铜转炉冶炼过程中余热锅炉水位的优化控制

凌玉华,陈 琳,廖力清,杨欣荣

(中南大学 信息科学与工程学院,湖南 长沙,410083)

摘要: 以110 t铜转炉冶炼过程中余热锅炉为研究对象,探讨了锅筒水位的动态特性,推导了不同扰动之间的关系。分析了传统三冲量锅筒水位控制方案的不足,引入压力参数作为补充控制量,提出了改进的优化控制方案。通过对给水流量和蒸气流量信号的合成处理,简化了静态参数配合的调试和计算,提高了整个控制系统的鲁棒性。实际应用结果表明,锅筒水位的波动范围可控制在50 mm以内,产气量达12 t,同比增加40%,蒸气温度提高30%。

关键词: 余热锅炉; 锅筒水位; 三冲量控制; 优化控制

中图分类号:TP274 文献标识码:A 文章编号: 1672-7207(2005)01-0108-05

Optimum Water Level Control and Realization of Waste

Heat Boiler in Copper Converter Smelting Process

LING Yu-hua, CHEN Lin, LIAO Li-qing,YANG Xin-rong

(School of Information Science and Engineering, Central South University, Changsha 410083, China)

Abstract: Waste heat boiler and the dynamic characteristic of barrel water level in the 110 t copper converter smelting process were discussed, and the relationship between different disturbances was studied. Advanced optimum control scheme was presented after the analysis of shortage in traditional three wash control scheme of boiler water level. In the new control scheme, the pressure of steam was used to be a complement control parameter. By integrating the water and steam flow signals, the robustness of the whole system was improved. And the calculation and adjustment of static parameters became simple. Results of the application show that the maximum variation of barrel water level is less than 50 mm; the output of steam reaches 12 t and the temperature of steam increases by a factor of 3/10.

Key words: waste heat boiler; barrel water levels; three wash control; optimum control

在铜转炉冶炼生产金属铜的工艺过程中,首先是从进料口送入原料,经皮带秤将原料送至转炉内高温熔炼,主要的生产设备有铜转炉、余热锅炉、除氧水箱等。转炉在吹炼过程中会产生大量的高温烟气;余热锅炉的主要作用是对烟气进行降温,同时产生蒸气供其他生产工序使用。由于余热锅炉位于铜转炉烟气出口,一旦发生事故停运,就会直接影响铜转炉的生产,从而造成重大经济损失。因此,在整个冶炼过程中,余热锅炉的控制至关重要。

余热锅炉是一个多输入、多输出且相互关联的复杂控制对象[1],汽包水位是锅炉运行的主要指标。若水位过低,则容易导致锅炉烧坏和爆炸;若水位过高,则会影响汽包的汽水分离,产生蒸气带液现象,易使过热器管壁结垢导致破坏,甚至影响后续生产设备的安全。因此,在生产过程中,维持汽包水位在给定范围是锅筒正常运行的重要指标[2]。

为了实现110 t转炉余热锅炉汽包水位的自动控制,作者对传统的三冲量控制方案进行改进和优化,并在工业生产现场予以实施。

1 余热锅炉水位波动的原因

余热锅炉水位波动的产生与转炉的生产工序紧密相关。转炉生产是间断的,转炉余热锅炉频繁启动和停炉,使汽包水位频繁上升和下降。转炉在非吹氧期间,余热锅炉的下降管、受热管及上升管中充满了水。当转炉开始吹氧时,受热管中的水开始蒸发并形成汽水混合物,体积急剧膨胀,导致汽包内的水位急剧上升。吹氧结束后,余热锅炉停止运行,受热管中的水停止蒸发,由吹氧期间的汽水混合物变成水,体积急剧缩小,导致汽包水位急剧下降。汽包水位波动范围与转炉容量、汽包容积、压力、余热锅炉受热面面积、转炉在吹氧期间的脱碳速度和不同阶段、转炉煤气是否回收等因素有关[3]。

110 t转炉余热锅炉的锅筒容量小,扰动对水位影响明显。根据实测结果,当转炉开始吹氧后3 min,锅炉汽包内的水位比吹氧前上升约200 mm,最高时为250 mm。这种大的水位波动范围,其他锅炉只有在启动和停止时才可能出现,这是转炉余热锅炉与其他锅炉的不同之处。

2 锅炉汽包水位的动态特性

锅炉汽包水位的动态特性包括干扰通道的动态特性和控制通道的动态特性[4]。其中干扰通道的动态特性是指蒸气负荷(蒸气流量)对水位的影响,而控制通道的动态特性是给水流量对水位的影响[2]。锅炉汽包水位的动态特性如下。

2.1 给水流量扰动FW

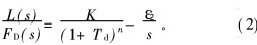

在给水流量扰动下,锅筒水位对象的传递函数为:

式中: ,为给水流量作用下,相应阶跃曲线的飞升速度(即给水流量变化单位流量时,水位的变化速度);ΔFW为给水流量的变化值;ΔL为水位变化值;τ为纯延迟时间。

,为给水流量作用下,相应阶跃曲线的飞升速度(即给水流量变化单位流量时,水位的变化速度);ΔFW为给水流量的变化值;ΔL为水位变化值;τ为纯延迟时间。

由式(1)可知,在给水流量扰动下,水位对象相当于一个积分环节和一个纯滞后环节串联的对象。

2.2 蒸气流量扰动FD

在蒸气流量阶跃增加的开始阶段,由于锅筒压力减小,锅筒内汽水混合物体积膨胀,对水位的影响大于对汽水流量不平衡的影响,导致水位在短时间内升高的“假水位”现象。在蒸气流量扰动FD下,水位对象的传递函数为:

式中:K为惯性环节放大倍数;Td为蒸气流量扰动下惯性环节的时间常数;n为惯性环节的阶数,n=1~3,与汽包压力等因素有关; ,为蒸气流量作用下,阶跃相应曲线的飞升速度。

,为蒸气流量作用下,阶跃相应曲线的飞升速度。

由式(2)可知,在蒸气流量扰动下,水位对象相当于一个由一阶或高阶惯性环节与一阶积分环节反向并联的对象。

2.3 燃烧率扰动Ff

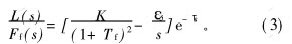

在燃烧率扰动Ff作用下,水位对象的传递函数为:

式中:Tf为燃烧率扰动下惯性环节的时间常数; ,为燃烧率扰动作用下,阶跃相应曲线的飞升速度;τ为纯滞后时间,与热交换面积有关,面积越大,滞后时间越长。

,为燃烧率扰动作用下,阶跃相应曲线的飞升速度;τ为纯滞后时间,与热交换面积有关,面积越大,滞后时间越长。

由式(3)可知,燃烧率扰动与蒸气流量扰动类似,但多了一个延时时间为τ的纯滞后环节。

3 余热锅炉的控制方案

3.1 传统三冲量控制方案分析

锅炉水位控制的目的是要克服锅炉负荷变化以及各种干扰对水位的影响,保证水位在允许的范围内变化。锅炉汽包水位的经典控制方案是三冲量控制方案[5],它实际上是一个把蒸气流量作为前馈信号的串级控制系统。系统中的汽包水位h是被控变量,是主冲量信号;蒸气流量qD和给水流量qW是2个辅助冲量信号。当锅炉产生的蒸气量与进入锅炉筒体的给水量相等时,锅炉汽包水位保持稳定;否则,就需要由蒸气前馈及补偿系统通过相应的计算(含PID运算)和输出来保证水位稳定。

在余热锅炉的水位控制中,当烟气温度稳定时,传统的三冲量控制方案基本能够满足控制要求。但是,由于铜转炉冶炼过程余热锅筒容量小,扰动对水位影响明显,当烟气温度下降或上升时,传统的三冲量控制不能满足要求[6]。因为当烟气温度下降时,锅筒压力减小,锅筒内的水迅速汽化,导致假水位迅速上升。此时,传统的三冲量控制虽然能够维持物料平衡,但是由于2个控制回路的作用相反,锅筒水位的变化幅度过大,锅筒给水流量会产生剧烈波动甚至误动作;在烟气的升温过程中,锅筒内的水温迅速升高,水会迅速汽化,导致虚假水位急剧上升。这时,如果采用传统三冲量控制,将导致锅筒补水不及时,产生不安全因素。因此,需对传统的三冲量控制方案进行改进,以满足控制要求。

3.2 三冲量控制方案的改进

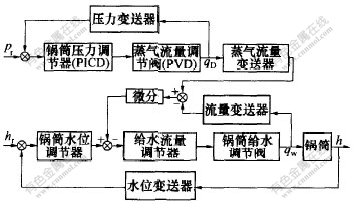

蒸气流量扰动FD和燃烧率扰动Ff对水位对象的传递函数类似。根据现场调试发现,可以通过调节蒸气流量来控制燃烧率扰动对水位的影响。只要压力给定值pr能跟随燃烧率扰动,就可以通过对压力的控制来消除水位的变化[7,8]。改进控制方案如图1所示,其中,hr为汽包水位给定值,h为汽包水位实测值。

图 1 改进三冲量控制框图

Fig. 1 Diagram of improved three wash control

based on drum water level

在改进控制方案中,将锅筒压力作为1个单独控制量,用1个独立的PID控制器进行控制,压力回路通过调节锅筒蒸气流量进行控制。蒸气流量qD和给水流量qW不直接引入控制回路的前馈,而是将d(qW-qD)/dt作为前馈信号[9]。这种做法的优越性在于:

a. 响应速度加快。因为微分作用可以提前反映扰动的变化。由于蒸气流量频繁变化,因此,要求给水流量跟随速度快,反应敏捷。当蒸气流量加大时,微分作用加强,前馈信号加大,给水调节控制器动作迅速,可以消除qD和qW对锅筒水位的影响。

b. 参数整定简化。常规控制方案必须要考虑控制系统的静态特性,即在实现控制方案时需要按照静态配比来整定各参数。使用d(qW-qD)/dt作为前馈信号后,在稳态条件下,微分的输出为0,故不需要考虑水位控制的静态特性。只要调节微分器的作用强度,便可以达到较好的控制效果。

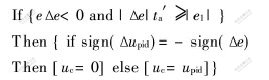

余热锅炉水位具有大惯性、大滞后的特点,采用常规PID控制器进行调节会存在较大的超调,需对PID控制算法进行改进[10-12],并引入如下控制规则[13-15]:

其中:e为给定值和实测值的偏差;Δe为偏差的变化量;ta′为响应时间;uc为控制器的实际输出;upid为PID控制器的计算输出。

实际运行结果证明,采用优化算法后,水位的超调现象明显减少,如图2所示。图中T为采样周期,实线和虚线分别表示采用常规算法和优化算法时的水位阶跃响应曲线。

1—常规算法; 2—优化算法

图 2 水位阶跃响应曲线示意图

Fig. 2 Sketch of step response curves of

drum water level

3.3 锅筒压力设定

由于烟气温度不稳定,需要跟随温度变化曲线对锅筒压力进行设定。本系统采用了浮动设定的办法,其具体思路如下[15]:

a. 在升温过程中,首先根据锅筒的设计参数确定一个基准值ph,14 t锅炉的设计压力为300 N,根据经验设定200 N为升温时蒸气流量调节阀的开启压力,当锅筒压力达到200 N时,调节阀开始动作,直至阀门全开,然后跳入下一个过程。

b. 在降温过程中,首先要根据稳定工况时锅筒的压力设定一个阀值,阀值的设定方法为:

式中:ps为压力设定值;pv为阀门全开时锅筒压力,k1为设定差值。

当锅筒压力开始下降时,蒸气流量调节阀便能及时动作,减缓锅筒压力的变化速度,达到消除假水位的目的;当锅筒压力下降,调节阀开始关断时,设定值维持最高值,不再进行变化;当锅筒压力持续下降到基准值ph时,将基准值作为压力回路的设定值。

4 控制方案的实现

4.1 控制系统的硬件选型

若采用常规仪表对锅炉水位进行控制,则不仅系统所用仪表设备多、结构复杂、实施及调试难度大,而且难以保证系统的可靠性。而可编程控制器可靠性高,组态灵活,编程简易,系统设计安装和调试周期短,为实现锅炉水位控制的设计、调试提供了有利条件。用可编程控制器进行控制,软件设计的工作主要是系统组态,即如何调用一系列控制子程序和填写菜单,许多具体的工作均由系统内部程序完成,因此,使用可编程控制器对余热锅炉水位进行控制,能大大加快系统设计和调试的进程。

通过对比分析,本系统选用美国通用电气(GE)公司生产的GE FANUC 90-30型PLC。90-30型PLC是GE Fanuc系统90可编程控制器中的一种,功能强,易于组态,便于安装。其364CPU自带PID回路控制功能,支持TCP/IP通讯协议,为上位机的监控提供了便利条件。系统采用可编程控制器结合上位机监控的设计方案,所有的模拟量经采集以后都转化成整型数进行处理,开方器、加法器、阻尼器和分流器都可以通过程序计算实现,节约了大量的硬件成本。监控软件采用CITECT5.4。

4.2 控制方案的程序实现

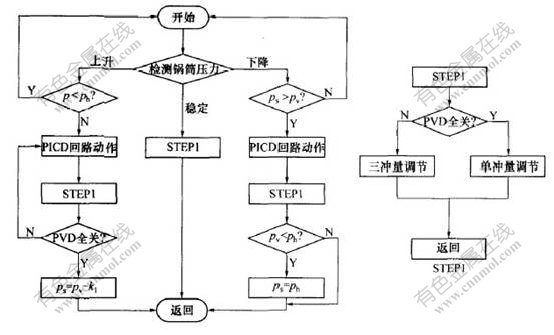

程序充分利用了GE90-30PLC的控制功能。该PLC本身具有单回路PID运算功能,因而使得控制方案的实现非常方便。系统控制程序框图如图3所示,该控制框图中共有3个分支,在建立3个单独PID回路以后,剩下的工作就是将它们根据框图进行组合。同时,需要注意的是应合理设置各个信号的比例系数,保证控制系统的快速、稳定和准确性[2]。PID回路的算法改进和模糊控制规则通过上位机监控软件编程实现。

图 3 控制程序流程图

Fig. 3 Diagram of control program

5 结 语

a. 所研制的余热锅炉在某冶炼厂110 t铜转炉冶炼生产过程中投入运行,通过上位机和PLC的混合编程,降低了成本和运行风险。

b. 使用所研制的余热锅炉,锅筒水位的波动范围可控制在50 mm以内,产气量达到12 t,同比增加40%,蒸气温度提高30%。

c. 该余热锅炉控制系统抗干扰能力强,动作及时,可实现锅炉的自动运行,运行效益大幅度提高。

参考文献:

[1]金以慧.过程控制 [M].北京:清华大学出版社,1998.

JIN Yi-hui. Process Control[M]. Beijing: Tsinghua University Press,1998.

[2]RAY K S, MAJUMDER D D. Application of Circle Criteria for Stability Analysis of Linear SISO and MIMO Systems Associated with Fuzzy Logic Controller[J]. IEEE Trans Syst Man Cybern, 1984,14:345-349.

[3]王嵩岐. 废热锅炉两种非正常运行的原因分析 [J].齐鲁石油化工,1994,22(1):44-46.

WANG Song-qi. Reasonable Analysis on Two Kinds Abnormal Running of Waste Heating Boiler [J]. Qi-lu Petrochemical Technology, 1994,22(1):44-46.

[4]张亮明,夏桂娟.工业锅炉热工检测与过程控制[M]. 天津:天津大学出版社,1992.

ZHANG Liang-ming, XIA Gui-juan. Process Examine and Control of Industrial Boiler [M]. Tianjin: Tianjin University Press,1992.

[5]刘吉臻. 协调控制与给水全程控制[M]. 北京:水利电力出版社,1996.

LIU Ji-zhen. Harmonize Control and the Control of Water Supplying Process[M]. Beijing: Irrigator and Electric Press,1996.

[6]KUNDU K M, BANEVJEE D, BHADURI D. Theoretical Analysis on Flame Stabilization by a Bluff-body[J]. Combustion Science and Technology, 1977,17:53-57.

[7]张蕴端. 自动化及仪表[M]. 上海:华东化工学院出版社,1990.

ZHANG Yun-duan. Automatic and Meters[M]. Shanghai: East China College of Chemistry Press,1990.

[8]赵景波,周祥龙. 预测函数控制在工业锅炉燃烧系统上的应用[J].工业仪表与自动化装置,2003,(3):24-26.

ZHOU Jing-bo, ZHOU Xiang-long. The Application of Forecast Function-based Control in Boiler′s Burning System[J]. Industrial Meters and Auto-Instrument, 2003, (3):24-26.

[9]程昱宁. 基于模糊Smith串级复合控制的温室加热系统研究[J].上海大学学报,2000,4(增刊):143-147.

CHENG Yi-ning. Fuzzy-smith Based Control of a Hothouse Heating System[J]. Journal of Shanghai University, 2000, 4(Supplement):143-147.

[10]ASTROM K J, HANG C C, PERSON P. Towards Intelligent PID Control[J]. Automatic,1998, 28(1):251-261.

[11]TZAFESTAS S, NIKOLAOS P P. Incremental Fuzzy Expert PID Control[J]. IEEE Transactions on Industrial Electronics,1990,37(5):365-371.

[12]孙伟.三冲量锅筒水位自适应神经元控制算法[J],中国矿业大学学报, 1996,25(3):43-47.

SUN Wei. A Self-adaptive Neural Network-based Control of Boiler′s Tri-parameters Controller[J]. Journal of Chinese Mineral University, 1996,25(3):43-47.

[13]TONG R M. Some Properties of Fuzzy Feedback Systems[J]. IEEE Trans Syst Man Cybern, 1980,10:327-330.

[14]BARTO A G, SUTTON R S, ANDARSON C W. Neuron Like Adaptive Elements That Can Solve Difficult Learning Control Problems[J]. IEEE Trans Syst Man Cybern, 1983, 13(5): 834-846.

[15]KICKERT W J M, MATNDANI E H. Analysis of a Fuzzy Logic Controller[J]. Fuzzy Sets and Systems, 1978,1(1):29-44.

收稿日期:2004-02-16

基金项目:国家技术创新项目(02CJ-06-01-11)

作者简介:凌玉华(1965 -),女,湖南衡阳人,教授,从事智能检测与智能仪器应用研究

论文联系人: 凌玉华,女,教授;电话:0731-8830751(O);E-mail:yhling@mail.csu.edu.cn