文章编号:1004-0609(2013)06-1536-06

基于激光预焊芯板夹层的超塑成形/扩散连接先进工艺

王大刚,陈明和,王 宁,谢兰生

(南京航空航天大学 机电学院,南京 210016)

摘 要:针对传统多层空心整体结构在超塑成形/扩散连接(SPF/DB)工艺过程中存在的中心夹层焊接可靠性差的关键工艺问题,以某飞行器TC4(T-6Al-4V)钛合金舵体四层空心复合整体结构为对象,提出了激光预焊芯板夹层的超塑成形/扩散连接新工艺。基于有限元软件模拟仿真分析及相应的试验研究,采用激光预焊芯板夹层的SPF/DB先进工艺,进行某飞行器TC4钛合金四层空心复合整体舵体零件的研制。结果表明:运用SPF/DB新工艺,在920 ℃、真空度为5×10-3 Pa、最大气压压力为1.2 MPa 条件下超塑成形/扩散连接成形出合格的舵体零件,其焊合率达95%以上,壁厚分布均匀性大于90%,晶粒尺寸长大控制在35%以内。

关键词:TC4钛合金;激光焊接;超塑成形;扩散连接;有限元模拟;舵体

中图分类号:TG457.19 文献标志码:A

Advanced technology of superplastic forming and diffusion bonding with laser pre-welding core sheets

WANG Da-gang, CHEN Ming-he, WANG Ning, XIE Lan-sheng

(College of Mechanical and Electrical Engineering, Nanjing University of Aeronautics and Astronautics, Nanjing 210016, China)

Abstract: In view of the traditional multilayer hollow structure superplastic forming and diffusion bonding (SPF/DB) process which leads to a poor reliability of welding core interlayer, a new method based on laser pre-welding for core layers was raised up for the aircraft rudder of four TC4 (Ti-6Al-4V) titanium alloy layers with composite hollow structure. With the experimental study and corresponding finite element simulation analysis carried out, a forming method of the four layers aircraft rudder body part was developed based on the new SPF/DB process of laser pre-welding core sheets. The results show that: adopting the new SPF/DB technology under the conditions that at the temperature of 920 ℃, vacuum degree of 5×10-3 Pa, and the maximum pressure of 1.2 MPa, the rudder body part is qualified reaching a welding rate above 95% and wall thickness distribution uniformity greater than 90%,and controlling the grain size growth in 35%.

Key words: TC4 titanium alloy; laser welding; superplastic forming; diffusion bonding; finite element simulation; rudder

轻量化、高可靠性是现代航空航天飞行器的发展趋势,整体结构代替传统的多部件组合结构是促进其实现的有效途径。SPF/DB技术能够实现飞行器异形件一次整体精密成形,从而减轻结构质量,降低生产成本,实现结构设计与制造的灵活性,尤其在多层板结构的制造方面具有很大优越性,为这一发展趋势提供了可能。但是传统的SPF/DB工艺存在一系列问题和局限性:止焊剂图形制备困难,易导致连接不充分或者气路堵死,成形零件晶粒粗大等。英国和俄罗斯等国研究者分别采用点滚焊来焊接芯板,该方法所得焊缝宽度大,焊缝边缘呈锯齿状且不连续,在超塑成形过程中容易导致板料破裂[1-8],故急需寻求一种更好的方法来弥补传统工艺的不足。

激光焊接具有能量密度高、效率高、精度高和操作方便等优势,而且所得焊缝窄、热影响区及焊接变形小,适用于多层板SPF/DB工艺芯板预焊[9-12]。近两年来,已有不少学者将激光焊接技术引入到SPF/DB中,YAN等[13]研究了5083铝合金三层板LBW/SPF (Laser beam welding,简称LBW)的成形;QU等[14]研究了Inconel718合金三层圆柱形加强结构LBW/SPF的成形;李保永[15]研究了TA15钛合金多层结构 LBW/SPF/DB 工艺;曲凤盛等[16]研究了GH4169高温合金三层板结构的LBW/SPF组合技术[13-16],但都仅限于基础研究,所研究零件结构比较简单,且对TC4钛合金,以往学者只限于对其激光焊缝微观组织及超塑性行为进行研究,并未对整套LBW/SPF/DB工艺进行研究。本文作者利用激光焊接芯板,结合SPF/DB工艺研究了某TC4钛合金舵体复杂结构的成形工艺。

1 实验

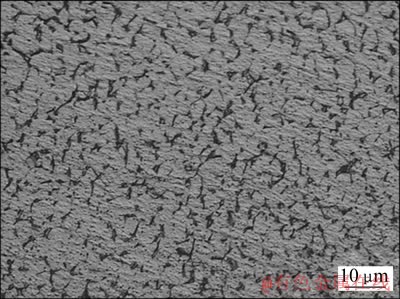

本实验所用TC4钛合金细晶板材面板和芯板厚度分别为1.0和0.6 mm。其主要化学成分见表1,原始显微组织如图1所示,常温下的力学性能见表2。实验前先用丙酮溶液清洗板料,再用HF、HNO3、H2O(体积比1:3:6)混合酸溶液清洗30 s,去除表面氧化膜。

图1 TC4钛合金的原始显微组织

Fig. 1 Original microstructure of TC4 titanium alloy

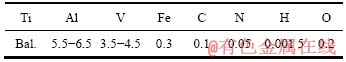

表1 TC4钛合金的主要化学组成

Table 1 Chemical components of TC4 titanium alloy (mass fraction, %)

表2 常温下TC4钛合金的力学性能

Table 2 Mechanical properties of TC4 titanium alloy at room temperature

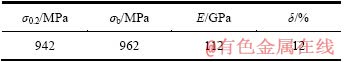

芯板的激光熔焊在BD-JG-600型Nd-YAG激光发生器上进行,激光器的最大输出功率为500 W。焊接时板料由合适的夹具夹持,正反两面均采用高纯氩气保护。设计正交试验来确定两层板激光熔焊的最优工艺参数,激光焊接接头的剪切强度测试在电子万能试验机上进行。舵体超塑成形/扩散连接实验在超塑成 形/真空扩散连接机床上进行,其示意图如图2所示。实验过程中真空度保持在5×10-3 Pa,待模具温度加热到920 ℃时保温30 min,开始向芯板之间通入高纯氩气,气压加载曲线由有限元软件ABAQUS模拟得出。

对成形后舵体扩散连接部分进行微观组织分析,金相试样经打磨抛光后用 5%HF+10%HNO3(体积分数)水溶液侵蚀腐蚀10 s,采用OLYMPNS-GX51显微镜观察金相组织。

图2 舵体超塑成形/扩散连接工艺示意图

Fig. 2 Schematic illustration of SPF/DB process for rudder

2 结果与分析

2.1 芯板激光熔焊

实验选取焦点在板料上表面以下0.3 mm处,通过设计的正交试验,在不同的激光焊接参数组合下分别焊接了剪切试样,对接头进行了室温单拉实验,根据接头的剪切强度(剪切断裂)或抗拉强度(拉伸断裂)以及外观形貌,确定了两层板激光熔焊的最优工艺参数如下:电流110 A,脉宽12 ms,频率12 Hz,焊接速度150 mm/min,由此组参数焊接的接头强度达780 MPa,为母材抗拉极限的81%。

根据已确定的激光焊接参数,进行两层芯板的激光穿透焊接,激光焊接后芯板照片如图3所示。由图3可以看出,焊缝外观良好,表面呈银白色,几乎没有氧化,焊缝热影响区未产生微裂纹,且整块板在合适的夹具作用下没有翘曲变形,保证了后续实验的顺利进行。

图3 激光焊接后芯板照片

Fig. 3 Photo of core sheets after laser welding

2.2 舵体超塑成形/扩散连接

在本实验中,上、下两层面板在680 ℃已预先成形,其照片如图4所示,仅需进行芯板的超塑成形,在芯板超塑成形的同时完成芯板和面板以及芯板直立筋之间的扩散连接。与传统方法相比,不仅省去了面板超塑成形这一步,减少了板料在高温环境中的时间,有效防止了板料晶粒尺寸的严重长大,能够保证成形后零件的力学性能,而且只需要一个通气管路,简化了气路设计。

图4 预成形面板照片

Fig. 4 Photo of face sheet after post forming

成形压力对控制多层结构的外形十分重要,压力的主要作用是确保芯板在超塑成形时完全贴膜以及贴膜后与面板的扩散连接,合理控制气压和时间,可使成形后的多层结构具有良好外观形状及均匀的壁厚分布,芯板超塑成形气压的加载曲线由有限元软件ABAQUS模拟得出,模拟分析所用本构关系模型如下:

(1)

(1)

其中: 为单轴等效蠕变应变速率;

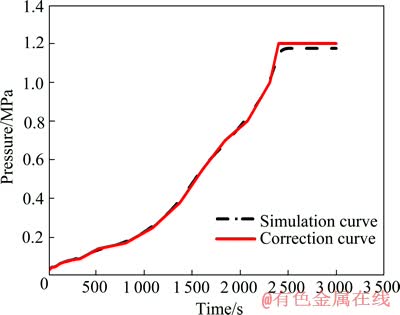

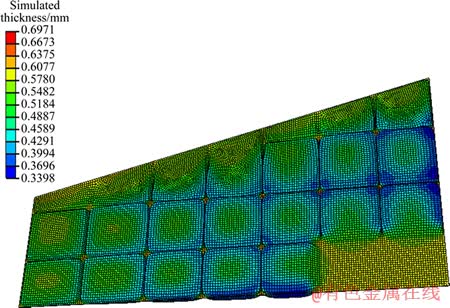

为单轴等效蠕变应变速率; 为米塞斯各项同性情况下的等效应力;A、n由材料、温度等因素决定,在本实验成形条件下,A=6.58×10-6,n=1.754。模拟过程中控制目标应变速率为9.8×10-4 s-1。图5所示为气压加载模拟曲线以及修正后曲线;图6所示为芯板超塑成形最终厚度分布模拟结果。由图6可知,模拟成形构件大部分区域厚度在0.45~0.60 mm,说明成形件壁厚是相对均匀的。

为米塞斯各项同性情况下的等效应力;A、n由材料、温度等因素决定,在本实验成形条件下,A=6.58×10-6,n=1.754。模拟过程中控制目标应变速率为9.8×10-4 s-1。图5所示为气压加载模拟曲线以及修正后曲线;图6所示为芯板超塑成形最终厚度分布模拟结果。由图6可知,模拟成形构件大部分区域厚度在0.45~0.60 mm,说明成形件壁厚是相对均匀的。

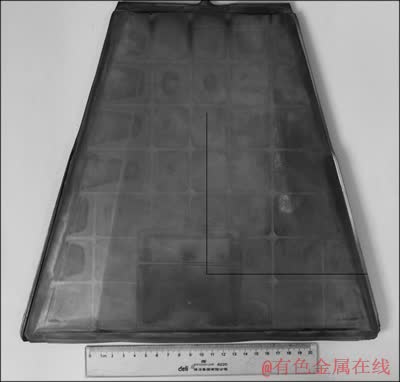

SPF/DB成形后的舵体零件照片如图7所示。在该工艺条件下成形的零件贴膜完全且外观质量良好,表面不存在沟槽、坍塌等传统工艺中常见的缺陷,表明SPF/DB所选取的参数较为合理。

图5 SPF/DB工艺中压力—时间关系曲线

Fig. 5 Relationship between gas pressure and time during SPF/DB process

图6 厚度分布云图

Fig. 6 Cloud picture of thickness distribution

图7 成形后舵体照片

Fig. 7 Photo of rudder after forming

2.3 成形零件壁厚分布

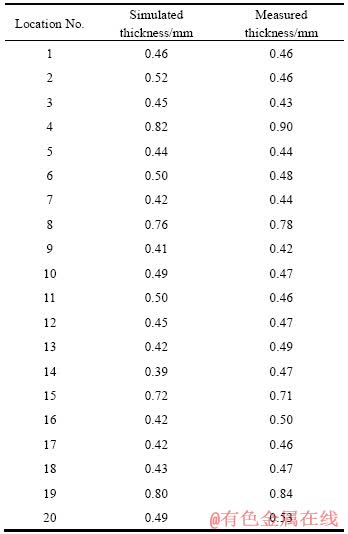

超塑成形质量优劣的一个重要指标是成形零件是否具有均匀一致的壁厚分布。图8所示为沿图7所示两条线所截取的舵体剖面图。从图8可以看出,舵体内部加强筋完全直立,上下对称,没有扭曲或者弯曲现象,激光焊接处也不存在撕裂现象。表4所列为成形后芯板各部位实测厚度(由于芯板厚度无法直接测量,通过测量面板和芯板总厚度,然后减去面板厚度1 mm)与模拟厚度分布对照。对表4中数据进行分析,可知超塑性成形后的芯板壁厚较均匀,平均尺寸为0.47 mm,直立加强筋扩散连接部分平均壁厚为0.81 mm,实测厚度与模拟厚度最大相差0.08 mm,说明模拟结果与实测结果有很好的一致性,为SPF/DB工艺提供了非常有价值的参考。另外,模拟结果与实测结果同时显示,加强筋附近的壁厚小于两加强筋中间位置的壁厚,这是由于靠近加强筋位置的材料在超塑成形过程中最后贴膜,在拉伸和剪切共同作用下,其塑性变形量较大,故相对于其他位置减薄较大,模拟结果显示芯板最大减薄率为43%,在可接受的范围内。

图8 舵体局部横截面实物图

Fig. 8 Photo of partial cross sections of rudder

表4 舵体局部厚度分布

Table 4 Thickness distribution of rudder shown in Fig. 8

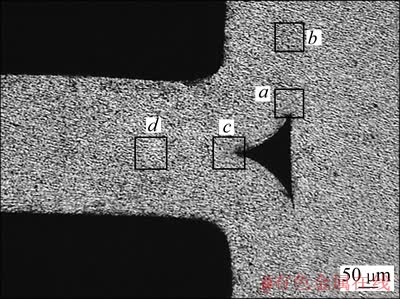

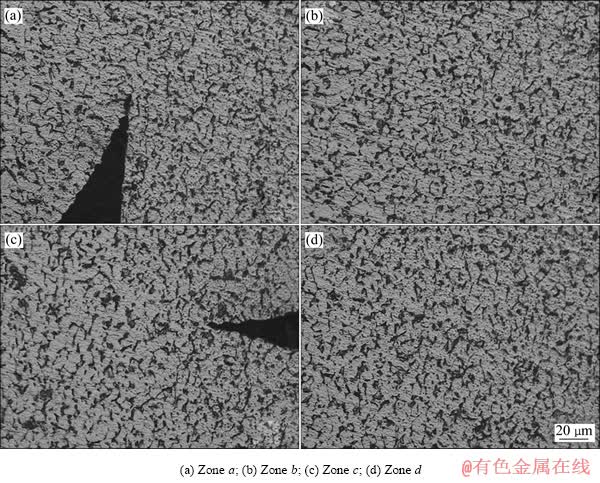

2.4 扩散连接微观组织分析

图9所示为直立筋与面板交汇处金相组织。从图9可以看出:芯板与芯板之间(即直立筋)以及芯板与面板之间已形成较好扩散连接,只是在芯板与面板交汇处未完全贴合,形成一个截面为三角形的未闭合区域。其原因是此区域材料在超塑性成形过程中最后贴膜,且直立筋与面板在此处形成直角,需要更大的压力才能成形完全,因此,可以考虑在最终成形时将压力提高到1.5 MPa,尽量减小此未闭合区域。此外,在直立加强筋之间即激光焊缝处也存在两条未闭合区域,需要提高成形压力以便消除此缺陷,对于这两处问题有待于进一步研究解决。

图9 直立筋与面板交汇处微观组织

Fig. 9 Microstructure at junction of vertical rib and face sheet

图10 扩散连接各部位的微观组织

Fig. 10 Microstructures of each part of diffusion bonding shown in Fig. 9

图10所示为图9中各部位的显微组织放大照片。图10(a)和(b)所示为面板与芯板焊缝金相组织,可以看出,绝大部分接合面都互相融合,扩散连接在一起,只有在直立筋与面板交汇处存在少量未闭合空洞;图10(c)和(d)所示为芯板与芯板之间的焊缝金相组织,从图中已找不到空洞的存在,说明焊合效果很好。国内外对扩散连接焊合率还没有完善的检测手段,目前主要通过金相组织观察焊缝,然后统计焊合率。本文作者通过对零件纵向和横向各部位等距离取样观察焊缝,结果显示整体焊合率可达95%。与材料的原始组织相比(见图1)可以看出,成形后材料晶粒明显长大, 晶粒尺寸增大了35%,但比较此工艺与传统的工艺可知[17](

晶粒尺寸增大了35%,但比较此工艺与传统的工艺可知[17]( 晶粒尺寸增大了69%),由于材料在高温环境中的时间大幅缩短,晶粒长大现象得到了很好控制,这对成形后零件的力学性能有很大改善。

晶粒尺寸增大了69%),由于材料在高温环境中的时间大幅缩短,晶粒长大现象得到了很好控制,这对成形后零件的力学性能有很大改善。

3 结论

1) 在920 ℃、真空度为5×10-3 Pa、最大气压压力为1.2 MPa情况下超塑成形/扩散连接成形得到合格的舵体零件,验证了芯板激光焊接代替扩散连接工艺的可行性,从而可以改进传统SPF/DB工艺中存在的一系列问题。

2) 有限元模拟可以获得优化的气压加载曲线,为实际超塑成形的压力控制提供重要依据,从而提高成形精度,并有利于提高成形件的质量。壁厚分布模拟结果也为SPF/DB工艺提供了非常有价值的参考。

3) 通过正交实验确定了厚度为0.6 mm的两层TC4板料激光熔焊的工艺参数如下:离焦量-0.3 mm,电流110 A,脉宽12 ms,频率12 Hz,焊接速度150 mm/min。

4) 成形零件晶粒尺寸较传统方法晶粒尺寸小,成形后零件力学性能较传统方法好,总体焊合率可达95%。

REFERENCES

[1] 王宝仁, 纪文海. TC4钛合金超塑成形/扩散连接组合工艺应用研究[J]. 航空学报, 1989, 10(6): B309-B314.

WANG Bao-ren, JI Wen-hai. The research of superplastic forming and diffusion bonding for Ti-6Al-4V alloy[J]. Chinese Journal of Aeronautics, 1989, 10(6): B309-B314.

[2] 于卫新, 李淼泉, 胡一曲. 材料超塑性和超塑成形/扩散连接技术及应用[J]. 材料导报, 2009, 23(6): 8-14.

YU Wei-xin, LI Miao-quan, HU Yi-qu. Superplasticity and application of superplastic forming/diffusion bonding technology[J]. Materials Review, 2009, 23(6): 8-14.

[3] 郭和平, 曾元松, 韩秀全, 李志强. 飞机钛合金整体结构的超塑成形/焊接组合工艺技术[J]. 航空航天焊接专题, 2008, 11: 41-45.

GUO He-ping, ZENG Yuan-song, HAN Xiu-quan, LI Zhi-qiang. Superplastic forming/welding combination technology of titanium alloy integrated structure of aircraft[J]. Welding Technology in Aeronautics and Astronautics, 2008, 11: 41-45.

[4] 韩文波, 张凯峰, 王国锋. Ti-6Al-4V合金多层板结构的超塑成形/扩散连接工艺研究[J]. 航空材料学报, 2005, 25(6): 29-32.

HAN Wen-bo, ZHANG Kai-feng, WANG Guo-feng. Superplastic forming and diffusion bonding for multilayer structure of Ti-6Al-4V alloy[J]. Journal of Aeronautical Materials, 2005, 25(6): 29-32.

[5] LI Zhi-qiang, GUO He-ping. Application of superplastic forming and diffusion bonding in the aerospace industry. Materials Science Forum[J]. 2005, 475: 3037-3042.

[6] HAN Wen-bo, ZHANG Kai-feng, WANG Guo-feng. Superplastic forming and diffusion bonding for honeycomb structure of Ti-6Al-4V alloy[J]. Journal of Materials Processing Technology, 2007, 183: 450-454.

[7] YOON J H, LEE H S, YI Y M. Finite element simulation on superplastic blow forming of diffusion bonded 4 sheets[J]. Journal of Materials Processing Technology, 2008, 201: 68-72.

[8] SANDERS D G, RAMULU M. Examination of superplastic forming combined with diffusion bonding for titanium: Prspective from experience[J]. Journal of Materials Engineering and Performance, 2004, 13: 744-752.

[9] CHENG Dong-hai, HUANG Ji-hua, ZHAO Xing-ke, ZHANG Hua. Microstructure and superplasticity of laser welded Ti-6Al-4V alloy[J]. Materials and Design, 2010, 31: 620-623.

[10] 程东海, 黄继华,林海凡, 赵兴科, 张 华. 钛合金激光焊缝的超塑性变形行为及显微组织[J]. 中国有色金属学报, 2010, 20(1): 67-71.

CHENG Dong-hai, HUANG Ji-hua, LIN Hai-fan, ZHAO Xing-ke, ZHANG Hua. Superplastic deformation behavior and microstructures of laser welded titanium alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(1): 67-71.

[11] 邹世坤, 汤 昱, 巩水利. 钛合金薄板激光焊接技术研究[J]. 焊接技术, 2003, 32(5): 16-18.

ZOU Shi-kun, TANG Yu, GONG Shui-li. Study on technology of laser welding titanium alloy sheets[J]. Welding Technology, 2003, 32(5): 16-18.

[12] 杨 静, 程东海, 黄继华, 张 华, 赵兴科, 孙 占. TC4 合金激光焊接工艺参数与接头组织性能研究[J]. 热加工工艺, 2007, 36(17): 15-18.

YANG Jing, CHENG Dong-hai, HUANG Ji-hua, ZHANG Hua, ZHAO Xing-ke, SUN Zhan. Effect of laser welding parameters on microstructure and mechanical properties of TC4 welded joints[J]. Hot Working Technology, 2007, 36(17): 15-18.

[13] YAN H H, ZHANG K F. Processing of multi-sheet structures of an aluminum alloy by laser welding/superplastic forming[J]. Materials and Design, 2010, 31: 2220-2223.

[14] QU F S, LU Z, XING F , ZHANG K F. Study on laser beam welding/superplastic forming technology of multi-sheet cylinder sandwich structure for Inconel718 superalloy with ultra-fine grains[J]. Materials and Design, 2012, 39: 151-161.

[15] 李保永. TA15钛合金多层结构 LBW/SPF/DB工艺[D]. 哈尔滨: 哈尔滨工业大学, 2010: 1-57.

LI Bao-yong. LBW/SPF/DB Processing of multi-sheet structure for TA15 titanium alloy[D]. Harbin: Harbin Institute of Technology, 2010: 1-57.

[16] 曲凤盛, 张凯锋, 吕宏军. GH4169高温合金多层板结构的激光连接/超塑成形组合技术[J]. 航空材料学报, 2009, 25(4): 27-32.

QU Feng-sheng, ZHANG Kai-feng,  Hong-jun. LBW/SPF complex forming for multi-sheet structure of GH4169 superalloy[J]. Journal of Aeronautical Materials, 2009, 25(4): 27-32.

Hong-jun. LBW/SPF complex forming for multi-sheet structure of GH4169 superalloy[J]. Journal of Aeronautical Materials, 2009, 25(4): 27-32.

[17] 门向南. TC4 三层板结构超塑成形/扩散焊接工艺研究[D]. 南京: 南京航空航天大学, 2010: 52-57.

MEN Xiang-nan. Research on superplastic forming and diffusion bonding for three-sheet structure of TC4 titanium alloy[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2010: 52-57.

(编辑 龙怀中)

收稿日期:2012-09-13;修订日期:2012-11-18

通信作者:陈明和,教授;电话:025-84892508;E-mail: meembchen@nuaa.edu.cn