DOI: 10.11817/j.issn.1672-7207.2020.04.001

硫化矿石常温氧化模拟及基于神经网络的氧化活性预测

刘正洲1,潘伟1, 2,吴爱祥2,吴超1,邓舵1,冯宴熙1,杨奉龙1

(1. 中南大学 资源与安全工程学院,湖南 长沙,410083;

2. 北京科技大学 金属矿山高效开采与安全教育部重点实验室,北京100083)

摘要:在实验室内开展硫化矿石常温氧化实验。以样品粒度、初始含水率和预氧化时间这3个因素作为输入单元,质量增大率作为输出单元,建立样品质量增大率的神经网络预测模型。研究结果表明:硫化矿石在常温条件下质量变化趋势包括3个阶段,依次为快速增大阶段、增幅减小阶段和保持不变阶段;未被氧化的矿样表面比较光洁,粒度分布较均匀,氧化后的矿样表面有明显结块现象;样品质量增大率与粒度和环境pH均呈负相关关系;随着初始含水率和预氧化时间增大,样品质量增大率均呈先增大后减小趋势;高温高湿环境可促进硫化矿石氧化;3个因素对样品质量增大率的影响重要度从高至低依次为初始含水率、预氧化时间和粒度;建立的神经网络模型具有较高的预测精度,相对误差小于10 %,可用于对实测样品质量增大率的可靠性进行验证。

关键词:硫化矿石;常温氧化;质量增大率;预测模型;神经网络

中图分类号:TD75 文献标志码:文献标识码:A

文章编号:1672-7207(2020)04-0863-09

Normal temperature oxidation simulation of sulfide ores and prediction of oxidation activity with neural network

LIU Zhengzhou1, PAN Wei1, 2, WU Aixiang2, WU Chao1, DENG Duo1, FENG Yanxi1, YANG Fenglong1

(1. School of Resources and Safety Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Ministry of Education of China for Efficient Mining and Safety of Metal Mines,University of Science and Technology Beijing, Beijing 100083, China)

Abstract: Normal temperature oxidation experiments of sulfide ores were carried out in laboratory. A neural network prediction model of mass increase rate of samples was established by taking particle size, initial moisture content and pre-oxidation time as input units and mass increase rate of samples as output units. The results show that mass trend of sulfide ore samples under normal temperature conditions includes three stages, i.e., rapidly increasing stage, slowly increasing stage and basically unchanged stage. Before oxidation, the surface of ore samples is relatively smooth and the particles are relatively uniform. After oxidation, there is obvious agglomeration phenomenon on the surface of ore samples. With the increase of particle size and environmental pH, mass increase rate of samples decreases. With the increase of initial moisture content and pre-oxidation time, mass increase rate of samples increases first and then decreases. High temperature and humidity can promote the oxidation of sulfide ores. Influence of the factors on mass increase rate of samples from high to low is initially moisture content, pre-oxidation time and ore particle size. The neural network has higher prediction accuracy, and the relative error is less than 10%. Therefore, it can be used to validate the reliability of the measured mass increase rate.

Key words: sulfide ores; normal temperature oxidation; mass increase rate; prediction model; neural network

硫化矿石被开采并暴露在空气中一段时间后,硫化矿物将开始氧化并释放反应热[1]。若发热速率超过外部条件下的散热速率,则氧化反应会加速至矿石自燃[2-4]。硫化矿石自燃是高硫矿山开采过程中面临的最严重灾害之一,一旦发生硫化矿石自燃火灾,将导致许多环境和安全问题[5-8]。基于现有文献的分析结果可知,硫化矿石自燃的研究热点主要在氧化机理、自燃倾向性评价和防火与灭火技术等方面。PAYANT等[9]通过验证,得出某些硫化矿物之间的电相互作用可以促进自燃。YANG等[10]基于硫化矿石机械活化实验的结果,提出了硫化矿石自燃的机械活化机理。PAN等[11]通过小波变换、非线性特征参数提取和模糊综合评价,提出了一种新的硫化矿石自热倾向性评价方法。WANG等[12]验证了使用微生物氧化降低高硫矿石自燃危险性的有效性。硫化矿石堆具有不同类型的孔隙结构和大量的内表面积,因此,具有很强的吸氧能力。在常温条件下,硫化矿石缓慢氧化伴随着吸附氧的动态变化,这是硫化矿石自燃的先决条件。目前,硫化矿石常温氧化研究主要是在实验室内测量硫化矿石的氧化质量增大率,将其作为自燃倾向性的常用评价指标[13-14]。目前,人们对常温氧化过程的多因素效应研究较少。周惠斌等[15]研究了4种因素(温度、粒度、湿度和初始含水率)对硫化矿石5 d质量增大率的影响程度,但其主要目的是规范5 d质量增大率的实验条件。硫化矿石氧化活性的测量结果受多种因素的影响,一般的数学预测模型很难准确描述硫化矿石的常温氧化过程。如何解决各种影响因素之间的非线性关系,是建立硫化矿石氧化活性预测模型的难点。神经网络方法具有并行分布和存储、自组织和自学习的功能,可用于分析复杂的非线性系统[16],它在工程中的应用可提供解决这一问题的新途径。为此,本文作者在实验室开展硫化物矿石常温氧化的单因素和多因素影响实验,以便揭示多因素对硫化矿石常温氧化的影响规律,为提出有效的自燃火灾预防方法提供依据。根据实验结果建立硫化矿石氧化活性的神经网络预测模型,在多因素控制下取得预测结果,以便有效地验证实验结果的准确性。

1 实验

1.1 基本原理

对于黄铁矿,部分相关反应方程式如下:

2FeS2+7O2+2H2O=2FeSO4+2H2SO4 (1)

4FeSO4+2H2SO4+O2=2Fe2(SO4)3+2H2O (2)

12FeSO4+3O2+6H2O=4Fe2(SO4)3+4Fe(OH)3 (3)

1.2 氧化活性评价指标优选

质量增大率、水溶性铁离子和硫酸根离子的含量变化以及团聚特性可以从不同角度表征硫化矿石的氧化活性。根据反应方程式(1)~(3),硫化矿石在常温氧化过程中不产生气体。由质量守恒定律可知,反应过程中吸收的氧是造成矿样质量增大的主要原因。在常温氧化的早期阶段,会产生Fe2+,Fe2+进一步氧化成Fe3+(如硫酸铁和氢氧化铁)。硫酸铁在水中溶解度低,氢氧化铁不溶于水,因此,测定的化学成分含量不能准确反映实际氧化情况。团聚现象是物理和化学因素耦合作用的结果,且很难进行定量分析,为此,选择质量增大率作为氧化活性的评价指标。

1.3 单因素实验方案

实验矿样取自国内某铜矿,该矿属于典型的高硫矿床,平均含硫量(质量分数,下同)为20.0%,最高含硫量为41.3%。根据该矿的自燃统计,近10年来多次发生硫化矿石自燃火灾。2016年,矿山采场仍出现硫化矿石自燃现象,采用洒水、关闭采空区等措施都无法有效抑制自燃。本次实验选取含硫量为35.4%的矿样作为实验材料。目前,硫化矿石常温氧化的实验条件包括恒温恒湿环境(温度为40 ℃,湿度大于90%)和室内自然环境(温度低于40 ℃,湿度小于90%) 2种。常见的可控实验影响因素有矿石粒度、初始含水率和预氧化时间。此外,为了揭示环境pH对常温氧化过程的影响,为新型阻燃剂的制备提供参考,选择其作为单因素实验的影响因素。4种影响因素及其水平如表1所示。

表1 单因素实验影响因素及其水平

Table 1 Influencing factors and their levels of single factor experiments

在恒温恒湿环境下,将每个质量为50 g的样品放入实验台上的玻璃皿中。在实验过程中,每天用电子天平称样品质量,直到其质量变化不明显为止。质量增大率可以表示为

(4)

(4)

式中:P为质量增大率;△W为氧化反应增加的质量;W0为初始质量;W为氧化后的最终质量。

为了探讨不同外部环境对常温氧化的影响,将表1中的实验样品置于温度为17~29 ℃、湿度为70%~85%的自然环境中进行对比实验。此外,用扫描电子显微镜观察氧化前后部分典型样品的表面形貌,以揭示样品的表观特征变化。部分实验照片如图1所示。

图1 部分实验照片

Fig. 1 Part photos of experiment

1.4 多因素实验方案

多因素实验的目的是探讨多因素耦合作用对硫化矿石常温氧化的影响,并分析各因素的影响程度。在采矿过程中,采用某些技术措施可以较好地控制硫化矿石的破碎程度、含水率和堆积时间,且在硫化矿石快速氧化前,环境pH的变化一般不明显,因此,选择矿石粒度、初始含水率和预氧化时间这3个影响因素来分析其对常温氧化过程的影响程度。表2所示为多因素实验的影响因素及其水平。

表2 多因素实验影响因素及其水平

Table 2 Influencing factors and their levels of multi-factor experiments

基于单因素实验的结果进行多因素实验,若恒温恒湿环境下与自然环境下的单因素实验结果一致,则只在恒温恒湿环境下进行多因素实验,否则在2种环境下进行多因素实验。

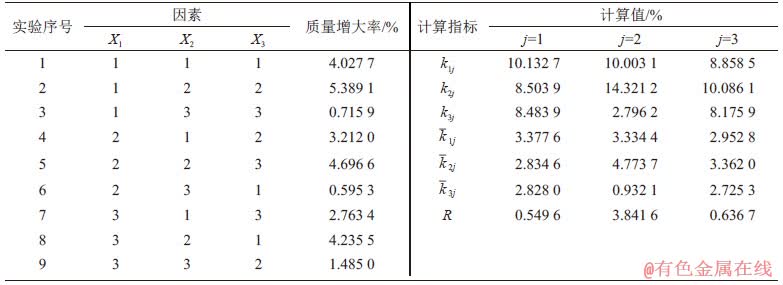

采用质量增大率作为矿石样品氧化活性的评价指标。根据表2中的因素及其水平,采用正交表L9(34)设计多因素实验方案。采用直观分析法,计算各因素在相应于同一水平下的质量增大率之和kij及其平均值 ,最后计算各列的极差R。R最大的列是影响实验结果的关键因素,计算式如下:

,最后计算各列的极差R。R最大的列是影响实验结果的关键因素,计算式如下:

(5)

(5)

(6)

(6)

2 单因素实验结果

根据单因素实验可知,自然环境和恒温恒湿环境下样品质量增大率曲线的变化趋势基本一致,只有氧化钝化时间节点和测得的氧化活性不同,因此,仅选择恒温恒湿环境下的氧化实验进行分析。

2.1 样品质量变化趋势

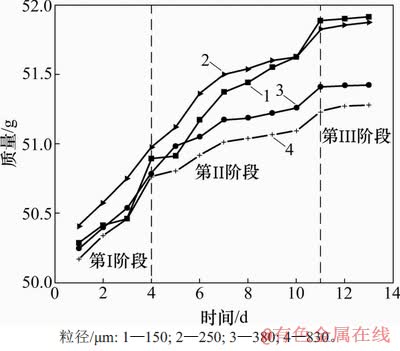

通过对质量变化曲线的分析可以发现矿石样品在常温条件下的质量变化趋势包括3个阶段:快速增大阶段(Ⅰ)、增幅减小阶段(Ⅱ)和基本不变阶段(Ⅲ)。在第Ⅰ阶段,氧化产物覆盖在矿石颗粒表面,表面积增加,氧分子更容易吸附在矿石颗粒表面,与中间产物发生反应,样品质量迅速增加;在第Ⅱ阶段,矿石颗粒表面逐渐被氧化并产生团聚,吸氧量特别是化学吸附减少,样品质量在此阶段缓慢增加;在第Ⅲ阶段,矿石颗粒表面完全被氧化,吸氧主要是物理吸附,样品质量在这一阶段基本趋于稳定。图2所示为部分样本的质量变化趋势。

图2 部分样品的质量变化趋势

Fig. 2 Mass varation trend of partial samples

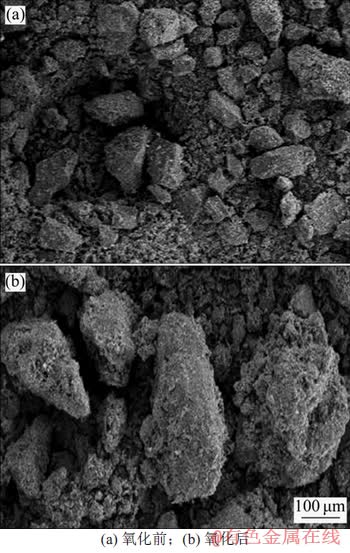

2.2 氧化前后样品的表观特征变化

典型矿石样品氧化前后的扫描电镜照片如图3所示。从图3可见:氧化前,矿样表面比较光洁,粒度较均匀;氧化后的矿石样品表面有明显的结块现象,这是由化学反应和溶解作用引起的;在氧化过程中,矿石中的可变价元素(Fe和S)发生变化,导致矿物成分、晶体形态、密度和比热容发生变化,这是形成结块的重要原因;此外,当矿石颗粒从空气中吸收水分或矿石颗粒内的水扩散到其表面时,会在表面形成溶液膜,若溶液膜的水分蒸发,则溶液膜就会变成饱和溶液,导致结晶;随着时间推移,结晶聚合形成结晶桥,矿石颗粒通过晶桥结合在一起,形成结块。

图3 典型样品的扫描电镜照片

Fig. 3 SEM photographs of typical sample

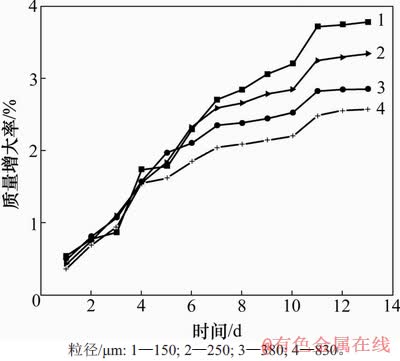

2.3 矿石粒度对样品质量增大率的影响

图4所示为不同矿石粒度的样品质量增大率变化曲线。由图4可知:样品质量增大率与矿石粒度呈负相关关系。这是因为矿石粒度越小,比表面积越大,矿石与氧气的接触面积越大,从而更易促进矿石氧化。在采矿生产过程中,通过优化爆破参数,可有效控制矿石块度,避免产生大量的粉状矿石,防止快速氧化自燃。

图4 不同粒径的样品质量增大率变化曲线

Fig. 4 Change curves of mass increase rate of samples with different particle sizes

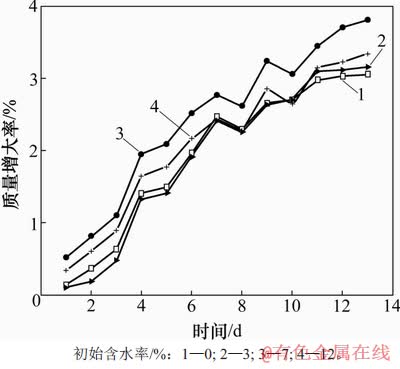

2.4 初始含水率对样品质量增大率的影响

实验结果表明,随着初始含水率增加,样品质量增大率先增大后减小,其原因是水对硫化矿石自燃具有催化和抑制双重作用。适量的水可以促进硫化矿石的氧化反应,因为它是氧化过程中的反应物,并且能使氧气和许多具有离子键的硫化物溶解参与电化学反应。但过量的水会因其冷却和隔氧的物理作用而抑制氧化反应,因此,只有当硫化矿石堆规模较小时,才能采取喷水灭火的措施。实验结果如图5所示。

图5 不同初始含水率的样品质量增大率变化曲线

Fig. 5 Change curves of mass increase rate of samples under different initial moisture contents

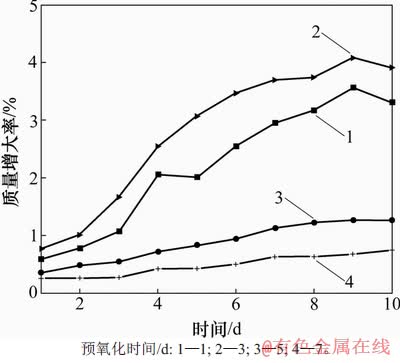

2.5 预氧化时间对样品质量增大率的影响

不同预氧化时间下样品质量增大率变化曲线如图6所示。由图6可知:随着预氧化时间增长,样品质量增大率先增大后减小;当预氧化时间太短时,硫化矿物没有完全溶解,其氧化活性也没有完全被激活,在这种情况下,矿石的氧化速度很慢;当预氧化时间太长时,在矿石表面会形成氧化膜,阻碍水和氧气的进一步反应。因此,在采矿过程中,出矿时间应在最佳预氧化时间之前,以抑制快速氧化。

图6 不同预氧化时间的样品质量增大率变化曲线

Fig. 6 Change curves of mass increase rate of samples under different pre-oxidation time

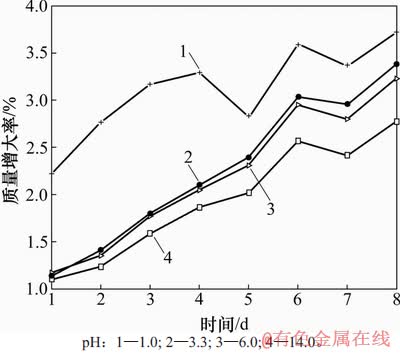

2.6 环境pH对样品质量增大率的影响

不同环境pH下的样品质量增大率如图7所示。从图7可见:随着环境pH降低,样品质量增大率增大。这是因为在低pH时可以防止铁离子沉淀。此外,硫杆菌和嗜酸菌的氧化活性也需要特定的酸性条件。李济吾[17]采用电化学方法测定了不同酸碱度下矿石样品的氧化速率,发现在低pH条件下,样品的氧化速率较快,这在本实验中得到了验证。因此,在保持硫化矿石的原有性质的前提下,可利用石灰水等碱性物质增大环境pH,以达到抑制自燃的目的。

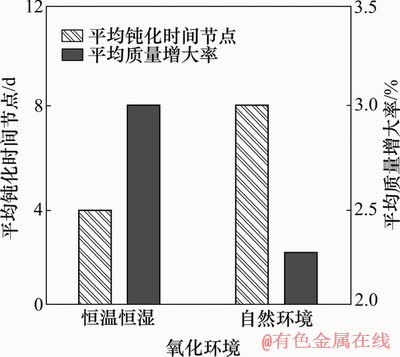

2.7 氧化环境对样品质量增大率的影响

不同氧化环境对样品质量增大率变化的影响主要体现在不同的氧化钝化时间节点和质量增大率。氧化钝化时间节点定义为样品质量增大率曲线的斜率下降点,图8所示为不同氧化环境对样品质量增大率的影响结果。从图8可知:在恒温恒湿环境和自然环境下,氧化钝化时间节点平均值分别为4 d和8 d,质量增大率平均值分别为3.018 3%和2.286 1%,说明较高的温度和湿度对硫化矿石氧化有促进作用。为了评价硫化矿石的最大吸氧能力,应在恒温恒湿环境下测定质量增大率。

图7 不同环境pH下的样品质量增大率变化曲线

Fig. 7 Change curves of mass increase rate of samples under different environmental pH

图8 氧化环境对样品质量增大率的影响

Fig. 8 Influence of oxidation environment on mass increase rate of samples

3 多因素实验结果

在恒温恒湿环境下进行多因素实验,实验结果如表3所示。从表3可见:初始含水率、预氧化时间、矿石粒度对样品质量增大率的影响依次降低。其原因可能是水分蒸发和高湿度环境作用,初始含水量的微弱变化会导致催化作用和阻化作用相互转换,因此,在这种情况下,初始含水率对质量增大率的影响最大;恒温恒湿箱的氧化环境非常适宜硫化矿石的氧化,矿样在一定的粒度变化范围内可以完全氧化,所以,粒度对质量增大率的影响最小。

4 基于神经网络的质量增大率预测

4.1 确定输入和输出单元

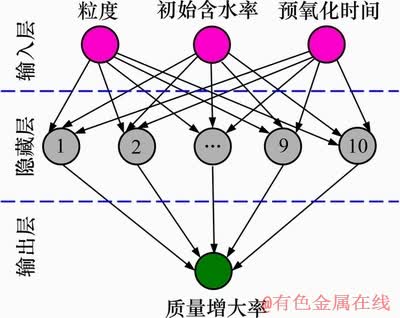

利用BP神经网络对硫化矿石的质量增大率进行预测,是因为它具有较强的局部搜索能力。选择粒度、初始含水率和预氧化时间作为输入单元,即输入层节点数n=3;输出单元为质量增大率,即输出层节点数m = 1。

4.2 网络训练

采用18组实测数据(单因素实验12组和多因素实验前6组)对网络进行训练。隐藏层节点数l由以下公式确定:

(7)

(7)

表3 多因素实验结果

Table 3 Multi-factor experimental results

其中:a为介于0和10之间的常数。

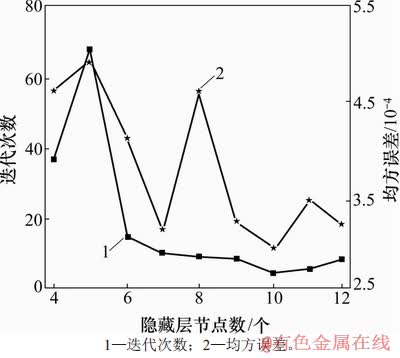

从式(7)可以看出:l介于2和12之间,通过试算确定隐藏层节点的最佳数目。将隐藏层和输出层的传递函数分别设置为tansig和purelin,网络训练函数为trainlm。学习率、训练迭代次数和网络误差分别取0.05,1 000和0.000 5,在网络训练前对数据进行归一化处理。计算结果表明:当隐藏层节点数小于4时,训练误差大于0.000 5。隐藏层节点数(从4到12)与迭代次数和训练误差之间的关系如图9所示。从图9可见:当隐藏层节点数为10时,仅需4次迭代就可达到设定结果,最小训练误差为0.000 29,因此,最佳隐藏层节点数为10。

用于预测样品质量增大率的神经网络结构为3-10-1,如图10所示。

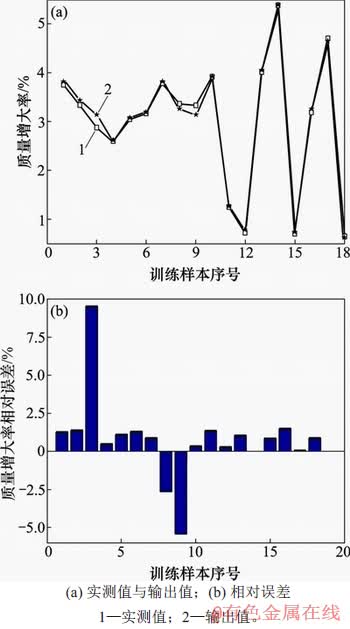

图11所示为神经网络的训练结果。从图11可见:样品质量增大率的输出值与实测值一致,相对误差的最大值和最小值分别为9.511 5%和0.002 0%。

4.3 质量增大率预测

选取最后3组多因素实验测量数据作为预测样本,预测效果如表4所示。从表4可见:与实测值相比,样品质量增大率预测相对误差小于10%,表明建立的BP神经网络具有较高的预测精度,可用于预测硫化矿石的质量增大率。

硫化矿石自燃是一个混沌演化过程[18],也就是说,初始实验条件的微小差异可能会导致测量结果发生较大变化。此外,在实验过程中,质量增大率的测量结果会受到许多不可控因素的影响,如水分蒸发、空气中的尘埃沉降和电子天平的测量误差等,因此,需要进一步验证测量结果的准确性。神经网络具有分析复杂非线性系统的优点,可以用来验证测量结果的可靠性。实际应用结果表明,本文建立的神经网络模型具有较高的预测精度。

图9 隐藏层节点数与迭代次数和训练误差之间的关系

Fig. 9 Relationship between number of hidden layer nodes and iterations and training error

图10 预测样品质量增大率的神经网络结构

Fig. 10 Structure of neural network for mass increase rate prediction of samples

图11 样品质量增大率的神经网络训练结果

Fig. 11 Training results of neural network for mass increase rate of samples

表4 样品质量增大率的神经网络预测效果

Table 4 Prediction effect of neural network for mass fraction rate of samples %

需要指出的是,硫化矿石的氧化过程不单受到本次实验提到的这些因素的影响。为了验证本次研究结果的普适性,下一步将在不同实验条件下开展多样本实验研究。

5 结论

1) 硫化矿石在常温条件下的质量变化趋势分为3个阶段:快速增大阶段、增幅减小阶段和保持不变阶段。氧化前矿样表面比较光洁,粒度较均匀。氧化后的矿样表面有明显结块现象。

2) 随着粒度和环境pH增大,样品质量增大率降低。随着初始含水率和预氧化时间增大,样品质量增大率先增大后减小。在恒温恒湿环境和自然环境下,氧化钝化时间节点平均值分别为4 d和8 d,样品质量增大率平均值分别为3.018 3%和2.286 1%,表明高温高湿环境对硫化矿石氧化有促进作用。

3) 3种因素对样品氧化质量增大率的影响程度由大至小依次为初始含水量、预氧化时间、粒度。

4) 用于样品质量增大率预测的神经网络具有3-10-1的结构,该神经网络具有较高的预测精度,相对误差小于10%。

参考文献:

[1] WU Chao, LI Zijun, YANG Fuqiang, et al. Risk forecast of spontaneous combustion of sulfide ore dump in a stope and controlling approaches of the fire[J]. Archives of Mining Science, 2008, 53(4): 565-579.

[2] ROSENBLUM F, NESSET J, SPIRA R. Evaluation and control of self-heating in sulphide concentrates[J]. Cim Bulletin, 2001, 94(1056): 92-99.

[3] BOUFFARD S C, SENIOR G D. A new method for testing the self-heating character of sulphide concentrates[J]. Minerals Engineering, 2011, 24(13): 1517-1519.

[4] PAYANT R A, FINCH J A. The effect of sulphide mixtures on self-heating[J]. Canadian Metallurgical Quarterly, 2010, 49(4): 429-434.

[5] ROSENBLUM F, NESSET J E, MOON S, et al. Reducing the self-heating of sulphides by chemical treatment with lignosulfonates[J]. Minerals Engineering, 2017, 107: 78-80.

[6] NGABE B, FINCH J A. Self-heating activation energy and specific heat capacity of sulphide mixtures at low temperature[J]. Minerals Engineering, 2014, 55: 154-161.

[7] WU Chao, LI Zijun, LI Ming. Chemical thermodynamic mechanism of sulfide ores during oxidation and self-heating process[C]//Proceedings of the 2007 International Symposium on Mining Safety Science and Technology. Beijing: Science Press, 2007: 2435-2439.

[8] PAN Wei, LIAO Jun, WU Chao, et al. Numerical simulation of self-heating and its influence factors of sulfide ore heap[C]//Proceedings of International Symposium on Rock Mechanics and Mine Dynamic Disaster Prevention. Beijing: China Coal Industry Publishing House, 2013: 221-227.

[9] PAYANT R, ROSENBLUM F, NESSET J E, et al. The self-heating of sulfides: Galvanic effects[J]. Minerals Engineering, 2012, 26: 57-63.

[10] YANG Fuqiang, WU Chao. Mechanism of mechanical activation for spontaneous combustion of sulfide minerals[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(1): 276-282.

[11] PAN Wei, WU Chao, LI Zijun, et al. Self-heating tendency evaluation of sulfide ores based on nonlinear multi-parameters fusion[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(2): 582-589.

[12] WANG Hongjiang, XU Chaoshui, WU Aixiang, et al. Inhibition of spontaneous combustion of sulfide ores by thermopile sulfide oxidation[J]. Minerals Engineering, 2013, 49: 61-67.

[13] 邓艳星. 硫化矿石结块机理及其检测技术研究[D]. 长沙: 中南大学资源与安全工程学院, 2010: 40-41.

DENG Yanxing. Research on caking mechanism of sulfide ores and its detection technology[D]. Changsha: Central South University. School of Resources and Safety Engineering, 2010: 40-41.

[14] 李孜军, 徐志国, 邓艳星. 氧化增重法测试硫化矿石低温氧化性参数优化[J]. 中国安全科学学报, 2012, 22(6): 54-59.

LI Zijun, XU Zhiguo, DENG Yanxing. Parameter optimization of oxidation weight increase method for oxidability detection of sulfide ores at low temperature[J]. China Safety Science Journal, 2012, 22(6): 54-59.

[15] 周惠斌, 李孜军, 牛娇. 硫化矿石5天氧化质量增大率测定值影响因素实验研究[J]. 世界科技研究与发展, 2016, 38(2): 377-381.

ZHOU Huibin, LI Zijun, NIU Jiao. Study on 5 days oxidation weight growth rate measure factors of sulfide ores[J]. World Sci-Tech R & D, 2016, 38(2): 377-381.

[16] 吴谦, 王常明, 王天佐, 等. 路基边坡降雨试验及基于神经网络的水分场研究[J]. 中南大学学报(自然科学版), 2016, 47(4): 1237-1244.

WU Qian, WANG Changming, WANG Tianzuo, et al. Rainfall infiltration test on subgrade slope and study on moisture migration by neural network[J]. Journal of Central South University(Science and Technology), 2016, 47(4): 1237-1244.

[17] 李济吾. 溶液pH值对硫化矿石氧化速度的影响研究[J]. 南方冶金学院学报, 1993, 14(2): 95-101.

LI Jiwu. Research for the effect of pH value on oxidation rate of sulfide ore[J]. Journal of Southern Institute of Metallurgy, 1993, 14(2): 95-101.

[18] PAN Wei, WU Chao, LI Zijun, et al. Nonlinear characteristics of induced spontaneous combustion process of sulfide ores[J]. Journal of Central South University, 2016, 23(12): 3284-3292.

(编辑 陈灿华)

收稿日期: 2019 -05 -01; 修回日期: 2019 -07 -10

基金项目(Foundation item):国家重点研发计划项目(2018YFC008404);国家自然科学基金资助项目(51304238, 51534008);中央高校基本科研业务费专项资金资助项目(2018zzts074); 金属矿山高效开采与安全教育部重点实验室基金资助项目(ustbmslab201805) (Project(2018YFC0808404) supported by the National Key R&D Program of China; Projects(51304238,51534008) supported by the National Natural Science Foundation of China; Project(2018zzts074) supported by the Fundamental Research Funds for the Central Universities; Project(ustbmslab201805) supported by the Foundation of Key Laboratory of Ministry of Education of China for Efficient Mining and Safety of Metal Mines)

通信作者:潘伟,博士,副教授,从事矿山安全、环境保护等研究;E-mail: panwei2012@csu.edu.cn