Conception of tooling adapted to thixoforging of high solid fraction hot-crack-sensitive aluminium alloys

来源期刊:中国有色金属学报(英文版)2010年第9期

论文作者:G. VANEETVELD A. RASSILI J. C. PIERRET J. LECOMTE-BECKERS

文章页码:1712 - 1718

Key words:thixoforging; solid fraction; near-net-shaping; tooling; 7075 aluminium alloys

Abstract: Thixoforging is a type of semi-solid metal processing at high solid fraction (0.7<φs<1), which involves the processing of alloys in the semi-solid state. Tooling has to be adapted to this particular process to benefit shear thinning and thixotropic behaviour of such semi-solid material. Tooling parameters, such as the forming speed and tool temperature, have to be accurately controlled because of their influence on thermal exchanges between material flow and tool. These thermal exchanges influence the high-cracking tendency and the rheology of the semi-solid material during forming, which affects parts properties and therefore their quality. Extrusion tests show how thermal exchanges influence quality of thixoforged parts made of 7075 aluminium alloys at high solid fraction by modifying process parameters like forming speed, tool temperature and tool thermal protector. Thus an optimum in terms of thermal exchanges has to be found between surface quality and mechanical properties of the part. A direct application is the evaluation of surface quality of thixoforged thin wall parts made of 7075 aluminium alloy.

G. VANEETVELD1, A. RASSILI1, J. C. PIERRET1, J. LECOMTE-BECKERS2

1. Thixo Unit, B56, University of Liège, 4 Boulevard de Colonster, Sart Tilman, 4000 Liège, Belgium;

2. Special Metallic Materials, B52, University of Liège, 1 Chemin des Chevreuils, Sart Tilman, 4000 Liège, Belgium

Received 13 May 2010; accepted 25 June 2010

Abstract: Thixoforging is a type of semi-solid metal processing at high solid fraction (0.7<φs<1), which involves the processing of alloys in the semi-solid state. Tooling has to be adapted to this particular process to benefit shear thinning and thixotropic behaviour of such semi-solid material. Tooling parameters, such as the forming speed and tool temperature, have to be accurately controlled because of their influence on thermal exchanges between material flow and tool. These thermal exchanges influence the high-cracking tendency and the rheology of the semi-solid material during forming, which affects parts properties and therefore their quality. Extrusion tests show how thermal exchanges influence quality of thixoforged parts made of 7075 aluminium alloys at high solid fraction by modifying process parameters like forming speed, tool temperature and tool thermal protector. Thus an optimum in terms of thermal exchanges has to be found between surface quality and mechanical properties of the part. A direct application is the evaluation of surface quality of thixoforged thin wall parts made of 7075 aluminium alloy.

Key words: thixoforging; solid fraction; near-net-shaping; tooling; 7075 aluminium alloys

1 Introduction

Most of the parts of wrought aluminium alloys are machined for small series production or forged and then machined for mass production. Machining operations are expensive and not adapted for mass production. Another disadvantage is the waste of material during forging and machining operation. To lower the part cost for mass production, machining has to be reduced to a minimum by near-net-shaped parts forming.

To increase geometry complexity, the resistance of the material during deformation can be reduced by using shear thinning and thixotropic forming[1-2]. This can be done if the microstructure of the material in the semi-solid state is composed of globular grains surrounded by a liquid matrix[3]. For wrought alloys, the higher the liquid fraction is, the more the defects are[4]. A solution is to limit the liquid phase by using thixoforging process which is a thixoforming process at high solid fraction[5]. Thixoforged parts are formed in one step and their mechanical properties are comparable to those from forging process with more complex geometries[5].

The quality of thixoforged parts depends on the composition of the feedstock material, the homogenization of the temperature at the end of the heating as well as the thermal exchanges with the tool during forming. From extrusion tests, this work shows how thermal exchanges between tool and semi-solid material help to improve the quality of thixoforged parts of 7075 alloys which are hot-crack-sensitive aluminium alloys. The idea is that by lowering the strain and deformation during the solidification at the end of the forming, the hot cracking tendency of hot-crack-sensitive wrought aluminium alloys is lowered[6-7]. A direct application is the evaluation of surface quality of thixoforged thin wall parts made of 7075 aluminium alloys shown in Fig.1.

2 Experimental

2.1 Feedstock material

The hot-crack-sensitive aluminium wrought alloy chosen for experiments is the 7075 aluminium alloy composed by Al-5.88Zn-2.45Mg-1.54Cu-0.2Cr-0.18Fe- 0.1Si-0.06Mn-0.025Ti-0.025Zr (mass fraction, %). Its solid fraction fits to high solid fraction thixoforging because of its low sensitivity to temperature variation at such high solid fraction (Fig.2).

Fig.1 Thin-wall thixoforged part in 3D dimensions (Unit: mm)

Fig.2 Solid fraction vs temperature obtained by DSC with heating rate of 15 °C/min

For tests, the diameter of slugs used was 30 mm which were machined from an extruded bar of 35 mm in diameter with an extrusion ratio of 16?1. These slugs were heated to the semi-solid state by induction to reach a temperature of 600 °C. The effective liquid fraction, which helped in shear-thinning process unlike entrapped liquid[8], was measured by using intercept lines method (ASTM E112-96 type). The measured solid fraction was 0.84±0.02 and the effective liquid fraction reached 0.14. Indeed, DSC results were not fully adaptable to high heating rate because of curve displacement due to the higher heating rate of inductive heating[9].

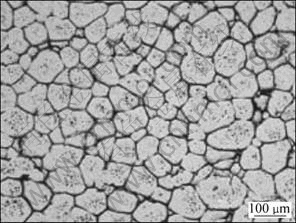

The recrystallization and partial melting (RAP) process[10] was used to recrystallize 7075 aluminium alloys with optimized parameters[11]. The corresponding microstructure of 7075 aluminium alloy is shown in Fig.3. Keller reagent was used to highlight in black the liquid fraction. Solid grains, in grey, are globular and do not exceed a diameter of 150 μm.

2.2 Material device

To perform the experiments, a hydraulic press of the Thixo Unit ULg was used with two punches performing at 100 t each. The maximal punch speed during the forming was 750 mm/s for the maximal stroke. Induction heating was provided by a 150 kW generator at a frequency of 2.3 kHz.

Fig.3 Microstructure of 7075 aluminium alloy heated to 600 °C and then water quenched

2.3 Extrusion process

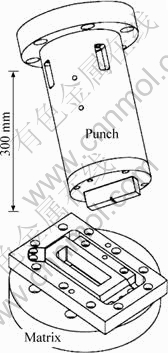

The extrusion process set-up is shown in Fig.4. The extrusion was done in about 1 s depending on piston speeds (41 mm/s and 82 mm/s), leading to the deformation rates of 14 s-1 and 63 s-1, respectively [12]. The temperature of the extrusion tool varied from room temperature at 20 °C to 250 °C. Ceraspray, which is ceramic particle in solution, was used as tool thermal protector agent to limit thermal exchanges with the extrusion tool and to limit aluminium chemical attack.

Fig.4 Schematic diagram of extrusion process setup

2.4 Thin wall part tooling process

Thin wall part tooling is shown in Fig.5. The tooling parts were made of X38CrMoV5 tool steel because of its good hardness (HRC 52) to a temperature of 500 °C and were isolated with composite spacer from the rest of the tool. All tool parts in contact with the semi-solid material could be heated to 250 °C by heating collars and could reach 300 °C if cartridge heaters located in the matrix/ejector were used, as shown in Fig.6. Punch has the same cartridge heater holes as the ejector.

Forming speed is important in thixoforming: 1) to lower the forming load due to the shear-thinning behaviour of the semi-solid material; and 2) to limit thermal exchanges due to the contact between tool and material. Punch speed from the thin wall part tooling could reach 560 mm/s.

Fig.5 Thin wall parts tooling scheme

Fig.6 Thin wall parts tooling showing heating devices

3 Results and discussion

3.1 Influence of thermal exchanges on hot-cracking tendency

The results of extrusion tests show that limiting thermal exchanges between semi-solid material and extrusion tool leads to some cracks as shown in Fig.7 and Fig.8. Thermal exchanges can be limited by increasing forming speed, increasing tool temperature, and adding a tool thermal protector coating.

The presence of cracks can be explained by the shrinkage due to the solidification of the material flow during the forming. Fig.9 shows that during compression (step 1), the top of the billet is in contact with the tool and forms a skin due to thermal exchanges. The thickness of this solid skin depends on the thermal exchanges between the semi-solid material and the extrusion tool. This solid skin is broken when the extrusion starts (step 2) and forms a stopper in the funnel[13].

Fig.7 Comparison between microstructure for two different deformation rates at section variation in tool heated at 125 °C: (a) 14 s-1; (b) 63 s-1

Fig.8 Overview of cracks on extruded part for high deformation rate of 63 s-1 in tool heated at 180 °C

Fig.9 Extrusion process steps

This stopper is represented in black in Fig.10 for high thermal exchanges and in Fig.11 for low thermal exchanges. The stopper carries a pressure on the material, forcing contact of the material flow with the tool surface during the tool filling. It is noticed that this continuous pressure during the forming has an influence on the surface quality of the part.

The higher the thermal exchanges are, the bigger the stopper is, the higher the pressure is carried on the material flow, the larger the contact area between tool and material is and the higher the solidification rate of the flowing material is during the tool filling. This solidification makes a material shrinkage during the tool filling, reducing the final shrinkage as shown in Step 3 of Fig.10. By reducing the shrinkage during cooling at the end of the forming, deformation and strain are reduced, which decreases the hot-cracking tendency of the material.

Fig.10 Thixoforging of aluminium alloys at high solid fraction with high thermal exchanges: case of cold tool and/or low forming speed

Fig.11 shows the case of lower thermal exchanges during filling. The stopper is thinner, which reduces the continuous pressure and the contact between material flow and tool surface. This less contact reduces the shrinkage during the tool filling. At the end of the forming, the shrinkage, during cooling, is higher than that for higher thermal exchanges, which induces the hot-cracking tendency of the material.

Fig.11 Thixoforging of aluminium alloys at high solid fraction with low thermal exchanges: case of hot tool and/or high forming speed

This mechanism could explain the good mechanical properties obtained in cold tool for small thixoforged parts in 7075 rather than for hot tool temperature[14]. To improve mechanical properties of thixoforged hot- crack-sensitive material, thermal exchanges should not be low.

3.2 Influence of thermal exchanges on surface quality of thixoforged parts

The solidification rate of high solid fraction material is high (Fig.1) and increases with the tool contact during the filling as shown in Fig.12. At the end of the tool filling, compression of semi-solid material forces the contact between the semi-solid material and the tool surface. The lower the thermal exchanges are, the lower the solidification rate of the semi-solid material is, the more the pressure at the end of the compression allows the material to fit exactly the form of the tool surface and the smoother the surface is[12].

Fig.12 Extrusion tool filling in three steps

This mechanism could explain the good surface quality observed on the extrusion parts in hot tool at high speed rather than in cold tool at low speed[12].

Concerning the fineness of the engraving, Fig.13 shows the fitting by the high solid fraction semi-solid material of a thin engraving of 30 μm deep and 100 μm wide. The measured roughness of the thixoforged part is Ra=1.67 μm and a measured tool roughness of Ra=0.75 μm.

Fig.13 Fine engraving moulded by semi-solid material for solid fraction of 0.85

3.3 Influence of tool thermal protector on surface quality of thixoforged parts

Tool thermal protector coating is important to avoid chemical attack on tool steel and galling as shown in Fig.14.

Fig.14 Galling of thin wall parts thixoforged with same set of process parameters: (a) With tool thermal protector; (b) Without tool thermal protector

The volume of tool thermal protector affects the surface quality of thixoforged parts. The higher the volume of tool thermal protector is, the higher penetration the surface of the parts has, as shown in Fig.15, and the deeper the polishing should be to remove the tool thermal protector coating.

Fig.15 Polishing and etching on two thin wall parts thixoforged with same set of process parameters: (a) Without tool thermal protector; (b) With tool thermal protector

3.4 Influence of thermal treatment on surface quality of thixoforged parts

The high solid fraction semi-solid part cracks during forming are shown in Fig.16.

At the end of the forming, the compression packs the material and makes some welding lines. If the part is etched, these welding lines appear as shown in Fig.17(a). These weldings are harmful to mechanical properties of the part. To improve mechanical properties, a T6 thermal treatment can help by modifying the microstructure as shown in Fig.17(b).

Fig.16 Cracking of high solid fraction 7075 aluminium alloy during forming

Fig.17 Welding lines on two thin wall parts thixoforged with same set of process parameters: (a) Before T6 thermal treatment; (b) After T6 thermal treatment

After T6 thermal treatment, the diameter of surface porosity after a light polishing is limited to 30 ?m as shown in Fig.18.

Fig.18 Morphologies of surface porosity (black), solidified liquid (grey) and solid phase (white) after T6 thermal treatment

3.5 Influence of tooling conception for thixoforging of hot-crack-sensitive aluminium alloys

These observations highlight the importance of thermal exchanges between tool surface and material about parts quality. Tooling parameters like forming speed or tool temperature directly affect the thermal exchanges which influence the surface quality and mechanical properties of parts. Thermal exchanges are managed by modifying the forming speed and the tool temperature. The larger the range of tool temperature and the range of forming speed are, the easier it is to adjust the process. The matrix is preheated to 250 °C using a disc surrounded by a heating collar as shown in Fig.6. Tooling conception has to integrate, inside parts in contact with the semi-solid material, cartridge heaters which have high heating rate to control accurately thermal exchanges. The disc surrounded by heating collar is also an energy tank which is useful to absorbing peaks and falls of the tooling temperature during parts production. Power of cartridge heaters depends on the desired thermal exchanges which are related to the solidification rate of the thixoforged part and the tool temperature. To make parts with good mechanical properties, the solidification rate of the material flow should not be too high to fully fill the tool, and should not be too low to limit the hot-crack tendency of hot-crack-sensitive aluminium alloys. This means that for thin section parts, thermal exchanges between the material flow and the tool should be lower during forming than those for thicker section parts.

To limit the damage of tool thermal protector on the surface quality of thixoforged parts, thermal barrier like glazing[15] or oxidation could be useful.

Simulation of semi-solid material flow during forming is necessary to predict the tool filling in order that the material flow fills simultaneously the tool to limit the forming load.

4 Conclusions

Some cracks appear for parts made of 7075 aluminium alloy, which is a hot-crack-sensitive aluminium alloy, formed with low thermal exchanges. The shrinkage at the end of the forming could be the reason. A solution to reduce this shrinkage is using the thixoforging process with a high solid fraction material. Thermal exchanges create a stopper, which enhances the contact between the semi-solid material and the tool during the forming. The solidification is higher, which reduces the final shrinkage due to the part cooling. By reducing the final shrinkage, deformation and strain of the part are reduced, which is positive to inhibit the hot-cracking tendency of the hot-crack-sensitive material and improves its mechanical properties. However, if thermal exchanges are too low, the tool could not be fully filled because of the high solidification rate of the high solid fraction material, which implies a poor surface quality and decreased mechanical properties due to the low compaction of the material. These observations show that optimum thermal exchanges have to be found to optimize mechanical properties and surface quality of thixoforged parts made of hot-crack-sensitive aluminium alloys. This requires a tool temperature control for tool parts in contact with the material. Thermal exchanges between the material flow and the tool should be lower during forming for thin section parts than for thicker section because of the higher solidification rate of the semi-solid material.

A direct application of these observations is the conception of tooling adapted to the thixoforging of thin wall parts made of hot-crack-sensitive aluminium alloys. Material flow has to fill simultaneously the tool to limit the forming load. Tool parts in contact with the material are heated and isolated by composite spacer to reach high temperature. Analysis of thin wall parts reveals that a good surface quality is obtained with few tool thermal protector coating and that surface pore diameter is less than 30 ?m after T6 heat treatment. However, tool thermal protector is required to avoid galling and chemical attack of aluminium on tool steel. Another solution is to create a thermal barrier by treating the tool surface using glazing or oxidation. Fine engraving is possible with thixoforging of high solid fraction material.

Acknowledgements

The authors gratefully acknowledge University of Liège, Walloon Region (First Europe Program Convention n°”NEP” 415824, THIXALU Project and MAGAL Project) and the COST 541 for their financial support.

We would like to thank S. SALIERI for the help in the samples preparations.

References

[2] SPENCER D B, MEHRABIAN R, FLEMINGS M C. Rheological behavior of Sn-15%Pb in the crystallization range [J]. Metallurgical and Materials Transactions A, 1972, 3: 1925-1932.

[3] JOLY P A, MEHRABIAN R. The rheology of a partially solid alloy [J]. Journal of Materials Sciences, 1976, 11: 1393-1418.

[4] BOYER H E. Metals handbook desk [M]. Ohio: Asm Intl, 1984: 237.

[5] VANEETVELD G, RASSILI A, LECOMTE-BECKERS J, ATKINSON H V. Thixoforging of 7075 aluminium alloys at high solid fraction [J]. Trans Tech Publications, 2006, 116/117: 762-765.

[6] CHU M G, GRANGER D A. The tensile behaviour and cracking tendency of partially solidified aluminium alloys [C]//Proceedings of the 4th Decennial International Conference on Solidification Processing. Sheffield, 1997: 198-202.

[7] ESKIN D G, SUYITNO, KATGERMAN L. Mechanical properties in the semi-solid state and hot-tearing of aluminium alloys [J]. Progress in Materials Science, 2004, 49: 629-711.

[8] ITO Y, FLEMINGS M C, CORNIE J A. Rheological behavior and microstructure of Al6.5wt%Si alloy [J]. Nature and Properties of Semi-Solid Materials, 1992: 3-18.

[9] LECOMTE-BECKERS J, RASSILI A, CARTON M, ROBELET M, KOEUNE R. Study of the liquid fraction and thermophysical properties of semi-solid steels and application to the simulation of inductive heating for thixoforming [J]. Advanced Methods in Material Forming, 2007: 321-347.

[10] KIRKWOOD D H, SELLARS C M ELIAS-BOYED L G. Thixotropic Materials: EU 0305375 B1 [P]. 1992.

[11] VANEETVELD G, RASSILI A, PIERRET J C, LECOMTE-BECKERS J. Influence of parameters during induction heating cycle of 7075 aluminium alloy with RAP process [J]. Trans Tech Publications, 2008, 141/142/143: 719-724.

[12] VANEETVELD G, RASSILI A, PIERRET J C, LECOMTE- BECKERS J. Extrusion tests of 7075 aluminium alloy at high solid fraction [J]. International Journal of Material Forming, 2008, 1(Suppl.1): 1019-1022.

[13] ROUFF C. Contribution to the characterization and modelling of the behaviour of steel in a semi-solid. Application to thixoforging [D]. METZ, France: ENSAM, 2003.

[14] VANEETVELD G, RASSILI A, PIERRET J C, LECOMTE- BECKERS J. Improvement in thixoforging of 7075 aluminium alloys at high solid fraction [J]. Trans Tech Publications, 2008, 141/142/143: 707-712.

[15] AQIDA S N, MAUREL M, BRABAZON D, NAHER S, ROSSO M. Thermal stability of laser treated die material for semi-solid metal forming [J]. International Journal of Material Forming, 2009, 2(Suppl.1): 761-764.

Corresponding author: G. VANEETVELD; Tel: +32-4-3615951; E-mail: a.rassili@ulg.ac.be

DOI: 10.1016/S1003-6326(09)60363-0