合金化和形变处理对Cu-Mg-Te-Y合金组织性能的影响

来源期刊:中国有色金属学报(英文版)2013年第12期

论文作者:陈 亮 周秉文 韩建宁 薛彦燕 贾 非 张兴国

文章页码:3697 - 3703

关键词:Cu-Mg-Te-Y合金;合金化;形变处理;力学性能;导电率

Key words:Cu-Mg-Te-Y alloys; alloying; deformation; mechanical properties; electrical conductivity

摘 要:制备具有高强高导性能的铜合金,研究添加Mg和微量的Y对合金的组织和性能的影响。通过变形和退火等工艺处理后,Cu-0.47Mg-0.2Te-0.04Y合金的性能指标可达到:抗拉强度510 MPa,伸长率11%,导电率大于63% IACS。稀土元素Y的熔体净化作用、细晶强化作用和添加适量Mg产生的固溶强化作用能够提高合金的力学性能和导电率。

Abstract: New copper alloys with high mechanical properties and high electrical conductivity were prepared, and the effects of addition of minor Mg and Y elements on microstructures and properties were studied. The high tensile strength of above 510 MPa, high elongation of 11% and high electrical conductivity of over 63% IACS can be simultaneously obtained in Cu-0.47Mg-0.20Te- 0.04Y alloy after deforming and annealing treatment. Effects of purification together with the grain refining by Y and solid-solution strengthening by Mg are appropriate for enhancing mechanical properties and electrical conductivity of the copper alloys.

Trans. Nonferrous Met. Soc. China 23(2013) 3697-3703

Liang CHEN, Bing-wen ZHOU, Jian-ning HAN, Yan-yan XUE, Fei JIA, Xing-guo ZHANG

School of Materials Science and Engineering, Dalian University of Technology, Dalian 116024, China

Received 31 December 2012; accepted 13 March 2013

Abstract: New copper alloys with high mechanical properties and high electrical conductivity were prepared, and the effects of addition of minor Mg and Y elements on microstructures and properties were studied. The high tensile strength of above 510 MPa, high elongation of 11% and high electrical conductivity of over 63% IACS can be simultaneously obtained in Cu-0.47Mg-0.20Te-0.04Y alloy after deforming and annealing treatment. Effects of purification together with the grain refining by Y and solid-solution strengthening by Mg are appropriate for enhancing mechanical properties and electrical conductivity of the copper alloys.

Key words: Cu-Mg-Te-Y alloys; alloying; deformation; mechanical properties; electrical conductivity

1 Introduction

Pure copper and copper alloys have been widely applied in many technique fields such as electronic/ electrical industries because of their excellent electrical, thermal conductivity and good corrosion resistance [1-5]. However, copper in pure form has poor mechanical properties: the tensile strength of as-cast copper is only in the range of 200-290 MPa and less than 400 MPa after being work-hardened, which is hardly used as high-strength and high-conductivity materials in the modern industry.

Since 1970s, many kinds of high-strength and high-conductivity copper alloys have been developed for hi-tech electrical conductors. Series of promising copper alloys based on Cu-Ag [6-8], Cu-Mg [9], Cu-Cr-Zr [10-13], Cu-Fe-P [14,15] and Cu-Ni-Si [16-18] alloys have attracted considerable interests. Their tensile strength and electrical conductivity are above 450 MPa and 60% IACS, respectively.

Generally, rare earth (RE) elements such as cerium [19], lanthanum [20] and yttrium are added to improve properties in most metallic materials. Previous work [21] showed that a very small addition of RE into copper alloys could not only refine grains, but also effectively remove low-melting-point impurities such as Pb, S and Bi. Until now, it has been reported that Cu-Mg alloys with trace Mg possess high strength and high conductivity. Moreover, Cu-Te alloys exhibit special properties of easy-cutting and arc-resistance. But Cu-Te alloys with Te more than 0.4% (mass fraction) will dehisce during the following hot-rolling processes [22].

In this work, a new type of Cu-Mg-Te copper alloy with minor addition of Y has been studied. The aim of this work is mostly to investigate how the alloying elements affect the microstructures, mechanical properties and electrical conductivity of the copper alloys. The effects of rolling and annealing treatments on the properties of the present alloys are further studied. The reasons for high mechanical properties and electrical conductivity of Cu-Mg-Te-Y alloys will also be discussed.

2 Experimental

Cu-Mg-Te-Y alloys were prepared in an SPZ-15 medium-frequency induction furnace with starting materials of small pieces of oxygen-free electronic copper (OFEC, 99.99% (mass fraction)), Cu-20%Mg master alloy, Cu-66.7%Te master alloy and Y (99.9%), which were molten sequently in a graphite crucible. High purity argon was used to prevent and purify the liquid alloy in the induction unit. Cu-Mg-Te-Y alloy samples of different compositions were prepared separately.

The as-cast ingots were solution treated at 850 °C for 2 h in an electric resistance furnace, and then 70% hot-rolled and 80% cold-rolled by 250 double-roller mill at 25 °C. Finally, the cold-rolled sheets were annealed at 350 °C for 1 h.

The microstructures of samples were observed by MEF-3 optical microscopy (OM) after etching for 10 s at 25 °C in a mixture of ferric chloride (3 g), hydrochloric acid (30%, 10 mL) and distilled water (100 mL). Samples with gauge length of 70 mm were used for tensile strength test at a strain rate of 2 mm/min by CSS-2205 tensile machine at 25 °C. Electrical conductivity of the samples was measured by D60K digital electrical instrument, the gauge size of which was 20 mm × 20 mm × 10 mm. These measurements were carried out three times for each sample. The fracture behavior was examined by JSM-5600LV scanning electron microscopy (SEM). The elements compositions and distributions were analyzed by XRF-1800 and EPMA-1600, respectively.

3 Results and discussion

3.1 Effects of Y on properties of Cu-Mg-Te-Y alloys

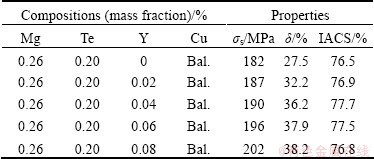

The analysis results of the composition, mechanical properties and electrical conductivity of the copper alloys are listed in Table 1. It can be seen that the tensile strength and elongation of the alloys monotonously increased from 182 to 202 MPa and 27.5% to 38.2% with Y content increasing from 0 to 0.08% (mass fraction), respectively. However, the electrical conductivity only slightly increased from 76.5% to 77.7% IACS with Y addition from 0 to 0.04% and decreased to 76.8% IACS when Y content is 0.08%.

Table 1 Properties of Cu-Mg-Te-Y alloys with different content of Y

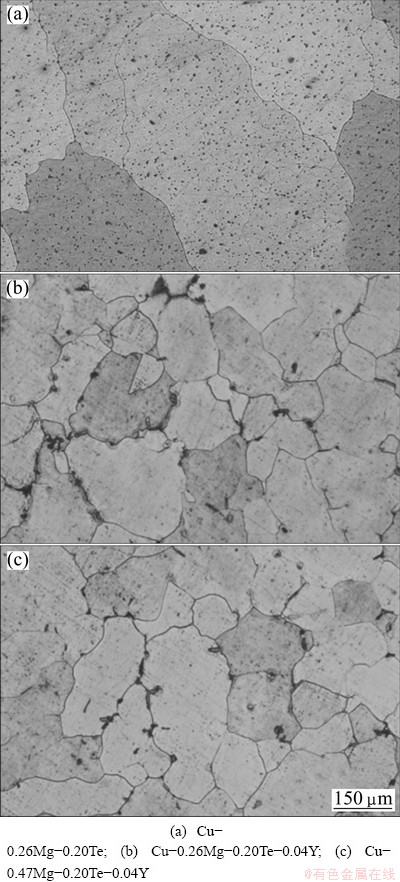

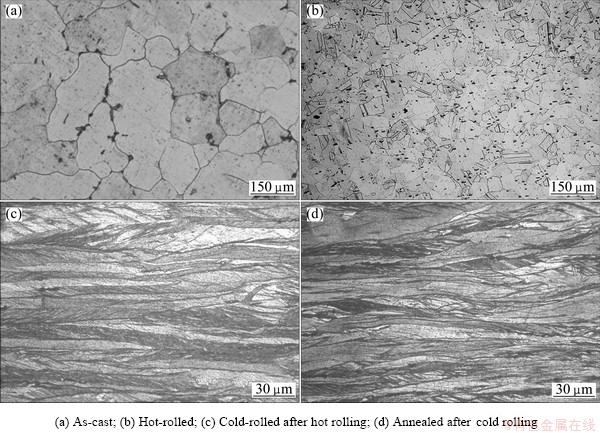

Figure 1(a) shows the microstructure of the as-cast Cu-0.26Mg-0.20Te alloy. A massive amount of particles ranging from 3-10 μm distribute in the crystalline grain. It can be concluded that a few small particles are some Cu-O impurity substances that is harmful to both mechanical properties and electrical conductivity. With 0.04% Y addition, the impurity substances are reduced and the crystalline grains are refined at the same time (Fig. 1(b)). This is because the casting process of Cu alloys is oxygen content sensitive [23], and plenty of Cu-O particles are easily formed in the alloy liquid. The microalloying element Y, which has a larger enthalpy of mixing (-1903 kJ/mol) with oxygen than Cu, is known to preferentially react with oxygen in the alloy liquid, while the formed yttrium oxide does not only promote crystal nucleation but also purify the alloy liquid [24]. On the other hand, Y is also propitious to react with some trace impurities such as Pb, Bi. The refractory high-melting-point compounds uniformly distribute as crystal nuclei in the melt, leading to the grain refinement of the microstructure.

Fig. 1 Microstructures of as-cast copper alloys

The Hall-Petch [25] equation relates the grain size with the strength as follows:

σs=σ0+Kd -1/2 (1)

According to the Hall-Petch equation, the smaller the grains are, the higher the strength and elongation are. The dispersion of the small particles and the mechanical properties of the alloys are improved by the addition of Y as a consequence.

In this work, when the Y content is low enough (<0.06%), it plays predominant roles in the purification of the alloys, which decreases the influence of the impurities to the alloys and improves both mechanical and electrical properties of the alloys. However, if the content is raised up to 0.08%, the electrical conductivity declines dramatically. Y in the alloys has a function of grain refining, which increases the area and quantity of grain boundaries. To some degree, electrons movement will be hindered, which contributes to the reduction of electrical conductivity.

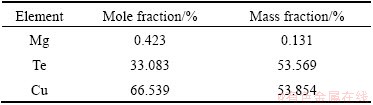

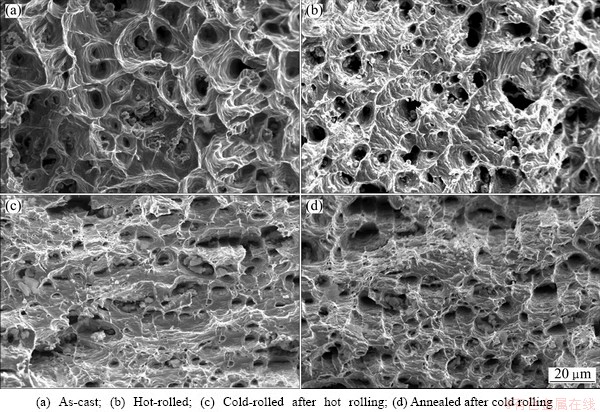

The SEM fracture images of as-cast alloys are shown in Figs. 2(a) and (b). Many circular dimples and precipitated particles are distributed uniformly in each as-cast sample fracture surface. The compositions of precipitated particles in the SEM images measured by EDS are shown in Table 2, and the particle surely consists of 66.539% Cu (mole fraction) and 33.083% Te. According to Cu-Te alloy phase diagram, the precipitated phase is concluded to be Cu2Te. It is noticed that the size of Cu2Te particle has been refined by minor addition of Y as shown in Fig. 2(b). Moreover, the number of dimples also increases with the addition of Y, indicating that the structure is refined.

Fig. 2 Fracture morphologies of as-cast copper alloys

Table 2 Composition of precipitated particles

3.2 Effects of Mg on structures and properties of Cu-Mg-Te-Y alloys

Figure 3 shows the EPMA results of Cu-0.47Mg- 0.20Te-0.04Y alloy. For the present as-cast alloy, in spite of the inhomogeneous segregation of Mg during solidification of alloy, Mg and Y are uniformly distributed in the copper matrix. Because of the solubility of Te in copper is quite small, Te is detected as the form of Cu2Te precipitated phases in the matrix.

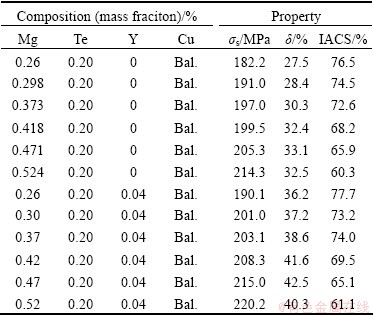

Table 3 lists the results of the compositions, mechanical properties and electrical conductivity of Cu-Mg-Te-Y alloys. Mechanical properties and electrical conductivity with Y content of 0 and 0.04% as a function of Mg content are shown in Figs. 4 and 5, respectively. It can be observed that the property curve trend of alloys without and with 0.04% Y is consistent. When Mg content increases, the mechanical properties are improved and electrical conductivity goes down.

The mechanical properties of the alloys are enhanced by increasing the content of Mg as a result of solid-solution strengthening. The more the Mg is added, the higher the tensile strength will be. The raise of elongation is less obvious than tensile strength. According to the theory of solid-solution strengthening, the quantity of solid-solution atoms will decrease the elongation of alloys. As known that Mg element is rather active that is usually applied in deoxidizing of copper melting. The casting quality and the elongation of the as-cast alloys are reformed because of the deoxidizing function of Mg addition. When Mg content is over 0.47%, the elongation declines to some extent. The microstructure of high Mg content (0.47%) alloy seems similar to the low Mg content (0.26%) alloy under optical microscopy, as shown in Figs. 1(b) and (c), resulting from the fact that solid-solution is the main form of Mg element in the copper alloy. At room temperature, the solubility of Mg in copper is rather high, up to 1%. So in spite of the Mg content, α-phase solid solution will keep no changes in microstructure.

Fig. 3 Microstructures (a) and Mg (b), Te (c) and Y (d) element distributions of Cu-0.47Mg-0.20Te-0.04Y as-cast alloy

Table 3 Compositions and properties of alloy samples

Although the mechanical properties are increased with the increase of Mg content, electrical conductivity falls down gradually. When the Mg atoms enter the copper lattices, forming substitution solid solution, the density of lattice distortion increases with the Mg solubility, leading to the significant decrease of electrical conductivity.

Fig. 4 Mechanical properties of alloys with or without Y element

According to Matthissen’s law, which can be described as follows:

ρ=ρ0+ΔρC+K (2)

where ρ0 is the resistivity of solid solution component, C is the solute atom concentration, Δρ is the additional resistivity resulting from 1% addition of solute atom, K is relative to temperature and concentration. The higher the concentration of solute atom is, the lower the electrical conductivity of alloy will be. Consequently, the content of Mg should be controlled under 0.6% for improving mechanical properties without impairing electrical conductivity below 60% IACS.

Compared to the alloys without Y, the mechanical properties and the electrical conductivity of the alloy with 0.04% Y are improved to some extent. It can be explained by the purification and grain refinement strengthening effects of the Y addition.

Fig. 5 Electrical conductivity of alloys with or without Y element

3.3 Rolling and annealing treatments

In order to obtain better mechanical properties and electrical conductivity, the properties of alloys treated by rolling and annealing were studied. In Table 3, it is noticed that the alloy with 0.47% Mg content possesses high tensile strength over 210 MPa, the elongation over 42% and electrical conductivity over 65% IACS, indicating best polytechnic properties in this alloy series. After rolling and annealing, the properties of the alloys are listed in Table 4, respectively. The Cu-0.47Mg- 0.20Te-0.04Y alloy exhibits much better properties: tensile strength of 510 MPa, elongation of 11% and electrical conductivity of over 63% IACS.

Table 4 Properties of alloys with different preparation process

As shown in Fig. 6(b), after 70% deformation by hot rolling, the crystal grains of the alloy are obviously refined, according with appearance of quantities of deformation twins. The morphology of tensile fracture of alloy after 70% deformation by hot rolling is shown in Fig. 7(b). It shows that the dimples get much smaller and more uniform than the as-cast alloys (Fig. 7(a)), so are the precipitations in the dimples. The precipitates are crushed into pieces and re-distributed during hot rolling. Tensile strength and elongation of alloys increase to some extent, resulting from grain refinement strengthening and casting defects diminishing during hot rolling. In addition, thermal insulation at 800 °C for 2 h and consequently quenching are the solid solution strengthening process before hot rolling, during which Mg is sufficiently dissolved in the copper alloy matrix. But the increase of grain boundaries resulting from grain refinement is the main reason that electrical conductivity reduces.

Cold rolling with 80% deformation is presented as a consequence. As shown in Fig. 6(c), during cold rolling, the texture structure has been produced and is beneficial to obtaining high strength along the axis of the samples [26]. However, the original cold-rolled microstructure is composed of deformed grains with large numbers of dislocations. It also can be observed that the dimples of cold-rolled alloy become much finer and deeper, as shown in Fig. 7(c). At the bottom of the dimples, the quantities of precipitated phases attributing to the voids formation are observed. The finer deforming grains slide along with rolling direction, resulting in plenty of thin dimple walls and smooth vein patterns. Cold rolling generates cold-harden strengthening and lattice distortion while tensile strength increases but the elongation and electrical conductivity decrease [27].

Although the mechanical properties of the alloy after hot and cold rolling are rather high, tensile strength of 518 MPa and elongation of 8.3%, annealing treatment is also needed to relief cold-harden strengthening which strongly degrades electrical conductivity. Consequently, the following annealing at 350 °C for 1 h was introduced to restore the electrical conductivity. Changes between annealed alloy and cold-rolled alloy are still difficult to distinguish (Figs. 6(c) and (d) and Figs. 7(c) and (d)). Under low-temperature treatment, the additional thermal energy permits the dislocations to move and form sub-grain boundaries without dislocation density changing. However, since the dislocations are rearranged and the precipitations are formed during the process, electrons scattering decreases, resulting in the increasing of electrical conductivity with less decrease of strength. After treatment mentioned above, the Cu-Mg-Te-Y alloys with high strength and high conductivity are finally gained as shown in Table 4.

Fig. 6 Microstructures of Cu-0.47Mg-0.20Te-0.04Y

Fig. 7 Fracture morphologies of Cu-0.47Mg-0.20Te-0.04Y

4 Conclusions

1) Y addition is responsible for removing impurities and improving both mechanical properties and electrical conductivity. But electrical conductivity of alloys with above 0.06% Y is lower than those with trace Y addition.

2) The mechanical properties are improved when the Mg content increases in the range of 0.2%-0.6%, leading to solid-solution strengthening without impairing electrical conductivity.

3) The high tensile strength of above 510 MPa, high elongation of 11 % and high electrical conductivity of over 63% IACS can be simultaneously obtained in Cu-0.47Mg-0.20Te-0.04Y alloy after final treatment containing rolling and annealing.

References

[1] HUANG Chong-qi. On contact wire line used in catenary of high speed wheel-rail electrified railway [J]. China Railway Science, 2001, 22(1): 1-5. (in Chinese)

[2] WANG Zhu-tang, TIAN Rong-zhuang. Copper alloy and its processing manual [M]. Changsha: Central South University Press, 2002. (in Chinese)

[3] ZHAO Dong-mei, DONG Qi-ming, Liu Ping, Jin Zhi-hao, Huang Jin-liang. Development of copper alloy for leadframe [J]. Materials Review, 2001, 15(5): 18-20. (in Chinese)

[4] BATRA I S. Microstructure and properties of a Cu-Cr-Zr alloy [J]. Journal of Nuclear Materials, 2001, 299: 91-100.

[5] YANG Yun-chuan, CHEN Jing-chao, FENG Jing. Microstructure and performance of Cu-Sn-Zr alloy [J]. Rare Metal Materials and Engineering, 2011, 40(2): 351-355. (in Chinese)

[6] SAKAI Y, SCHNEIDER-MUNTAU H J. Ultra-high strength, high conductivity Cu-Ag alloy wires [J]. Acta Materialia, 1997, 46(3): 1017-1023.

[7] NING Yuan-tao, ZHANG Xiao-hui, WU Yue-jun. Strain strengthening of Cu-Ag alloy in situ filamentary composites [J]. Transactions of Nonferrous Metals Society of China, 2007, 17(1): 68-74.

[8] TIAN Y Z, WU S D, ZHANG Z F, FIGUEIREDO R B, GAO N, LANGDON T G. Comparison of microstructures and mechanical properties of a Cu-Ag alloy processed using different severe plastic deformation modes [J]. Materials Science and Engineering A, 2011, 528(13-14): 4331-4336.

[9] ZHANG Qiang. Introduction and innovation of the technology for producing CuMg contact wire for high-speed railway [J]. Railway Locomotive & Car, 2009, 29(3): 77-79.

[10]  K. Effect of ageing treatment on wear properties and electrical conductivity of Cu-Cr-Zr alloy [J]. Bulletin of Materials Science, 2011, 34(7): 1465-1470.

K. Effect of ageing treatment on wear properties and electrical conductivity of Cu-Cr-Zr alloy [J]. Bulletin of Materials Science, 2011, 34(7): 1465-1470.

[11] BATRA I S, DEY G K, KULKARNI K D, BANERJEE S. Precipitation in a Cu-Cr-Zr alloy [J]. Materials Science and Engineering A, 2002, 356: 32-36.

[12] WANG Zhi-qiang, ZHONG Yun-bo, RAO Xian-jun, WANG Chao, WANG Jiang, ZHANG Zeng-guang, REN Wei-li, REN Zhong-ming. Electrical and mechanical properties of Cu-Cr-Zr alloy aged under imposed direct continuous current [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(5): 1106-1111.

[13] JIA Shu-guo, LIU Ping, SONG Ke-xing. CHEN Jiang-biao, CHEN Xiao-hong, TIAN Bao-hong, REN feng-zhang. Microstructures and properties of Cu-Cr-Zr in-situ composites [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(7): 1334-1338.

[14] DAI Jiao-yan, YIN Zhi-min, JIANG Rong-rong. SONG Lian-peng, YUAN Yuan. Features of Cu-Fe-P alloy strip prepared by process of horizontal continuous casting-cold rolling-annealing [J]. Transactions of Nonferrous Metals Society of China, 2009, 19(10): 1840-1847.

[15] GUO F A, XIANG C J, YANG C X, CAO X M, MU S G, TANG Y Q. Study of rare earth elements on the physical and mechanical properties of a Cu-Fe-P-Cr alloy [J]. Materials Science and Engineering B, 2008, 147: 1-6.

[16] MONZEN R, WATANABE C. Microstructure and mechanical properties of Cu–Ni–Si alloys [J]. Materials Science and Engineering: A, 2008, 483-484: 117-119.

[17] SUZUKI S, SHIBUTANI N, MIMURA K, ISSHIKI M, WASEDA Y. Improvement in strength and electrical conductivity of Cu-Ni-Si alloys by aging and cold rolling [J]. Journal of Alloys and Compounds, 2006, 417(1-2): 116-120.

[18] KHEREDDINE, HADJ LARBI F, DJEBALA L, AZZEDDINE H, ALILI B, BRADAI D. X-ray diffraction analysis of cold-worked Cu-Ni-Si and Cu-Ni-Si-Cr alloys by Rietveld method [J]. Transactions of Nonferrous Metals Society of China, 2011, 21(3): 482-487.

[19] ZHANG Zhen-feng, LIN Gao-yong, ZHANG Sheng-hua, ZHOU Jia. Effects of Ce on microstructure and mechanical properties of pure copper [J]. Materials Science and Engineering A, 2007, 457: 313-318.

[20] ZHOU Shi-jie, ZHAO Bing-jun, ZHAO Zhen, JIN Xin. Application of lanthanum in high strength and high conductivity copper alloys [J]. Journal of Rare Earths, 2006, 24: 385-388.

[21] LI Peng-fei, WU Zhi-gang, WANG Yun-li, GAO Xi-zhu, WANG Zai-yun, LI Zhi-qiang. Effect of cerium on mechanical performance and electrical conductivity of aluminum rod for electrical purpose [J]. Journal of Rare Earths, 2006, 24: 355-357.

[22] SONG Ming-zhao. The Preparation of Cu-Te series alloys and research on their performance [D]. Chengdu, China: Sichuan University, 2006. (in Chinese)

[23] LIU C T, CHISHOLM M F, MILLER M K. Oxygen impurity and microalloying effect in a Zr-based bulk metallic glass alloy [J] Intermetallics, 2002, 10(11-12): 1105-1112.

[24] de BOER F R, BOOM R, MATTENS W C M, MIEDEMA A R, NIESSEN A K. Cohesion in metals [M]. Amsterdam: North-Holland, 1988.

[25] LU, L, CHEN X, HUANG X, LU K. Revealing the maximum strength in nanotwinned copper [J]. Science, 2009, 323(5914): 607-610.

[26] DIETER G E. Mechanical metallurgy [M]. New York: McGraw-Hill, 2006.

[27] PAN Zhi-yong, WANG Ming-pu, LI Zhou. Effect of aging and cold deforming on microstructure and performance of Cu-5.2Ni-1.2Si alloy [J]. Rare Metal Materials and Engineering, 2009, 38(1): 485-489. (in Chinese).

陈 亮,周秉文,韩建宁,薛彦燕,贾 非,张兴国

大连理工大学 材料科学与工程学院,大连 116024

摘 要:制备具有高强高导性能的铜合金,研究添加Mg和微量的Y对合金的组织和性能的影响。通过变形和退火等工艺处理后,Cu-0.47Mg-0.2Te-0.04Y合金的性能指标可达到:抗拉强度510 MPa,伸长率11%,导电率大于63% IACS。稀土元素Y的熔体净化作用、细晶强化作用和添加适量Mg产生的固溶强化作用能够提高合金的力学性能和导电率。

关键词:Cu-Mg-Te-Y合金;合金化;形变处理;力学性能;导电率

(Edited by Chao WANG)

Foundation item: Project (50875031) supported by the National Natural Science Foundation of China; Project (20095263005) supported by Aviation Science Foundation of China

Corresponding author: Xing-guo ZHANG; Tel: +86-411-84706183; E-mail: zxgwj@dlut.edu.cn

DOI: 10.1016/S1003-6326(13)62919-2