石墨烯/Inconel 718复合材料的力学性能和摩擦磨损行为

来源期刊:中国有色金属学报(英文版)2018年第10期

论文作者:肖纬汗 鲁世强 王亚超 石京

文章页码:1958 - 1969

关键词:石墨烯;石墨烯/Inconel 718复合材料;力学性能;摩擦磨损性能;显微组织;选择性激光熔化

Key words:graphene; graphene/Inconel 718 composite; mechanical properties; friction and wear properties; microstructure; selective laser melting

摘 要:采用选择性激光熔化法制备石墨烯/Inconel 718复合材料,并评价其力学性能和摩擦磨损性能。采用 XRD、SEM和拉曼光谱技术对复合材料的显微组织进行表征。结果表明,采用选择性激光熔化法制备石墨烯/ Inconel 718复合材料是合理可行的,添加石墨烯纳米片对Inconel 718合金不仅产生了显著的强化效果,而且改善了摩擦学性能。1.0% 石墨烯/Inconel 718复合材料(质量分数)的屈服强度和抗拉强度比未添加石墨烯纳米片的Inconel 718合金分别提高了42%和53%,而其摩擦因数和磨损率分别降低了22.4%和66.8%。石墨烯纳米片增强Inconel 718合金的硬度增加以及在磨损表面形成的石墨烯纳米片保护层是导致摩擦因数和磨损率降低的直接 原因。

Abstract: Graphene/Inconel 718 composites were innovatively synthesized through selective laser melting, and the mechanical and tribological performances of the grapheme-reinforced Inconel 718 matrix composites were evaluated. The composite microstructures were characterized by XRD, SEM and Raman spectroscopy. The results show that selective laser melting is a viable method to fabricate Inconel 718 matrix composite and the addition of graphene nanoplatelets leads to a significant strengthening of Inconel 718 alloy, as well as the improvement of tribological performance. The yield strength and ultimate tensile strength of 1.0% graphene/Inconel 718 composites (mass fraction) are 42% and 53% higher than those of pure material, and the friction coefficient and wear rate are 22.4% and 66.8% lower than those of pure material. The decrease of fraction coefficient and wear rate is attributed to the improved hardness of composites and the formation of graphene nanoplatelet protective layer on the worn surfaces.

Trans. Nonferrous Met. Soc. China 28(2018) 1958-1969

Wei-han XIAO1, Shi-qiang LU2, Ya-chao WANG3, Jing SHI3

1. School of Materials Science and Engineering, Nanchang Hangkong University, Nanchang 330063, China;

2. School of Aeronautical Manufacturing Engineering, Nanchang Hangkong University, Nanchang 330063, China;

3. Department of Mechanical and Materials Engineering, University of Cincinnati, Cincinnati, OH 45221, USA

Received 1 July 2017; accepted 8 March 2018

Abstract: Graphene/Inconel 718 composites were innovatively synthesized through selective laser melting, and the mechanical and tribological performances of the grapheme-reinforced Inconel 718 matrix composites were evaluated. The composite microstructures were characterized by XRD, SEM and Raman spectroscopy. The results show that selective laser melting is a viable method to fabricate Inconel 718 matrix composite and the addition of graphene nanoplatelets leads to a significant strengthening of Inconel 718 alloy, as well as the improvement of tribological performance. The yield strength and ultimate tensile strength of 1.0% graphene/Inconel 718 composites (mass fraction) are 42% and 53% higher than those of pure material, and the friction coefficient and wear rate are 22.4% and 66.8% lower than those of pure material. The decrease of fraction coefficient and wear rate is attributed to the improved hardness of composites and the formation of graphene nanoplatelet protective layer on the worn surfaces.

Key words: graphene; graphene/Inconel 718 composite; mechanical properties; friction and wear properties; microstructure; selective laser melting

1 Introduction

Graphene nanoplatelets (GNPs) are sheets of sp2-bonded carbon atoms that are densely packed in a honeycomb crystal lattice [1]. They possess excellent mechanical properties, unique tribological properties, extraordinary electronic and thermal properties. GNPs show attractive prospect for being used as a nano filler material to reinforce metals, due to the superior properties such as high fracture toughness (125 GPa) [2], thermal conductivity (5 kW/(m·K)) [3], charge-carrier mobility (2×105 cm2/(V·s)) [4], and specific surface area (2630 m2/g) [5]. Recently, many studies have shown that the wear resistance, anti-seizing and thermal conductivity of metal parts can be enhanced by addition of GNPs due to their excellent mechanical properties and self-lubricating nature. Moreover, GNPs usually form a self-lubricating layer at the sliding contact interfaces, avoiding the direct contact of sliding surfaces and alleviating the plowing effect of hard protrusions on wear counterparts [6,7]. Although GNPs are regarded as ideal reinforcement and effective solid lubricant in metal matrix composites (MMCs), the investigation of GNPs reinforced MMCs produced by additive manufacturing method is still at preliminary stage and the tribological properties of this composite are rarely studied [8-10]. In other related studies on MMCs produced by other methods, more information can be found. SHIN et al [11] demonstrated the ultra-low friction coefficient (approximately 0.03) of exfoliated and epitaxial GNPs in micro-scale scratch tests under ambient conditions. XU et al [8] studied the tribological properties of TiAl matrix self-lubricating materials reinforced by GNPs. It is found that GNPs are easily sheared and the island-like plates with different sizes smear on the worn surfaces, forming an anti-wear protective layer at the sliding contact interfaces, and therefore drastically reducing the friction coefficients and wear rates of TiAl matrix materials.

On the other hand, Inconel 718 alloy is widely used in turbine disk blades, axis, support, and fasteners [12], thanks to its excellent hot corrosion resistance, fatigue resistance, wear resistance and good weldability with outstanding high strengths at elevated temperatures [13]. The requirements of mechanical and tribological properties for such a material are strictly high as they are frequently used for structural components in many extreme working environments (e.g., high temperature and pressure). At present, it is very difficult to further improve the mechanical properties and the wear performance of Inconel 718 alloy by merely changing the preparation method, adjusting the heat treatment scheme or the processing technology. It is reasonable to consider GNPs as an effective reinforcing phase to further improve the mechanical and tribological properties of Inconel 718 alloy.

Selective laser melting (SLM) process is a vital additive manufacturing technique in industry and it offers several advantages in comparison to traditional manufacturing technologies, such as the simplification of production process, high flexibility, low material waste, and the availability to manufacture parts with high geometrical complexity [14]. SLM is usually accompanied with high cooling rate (105 °C/s) and large thermal gradient [15,16]. The fast solidification suppresses the possible chemical reaction between GNPs and matrix, therefore preserving the superior two-dimensional structure and excellent mechanical properties of GNPs. Meanwhile, fine microstructure can be obtained due to rapid solidification process [16]. Due to the above stated reasons, the fabrication of GNPs-reinforced Inconel 718 matrix composites using SLM is a promising approach and it carries significant innovativeness.

In this study, GNPs-reinforced Inconel 718 matrix composites were fabricated using SLM, the reinforcing effect of GNPs on Inconel 718 matrix was investigated and the feasibility of synthesizing GNPs/Inconel 718 composites through SLM was evaluated. The microstructure and properties of the obtained composites were characterized, and the strengthening mechanism was discussed. The investigation aimed at probing the feasibility of producing GNPs-reinforced Inconel 718 matrix composites by using SLM, which can offer a new approach for fabricating Inconel 718 alloy with high properties and its parts.

2 Experimental

2.1 Composite preparation

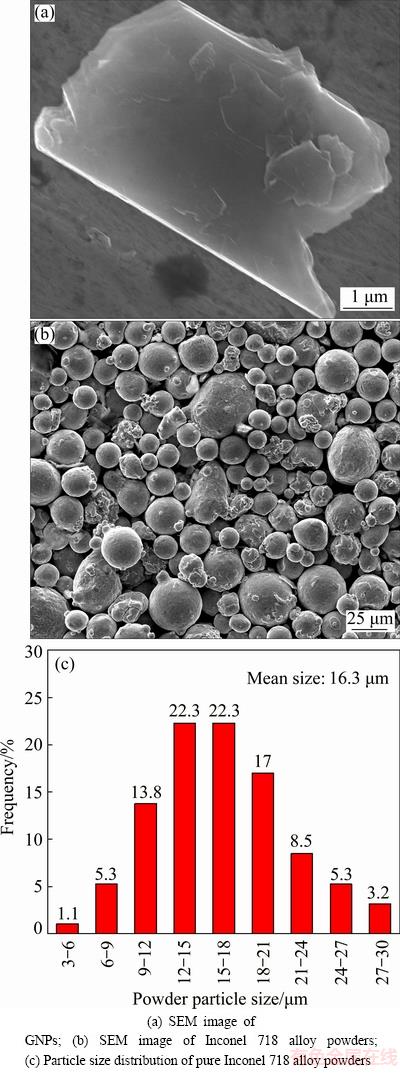

Figure 1(a) shows that the multilayer GNPs have a platelet size ranging from 5 to 50 μm. Multilayer GNPs are easier to be uniformly dispersed in MMCs than single layer graphene [17]. Inconel 718 alloy powders are used as the matrix materials in this study. As shown in Fig. 1(b), the Inconel 718 alloy powders have a fairly good spherical shape, which ensures high powder flowability. Figure 1(c) shows particle size distribution of the Inconel 718 alloy powders, and the average particle size is 16.3 μm.

Fig. 1 Initial condition of raw materials

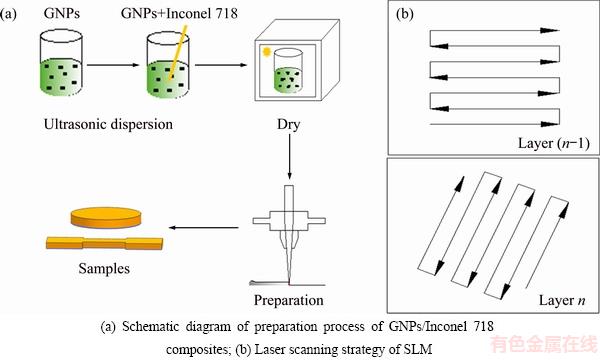

In order to obtain the homogeneous dispersion of GNPs in Inconel 718 powders, we adopt the following routine for powder mixing operation. Firstly, GNPs are added into ethanol with ultrasonic wave applied. Secondly, Inconel 718 powders are added into the GNPs suspension followed by 3 h of stirring and sonication. Thirdly, the suspension is placed into a drying oven at 60 °C for 48 h to vaporize ethanol and obtain the mixture of metal composite powders that are ready for SLM processing. Finally, GNPs/Inconel 718 composites are prepared by SLM that is carried out using an EOS M280 SLM system. The schematic diagram of preparation process is shown in Fig. 2(a). The SLM process controlling parameters are set to be fixed according to the manufacturer’s recommendation and other reports, with the laser power of 200 W, scanning speed of 7 m/s, powder layer thickness of 30 μm, hatch space of 100 μm, and the direction of laser scanning rotates 67° between two adjacent powder layers (see Fig. 2(b)). The entire SLM process is protected by argon to avoid oxidation of powders. By following this procedure, 0.25% and 1.0% GNPs/Inconel 718 composites (mass fraction) were fabricated. Pure Inconel 718 alloy was also fabricated using the same controlling parameters for convenient comparison.

2.2 Characterization method

Tensile tests of GNPs/Inconel 718 composites were conducted at room temperature using a W9W-50 universal tester at a tension rate of 0.5 mm/min. Vickers hardness tests were carried out using an HVS-1000 microhardness tester at a load of 200 g for 20 s. The microstructures of composites were examined by OM and SEM. The worn surfaces were also characterized by SEM. Phase constitution of the composite was examined using XRD and the structural information of GNPs was characterized by Raman spectroscopy. The tribological test of the as-prepared flat samples was conducted under ambient condition (temperature of (13±5) °C and relative humidity of 55%-65% using a WTM-2E tribological tester based on ball-on-disk contact method. The wear counterpart is a GCr15 ball with 3 mm in diameter. Prior to the test, the samples were polished and cleaned by ethanol for 5 min with ultra-sonication. The applied load was maintained at 6 N. The rotation speed, testing time and sliding radius were 560 r/min, 60 min and 2 mm, respectively. The coefficient of friction was continually recorded during the tests and the average value was calculated. The wear volume was calculated from the cross-section area of worn surface profile traces using a 3D digital microscope (HIROX KH-7700, Japan) following ASTM standard G99 [18] and the wear volume was then converted into the volumetric wear rate.

The wear volume, V, can be calculated according to the following equation:

(1)

(1)

where V is the wear volume in mm3, R and d are the sliding radius and the average width of the wear track in mm, respectively, and r is the radius of the GCr15 ball in mm. The wear rate, W, can be calculated by the following formula:

(2)

(2)

where F is the applied load in N and S is the sliding distance in m.

3 Results and discussion

3.1 Microstructures of composites

The SEM images of composite powders obtained through ultra-sonicate dispersion are shown in Figs. 3(a) and (b). It can be seen that GNPs (highlighted by red and yellow circles) are uniformly dispersed in Inconel 718 powders without significant agglomeration. GNPs exist in inter-particles regions (highlighted by red circles) or are attached to the Inconel 718 powder surface (highlighted by yellow circles). Raman spectra of composite powders are shown in Fig. 3(c). The Raman D, G and 2D band peaks are observed at 1356, 1581 and 2726 cm-1, respectively. The intensity ratio of the D band to G band, ID/IG, is generally related to the amount of defects presented in carbon structures [19]. The low values of ID/IG ratio (0.227 and 0.31) of GNPs as shown in Fig. 3(c) indicate low defect density of graphene structure, which suggests that during the preparation of composite powders the structure integrity of GNPs is conserved.

Fig. 2 Method to fabricate GNPs/Inconel 718 composites

Fig. 3 SEM images (a, b) and Raman results of composite powders

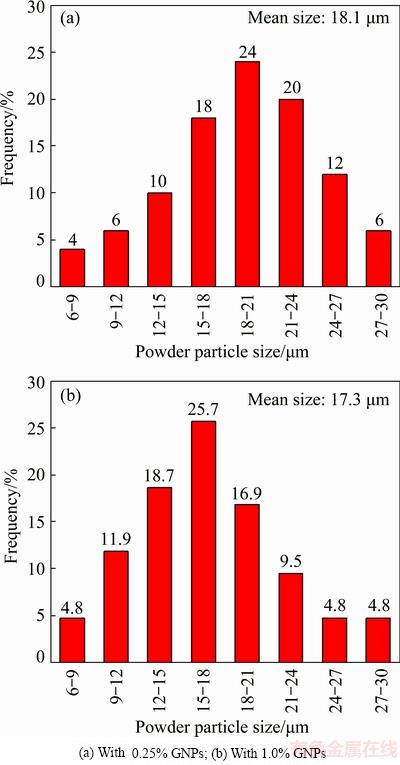

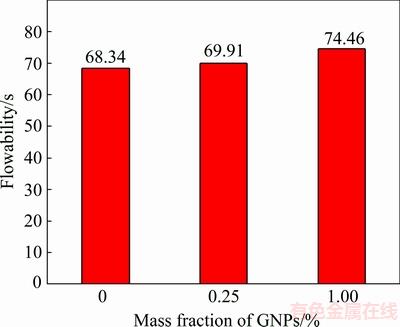

Figure 4 shows the particle size distribution of composite powders. It is apparent that the majority of particles have a diameter less than 30 μm, less than the layer thickness, and this leads to successful powder dispensing. Flowability was tested using the Hall flowmeter funnel following the ASTM standard B213-13. As shown in Fig. 5, the flowability (relative to 50 g sample) values corresponding to pure Inconel 718 powders, composite powders with 0.25% GNPs, and composite powders with 1.0% GNPs, are 68.34, 69.91 and 74.46 s, respectively. Clearly, the addition of GNPs leads to slight decrease of flowability due to the nature of agglomeration of nano materials, but the effect is not regarded to be significant and can be neglected for SLM process.

Fig. 4 Particle size distribution of composite powders

Fig. 5 Flowability (relative to 50 g sample) comparison of powders

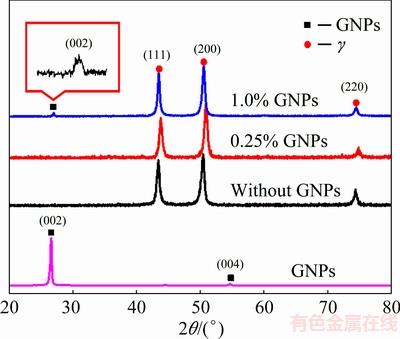

XRD characterization was conducted to further investigate the phase constitution of the obtained composite parts. Figure 6 shows the XRD patterns of as-built pure Inconel 718 as well as the reinforced Inconel 718 composites at various reinforcement fractions. Generally, all XRD spectra exhibit strong diffraction peaks corresponding to 2θ values of about 43.5°, 50.5° and 74.6°, marked with red circles, and they belong to Ni-Cr-Fe matrix phase (γ matrix) [20]. For pure GNPs, a major peak at 2θ value of 26.5° and a minor peak at 2θ value of 54.4° are observed, and they correspond to the (002) and (004) planes of graphitic crystalline due to its nature of multi-layer structure, and similar pattern is observed in a graphene/Ni composite system [21]. For as-built GNPs/Inconel 718 composites, the main peaks corresponding to γ matrix occur, but at a reinforcement fraction of 0.25%, the main peak of GNPs (2θ value of 26.5°) is hardly seen due to its low concentration, while at higher reinforcement fraction of 1.0%, more prominent peaks corresponding to GNPs are observed.

Fig. 6 XRD patterns of pure Inconel 718 and GNPs/Inconel 718 composites

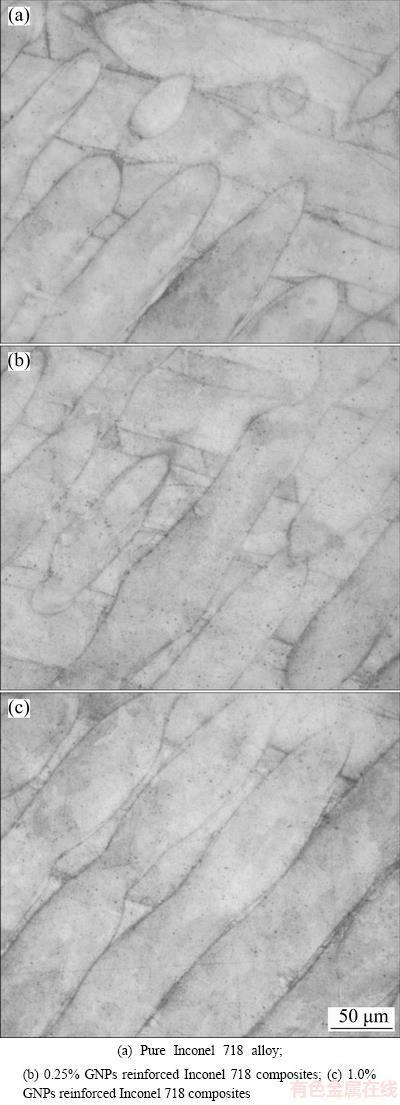

The optical micrographs of pure Inconel 718 and GNPs/Inconel 718 composites are shown in Fig. 7. Alternative scanning strategy is seen as the direction of laser tracks rotated by 67° between two adjacent layers (see Fig. 2(b)), avoiding anisotropy of material’s properties. Moreover, at any reinforcement concentration, manufacturing defects such as pores and cracks are hardly observed, indicating reasonable selection of SLM process parameters.

Fig. 7 Optical micrographs of SLMed parts (cross-sections vertical to building direction)

Figure 8 shows the microstructures of SLM-produced pure and GNPs reinforced samples. In SLM process, material experiences ultrafast cooling due to the small focused laser beam and fast laser scan speed, and the coaling rate can be as high as 1×108 K/s [22]. Such high cooling rate results in highly directional crystal growth along the opposite direction of heat flux. This can be observed in Fig. 8, in which the directional dendrites dominate the microstructure. Inconel 718 matrix phase is γ-FCC structure, and the dendrite structures generally grow along <100> crystallographic orientation [23]. Generally, dendrites grow along the building direction (upward); however, due to the fact that alternative scanning strategy is used (e.g., laser scan direction changes by a certain angle every layer as the material builds up), heat flux direction changes significantly in every adjacent layer and this explains why the dendrite direction exhibits certain randomness. In addition, the average interdendritic spacing (AIS) of all obtained materials is very small as compared to that of conventional casting process, indicating the extreme high cooling rate caused by the focused laser energy. For pure Inconel 718 alloy, 0.25% and 1.0% GNPs/Inconel 718 composites, the AIS values are about 0.7, 0.5 and 0.3 μm, respectively. Compared to that of pure Inconel 718 alloy, the AIS of GNPs/Inconel 718 composites significantly decreases. The refinement of dendrites is possibly attributed to the increase of thermal conductivity. The thermal conductivity of GNPs is 5 kW/(m·K) [3], which is much higher than that of Inconel 718 alloy (15 W/(m·K) [24]). Although the addition amount of GNPs is small, the huge discrepancy in thermal conductivity still significantly accelerates the heat dissipation from the melt pool during solidification, leading to the formation of finer dendritic structure.

Fig. 8 Dendrite structures observed by SEM for cross-sections parallel to building direction

To investigate the distribution of GNPs on horizontal and vertical cross-sections, magnified SEM images of carbon enriched regions are presented in Figs. 9(a) and (c), respectively. However, GNPs can be hardly observed in SEM images due to the damaging effect of polishing and etching during sample preparation process. Point and line EDS scan results respectively shown in Fig. 9(b) and (d) reveal high carbon concentration in inter-dendritic regions, indicating the presence of GNPs. GNPs agglomerate in inter-dendritic regions due to the pushing effect of fast advancing solidification front. Due to the crystal anisotropy and resulted difference in dendrite morphology, the distribution of GNPs is found to be very different in horizontal and vertical planes.

3.2 Mechanical properties of composites

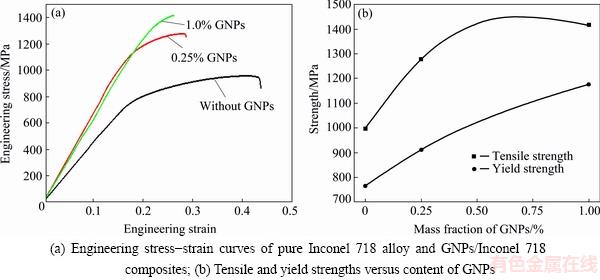

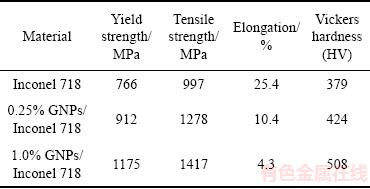

The engineering stress-engineering strain curves, tensile and yield strengths of GNPs/Inconel 718 composites with respect to different contents of GNPs are shown in Fig. 10 and the mechanical properties of GNPs/Inconel 718 composites are shown in Table 1. As shown in Table 1, the yield strength, tensile strength and Vickers hardness of 0.25% GNPs/Inconel 718 composites are 912 MPa, 1278 MPa and HV 424, which are improved by about 19%, 28% and 12% compared to those of the pure Inconel 718 alloy, respectively. It is also clear that the addition of 1.0% GNPs to Inconel 718 alloy leads to the increase of yield strength, ultimate tensile strength, and Vickers hardness to 1175 MPa, 1417 MPa, and HV 508, respectively (corresponding to 42%, 53% and 34% of relative increase, respectively). However, it is accompanied by a reduction of elongation. The tensile and yield strengths of 1.0% GNPs/Inconel 718 composites are comparable with those of wrought Inconel 718 (reported in literature [25]). In terms of tensile strength, the reinforcing effect of GNPs exceeds that of any other conventional filler materials reported in literature [20]. The increase of tensile and yield strengths, and Vickers hardness caused by the introduction of GNPs is remarkable, and this is believed to relate to the unique structural characteristic of GNPs and the finer microstructure of composites (Fig. 8). Table 2 summarizes the standard deviations of mechanical testing results. From Table 2 it can be seen that higher GNPs content leads to higher standard deviations on strengths and hardness. It might be attributed to the uneven distribution of GNPs during the powder blending process. Meanwhile, the standard deviations are generally low compared with the mean value for mechanical properties measured. This indicates that the variation of testing results is within acceptable range.

Fig. 9 SEM images (a, c) and EDS results (b, d) of GNPs/Inconel 718 composites with 1.0% GNPs

Fig. 10 Tensile performance comparison

Table 1 Mechanical properties of GNPs/Inconel 718 composites

Table 2 Standard deviations for mechanical properties of GNPs/Inconel 718 composites

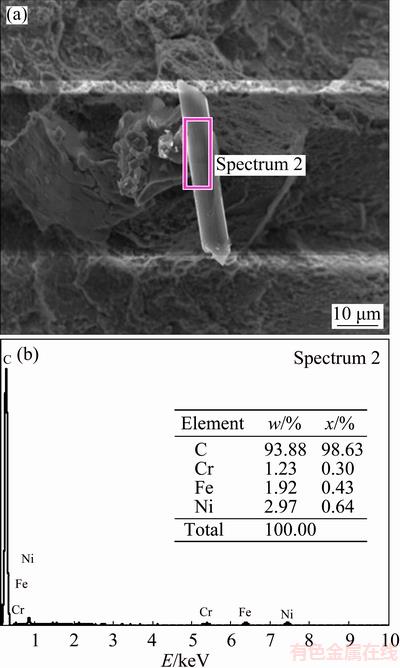

Fig. 11 SEM image of facture surface (a) and EDS results (b) of marked area in (a) of GNPs/Inconel 718 composites with 0.25% GNPs

Figure 11(a) shows a plate-like feature on the fracture surface, and EDS analysis of the marked area indicates high carbon content as shown in Fig. 11(b), suggesting that it is most possibly GNPs. It can be observed that this particular GNP exhibits intact surface morphology and its size is about 40 μm, which is close to initial condition of GNPs in this experiment. Therefore, we can reasonably claim that the GNPs can be well retained through the repetitive rapid material melting and solidification cycles during SLM process. This particular GNP is inserted into the matrix even after drastic plastic deformation, indicating excellent bonding between GNPs and matrix material. Since the strength of GNPs is much higher than that of matrix material, the load transfer from matrix to GNPs is believed to play an important role in reinforcing the composite. Loading can be effectively transferred from metal matrix to GNPs by interface shear stress (shear lag), and thus the high stiffness of GNPs is utilized directly. The yield strength σs of the nanocomposites can be analyzed by the modified shear lag model as follows [26]:

(3)

(3)

where σm is the yield strength of Inconel 718 alloy matrix, s is the aspect ratio of GNPs filler, and Vf is the volume fraction of GNPs. According to Eq. (3), the significantly enhanced yield strength of GNPs/Inconel 718 composites mainly results from the large aspect ratio characteristic of GNPs.

Besides the load transfer effect, several other strengthening effects also account for the increase of strength. Firstly, Orowan strengthening results from the interaction between reinforcement particles and dislocations, and it becomes significant when the size of reinforcement comes down to nano scale. In the present study, GNPs with nanometer dimension would effectively impede the dislocation motion and reinforce the Inconel 718 matrix. Secondly, Hall-Petch effect is a well-known strengthening mechanism which states that the strength of polycrystalline materials is expected to increase if the grain size decreases. It is expressed by the Hall-Petch relationship [27,28]:

σs=σ0+kd-1/2 (4)

where σ0 is a constant, which is rationalized as either a friction stress from dislocation glide or an internal back stress, d is the grain size of Inconel 718 alloy matrix, and k is the Hall-Petch slope. The addition of GNPs provides more nucleation sites to the molten metal and the grain boundary pining effect of GNPs impedes the grain growth, therefore more grains will nucleate and result in smaller grain size (Figs. 8(b) and (c)). Thirdly, the significant mismatch of thermal expansion coefficients (CTE) in GNPs/Inconel 718 composites (CTE for GNPs is 0.9×10-6 K-1 [29,30]; CTE for Inconel 718 is 12.8×10-6 K-1 [31]) also induces high-density of dislocation around GNPs. The lattice distortion at the interface impedes the movement of dislocation and thus strengthens the composites. Previous study performed by ZHANG and ZHAN [32] has demonstrated high dislocation density around GNPs in a GNP/Cu composite system.

3.3 Tribological properties of composites

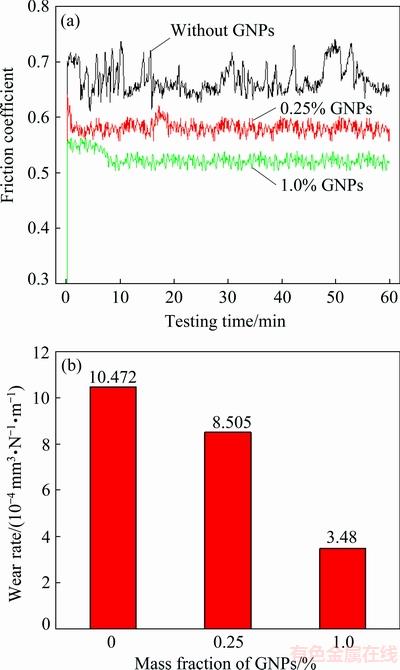

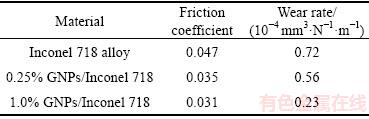

The relation between friction coefficient and testing time is shown in Fig. 12(a), and the wear rates corresponding to different reinforcement contents are presented in Fig. 12(b). It can be clearly observed that the friction coefficient and wear rate decrease significantly when GNPs are added. The wear resistance of a material is mainly determined by material hardness, and it can be estimated using Archard’ s equation [33]:

(5)

(5)

where K is the friction coefficient and H is the hardness. For Inconel 718 alloy with 0.25% GNPs, the average friction coefficient and wear rate are 0.58 and 8.505×10-4 mm3/(N·m), respectively. They are 13.4% and 18.8%, lower than those of pure Inconel 718 alloy, respectively. It also obviously shows that with 1.0% GNPs addition, the average friction coefficient and wear rate decrease by about 22.4% and 66.8%, respectively, as compared to those of pure Inconel 718 alloy. As shown by the standard deviations in Table 3, the friction coefficient of pure Inconel 718 exhibits larger fluctuation as compared with that of GNPs/Inconel 718 composites, indicating that the addition of GNPs helps to stabilize the tribological performance of material during the tests. The above results demonstrate that GNPs can be used as an effective nanofiller material to enhance the wear resistance and tribological performance of additively produced superalloys.

Fig. 12 Friction coefficient (a) and wear rate (b) of Inconel 718 alloy and GNPs/Inconel 718 composites

Table 3 Standard deviations for tribological properties of GNPs/Inconel 718 composites

The SEM images of worn surfaces of pure Inconel 718 alloy and GNPs/Inconel 718 composites after sliding wear are shown in Fig. 13. Obvious grooves and micro-cracks accompanied delamination can be seen on the worn surface of pure Inconel 718 alloy, as shown in Fig. 13(a). This illustrates the occurrence of serious plastic deformation, and the abrasive wear is the main wear mechanism. However, with the addition of 0.25% GNPs and 1.0% GNPs, the worn surface of composite is found to be very different. It generally shows smoother characteristic with shallow grooves shown in Figs. 13(b) and (c), suggesting that the dominating wear mechanism is mild abrasive wear. Besides the self-lubricating effect of GNPs, the enhancement of wear properties can also be attributed to the significant increase of hardness according to Eq. (5). Due to the higher material strength and hardness resulted from the addition of GNPs, the material underneath sliding contact surface experiences less flow stress and considerably less plastic deformation. Therefore, the nucleation of cracks is less likely to occur.

The EDS spectrum of the worn surface of 1.0% GNPs reinforced Inconel 718 composites (Fig. 13(d)) shows the elemental distribution of carbon. GNPs are highlighted by bright green color, and it can be clearly observed that they are evenly dispersed on the worn surfaces. The results confirm that the addition of GNPs facilitates the formation of protective and lubricating layer of the reinforced composites during the sliding wear process in such a way that the workpiece surface is almost free from direct contact with the counterpart, leading to lower friction coefficient and wear rate. Previous study from ZHAI et al [9] has proved that GNPs act as tribofilm on the surface of GNPs/Ni3Al composites during the sliding wear test, and this effectively enhances the wear resistance of material.

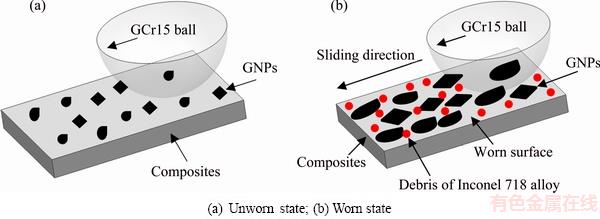

In attempt to reveal the lubricating mechanism of GNPs on the enhancement of tribological performance, a schematic diagram (sketch of the ball-on-disk pair) representing the wear process is shown in Fig. 14. As shown in Fig. 14(a), GNPs are homogeneously distributed in the Inconel 718 matrix. GCr15 ball has much higher stiffness than the composites to be tested and it can be regard as rigid body. Thus, under applied contact pressure during the wear test process, hard protrusions on the GCr15 ball surface penetrate into the surface of composites and remove the softer Inconel 718 materials, resulting in the formation of rough worn surface with large amount of debris highlighted in red color as shown in Fig. 14(b). This explains the large fluctuation of friction coefficient in the run-in friction process (0-10 min), as is confirmed in Fig. 12(a). As the wear test continues, GNPs on the rough worn surface can be easily sheared under the cyclic stress, and part of them experience significant delamination and spread out along the sliding direction in the process of subsequent friction, resulting in the island-like plates of GNPs with different sizes on the smooth frictional surface, as shown in Fig. 14(b). Consequently, an anti-wear protective layer at the sliding contact interfaces is formed, as evidenced by Fig. 13(d), meanwhile, the friction coefficients and wear rates of GNPs/Inconel 718 composites can be drastically reduced.

In summary, the strength and hardness of GNPs/Inconel 718 composites are remarkably improved by the addition of GNPs, and the in-situ generated tribo-film covers contact surface, leading to outstanding wear resistance of composite under dry sliding wear test.

Fig. 13 SEM images (a-c) of worn surfaces and EDS analysis result (d) of samples

Fig. 14 Schematic representation of enhancement of tribological behaviors of GNPs/Inconel 718 composites

4 Conclusions

1) The addition of 1.0% GNPs to Inconel 718 alloy leads to increase in yield strength (1175 MPa), ultimate tensile strength (1417 MPa) and Vickers hardness (HV 508), corresponding to 42%, 53% and 34%, respectively, of increase as compared with unreinforced Inconel 718 alloy.

2) The friction coefficient and wear rate decrease significantly when GNPs are incorporated as the reinforcement. The average friction coefficient is decreased by 22.4%, to the value of 0.52, and the wear rate is decreased by 66.8%, to a value of 3.48×10-4mm3/(N·m) for the Inconel 718 alloy with 1.0% GNPs as compared with pure Inconel 718 alloy.

3) The superior wear resistance of GNPs/Inconel 718 composites can be attributed to the conventional reinforcing mechanisms through GNPs and the in-situ formation of anti-wear protective layer at the sliding contact interface.

References

[1] GEIM A K, NOVOSELOV K S. The rise of graphene [J]. Nature Materials, 2007, 6: 183-191.

[2] LEE C G, WEI X D, KYSAR J W, HONE J. Measurement of the elastic properties and intrinsic strength of monolayer graphene [J]. Science, 2008, 321: 385-388.

[3] BALANDIN A A, GHOSH S, BAO W Z, CALIZO I, TEWELDEBRHAN D, MIAO F, LAU C N. Superior thermal conductivity of single-layer graphene [J]. Nano Letters, 2008, 8: 902-907.

[4] BOLOTIN K I, SIKES K J, JING Z, KLIMA M, FUDENBERG G, HONE G, KIM P, STORMER H L. Ultrahigh electron mobility in suspended graphene [J]. Solid State Communications, 2008, 146: 351-355.

[5] CHEN J H, JANG C, XIAO S D, ISHIGAMI M, FUHRER M S. Intrinsic and extrinsic performance limits of graphene devices on SiO2 [J]. Nature Nanotechnology, 2008, 3: 206-209.

[6] ZHANG Dan-dan, GUO Chang-hong, GOU Xing-jun, ZHAN Zai-ji. Review of metal matrix nanocomposites reinforced by graphene [J]. Journal of Yanshan University, 2014, 38: 484-490. (in Chinese)

[7] LI Jing-fu, ZHANG Lei, XIAO JIN-kun, ZHOU Ke-chao. Sliding wear behavior of copper-based composites reinforced with graphene nanosheets and graphite [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 3354-3362.

[8] XU Zeng-shi, SHI Xiao-liang, ZHAI Wen-zheng, YAO Jie, SONG Si-yuan, ZHANG Qiao-xin. Preparation and tribological properties of TiAl matrix composites reinforced by multilayer graphene [J]. Carbon, 2014, 67: 168-177.

[9] ZHAI Wen-zheng, SHI Xiao-liang, WANG Mang, XU Zeng-shi, YAO Jie, SONG Si-yuan, WANG Yu-fu. Grain refinement: A mechanism for grapheme nanoplatelets to reduce friction and wear of Ni3Al matrix self-lubricating composites [J]. Wear, 2013, 310: 33-40.

[10] ZHAI Wen-zheng, SHI Xiao-liang, XU Zeng-shi, ZHANG Qiao-xin. Formation of friction layer of Ni3Al matrix composites with micro- and nano-structure during sliding friction under different loads [J]. Materials Chemistry and Physics, 2014, 147: 850-859.

[11] SHIN Y J, STROMBERG R, NAY R, HUANG H, WEE A T, YANG H, BHATIA C S. Frictional characteristics of exfoliated and epitaxial graphene [J]. Carbon, 2011, 49: 4070-4073.

[12] CHANG Shuai. Research on fiber laser additive manufacturing technology of IN718 superalloy [D]. Harbin: Harbin Institute of Technology, 2013: 1. (in Chinese)

[13] WANG Ze-min, GUAN Kai, GAO Ming, LI Xiang-you, CHEN Xiao-feng, ZENG Xiao-yan. The microstructure and mechanical properties of deposited-IN718 by selective laser melting [J]. Journal of Alloys and Compounds, 2012, 513: 518-523.

[14] CHLEBUS E, GRUBER K, KUZNICKA B, KURZAC J, KURZYNOWSKI T. Effect of heat treatment on the microstructure and mechanical properties of Inconel 718 processed by selective laser melting [J]. Materials Science and Engineering A, 2015, 639: 647-655.

[15] ZHANG Dong-yun, NIU Wen, CAO Xuan-yang, LIU Zhen. Effect of standard heat treatment on the microstructure and mechanical properties of selective laser melting manufactured Inconel718 superalloy [J]. Materials Science and Engineering A, 2015, 644: 32-40.

[16] LIU Fen-cheng, LIN Xin, YANG Gao-lin, SONG Meng-hua, CHEN Jing, HUANG Wei-dong. Microstructure and residual stress of laser rapid formed Inconel 718 nickel-base superalloy [J]. Optics and Laser Technology, 2011, 43: 208-213.

[17] ZHAI W Z, SHI X L, YAO J, IBRAHIM A M M, XU Z S, ZHU Q S, XIAO Y C, CHEN L, ZHANG Q X. Investigation of mechanical and tribological behaviors of multilayer graphene reinforced Ni3Al matrix composites [J]. Composites (Part B): Engineering, 2015, 70: 149-155.

[18] SHAFIEI M, ALPAS A T. Effect of sliding speed on friction and wear behavior of nanocrystalline nickel tested in an argon atmosphere [J]. Wear, 2008, 265: 429-438.

[19] INAM F, VO T, BHAT B R. Structural stability studies of graphene in sintered ceramic nanocomposites [J]. Ceramics International, 2014, 40: 16227-16233.

[20] HONG C, GU D D, DAI D H, GASSER A, WEISHEIT A, KELBASSA I, ZHONG M L, POPRAWE R. Laser metal deposition of TiC/Inconel 718 composites with tailored interfacial microstructures [J]. Optics & Laser Technology, 2013, 54: 98-109.

[21] HU Z R, TONG G Q, LIN D, NIAN Q, SHAO J Y, HU Y W, SAEIB M, JIN S Y, CHENG G J. Laser sintered graphene nickel nanocomposites [J]. Journal of Materials Processing Technology, 2016, 231: 143-150.

[22] ZHANG B C, DEMBINSKI L, CODDET C. The study of the laser parameters and environment variables effect on mechanical properties of high compact parts elaborated by selective laser melting 316L powder [J].Materials Science and Engineering A,2013,584: 21-31.

[23] AMATO K N, GAYTAN S M, MURR L E, MARTINEZ E, SHINDO P W, HERNANDEZ J, COLLINS S, MEDINA F. Microstructures and mechanical behavior of Inconel 718 fabricated by selective laser melting [J]. Acta Materialia, 2012, 60: 2229-2239.

[24] ARDILA L C, GARCIANDIA F, GONZALEZ-DIAZ J B, ALVAREZ P, ECHEVERRIA A, PETITE M M, DEFFLEY R, OCHOA J. Effect of IN718 recycled powder reuse on properties of parts manufactured by means of selective laser melting [J]. Physics Procedia, 2014, 56: 99-107.

[25] ZHAO Xiao-ming, CHEN Jing, LIN Xin, HUANG Wei-dong. Study on microstructure and mechanical properties of laser rapid forming Inconel 718 [J]. Materials Science and Engineering A, 2008, 478: 119-124.

[26] LIU Z Y, XIAO B L, WANG W G, MA Z Y. Singly dispersed carbon nanotube/aluminum composites fabricated by powder metallurgy combined with friction stir processing [J]. Carbon, 2012, 50: 1843-1852.

[27] CHOI H J, KWON G B, LEE G Y, BAE D H. Reinforcement with carbon nanotubes in aluminum matrix composites [J]. Scripta Materialia, 2008, 59: 360-363.

[28] TJONG S C. Recent progress in the development and properties of novel metal matrix nanocomposites reinforced with carbon nanotubes and graphene nanosheets [J]. Materials Science and Engineering R, 2013, 74: 281-350.

[29] MIN K, ALURU N R. Mechanical properties of graphene under shear deformation [J]. Applied Physics Letters, 2011, 98: 013113.

[30] RASHAD M, PAN F S, YU Z W, ASIF M, LIN H, PAN R J. Investigation on microstructural, mechanical and electrochemical properties of aluminum composites reinforced with graphene nanoplatelets [J]. Progress in Natural Science: Materials International, 2015, 25: 460-470.

[31] WANG Ya-chao, SHI Jing, LU Shi-qiang, WANG Yun. Selective laser melting of graphene reinforced Inconel 718 superalloy: Evaluation of microstructure and tensile performance [J]. Journal of Manufacturing Science and Engineering, 2016, 139: 41-45.

[32] ZHANG Dan-dan, ZHAN Zai-ji. Strengthening effect of graphene derivatives in copper matrix composites [J]. Journal of Alloys and Compounds, 2016, 654: 226-233.

[33] LIU R, LI D Y. Modification of Archard’s equation by taking account of lastic/pseudoelastic properties of materials [J]. Wear, 2001, 250: 956-964.

肖纬汗1,鲁世强2,王亚超3,石 京3

1. 南昌航空大学 材料科学与工程学院,南昌 330063;

2. 南昌航空大学 航空制造工程学院,南昌 330063;

3. Department of Mechanical and Materials Engineering, University of Cincinnati, Cincinnati, OH 45221, USA

摘 要:采用选择性激光熔化法制备石墨烯/Inconel 718复合材料,并评价其力学性能和摩擦磨损性能。采用XRD、SEM和拉曼光谱技术对复合材料的显微组织进行表征。结果表明,采用选择性激光熔化法制备石墨烯/ Inconel 718复合材料是合理可行的,添加石墨烯纳米片对Inconel 718合金不仅产生了显著的强化效果,而且改善了摩擦学性能。1.0% 石墨烯/Inconel 718复合材料(质量分数)的屈服强度和抗拉强度比未添加石墨烯纳米片的Inconel 718合金分别提高了42%和53%,而其摩擦因数和磨损率分别降低了22.4%和66.8%。石墨烯纳米片增强Inconel 718合金的硬度增加以及在磨损表面形成的石墨烯纳米片保护层是导致摩擦因数和磨损率降低的直接原因。

关键词:石墨烯;石墨烯/Inconel 718复合材料;力学性能;摩擦磨损性能;显微组织;选择性激光熔化

(Edited by Wei-ping CHEN)

Foundation item: Project supported by the Ganpo 555 Program for Leading Talents of Jiangxi Province, China

Corresponding author: Wei-han XIAO; Tel: +86-791-83863039; E-mail: 782163873@qq.com

DOI: 10.1016/S1003-6326(18)64841-1