experimental device consists of air flow channel with thermal insulation layer, axial flow fan system, rotary table and drive system for wheels, multi nozzle snow making system, and single stage screw refrigeration unit. The flow field in a real bogie cavity (1:1) at the lower temperature with different yaw angles can be measured. The heat produced by motor, gear cover and brake calipers will be considered during the wind-snow experiment. The movement characteristics of snow particles and the sprayed water around the bogie will be recorded using high-speed camera. The final accumulating mass of snow and ice on the bogies can be accurately measured, in order to provide a quantitative assessment on the snow and ice issue. This experimental device has the ability to continue working for six hours, which will reproduce the real operational environment of HST in the cold regions. Besides, based on this experimental device, the anti-snow ability of previously proposed guide structures can be validated. Besides, the effective snow melting technology for the key components of bogies and the equipment cabin covers will be developed.

Figure 14 Low-temperature wind-snow experimental devices for further investigation on snow and ice issue of HSTs

6 Summary

This study reviews the current status of investigation on the snow issue of HST running in snowy and cold regions conducted by High-Speed Train Research Center of Central South University, consisting of the in dependently developed methodology and proposed effective anti-snow flow control schemes to improve the snow-resistance ability of HST. The remaining investigating challenge and the future research work are also presented in this study.

1) The serious snow accumulation on the bogies of the HSTs has a great effect on the working reliability of the key components of bogies, which thereby significantly affects the passenger comfort, operational quality and running safety of the HST running on HSRs in the snowy and cold regions.

2) The previously proposed anti-snow solutions, including removing snow from the subgrade, melting the snow and ice from the bogie surface at vehicle depot and optimizing the vehicle design are found to be the inefficient solutions for the long-distance HSRs located in snowy and cold regions.

3) The snow issue occurring to the bogies of HSTs, induced by the shear flow between underbody slipstream and snow particles, is a typical wind-snow two-phase flow phenomenon, which can be investigated using both CFD simulation and wind tunnel test.

4) The turbulence model selection, physical parameter of snow particles, running speed, and rotating wheels are found to have an important influence on the numerical prediction of the movement characteristics and accumulation distribution of snow particles around the bogie cavities.

5) The proposed anti-snow flow control schemes can effectively deflect the underbody flow characteristics downward at the entrance of the cavity and thereby optimizing the particles’ trajectories, which is of great meaning to avoid the strong impingement on the bogie surfaces caused by massive snow particles. The anti-snow solutions based on flow control method can achieve large snow reduction and thus are recommended for the HSTs.

6) The numerical methodology for the investigation of the snow accumulation around the railway constructions was proposed based on the adaptive mesh method and discrete phase model. The predicting accuracy of the proposed method was validated against the experimental data of previous numerical studies. Further validation work will be performed by comparing the future experimental data. After a comprehensive algorithm validation, the proposed numerical methodology will be employed to explore the anti-snow ability of railway constructions.

7) In the future, a low-temperature wind-snow experimental platform will be built for the investigation of the snow issue of bogie. The movement characteristics around a rear bogie cavity will be recorded using high-speed camera, and the accumulating mass and distribution on the bogies will be accurately measured. Moreover, the heat radiated by motors, gear covers brake calipers and rotating wheels will be reproduced during the experiment, and the complex phase-changing process among snow, water and ice will be considered simultaneously.

References

[1] ALLAIN E, PARADOT N, RIBOURG M. Experimental and numerical study of snow accumulation on a high-speed train [C]// International Symposium of Applied Aerodynamics. Lille: French Aeronautics and Space Society, 2014: FP18-2014-ALLAIN.

[2] CAO Y, HUANG J, YIN J. Numerical simulation of three-dimensional ice accretion on an aircraft wing [J]. International Journal of Heat & Mass Transfer, 2016, 92(3): 34-54. DOI: 10.1016/j.ijheatmasstransfer.2015.08.027.

[3] GIAPPINO S, ROCCHI D, SCHITO P. Cross wind and rollover risk on lightweight railway vehicles [J]. Journal of Wind Engineering & Industrial Aerodynamics, 2016, 153: 106-112. DOI: 10.1016/j.jweia,.03.013.

[4] KLOOW L. High-speed train operation in winter climate [D]. Stockholm, Sweden: KTH Railway Group and Transrail, 2011.

[5] CASA X D L, PARADOT N, ALLAIN E. A numerical modelling of the snow accumulation on a high-speed train [C]// International Conference in Numerical and Experimental Aerodynamics of Road Vehicles and Trains. Bordeaux, 2014.

[6] BETTEZ M. Winter technologies for high speed rail [D]. Trondheim: Norwegian University of Science and Technology, 2011.

[7] LIU M, WANG J, ZHU H. KRAJNOVIC S, GAO G. A numerical study of snow accumulation on the bogies of high-speed trains based on coupling improved delayed detached eddy simulation and discrete phase model [J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 2019, 233(7): 715-730. DOI: 10.1177/0954409718805817.

[8] HUANG Z W, FENG Y H, GAO G J, WANG J B, ZHANG Y. Numerical research of the snow and ice accumulation on the brake calipers of the high-speed trains [J]. Journal of Railway Science and Engineering, 2017, 14(3): 437-444. DOI: 10.19713/j.cnki.431423/u.2017.12.002.

[9] WANG J B, GAO G, ZHANG Y, HE K, ZHANG J. Anti-snow performance of snow shields designed for brake calipers of a high-speed train [J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 2019, 233(2): 121-140. DOI: 10.1177/ 0954409718783327.

[10] THOMAS J. De-icing solution [J]. International Railway Journal, 2009, 49(1): 24-25.

[11] WANG J B, GAO G, LIU M, XIE F, ZHANG J. Numerical study of snow accumulation on the bogies of a high-speed train using URANS coupled with discrete phase model [J]. Journal of Wind Engineering and Industrial Aerodynamics, 2018, 183: 295-314. DOI: 10.1016/j.jweia.2018.11.003.

[12] PAULUKUHN L, WU X. The low temperatures technology concepts and operational experience in Russian high-speed train velaro RUS [J]. Foreign Rolling Stock, 2012, 49(3): 16-19.

[13] ANDERSSON E. Concept proposal for a Scandinavian high-speed train [R]. KTH Railway Group, 2012: 44-53.

[14] BAKER C, JOHNSON T, FLYNN D, HEMIDA H, QUINN A, SOPER D, STERLING M, Train aerodynamics: Fundamentals and applications [M]. Amsterdam: Elsevier Inc, 2019.

[15] MASSO E, PARADOT N, ALLAIN E. The numerical prediction of the aerodynamic noise of the TGV POS high- speed train power car [C]// Noise and Vibration Mitigation for Rail Transportation Systems. Japan, 2012: 437-444.

[16] XIE F, ZHANG J, GAO G. Study of snow accumulation on a high-speed train’s bogies based on the discrete phase model [J]. J Appl Fluid Mech, 2017, 10: 1729-1745. DOI: 10.18869/acadpub.jafm.73.243.27410.

[17] OKAZE T, MOCHIDA A, TOMINAGA Y, NEMOTO M, SATO T, SASAKI Y, ICHINOHE K. Wind tunnel investigation of drifting snow development in a boundary layer [J]. J Wind Eng Ind Aerod, 2012, 104: 532-539. DOI: 10.1016/j.jweia.2012.04.002.

[18] SMEDLEY D J, KWOK K C S, KIM D H. Snow drifting simulation around Davis Station workshop, Antarctica [J]. J Wind Eng Ind Aerod, 1993, 50(93): 153-162. DOI: 10.1016/0167-6105(93)90070-5.

[19] UEMATSU T, NAKATA T, TAKEUCHI K. Three- dimensional numerical simulation of snowdrift [J]. Cold Reg Sci Technol, 2010, 20(1): 65-73. DOI: 10.1016/0165-232X (91)90057-N.

[20] BEYERS M, WAECHTER B. Modeling transient snowdrift development around complex three-dimensional structures [J]. J Wind Eng Ind Aerod, 2008, 96(10): 1603-1615. DOI: 10.1016/j.jweia.2008.02.032 .

[21] TSUCHIYA M, TOMABECHI T, HONGO T. Wind effects on snowdrift on stepped flat roofs [J]. J Wind Eng Ind Aerod, 2002, 90(12-15): 1881-1892. DOI: 10.1016/S0167-6105 (02)00295-7.

[22] Ansys Inc. Fluent user’s guide [M]. Canonsburg: Ansys Inc., 2011.

[23] WANG J B, GAO G J, ZHANGY, XIE F. Numerical simulation of snow accumulation on a bogie of a high-speed train [C]// 2nd International Conference on Industrial Aerodynamics. Qingdao: DEStech Transactions on Engineering and Technology Research, 2017: 771-778. DOI: 10.12783/ dtetr/icia2017/15701.

[24] ZHANG Y N, GAO G J. Investigation of the crosswind influence on the snow on train bogie based on discrete phase [C]// 2nd International Conference on Industrial Aerodynamics. Qingdao: DEStech Transactions on Engineering and Technology Research, 2017: 922-931. DOI: 10.12783/ dtetr/icia2017/15716.

[25] PAZ C, SUAREZ E, GIL C. Numerical study of the impact of windblown sand particles on a high-speed train [J]. J Wind Eng Ind Aerod, 2015, 145(1): 87-93. DOI: 10.1016/ j.jweia.2015.06.008.

[26] ZHOU H, FLAMANT G, GAUTHIER D. Numerical simulation of the turbulent gas-particle flow in a fluidized bed by an LES-DPM model [J]. Chem Eng Res Des, 2004, 82(7): 918-926. DOI: 10.1205/0263876041596788.

[27] ZHU J, HU Z, THOMPSON D J. Flow behaviour and aeroacoustic characteristics of a simplified high-speed train bogie [J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 2016, 230(7): 1642-1658. DOI: 10.1177/0954409715605 129.

[28] SUN W, ZHONG W, ZHANG Y. LES-DPM simulation of turbulent gas-particle flow on opposed round jets [J]. Powder Technol, 2015, 270: 302-311. DOI: 10.1016/j.powtec.2014. 10.039.

[29] CHOI Y, KIM H, YANG S, KIM T. Numerical analysis of particle concentration around the air-inlet of a train in a tunnel by using a discrete phase model [J]. J Mech Sci Technol, 2018, 32(2): 717-722. DOI: 10.1007/s12206-018- 0120-6.

[30] WAN F, PENG X Y, XIE Q F. Numerical simulation of atmosphere migration of uranium tailings grit based on DPM [J]. J Saf Environ, 2013, 13(1): 96-101.

[31] MA W, LIU W, LI L. Numerical simulation of unsteady-state particle dispersion in ferroalloy workshop [J]. Indoor Built Environ, 2015, 24(8): 1069-1081. DOI: 10.1080/19942060. 2019.1595729.

[32] LANDAZURI A C, BRAUNEIS J, SAEZ A E, BETTERTON E. Discrete phase modeling of atmospheric particulate transport from mine tailings [C]// Aiche Meeting Conference Proceedings. Minneapolis, Minnesota: Curran Associates Inc. 2011.

[33] LAI A C K, CHEN F Z. Comparison of a new Eulerian model with a modified Lagrangian approach for particle distribution and deposition indoors [J]. Atmos Environ, 2007, 41(25): 5249-5256. DOI: 10.1016/j.atmosenv.2006.05.088.

[34] ANSARI V, GOHARRIZI A S, JAFARI S. Numerical study of solid particles motion and deposition in a filter with regular and irregular arrangement of blocks with using lattice Boltzmann method [J]. Comput Fluids, 2014, 108: 170-178. DOI: 10.1016/j.compfluid.2014.11.022.

[35] PANKAJAKSHAN R, MITCHELL B J, TAYLOR L K. Simulation of unsteady two-phase flows using a parallel Eulerian–Lagrangian approach [J]. Comput Fluids, 2011, 41(1): 20-26. DOI: 10.1016/j.compfluid.2010.09.020.

[36] ZHOU X, KANG L, GU M. Numerical simulation and wind tunnel test for redistribution of snow on a flat roof [J]. J Wind Eng Ind Aerod, 2016, 153: 92-105. DOI: 10.1016/ j.compfluid.2010.09.020.

[37] WANG J B, ZHANG J, ZHANG Y, XIE F, KRAJNOVIC S, GAO G J. Impact of bogie cavity shapes and operational environment on snow accumulating on the bogies of high-speed trains [J]. Journal of Wind Engineering and Industrial Aerodynamics, 2018, 176: 211-224. DOI: 10.1016/j.jweia.2018.03.027.

[38] GAO G J, TIAN Z, WANG J B, ZHANG Y, SU X C, ZHANG J. Optimization of the anti-snow performance of a high-speed train based on passive flow control [J]. Wind and Structures, 2019. (in Press)

[39] WANG J B, ZHANG J, ZHANG Y, LIANG X F, KRAJNOVIC S, GAO G J. Impact of rotation of wheels and bogie cavity shapes on snow accumulating on the bogies of high-speed trains [J]. Cold Regions Science and Technology, 2019, 159: 58-70. DOI: 10.1016/j.coldregions.2018.12.003.

[40] WANG J B, ZHANG J, XIE F, ZHANG Y, GAO G J. A study of snow accumulating on the bogie and the effects of deflectors on the de-icing performance in the bogie region of a high-speed train [J]. Cold Regions Science and Technology, 2018, 148: 121-130. DOI: 10.1016/j.coldregions.2018.01. 010.

[41] GAO G J, ZHANG Y N, ZHANG J, XIE F, ZHANG Y, WANG J B. Effect of bogie fairings on the snow reduction of a high-speed train bogie under crosswinds using a discrete phase method [J]. Wind and Structures, 2018, 27(4): 255-267. DOI: 10.12989/was.2018.27.4.255.

[42] GAO G J, ZHANG Y, XIE F, ZHANG J, HE K, WANG J B, ZHANG Y N. Numerical study on the anti-snow performance of deflectors in the bogie region of a high-speed train using the discrete phase model [J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 2018, 233: 141-159. DOI: 10.1177/ 0954409718785290.

[43] WANG J B, ZHANG Y, ZHANG J, LIANG X F, KRAJNOVIC S, GAO G J. A numerical investigation on the improvement of anti-snow performance of the bogies of a high-speed train [J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 2019. DOI: 10.1177/0954409719893494.

[44] MIAO X J, HE K. Cause analysis of snow packing in high-speed train’s bogie regions and anti-snow packing design [J]. Journal of Central South University: Science and Technology, 2018, 49(3): 756-763. DOI: 10.11817/j.issn.1672- 7207-2018.03.032. (in Chinese)

[45] ZHANG J, GAO G J, LI L J. Optimization of bottom cover with flow control for CRH380B [C]// 2nd International Conference on Industrial Aerodynamics. Changsha, 2013: 69-76.

[46] GAO G J, CHEN Q R, ZHANG J, ZHANG Y, TIAN Z, JIANG C. Numerical study on the anti-snow performance of deflectors on a high-speed train bogie frame [J]. J Appl Fluid Mech, 2020, 13(5): 1377-1389.

[47] TOMINAGA Y, OKAZE T, MOCHIDA A. CFD modeling of snowdrift around a building: An overview of models and evaluation of a new approach [J]. Build Environ, 2011, 46(4): 899-910. DOI: 10.1016/j.buildenv.2010.10.020.

[48] BEYERS J H M, SUNDSBO P A, HARMS T M. Numerical simulation of three-dimensional, transient snow drifting around a cube [J]. Journal of Wind Engineering & Industrial Aerodynamics, 2004, 92(9): 725-747. DOI: 10.1016/j.jweia. 2004.03.011.

[49] MURAKAMI S, MOCHIDA A, HAYASHI Y. Examining the k-ε model by means of a wind tunnel test and large-eddy simulation of the turbulence structure around a cube [J]. J Wind Eng Ind Aerodyn, 1990, 35: 87-100. DOI: 10.1016/0167-6105(90)90211-T.

[50] OIKAWA S, TOMABECHI T. Daily observation of snowdrifts around a model cube [M]// Snow Engineering. Rotterdam: Balkema, 2000: 369-375. ISBN 90 5809 148 1.

[51] THIIS T K, POTAC J, RAMBERG J F. 3D numerical simulations and full scale measurements of snow depositions on a curved roof [C]// The 5th European & African Conference on Wind Engineering. Florence, Italy, 2009: 4371-4374.

[52] ZHOU X, KANG L, YUAN X, GU M. Wind tunnel test of snow redistribution on flat roofs [J]. Cold Reg Sci Technol, 2016b, 127: 49-56. DOI: 10.1016/j.coldregions.2016.04.006.

[53] TAYLOR D A. Roof snow loads in Canada [J]. Can J Civ Eng, 1980, 7(1): 1-18. DOI: 10.1139/l80-001.

[54] SANT’ANNA F D M, TAYLOR D A. Snow drifts on flat roofs: Wind tunnel tests and field measurements [J]. J Wind Eng Ind Aerodyn, 1990, 34(3): 223-250. DOI: 10.1016/0167- 6105(90)90154-5.

[55] SUNDSBO P A, HANSEN E W M. Modelling and numerical simulation of snow drift around snow fences [M]// Snow Engineering: Recent Advances. Rotterdam: Balkema, 1997: 353-359. ISBN90 54108657.

[56] IVERSEN J D. Comparison of wind-tunnel model and full-scale snow fence drifts [J]. J Wind Eng Ind Aerodyn, 1981, 8(3): 231-249. DOI: 10.1016/0167-6105(81)90023-4.

[57] TOMINAGA Y, OKAZE T, MOCHIDA A. CFD modeling of snowdrift around a building: An overview of models and evaluation of a new approach [J]. Building and Environment, 2011, 46(4): 899-910. DOI: 10.1016/j.buildenv.2010.10.020.

[58] ZHOU X, KANG L, GU M, QIU L, HU J. Numerical simulation and wind tunnel test for redistribution of snow on a flat roof [J]. J Wind Eng Ind Aerodyn, 2016, 153: 92-105. DOI: 10.1016/j.jweia.2016.03.008.

[59] BEYERS J H M, HARMS T M. Outdoors modelling of snowdrift at SANAE IV Research Station, Antarctica [J]. J Wind Eng Ind Aerodyn, 2003, 91(4): 551-569. DOI: 10.1016/s0167-6105(02)00409-9.

[60] BLOCKEN B, STATHOPOULOS T, CARMELIET J, HENSEN J L M. Application of computational fluid dynamics in building performance simulation for the outdoor environment: An overview [J]. J Build Perform Simul, 2011, 4(2): 157-184. DOI: 10.1080/19401493.2010.513740.

[61] MOORE I, MOBBS S D, INGHAM D B, KING J C. A numerical model of blowing snow around an Antarctic building [J]. Ann Glaciol, 1994, 20(1): 341-346. DOI: 10.3189/1994AoG20-1-341-346.

[62] TOMINAGA Y. Computational fluid dynamics simulation of snowdrift around buildings: Past achievements and future perspectives [J]. Cold Regions Science and Technology, 2018, 150: 2-14. DOI: 10.1016/j.coldregions.2017.05.004.

[63] ZHAO L, YU Z X, ZHU F, QI X, ZHAO S C. CFD-DEM modeling of snowdrifts on stepped flat roofs [J]. Wind Struct, 2016, 23(6): 523-542. DOI: 10.12989/was.2016.23.6.523.

[64] KANG L Y, ZHOU X Y, TWANVAN H. CFD simulation of snow transport over flat, uniformly rough, open terrain: Impact of physical and computational parameters [J]. J Wind Eng Ind, 2018, 177: 213-226. DOI: 10.1016/j.jweia.2018. 04.014.

[65] ZHOU X Y, ZHANG Y, GU M. Coupling a snowmelt model with a snowdrift model for the study of snow distribution on roofs [J]. J Wind Eng Ind, 2018, 182: 235-251. DOI: 10.1016/j.jweia.2018.09.014.

(Edited by HE Yun-bin)

中文导读

高速列车转向架积雪的数值与试验研究

摘要:本文综述了降雪区域高速列车转向架积雪问题研究的现状。首先,通过回顾前人研究,调研了高速列车积雪问题产生的背景和近几十年来提出的应对措施。其次,介绍了中南大学高速列车研究中心关于积雪结冰问题的研究方法,包括针对连续相和两相流风洞试验的数值模拟研究平台和实验装置。在此基础上,提出了引导车体底部气流的有效防积雪流动控制方案及其对转向架安装区域积雪运动和累积的影响。最后,从工程应用的角度,提出了高速铁路积雪结冰问题尚待解决的问题与挑战和展望。

关键词:高速列车;积雪问题;转向架;数值仿真;实验

Foundation item: Project(2016YFB1200404) supported by the National Key Research and Development Program of China; Projects(51605044, U1534210) supported by the National Science Foundation of China

Received date: 2019-12-04; Accepted date: 2020-01-13

Corresponding author: GAO Guang-jun, PhD, Professor; Tel: +86-731-82656673; E-mail: gjgao@csu.edu.cn; ORCID: 0000-0002- 8876-4528