Effects of minor Sc on microstructure and mechanical properties of Al-Zn-Mg-Zr alloy welded joint

XIAO Jing(肖静)1, YIN Zhi-min(尹志民)1, LEI Xue-feng(雷学锋)1, 2,

JIANG Feng(姜锋)1, NIE Bo(聂波)1, 3, HE Zhen-bo(何振波)1, 3

1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Institute of Aerospace Materials and Technology, Beijing 100076, China;

3. Northeast Light Alloy Co. Ltd., Harbin 150060, China

Received 15 July 2007; accepted 10 September 2007

Abstract: Two kinds of Al-6.0Zn-2.0Mg-0.12Zr and Al-6.0Zn-2.0Mg-0.2Sc-0.12Zr alloy plates were prepared by ingot-metallurgy. The alloy plates with 3 mm thickness were welded by argon shield welding method, and the mechanical properties and microstructures of the two welded joints filled with Al-Mg-Sc welding wire were studied comparatively. The results show that firstly, minor Sc can raise the mechanical properties of the Al-Zn-Mg-Zr base alloy greatly. The reason for the increment is the fine grain strengthening, precipitation strengthening and the substructure strengthening caused by Al3(Sc, Zr). Secondly, η′ phase (MgZn2) and grain size in the heat-affected zone of the alloy without Sc become coarse obviously, the η′ phase (MgZn2) in the heat-affected zone of the alloy with Sc becomes coarse also, but the grain size has no visible change. Al3(Sc, Zr) particles are rather stable and can inhibit the movement of dislocation and sub-grain boundaries, overaging softening is not serious. Thirdly, adding minor Sc can raise the strength of welded joint remarkably, the tensile strength of alloy with Sc increases from 395 MPa to 447 MPa and the welding coefficient increases from 0.7 to 0.8 as well. The reason for the high strength of welded joint with Sc addition is the fine grain strengthening, precipitation strengthening and the increasing of resistance to thermal cycling softening caused by Al3(Sc, Zr).

Key words: Al-Zn-Mg-Zr alloy; welding; Sc; microstructure; tensile properties

1 Introduction

Al-Zn-Mg alloy which has 8% (mass fraction) of total zinc and magnesium is a medium strength alloy. It has good corrosion resistance and excellent weldability. It also has a wide ranging application in aerospace and aviation. After solutioning and then aging, η′ phase distributes on the matrix of Al-Zn-Mg alloy homogeneously, resulting in a high strength and good plastic property of the alloy. However, during welding η′ phase and T phase grow and coarsens, mechanical properties of welding joints considerably reduce[1]. Therefore, it is necessary to raise the properties of alloy after welding. Reinforcement design on welding joints and selecting proper welding wire are effective methods to improve the mechanical properties of welded joints[2]. On the basis of medium strength and weldability Al-Zn-Mg alloy, using Sc and Zr as an additive, VELS in Russia developed a new Al-Zn-Mg alloy, namely 01970, later they developed 01970, 01981 alloys[2-4]. Recently, there is a greater interest in aluminium alloys containing minor Sc and Zr, however, a few reports have been given to the exact effect of Sc and Zr on the microstructure and properties of welding joints in Al-Zn-Mg alloy. In this work, two kinds of Al-Zn-Mg-Zr and Al-Zn-Mg-Zr-Sc base alloys were prepared, the effects of Sc on the microstructure and properties of the two welded joints filled with Al-Mg-Sc welding wires were investigated, in order to provide available experimental data for the engineering application of this alloy plate.

2 Experimental

2.1 Materials

The base alloys used in this study are two kinds of Al-6.0Zn-2.0Mg-0.12Zr and Al-6.0Zn-2.0Mg-0.2Sc- 0.12Zr alloy plates with 3 mm thickness. The welding wire developed by the authors was chosen. The chemical compositions of base alloy and welding wire are given in Table 1.

2.2 Experimental and testing method

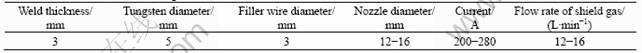

Before welding, prior surface treatment of the plates was done. The processing parameters of the MIG welding are listed in Table 2.

Tensile specimens were intercepted from the welding joint. They were processed according to Chinese welding standard. Mechanical tests were proceeded on Instron 8019 machine; the hardness test was measured perpendicularly to the welding direction on Brinell hardness press; microstructure feature of the welded joint was observed by SUNNY optical microscope; thin foils for transmission electron microscopy made from different regions of welded joint were prepared by twin-jet polishing with an electrolyte solution consisting of 1% HNO3 and 2% absolute CH3OH below -20℃. The foils were observed on a Tecnai G2 20 ST operated at 200 kV.

3 Results

3.1 Mechanical properties of welded joints

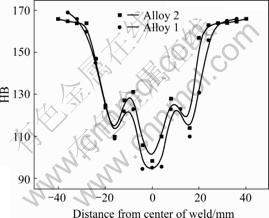

The hardness distribution of welded joints is shown in Fig.1.

The result in Fig.1 shows that the hardness distributions of two welded joints have the same features, i.e. the hardness value of the welded seam is the lowest. It increases with the increment of distance from the center of the weld, then a softening occurs on the area about 18 mm away from the center of the weld. Finally the hardness value increases to the hardness level of base metal. It can also be seen that hardness of welded joint 2 is higher than welded joint 1 in each region.

Fig.1 Hardness distributions of two studied welded joints

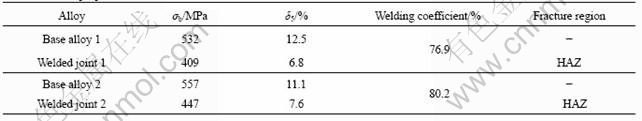

The tensile properties of the two welded joints are listed in Table 3.

As listed in Table 3, the strength and elongation of welded joint 2 with the addition of scandium have a remarkable enhancement compared with welded joint 1. The tensile strength of welded joint 2 is higher by 38 MPa and the welding coefficient reaches 0.8.

3.2 Microstructure of welded joints

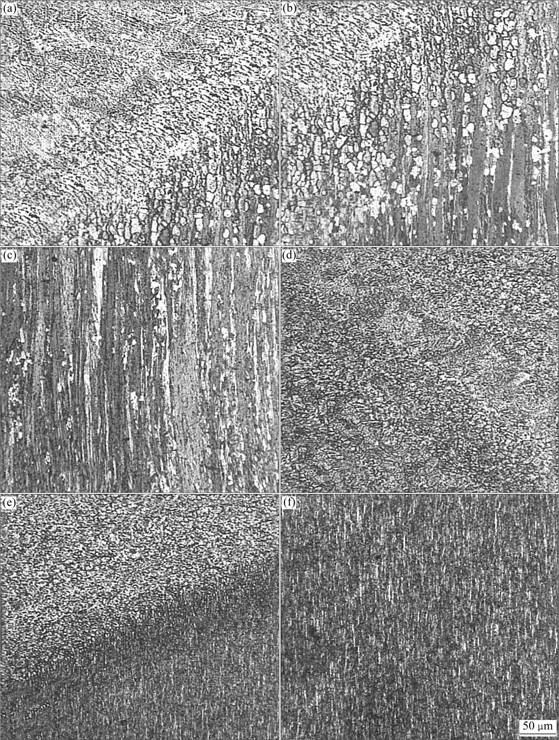

The optical microstructure of the two welded joints is shown in Fig.2.

Fig.2 shows that the weld centers exhibit the same equiaxed dendritic grain structures (Fig2(a)), but there are different features on the heat affected zones between two welded joints. Firstly, fine equiaxed grains formed in the fusion zone of welded joints 2 (Fig2(c)). Secondly, heat affected zone of welded joints 1 was partly recrystallized (Figs.2(b) and (c)), but the heat affected zone of welded joints 2 was still fiber grain structure, showing that no recrystallization occur (Figs.2(e) and (f)).

Table 1 Chemical compositions of solder wire and base alloys (mass fraction, %)

Table 2 Parameters of MIG welding

Table 3 Tensile properties of two studied welds

Fig.2 Optical microstructures of two welded joints: (a) Weld 1; (b) Fusion zone 1; (c) HAZ 1; (d) Weld 2; (e) Fusion zone 2; (f) HAZ 2

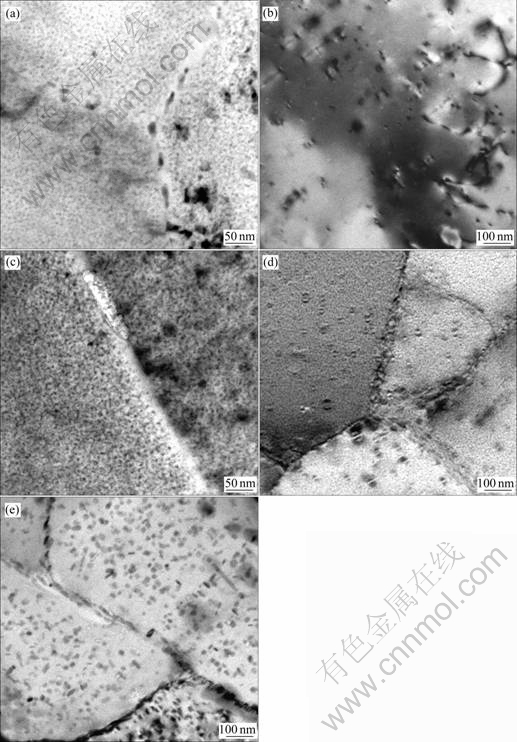

The TEM micrographs of two welded joints are presented in Fig.3.

It can be seen that for welded joint 1, η′ phases (MgZn2) in HAZ become coarser compared with the base alloy and the grains becomes coarse too, for welded joint 2, η′ phases (MgZn2) in HAZ also become coarser but the grain size in HAZ has no visible change. At the same time, under the double-beam condition, we can see many bean-like precipitates(Fig.3(d)). According to Ref.[5], this kind of precipitates should be Al3(Sc, Zr).

Fig.3 TEM microstructures of studied welded joints: (a) Base alloy 1; (b) HAZ of welded joint 1; (c) Base alloy 2; (d) HAZ of welded joint 2 (in double beam condition); (e) HAZ of welded joint 2

4 Discussion

4.1 Effect of minor Sc and Zr on microstructure and properties of weld joints

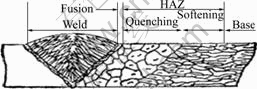

After welding the aluminum alloy can be divided into three distinctive regions, namely the weld, heat affected zone(HAZ) and base metal (see Fig.4).

During welding, the heat input makes welding wire melt and then the weld forms. The weld is a solidification structure which is in the weakest area in the tensile test and much easier to fracture[6-8].

When choosing Al-Mg-Sc as welding wire, some primary phases such as Al3Sc, Al3Zr and Al3(Sc, Zr) will form during the non-equilibrium solidification process. This kind of particles belongs to face central cubic system, the lattice constant is similar to α(Al)[9-10]. They can be ideal grain refiner of solid solution matrix. The strength of the weld mainly comes from solution strengthening of magnesium, fine grain strengthening and precipitation strengthening of these particles.

Fig.4 Sketch map of studied welded joint

4.2 Effect of minor Sc and Zr on HAZ

During welding, different regions of the welded joint have different temperature distribution. The temperature of the weld seam is above 800 ℃, and declines from the seam to the base metal[11]. When the thermal cycling temperature is higher than the solution temperature of Al-Zn-Mg alloy, the base metal will solve again. When held at room temperature, a natural aging will take place. As the thermal cycling temperature is lower than the solution temperature but higher than the aging treatment temperature of the Al-Zn-Mg alloy, the strengthening phases will gather and grow, and recrystallization may take place[12]. However, for the Al-Zn-Mg-Sc-Zr alloy recrystallization does not take place because it has Al3Sc and Al3(Sc,Zr) particles that strongly inhibit dislocation and subgrain boundaries movement[13-15].

4.3 Effect of minor Sc and Zr on mechanical pro- perties of welding joints

The results in Table 3 show that the base metal of Al-Zn-Mg-Zr containing Sc exhibits higher tensile strength. It comes from the fine grain strengthening, subgrain strengthening caused by hot working and precipitation strengthening of secondary Al3Zr, Al3Sc and Al3(Sc, Zr) particles. The tensile properties and elongation of the welding joints with Sc addition is higher too. It can also be explained that Sc addition raises the recrystallization temperature of the base metal and the ability of softening-resistance.

5 Conclusions

1) Minor Sc can increase the mechanical properties of the Al-Zn-Mg-Zr base alloy greatly. The reason is the fine grain strengthening, precipitation strengthening and the substructure strengthening caused by Al3(Sc, Zr).

2) During welding η′ phase (MgZn2) and grain in the HAZ of the alloy without Sc become coarse obviously, η′ phase (MgZn2) of the alloy with Sc also becomes coarse but the grain size has no visible change. Al3(Sc, Zr) particles are rather stable and can inhibit the movement of dislocation and sub-grain boundary, those overaging softening is not serious.

3) Adding of minor Sc can raise the strength of the welded joint remarkably due to fine grain strengthening, precipitation strengthening and the increase of resistance to thermal cycling softening caused by Al3(Sc, Zr).

References

[1] LECH-GREGA M, HAWR?KIEWICZ S, RICHERT M, SZYMA?SKI W. Structural parameters of 7020 alloy after heat treatment simulating the welding process [J]. Materials Characterization, 2001, 46: 251-257.

[2] JIANG Feng, YIN Zhi-min, HUANG Bai-yun, et al. Homogenization and recrystallization of Al-6Mg alloys with and without Sc and Zr [J]. Journal of Rare Earths, 2004, 22(5): 600-603.

[3] CHEN Su-li, JIANG Feng, YIN Zhi-min, LEI Xue-feng, NIE Bo. Microstructure and properties of Al-Mg-Sc alloy weld joints filled with Al-Mg-Zr and Al-Mg-Sc-Zr weld wires [J]. The Chinese Journal of Nonferrous Metals, 2006, 16(5): 836-840. (in Chinese)

[4] LATHABAI S, LLOYD P G. The effect of scandium on the microstructure, mechanical properties and weldability of a cast Al-Mg alloy [J]. Acta Materialia, 2002, 50(17): 4275-4292.

[5] WANG Sheng, LI Zhou, YIN Zhi-min, ZHOU Gu-xin, CHENG Jian-guo. Microstructures and properties of welded joint of 7A52 alloy welded by the solder wire containing Sc and Zr [J]. Ordnance Material Science And Engineering, 2005, 28(3): 26-30. (in Chinese)

[6] DEV S, STUART A A, DEV KUMAARA R C R, MURTYB B S, RAOB K P. Effect of scandium additions on microstructure and mechanical properties of Al-Zn-Mg alloy welds [J]. Materials Science and Engineering A, 2007(2): 1-7.

[7] RIDDLE Y W, HALLEM H, RYUM N. Highly recrystallization resistant Al-Mg-Mn alloys using Sc and Zr [J]. Materials Science Forum, 2002, 396(1): 563-568.

[8] YIN Zhi-min, YANG Lei, PAN Qing-lin, et al. Effect of minor Sc and Zr on microstructures and mechanical properties of Al -Zn -Mg based alloys [J]. Trans Nonferrous Met Soc China, 2001, 11(6): 822-825.

[9] HE Zhen-bo. Research on the structure and properties of welding joint for alloy Al-Mg(Sc, Zr) [J]. Light Alloy Working Technology, 2004, 34(8): 44-47. (in Chinese)

[10] OCENASEK V, SLAMOVA M. Resistance to recrystallization due to Sc and Zr addition to Al-Mg alloy [J]. Materials Characterization, 2001, 47(2): 157-162.

[11] FU Gao-feng, TIAN Fu-quan, WANG Hong. Studies on softening of heat-affected zone of pulsed-current GMA welded Al-Zn-Mg alloy [J]. Journal of Materials Processing Technology, 2006, 180: 216-220.

[12] MA T, DEN OUDEN G. Softening behaviour of Al-Zn-Mg alloys due to welding [J]. Materials Science and Engineering A, 1999, 266: 198-204.

[13] BALASUBRAMANIAN V, RAVISANKARA V, REDDYB G M. Effect of pulsed current and post weld aging treatment on tensile properties of argon arc welded high strength aluminium alloy [J]. Materials Science and Engineering A, 2007, 459: 19-34.

[14] NORMAN A F, PRANGNEKK P B, MCEWEN R S. The solidification behavior of dilute aluminum-scandium alloys [J]. Acta Mater, 1998, 46(16): 5715-5732.

[15] HE Yong-dong, ZHANG Xin-min, YOU Jiang-hai. Effect of minor Sc and Zr on microstructure and mechanical properties of Al-Zn-Mg-Cu alloy [J]. Trans Nonferrous Met Soc China, 2006, 16(5): 1228-1235.

Foundation item: Project(2005CB623705) supported by the National Basic Research Program of China

Corresponding author: XIAO Jing; Tel: +86-731-8830910; E-mail: xj_8659@163.com

(Edited by PENG Chao-qun)