反复镦压AZ31-Mg2Si原位复合材料的组织和力学性能

来源期刊:中国有色金属学报(英文版)2014年第12期

论文作者:郭 炜 王渠东 叶 兵 周 浩 刘鉴锋

文章页码:3755 - 3761

关键词:AZ31-Mg2Si复合材料;Mg2Si颗粒;反复镦压;组织;力学性能

Key words:AZ31-Mg2Si composite; Mg2Si particle; repetitive upsetting; microstructure; mechanical properties

摘 要:采用常规铸造方法制备AZ31-4.6% Mg2Si复合材料,在400 °C对铸态复合材料进行1、3和5道次的反复镦压(RU)剧烈变形。材料流动的有限元分析表明:1道次后变形集中于试样底部区域,5道次后可获得均匀的变形。多道次反复镦压过程中基体施加的剪切应力使树枝状和汉字状Mg2Si相破碎成小颗粒,随着反复镦压道次的增加,晶粒尺寸逐渐减小,Mg2Si颗粒分布逐渐均匀,同时强度和塑性显著提高,在400 °C 反复镦压5道次后,AZ31-4.6% Mg2Si复合材料抗拉强度和伸长率分别为248 MPa和9.8%,而原始铸态复合材料的抗拉强度和伸长率分别只有128 MPa和5.4%。

Abstract: AZ31-4.6% Mg2Si (mass fraction) composite was prepared by conventional casting method. Repetitive upsetting (RU) was applied to severely deforming the as-cast composite at 400 °C for 1, 3, and 5 passes. Finite element analysis of the material flow indicates that deformation concentrates in the bottom region of the sample after 1 pass, and much more uniform deformation is obtained after 5 passes. During multi-pass RU process, both dendritic and Chinese script type Mg2Si phases are broken up into smaller particles owing to the shear stress forced by the matrix. With the increasing number of RU passes, finer grain size and more homogeneous distribution of Mg2Si particles are obtained along with significant enhancement in both strength and ductility. AZ31-4.6% Mg2Si composite exhibits tensile strength of 284 MPa and elongation of 9.8% after 5 RU passes at 400 °C compared with the initial 128 MPa and 5.4% of original AZ31-4.6%Mg2Si composite.

Trans. Nonferrous Met. Soc. China 24(2014) 3755-3761

Wei GUO1,2, Qu-dong WANG1,2, Bing YE1,2, Hao ZHOU1, Jian-feng LIU1

1. National Engineering Research Center of Light Alloy Net Forming, Shanghai Jiao Tong University, Shanghai 200240, China;

2. State Key Laboratory of Metal Matrix Composites, Shanghai Jiao Tong University, Shanghai 200240, China

Received 17 October 2013; accepted 29 October 2014

Abstract: AZ31-4.6% Mg2Si (mass fraction) composite was prepared by conventional casting method. Repetitive upsetting (RU) was applied to severely deforming the as-cast composite at 400 °C for 1, 3, and 5 passes. Finite element analysis of the material flow indicates that deformation concentrates in the bottom region of the sample after 1 pass, and much more uniform deformation is obtained after 5 passes. During multi-pass RU process, both dendritic and Chinese script type Mg2Si phases are broken up into smaller particles owing to the shear stress forced by the matrix. With the increasing number of RU passes, finer grain size and more homogeneous distribution of Mg2Si particles are obtained along with significant enhancement in both strength and ductility. AZ31-4.6% Mg2Si composite exhibits tensile strength of 284 MPa and elongation of 9.8% after 5 RU passes at 400 °C compared with the initial 128 MPa and 5.4% of original AZ31-4.6%Mg2Si composite.

Key words: AZ31-Mg2Si composite; Mg2Si particle; repetitive upsetting; microstructure; mechanical properties

1 Introduction

Mg matrix composites are superior candidates for lightweight structural applications in the industry due to their low density and high specific strength. Mg–Si alloys are in situ Mg matrix composites containing hard Mg2Si particles [1]. It has been proved that adding Si to pure Mg or its alloys can produce substantial improvement in strength, hardness, creep resistance and wear property [2–4]. However, a mass of coarse dendritic Mg2Si and Chinese script type Mg2Si phases incline to form in the as-cast Mg–Si alloys when a high amount of Si is presented, and they are harmful to the mechanical properties [5]. For the sake of obtaining fine Mg2Si particles with beneficial shapes, different kinds of methods have been employed, such as rapid solidification [6], modification [7,8], solution treatment [9,10], mechanical alloying [11], and hot extrusion [12]. However, refining of Mg2Si is very limited, and it is difficult to achieve uniform distribution. Recently, researchers have paid much attention to the severe plastic deformation (SPD) techniques such as equal channel angular pressing (ECAP) [13,14], cyclic extrusion compression (CEC) [15,16], high pressure torsion (HPT) [17,18], cyclic closed-die forging (CCDF) [19], and repetitive upsetting (RU) [20]. SPD has been accepted as one of the most effective methods for processing bulk ultrafine-grained (UFG) materials. SERRE et al [21] studied the microstructure of AZ31 Mg alloy processed by HPT through 5 turns at 453 K. The results showed that HPT introduced significant grain refinement to an average grain size of ~0.5 μm. GAN et al [22] investigated the effect of ECAP on Mg–3.2Si alloy. They found that grains and eutectic Mg2Si particles were refined. Furthermore, the yield strength and tensile strength were notably increased. WANG et al [23] studied microstructure and mechanical properties of AZ31–0.5Si alloy processed by ECAP. The results indicated that the Chinese script type Mg2Si phase broken up and dispersed in the matrix, and the ductility was significantly improved. The study by ZHANG et al [24] revealed that most Mg2Si particles in Mg-9Al-6Si alloy were less than 20 μm after 12 CEC passes. In addition, the investigation by METAYER et al [25] showed that wear resistance of Mg-1.5Si alloy improved with CCDF process passes.

Compared with other SPD techniques, RU is a novel processing method and it produces higher strains per pass. More homogeneous structure of the material may be obtained because it involves multi-directional deformation. The relevant investigation showed that AZ31 alloy exhibited mean grain size of 1.3 μm and yield strength of 294 MPa after 5 RU passes at 250 °C. Moreover, more homogeneous microstructure of the AZ31 alloy was obtained [26]. The microstructure and texture evolution of Mg-9.8Gd-2.7Y-0.4Zr alloy processed by RU were also investigated. Reasonably equiaxed uniform microstructure was achieved and randomized texture was obtained [20]. The study by LIU et al [27] showed that with the increase of RU passes, the grains of the Mg-3.03Nd-0.24Zn-0.49Zr alloy were significantly refined and the alloy exhibited elongation of 30.1% after 8 RU passes. It is expected that the RU process will be an excellent candidate for refining Mg2Si particles and homogenizing their distribution in Mg matrix. However, few studies have been carried out on RU processing of Mg matrix composites.

In the present work, the deformation flow process of the sample during repetitive upsetting was simulated by using DEFORM-3D. Then, the improvements of microstructure and mechanical properties were examined in an as-cast AZ31-Mg2Si composite subjected to RU at high temperature. Emphases were put on the refinement of grain and the homogeneous distribution of Mg2Si particles induced by RU.

2 Experimental

Commercial AZ31 Mg alloy ingot (Mg-3Al-1Zn- 0.4 Mn, mass fraction, %) and Si particles (99.9%, mass fraction) were used as starting materials to fabricate the AZ31-Mg2Si composite. After the melt was poured into a steel mold and the ingot was obtained, the composition was measured and the actual Si mass fraction of the AZ31-Mg2Si composite was 1.7% (i.e., AZ31-4.6% Mg2Si).

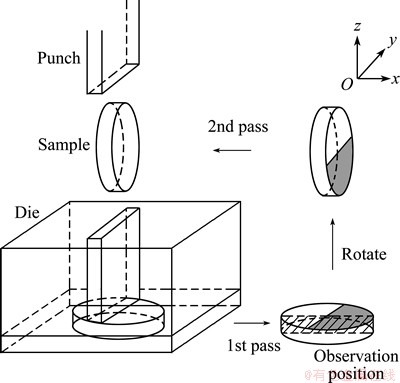

Before RU, as-cast AZ31-4.6%Mg2Si billet was machined into samples with dimensions of d100 mm×20 mm. The sketch of the RU process is shown in Fig. 1. The device consisted of upper die, lower die, and a punch for external loading. The chamber of the lower die and the sample were of equal dimension. A sample lubricated with graphite was placed into the upper die before being heated to 400 °C followed by holding at this temperature for 30 min. Then it was pressed into the lower die by the punch with a constant speed (4 mm/s). After pressing, each sample was taken out and rotated 90° around Y-axis, and reinserted into the upper die for next pressing. Samples were exposed to 1, 3, and 5 passes of RU processing, respectively.

Fig. 1 Schematic representation of RU processing

The position of microstructure observation is marked in Fig. 1, which locates at the largest Y-plane of the sample. The burnished AZ31-4.6% Mg2Si composite was eroded by a mixture of 1 g oxaldehyde, 1 mL nitric acid and 1 mL acetic acid in 150 mL water. Microstructure was observed by using optical microscopy. The flat tensile specimens (with a gage section of 10 mm×3.5 mm×2 mm) were machined from the central part of the RUed samples with the tensile axes parallel to Y-direction. Tensile tests were conducted at room temperature with an initial strain rate of 8.3×10-4 s-1.

3 Finite element modeling

The RU process of AZ31-4.6%Mg2Si composite at 400 °C was simulated by using the commercial finite element (FE) code DEFORM-3D. During RU processing, a flat-faced punch was applied to pushing the composite sample through the chamber of upper die for a total displacement of 80 mm, and the constant speed of the punch was 4 mm/s. The die geometry was taken with chamber angle Φ=90° and corner angle Ψ=0°. The cylindrical sample had a diameter of 100 mm and a height of 20 mm. The punch and die were modeled with rigid bodies. The sample was modeled as elastic-plastic material with Poisson ratio (ν) of 0.35 and elastic modulus (E) of 45 GPa, which were based on the data of AS41 alloy [28]. The stress-strain relationship of the plastic deformation of AZ31-4.6% Mg2Si at different strain rates were established using the testing data generated by GLEEBLE 3500 thermal simulator, and the data loaded into the software included material behavior at temperatures from 300 °C to 450 °C with strain rates from 0.005 to 0.5 s-1 [29]. The sample was meshed with 6001 four node tetrahedron elements. All simulations used automatic remeshing to adapt the high strains and the germination of flow localization during RU. A friction coefficient between the die and the sample was adopted to be 0.3, which was based on the data of AZ31 alloy [30].

4 Results and discussion

4.1 FE simulation of RU process

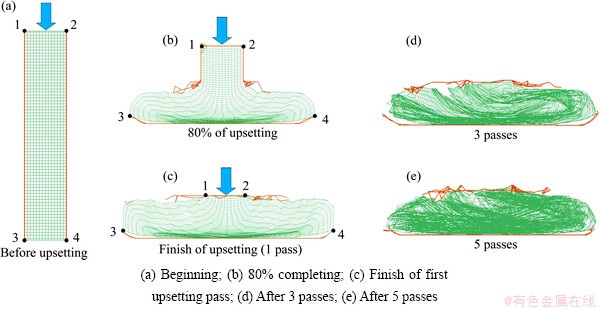

Figure 2 shows the different stages of deformation flow net of the sample from 1 to 5 RU passes. Figures 2(a), (b) and (c) show the beginning, 80 % completing, and the finish of the first upsetting pass, respectively. The flow net clearly reveals that the deformation is concentrated in the bottom region of the sample. In order to understand the deformation behavior easily, four corners (1, 2, 3, 4) of the sample are indicated. During the first upsetting pass, the bottom corners (3, 4) are extensively elongated. However, the top corners (1, 2) stay in the same location even at the finish of deformation. This explicitly shows that the initial bottom region of 20 mm is elongated to the final bottom region of about 100 mm, and the top region doesn’t experience any deformation. In addition, very high tensile deformation is attained in the bottom region. Figures 2(d) and (e) show flow net of the sample after 3 and 5 RU passes. After 3 passes, it can be seen that the flow net becomes very disorder. Furthermore, more homogeneous blend of the flow net is obtained after 5 passes. This suggests that more uniform deformation of the AZ31-4.6%Mg2Si composite will be achieved with the increase of pass number.

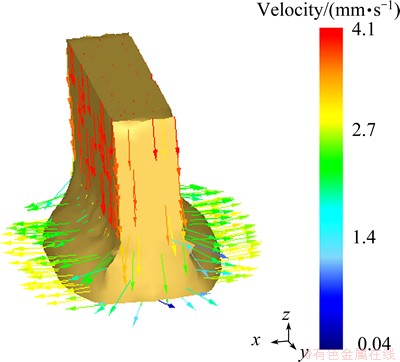

The velocity vector field of the sample during upsetting process at 50% of deformation is shown in Fig. 3. It is the stage that the sample is forced to flow through the 90° die-chamber intersection after the upper die is filled. The material divides into two flows in the lower die and each stream is similar to a typical ECAP. On X-plane, the material points at the upper end have quicker flowing speed.

4.2 Microstructural evolution during RU process

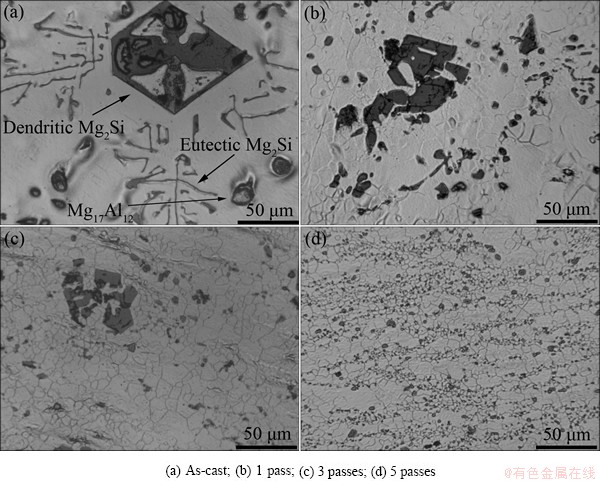

Figure 4(a) shows the microstructure of as-cast AZ31-4.6%Mg2Si composite, which is composed of a-Mg matrix (light gray color), Mg2Si phase (gray color) and Mg17Al12 phase (white color). The Mg2Si phases are presented as dendritic and Chinese script type morphologies. The dendritic primary Mg2Si particles have a length along the first axial direction more than 80 μm. The microstructures of the composite subjected to 1, 3, and 5 RU passes at 400 °C are shown in Figs. 4(b), (c) and (d), respectively. After 1 pass, the average grain size is greatly refined to ~11.3 μm, which is attributed to the dynamic recrystallization (DRX) during upsetting. Grain refining by DRX in deformed Mg has been widely observed, peculiarly at high temperatures [31,32]. Since Mg has fairly lower stacking fault energy (60-78 kJ/mol), DRX generally dominates in deformed Mg at elevated temperatures (above 513 K) [33]. SU et al [34] studied the microstructure evolution of AZ31 alloy during ECAP at 200 °C, and the results showed that the grain refinement mechanism was a combination of mechanical shearing and subsequent continuous recovery, recrystallization, growth of grains and subgrain cells to produce refined and equiaxed grains [34]. It is known that large particles (>1 μm) activate nucleation for recrystallization while small particles prohibit recrystallization [35]. In the present work, since the Mg2Si particles are much larger than 1 μm, the particles activate nucleation for recrystallization during upsetting. The grain distribution of the composite is still not homogeneous with blended microstructure of coarse and fine grains. The grains continue to be refined upon further upsetting. After 3 passes, the average grain size is refined to ~7.2 μm. A uniform grain structure is obtained after 5 passes and the mean grain size decreases to 6.3 μm. Activation of recrystallization and limitation of grain growth by the presence of the particles lead to the grain refinement.

Fig. 2 Deformed sample drawn by flow net during different stages of RU

Fig. 3 Velocity vector field of sample during upsetting process at 50% of deformation

The effect of RU processing on the Mg2Si morphology is also notable. After 1 pass, the orderly distribution of dendritic and Chinese script type Mg2Si particles is broken up. These coarse Mg2Si particles are divided into smaller ones and the microstructure is still very inhomogeneous. With more upsetting pass, higher strain is imposed to the composite and the proportion of broken particles increases. With continuous 90° revolve of the sample for following pass processing, a cross-shear exerts on the sample. Mg2Si particles are further broken into finer ones and their distribution becomes more homogeneous. After 5 passes, most of the Mg2Si particles are nearly equiaxed with a size less than 5 μm. In this work, upsetting introduces the mushrooming deformation and makes the Mg matrix as well as Mg2Si particles flow transversely at the former pass, and then upsetting makes them move longitudinally at the following pass. During the multi-pass processing, Mg2Si particles are broken into smaller fragments by the shearing stress imposed by the matrix. Thus, the Mg2Si particles are refined gradually and their distribution becomes uniform. It should be noticed that there are still some large polygonal Mg2Si particles of ~7 μm. This could be attributed to that the shearing stress imposed by the matrix flow is not sufficient to further break these Mg2Si particles into smaller ones.

Fig. 4 Microstructures of AZ31-4.6% Mg2Si composite after different passes of RU processing at 400 °C

Fig. 5 Tensile stress-strain curves of AZ31-4.6% Mg2Si composite processed by RU at 400 °C

4.3 Mechanical properties improvement after RU

The tensile stress–strain curves at room temperature for AZ31-4.6% Mg2Si composite after RU processing are shown in Fig. 5. The strength and ductility continuously improve with an increase of the RU pass number. Finally, the composite shows an improvement in the ultimate tensile strength (UTS) from 128 MPa for 0 pass (the as-cast sample) to about 284 MPa for 5 passes. The influence of RU on the yield strength (YS) is more effective, and the YS increases from 43 MPa for 0 pass to about 205 MPa for 5 passes. The composite after 5 passes exhibits higher elongation to fracture of about 9.8% in comparison to only 5.4% for the as-cast sample. The mechanical properties of Mg-Si alloys are widely known to strongly relate to the size, shape, and distribution of the Mg2Si phases in the microstructure [36,37]. In the as-cast AZ31-Mg2Si composite, coarse dendritic or Chinese script morphology Mg2Si particles make the AZ31 matrix discontinuous. The matrix may strongly deform and it leads to fracture during tensile testing. Also, stress concentrations and high strain occur easily in the AZ31matrix near the sharp tips of the coarse dendritic or Chinese script type Mg2Si particles. As such, the microcrack inclines to nucleate and propagate in the particles, and void is formed at the interface between the matrix and the particles. With the accumulation of strain, microcrack quickly grows and void coalesces. Thus, the tensile properties of as-cast composite are deteriorated. After 5 passes of RU, the refined Mg2Si particles distribute homogeneously in the grains and along grain boundaries. Acting as strong obstructor, the particles can pin and retard the dislocation’s movement and therefore strengthen the composite by dispersion strengthening mechanism. The finer Mg2Si particles are not easy to fracture under external stress and lead to higher UTS. The transformation of coarse irregular Mg2Si particles to polygonal ones reduces stress concentration on Mg2Si and the matrix. Thus, the fracture possibility of them decreases. Also, the uniform distribution of Mg2Si confines Mg matrix deformation path and results in complex deformation pattern for the enhancement of ductility. Refinement and uniformity of the matrix grain after RU also contribute to the improvement of strength and ductility. Mg alloy with large size grain is prone to form twins in a narrow region at higher strains leading to fracture under tension, whereas smaller size grain results in more homogeneous deformation.

5 Conclusions

1) The FE simulation by DEFORM-3D indicates that deformation is concentrated in the bottom region of the sample after 1 pass, and much more uniform deformation is obtained after 5 passes.

2) Mg2Si and grain size gradually decrease with the increasing pass number. After 5 passes, the original large dendritic and Chinese script type Mg2Si particles are broken up into much finer ones with homogeneous distribution in matrix with an average grain size of about 6.3 μm.

3) Both strength and ductility of the composite improve notably with the increasing RU pass number. AZ31-4.6% Mg2Si composite shows a tensile strength of 284 MPa and elongation of 9.8% after 5 RU passes at 400 °C compared with the initial 128 MPa and 5.4% of as-cast alloy.

References

[1] MABUCHI M, HIGASHI K. Strengthening mechanisms of Mg-Si alloys [J]. Acta Materialia, 1996, 44(11): 4611-4618.

[2] ALIZADEH R, MAHMUDI R. Effects of Sb addition on the modification of Mg2Si particles and high-temperature mechanical properties of cast Mg-4Zn-2Si alloy [J]. Journal of Alloys and Compounds, 2011, 509(37): 9195-9199.

[3] ASL K M, TARI A, KHOMAMIZADEH F. The effect of different content of Al, RE and Si element on the microstructure, mechanical and creep properties of Mg-Al alloys [J]. Materials Science and EngineeringA, 2009, 523 (1-2): 1-6.

[4] HU Yong, RAO Li. Effect of particulate reinforcement on wear behavior of magnesium matrix composites [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(11): 2659-2664.

[5] WANG Hui-yuan, ZHA Min, LIU Bo, WANG Dong-ming, JIANG Qi-chuan. Microstructural evolution behavior of Mg-5Si-1Al alloy modified with Sr–Sb during isothermal heat treatment [J]. Journal of Alloys and Compounds, 2009, 480(2): L25-L28.

[6] SHENG Shao-ding, CHEN Ding, CHEN Zhen-hua. Effects of Si addition on microstructure and mechanical properties of RS/PM (rapid solidificationand powder metallurgy) AZ91 alloy [J]. Journal of Alloys and Compounds, 2009, 470(1-2): L17-L20.

[7] HU Ji-long, TANG Chang-ping, ZHANG Xin-ming, DENG Yun-lai. Modification of Mg2Si in Mg-Si alloys with neodymium [J]. Transactions of Nonferrous Metals Society of China, 2013, 23(11): 3161-3166.

[8] TANG Shou-qiu, ZHOU Ji-xue, TIAN Chang-wen, YANG Yuan-sheng. Morphology modification of Mg2Si by Sr addition in Mg-4%Si alloy [J]. Transactions of Nonferrous Metals Society of China, 2011, 21(9): 1932-1936.

[9] CAO Li-jie, MA Guo-rui, TANG Chun-chong. Effects of isothermal process parameters on semisolid microstructure of Mg-8%Al-1%Si alloy [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(10): 2364-2369.

[10] JIA Shu-zhuo, XU Chun-jie, GUO Xue-feng, ZHENG Shui-yun, ZHANG Zhong-ming,  Tao. Influence of solution heat treatment and aging on microstructure and properties of in-situ Mg2Si/Mg-Al matrix composite [J]. Transactions of Materials and Heat Treatment, 2006, 27(6): 25-28. (in Chinese)

Tao. Influence of solution heat treatment and aging on microstructure and properties of in-situ Mg2Si/Mg-Al matrix composite [J]. Transactions of Materials and Heat Treatment, 2006, 27(6): 25-28. (in Chinese)

[11] LU L, LAI M O, HOE M L. Formaton of nanocrystalline Mg2Si and Mg2Si dispersion strengthened Mg-Al alloy bymechanical alloying [J]. Nanostructured Materials, 1998,10(4): 551-563.

[12] MABUCHI M, KUBOTA K,HIGASHI K. Effect of hot extrusion on mechanical properties of a Mg-Si-Al alloy [J]. Materials Letters, 1994, 19(5-6): 247-250.

[13] ZHA Min, LI Yan-jun, MATHIESEN R,  R, ROVEN H J. Microstructure, hardness evolution and thermal stability of binary Al-7Mg alloy processed by ECAP with intermediate annealing [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(7): 2301-2306.

R, ROVEN H J. Microstructure, hardness evolution and thermal stability of binary Al-7Mg alloy processed by ECAP with intermediate annealing [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(7): 2301-2306.

[14] REN Guo-cheng, ZHAO Guo-qun. Effects of deformation temperature on deformation behavior of AZ31 magnesium alloy during equal channel angular pressing [J]. The Chinese Journal of Nonferrous Metals, 2013, 23(7): 1789-1795. (in Chinese)

[15] GUO Wei, WANG Qu-dong, YE Bing, LI Xiao-chun, LIU Xin-tao, ZHOU Hao. Microstructural refinement and homogenization of Mg-SiC nanocomposites by cyclic extrusion compression [J]. Materials Science and EngineeringA, 2012, 556: 267-270.

[16] YANG Wen-peng, GUO Xue-feng, REN Fang, LIANG Shi-he. Characterization of recrystallized microstructure of reciprocating extruded magnesium alloy [J]. The Chinese Journal of Nonferrous Metals, 2013, 23(10): 2730-2737. (in Chinese)

[17] LIU Man-ping,ROVEN H J, LIU Xin-tao,MURASHKIN M,VALIEV R Z, T,BALOGH L. Grain refinement in nanostructured Al-Mg alloys subjected to high pressure torsion [J]. Journal of Materials Science, 2010, 45(17): 4659-4664.

T,BALOGH L. Grain refinement in nanostructured Al-Mg alloys subjected to high pressure torsion [J]. Journal of Materials Science, 2010, 45(17): 4659-4664.

[18] JIANG Ting-hui, LIU Man-ping, XIE Xue-feng, WANG Jun, WU Zhen-jie, LIU Qiang, ROVEN H J. Grain boundary structure of Al-Mg alloys processed by high pressure torsion [J]. Chinese Journal of Materials Research, 2014, 28(5): 371-379. (in Chinese)

[19] GUO Wei, WANG Qu-dong, YE Bing, ZHOU Hao. Microstructure and mechanical properties of AZ31 magnesium alloy processed by cyclic closed-die forging [J]. Journal of Alloys and Compounds, 2013, 558: 164-171.

[20] ZHOU Hao, YE Bing, WANG Qu-dong, GUO Wei. Uniform fine microstructure and random texture of Mg-9.8Gd-2.7Y-0.4Zr magnesium alloy processed by repeated-upsetting deformation [J]. Materials Letters, 2012, 83: 175-178.

[21] SERRE P, FIGUEIREDO R B, GAO N, LANGDON T G. Influence of strain rate on the characteristics of a magnesium alloy processed by high-pressure torsion [J]. Materials Science and Engineering A,2011, 528( 10-11): 3601-3608.

[22] GAN Wei-min, WU Kun, ZHENG Ming-yi, WANG Xiao-jun, CHANG H, BROKMEIER H G. Microstructure and mechanical property of the ECAPed Mg2Si/Mg composite [J]. Materials Science and Engineering A, 2009, 516 (1-2): 283-289.

[23] WANG Qu-dong, CHEN Yong-jun, ZHANG Lu-jun, LIN Jin-bao, ZHAI Chun-quan. Microstructure and mechanical properties of AZ31-0.5%Si alloy processed by ECAP [J]. Transactions of Nonferrous Metals Society of China, 2006, 16: s1660-s1663.

[24] ZHANG Zhong-ming, XU Chun-jie, GUO Xue-feng, JIA Shu-zhuo. Reciprocating extrusion of in situ Mg2Si reinforced Mg-Al based composite [J]. Acta Metallurgica Sinica (English Letters), 2008, 21(3): 169-177.

[25] METAYER J, YE Bing, GUO Wei, WANG Qu-dong, ZHOU Hao, MOLLET F. Microstructure and mechanical properties of Mg-Si alloys processed by cyclic closed-die forging [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(1): 66-75.

[26] GUO Wei, WANG Qu-dong, YE Bing, LIU Man-ping, PENG Tao, LIU Xin-tao, ZHOU Hao. Enhanced microstructure homogeneity and mechanical properties of AZ31 magnesium alloy by repetitive upsetting [J]. Materials Science and Engineering A, 2012, 540: 115-122.

[27] LIU Jian-feng, WANG Qu-dong, ZHOU Hao, GUO Wei. Microstructure and mechanical properties of NZ30K magnesium alloy processed byrepetitive upsetting [J].Journal of Alloys and Compounds, 2014, 589: 372-377.

[28] Mat Web. Magnesium AS41XA-F, die cast [EB/OL]. http://asia.matweb.com/search/SpecificMaterial.asp?bassnum=MMAS41. 2014-10-27.

[29] GUO Wei. Study on microstructure and properties of magnesium matrix composites fabricated by repeated compression severe plastic deformation [D]. Shanghai: Shanghai Jiao Tong University, 2013: 56-59. (in Chinese)

[30] LIM S C V, Yong M S. Plane-strain forging of wrought magnesium alloy AZ31 [J]. Journal of Materials Processing Technology, 2006, 171: 393-398.

[31] ZHENG Ming-yi, XU Shi-wei, WU Kun, KAMADO S, KOJIMA Y. Superplasticity of Mg-Zn-Y alloy containing quasicrystal phase processed by equal channel angular pressing [J]. Materials Letters, 2007, 61(22): 4406-4408.

[32] SHI Guo-dong, QIAO Jun, HE Min, ZHANG Qing-feng, ZHANG Yong-bin, CHEN Min. Dynamic recrystallization behaviors of twin-roll cast AZ31 magnesium alloy during high temperature tensile deformation [J]. The Chinese Journal of Nonferrous Metals, 2013, 23(7): 1796-1804. (in Chinese)

[33] MABUCHI M, AMEYAMA K, IWASAKI H, HIGASHI K. Low temperature superplasticity of AZ91 magnesium alloy with non-equilibrium grain boundaries [J]. Acta Materialia, 1999, 47(7): 2047-2057.

[34] SU C W, LU L, LAI M O. A model for the grain refinement mechanism in equal channel angular pressing of Mg alloy from microstructural studies [J]. Materials Science and Engineering A, 2006, 434(1-2): 227-236.

[35] WERT J A, PATON N E, HAMILTON C H, MAHONEY M W. Grain refinement in 7075 aluminum by thermomechanical processing [J]. Metallurgical Transactions A, 1981, 12(7): 1267-1276.

[36] ZHANG Zhong-ming, XU Chun-jie, JIA Shu-zhuo, GUO Xue-feng. Microstructure and mechanical properties of Mg-Al-Si alloy with high content of silicon [J]. Transactions of Materials and Heat Treatment, 2009, 30(5): 140-144. (in Chinese)

[37] SONG Pei-wei. Microstructures and mechanical properties of Mg-4Al-4Si magnesium alloy by reciprocating extrusion [J]. The Chinese Journal of Nonferrous Metals, 2012, 22(7): 1863-1870. (in Chinese).

郭 炜1,2,王渠东1,2,叶 兵1,2,周 浩1,刘鉴锋1

1. 上海交通大学 轻合金精密成型国家工程研究中心,上海 200240;

2. 上海交通大学 金属基复合材料国家重点实验室,上海 200240

摘 要:采用常规铸造方法制备AZ31-4.6% Mg2Si复合材料,在400 °C对铸态复合材料进行1、3和5道次的反复镦压(RU)剧烈变形。材料流动的有限元分析表明:1道次后变形集中于试样底部区域,5道次后可获得均匀的变形。多道次反复镦压过程中基体施加的剪切应力使树枝状和汉字状Mg2Si相破碎成小颗粒,随着反复镦压道次的增加,晶粒尺寸逐渐减小,Mg2Si颗粒分布逐渐均匀,同时强度和塑性显著提高,在400 °C 反复镦压5道次后,AZ31-4.6% Mg2Si复合材料抗拉强度和伸长率分别为248 MPa和9.8%,而原始铸态复合材料的抗拉强度和伸长率分别只有128 MPa和5.4%。

关键词:AZ31-Mg2Si复合材料;Mg2Si颗粒;反复镦压;组织;力学性能

(Edited by Yun-bin HE)

Foundation item: Projects (51074106, 51374145) supported by the National Natural Science Foundation of China; Project (09JC1408200) supported by the Science and Technology Commission of Shanghai Municipality, China; Project (2014M561466) supported by China Postdoctoral Science Foundation; Project (14R21411000) supported by Shanghai Postdoctoral Scientific Program, China

Corresponding author: Qu-dong WANG; Tel: +86-21-54742715; E-mail: wangqudong@sjtu.edu.cn

DOI: 10.1016/S1003-6326(14)63529-9