文章编号:1004-0609(2015)12-3397-07

高压实密度LiNi0.5Co0.2Mn0.3O2正极材料的制备及性能

陈 漾1, 2,唐朝辉1, 2,熊 学1, 2,李碧平1, 2,刘志立1, 2

(1. 湖南有色金属研究院,长沙 410015;

2. 湖南美特新材料科技有限公司,长沙 410200)

摘 要:将Ni0.5Co0.2Mn0.3(OH)2前驱体、碳酸锂与H3BO3按一定配比高效混合,采用固相烧结法制备高压实密度LiNi0.5Co0.2Mn0.3O2粉体正极材料,探讨H3BO3添加量对正极材料物理性能、极片压实密度及电化学性能的影响。使用X射线衍射(XRD)和扫描电镜(SEM)表征材料的物理性能,将正极材料制作成软包装全电池,并对其电化学性能进行测试。结果表明:H3BO3具有助熔作用;能增加一次粉体正极材料颗粒的粒径,并提高颗粒致密度,对正极材料的晶体结构没有影响,但对正极材料粒径、pH、比表面积及振实密度等产生影响。将H3BO3添加量为0.6%(质量分数)时制备的LiNi0.5Co0.2Mn0.3O2正极材料制成正极片后,其极限压实密度最高达到3.9 g/cm3;与采用常规LiNi0.5Co0.2Mn0.3O2正极材料制成的正极片(压实密度≤3.5 g/cm3)相比,其体积能量密度提高约11.4%;0.5C首次放电比容量为153.64 (mA·h)/g,1C循环首次放电比容量为152.22 (mA·h)/g,100次循环容量保持率为96.99%,其综合电化学性能优于常规LiNi0.5Co0.2Mn0.3O2正极材料的。

关键词:锂离子电池;LiNi0.5Co0.2Mn0.3O2;压实密度;H3BO3;助熔作用

中图分类号:TM912.9 文献标志码:A

Synthesis and properties of LiNi0.5Co0.2Mn0.3O2 cathode material with high compacted density

CHEN Yang1, 2, TANG Zhao-hui1, 2, XIONG Xue1, 2, LI Bi-ping1, 2, LIU Zhi-li1, 2

(1. Hunan Research Institute for Nonferrous Metals, Changsha 410015, China;

2. Hunan Metal New Materials Technology Co., Ltd., Changsha 410200, China)

Abstract: LiNi0.5Co0.2Mn0.3O2 cathode material with high compacted density was synthesized through solid-state sintering method using LiNi0.5Co0.2Mn0.3O2 precursor, lithium carbonate and H3BO3 at a certain proportion as raw materials. The effects of H3BO3 addition on the physical properties, compacted density and electrochemical properties of the cathode material were studied. The physical properties were investigated by X-ray diffractometry (XRD) and scanning electron microscopy (SEM). The flexible package batteries were fabricated to inspect the electrochemical properties. The results show that H3BO3 with fluxing action can refine the primary particle size and improve the compact level of the particles. H3BO3 has no influence on the crystal structure, but has impact on the particle size, pH, specific surface area and the tap density. The electrochemical property of LiNi0.5Co0.2Mn0.3O2 with 0.6% H3BO3 (mass fraction) is better than that of normal LiNi0.5Co0.2Mn0.3O2 cathode material. The operating limiting compacted density of the electrode increases from 3.5 g/cm3 to 3.9 g/cm3, so that the volume energy density improves by about 11.4%. The first discharge specific capacity is 153.64 (mA·h)/g and 152.22 (mA·h)/g at 0.5C and 1C, respectively. The discharge capacity retention is 96.99% after 100 cycles.

Key words: lithium ion battery; LiNi0.5Co0.2Mn0.3O2; compacted density; H3BO3; fluxing action

近几年来,锂离子电池逐渐从便携式电子产品市场延伸至高端电子产品和动力电池领域,对电池的能量密度、循环寿命和安全性能等提出了更高的要求。目前,商业化的锂离子电池主要采用钴酸锂LiCoO2和镍钴锰三元复合材料LiNixCoyMnzO2 (0<x, y, z<1)作为正极材料。但是,LiCoO2存在钴资源稀缺、钴毒性较大、热稳定性和过充安全性能较差等问题,限制了锂离子电池应用领域的拓展。LiNixCoyMnzO2则以其成本低、比容量高、倍率性能好、安全性能好等优点被认为最有可能取代LiCoO2的正极材料[1-4]。

在工业化应用中,与LiCoO2相比,LiNixCoyMnzO2主要缺点是压实密度偏低(≤3.5 g/cm3),极大地制约了它在高能量密度锂离子电池领域的应用。造成LiNixCoyMnzO2压实密度偏低的主要原因是它是由一次颗粒团聚成的二次颗粒,振实密度低,同时在辊压下容易发生破碎。

研究者们提出了一些提高LiNixCoyMnzO2压实密度的方法:掺杂Mg等微量元素、提高Li配比、提高烧结温度等[5-6],但是并没有进行详细地分析。硼氧化物具有助熔作用,能够促进晶体生长,应用于锂金属层状化合物[7-8]。ALCANTARA等[7]通过添加H3BO3在低温下制备了B掺杂的LiCoO2,其粒径从0.5~3 μm增加到了1.5~6 μm,首次放电容量和库伦效率提升。JOUANNEAU等[8]详细研究了B2O3作为烧结剂对Li[NixCo1-2xMnx]O2(0≤x≤1/2)振实密度的影响,证实了0.5%~1%(质量分数)B2O3可以使Li[Ni0.375Co0.25Mn0.375]O2的振实密度达到最大值,相应地提高了电极压实密度,对电性能影响较小。而将H3BO3用于合成高压实密度LiNi0.5Co0.2Mn0.3O2正极材料的研究却未见详细的报道。H3BO3作为一种弱酸,会与碱性镍钴锰氢氧化物Ni0.5Co0.2Mn0.3(OH)2发生化学反应,能使分解产物B2O3分散更均匀、与LiNi0.5Co0.2Mn0.3O2复合更紧密,助熔效果更显著。

本文作者以H3BO3为助熔剂,以镍钴锰氢氧化物Ni0.5Co0.2Mn0.3(OH)2、碳酸锂Li2CO3为原料,采用固相烧结法制备了高压实密度LiNi0.5Co0.2Mn0.3O2正极材料,考察H3BO3添加量对材料的物理性能、极片压实密度和电化学性能的影响。

1 实验

1.1 材料制备

镍钴锰氢氧化物Ni0.5Co0.2Mn0.3(OH)2(湖南邦普循环科技有限公司生产,电池级)与碳酸锂Li2CO3(电池级)、按理论化学计量比Li与(Ni+Co+Mn)摩尔比1.05:1配料,同时加入一定量的硼酸H3BO3(分析纯),用高效混料机混合均匀,其中H3BO3的添加量(质量分数)分别为0、0.3%、0.6%、0.9%,分别编号为N0、N1、N2、N3。放置于带有鼓风装置的特制马弗炉中,以5 ℃/min的升温速率升温至850 ℃,恒温5 h,之后又以升温速率5 ℃/min升至950 ℃,恒温5 h。整个烧结过程中,抽风机风量为10 m3/min。冷却至室温,破碎、过筛处理后即得到LiNi0.5Co0.2Mn0.3O2正极材料。

1.2 材料表征

使用X射线衍射仪(日本RigaKu公司生产,D/max2550VB型,18 kW)分析样品物相,Cu Kα靶辐射,扫描范围10°~80°,扫描速度2.0 (°)/min,管电压40 kV,管电流300 mA。采用美国FEI公司生产的Nova NanoSEM 250型超高分辨率场发射扫描电子显微镜观察样品的微观形貌和粒径大小等。使用Malvern 2000型激光粒度仪分析样品的粒度分布。使用振实密度仪测试样品的振实密度,每分钟振动300次,总共振动3000次,样品质量为500 g。使用康塔公司生产的nova2000e型比表面积测试仪测试样品的比表面积。使用雷磁PHS-3C型pH计(上海精密科学仪器有限公司生产)测试样品的pH。

1.3 实验电池制作及电化学性能测试

本实验中软包装全电池的设计容量为1500 mA·h,正极极片双面面密度设为38 mg/cm2,FSN-4型人造石墨(上海杉杉科技有限公司生产)负极极片双面面密度设为20 mg/cm2,负极压实密度固定为1.5 g/cm3。正极极片做2个不同的压实密度,即3.5 g/cm3和使用极限压实密度。

按照质量比93.5:3.5:3称取活性物质、聚偏四氟乙烯PVDF和导电剂Super P,经过调浆、涂布、烘干、滚压、分切、焊极耳、卷绕、压芯、注液、封口等过程。使用的电解液型号为国泰华容公司生产的LB-315。将电池进行化成后用于测试电性能。采用新威电池测试系统(深圳新威尔电子有限公司生产)测试电池充放电性能,测试条件如下:室温(25 ℃)、电压范围3.0~4.2 V、电池分容倍率为0.5C、循环测试倍率为1C。

2 结果与讨论

2.1 正极材料的物理性能表征

2.1.1 正极材料的物相组成

图1所示为N0、N1、N2、N3样品的XRD谱。由图1可知,4个样品的谱图非常相似,均为标准的а-NaFeO2层状结构,属 空间群,没有杂峰。图1中主要特征峰都比较尖锐,(003)和(104)的峰强度比值均大于1.2,且(106)与(102)峰、(108)与(110)峰分裂比较明显,表明制备的LiNi0.5Co0.2Mn0.3O2结晶度高,层状结构完整,且阳离子混排程度低[9-10]。由此可知,添加H3BO3对材料的晶体结构没有影响。

空间群,没有杂峰。图1中主要特征峰都比较尖锐,(003)和(104)的峰强度比值均大于1.2,且(106)与(102)峰、(108)与(110)峰分裂比较明显,表明制备的LiNi0.5Co0.2Mn0.3O2结晶度高,层状结构完整,且阳离子混排程度低[9-10]。由此可知,添加H3BO3对材料的晶体结构没有影响。

2.1.2 正极材料的显微形貌

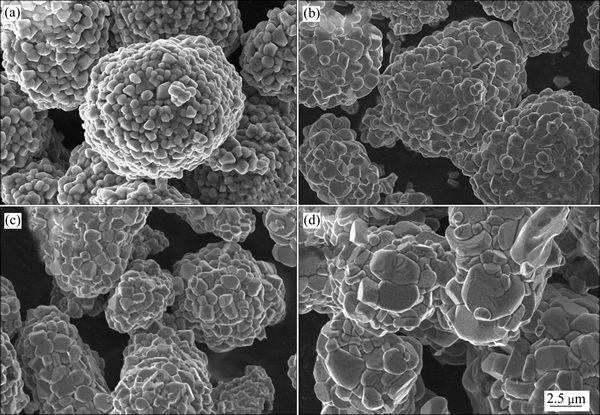

图2所示为N0、N1、N2、N3样品的SEM像。由图2可知,制备的LiNi0.5Co0.2Mn0.3O2正极材料粉体都为一次颗粒团聚成的类球形颗粒。N0样品中一次颗粒比较均匀,且粒径都在1 μm以下,颗粒之间较疏松(见图2(a))。而图2(b)~(d)中显示出材料的一次颗粒长大,颗粒之间更加致密,且随着H3BO3添加量的提高,一次颗粒粒径明显增大。这表明H3BO3具有助熔作用,其液相效应[11]促使一次颗粒晶体在相同温度下生长速度加快,烧结致密度增加。

图1 样品N0、N1、N2、N3的XRD谱

Fig. 1 XRD patterns of samples N0, N1, N2, N3

2.1.3 正极材料的其他主要物理性能表征

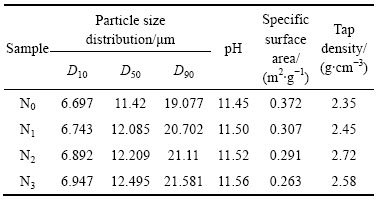

表1所列为样品N0、N1、N2和N3的物理性能参数。从粒度分析结果可知,随着H3BO3添加量的增加,颗粒粒度稍有增大,这与一次颗粒的长大程度有关。pH是LiNixCoyMnzO2材料很重要的一个产品指标,因为Ni含量偏高,若工艺条件控制不当,LiNi0.5Co0.2Mn0.3O2容易产生pH 过高的问题,影响材料的加工性能和循环性能等[12-13]。根据测试结果显示,H3BO3的加入会导致材料的pH升高,但是升高幅度不大,对电化学性能的影响将在后文中进一步讨论。比表面积也是影响LiNixCoyMnzO2材料电性能的重要指标之一。比表面积大会导致正极极片易吸水、首次库伦效率低、高温性能差等问题。由表1可知,随着H3BO3添加量的增加,样品的比表面积降低,有利于电性能的发挥。振实密度与压实密度并不成绝对的正比关系[8, 14],添加H3BO3后,材料的振实密度提高,但添加量为0.6%时,振实密度最高。

图2 样品N0、N1、N2、N3的SEM像

Fig. 2 SEM images of samples N0(a), N1(b), N2(c), N3(d)

表1 样品N0,N1,N2和N3的物理性能参数

Table 1 Physical properties parameter of samples N0, N1, N2 and N3

2.1.4 正极极片的使用极限压实密度及表面形貌

对制备好的极片进行压实密度试验,分别取不同样品的10 cm×10 cm大小的极片,利用DYG-703B型油压增压对辊机处理极片,获得不同的压实密度。压实密度的计算公式如下所示:

(1)

(1)

式中: 为压实密度;ms为极片质量;mAl为铝箔质量;As为极片面积;ls为压实后极片厚度;lAl为铝箔厚度。

为压实密度;ms为极片质量;mAl为铝箔质量;As为极片面积;ls为压实后极片厚度;lAl为铝箔厚度。

同时,采用极片对折后折痕处不断裂、对光观察不透光的方法判断使用极限压实密度。根据试验结果得到4种材料的使用极限压实密度分别如下:样品N0,3.5 g/cm3;样品N1,3.6 g/cm3;样品N2,3.9 g/cm3;样品N3,3.7 g/cm3。由此可以计算得知,当压实密度从3.5 g/cm3提高到3.9 g/cm3时,极片的体积能量密度提高约11.4%。N2正极极片的SEM像如图3所示。在未压实的正极极片中(见图3(a)),活性物质二次颗粒排列疏松,孔隙率较大;随着压实密度的增大,颗粒之间排列更加紧密,相互之间接触性更好,有利于电性能的发挥。压实密度为3.9 g/cm3的正极极片中活性物质的一次颗粒出现一定程度的破碎现象,即一次颗粒之间的间隙增加。

2.2 全电池电化学性能表征

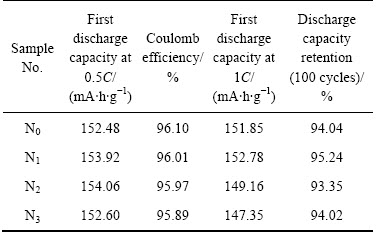

将样品N0、N1、N2和N3组装成软包装全电池,为了对比H3BO3添加量对正极材料电化学性能的影响,正极极片的压实密度都取为3.5 g/cm3。图4所示为0.5C首次充放电曲线,图5所示为1C循环100次的放电比容量和容量保持率曲线,具体电性能数据列于表2中。未添加H3BO3的样品N0在0.5C时的首次放电比容量为152.48 (mA·h)/g,首次库伦效率为96.10%。样品N1、N2、N3的首次放电比容量均有所上升,但是库伦效率有所降低。循环性能测试结果显示,在1C倍率下,随着H3BO3添加量从0.3%提高到0.9%,首次放电比容量明显降低,原因可能是H3BO3促进了一次颗粒长大,导致Li+在固相中扩散距离增加,从而降低了材料的倍率性能[15-16]。样品N0、N1、N2和N3的100周循环容量保持率差距不大。由此可见,添加适量的H3BO3对材料的循环性能没有明显不利影响。

图3 压实密度不同时样品N2的SEM像

Fig. 3 SEM images of sample N2 with different compacted densities

图4 样品N0,N1,N2和N3在0.5C倍率下的首次充放电曲线

Fig. 4 First charge-discharge curves of samples N0,N1,N2 and N3 at 0.5C

图5 样品N0,N1,N2和N3在1C倍率下的循环性能曲线

Fig. 5 Cycling performance curves of samples N0, N1, N2 and N3 at 1C

表2 样品N0,N1,N2和N3的全电池电化学性能

Table 2 Electrochemical performance of samples N0,N1,N2 and N3 for full cell test

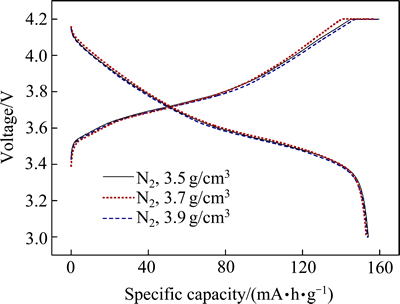

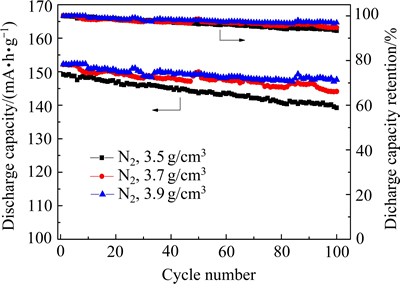

不同压实密度的N2在0.5C倍率下的首次充放电曲线如图6所示,具体数据见表3。随着极片压实密度的增加,电池的首次放电比容量降低幅度不到1 (mA·h)/g,首次库伦效率稍有提高,这表明压实密度对电池首次充放电比容量基本没有影响。不同压实密度下的N2在1C倍率下的循环曲线如图7所示,具体数据见表3。随着极片压实密度的提高,循环首次放电比容量提高,循环容量保持率也提高,压实密度为3.9 g/cm3时,首次放电比容量为152.22 (mA·h)/g,100次循环容量保持率为96.99%,这说明提高压实密度,材料的倍率性能和循环性能都得到了提高,这可能是由于提高压实密度,极片内部颗粒之间、颗粒与电解液之间接触更紧密,有利于锂离子的嵌入和脱出,从而倍率性能提高[15];同时,B元素可能以B2O3的形式包覆在材料表面,抑制了材料与电解液之间的副反应,从而提高了循环性能[17]。

图6 不同压实密度时样品N2在0.5C倍率下的首次充放电曲线

Fig. 6 First charge-discharge curves of sample N2 with different compacted densities at 0.5C

图7 不同压实密度时样品N2在1C倍率下的循环性能曲线

Fig. 7 Cycling performance curves of sample N2 with different compacted densities at 1C

表3 N2不同压实密度的全电池电化学性能

Table 3 Electrochemical performance of N2 with different compacted densities for full cell test

3 结论

1) Ni0.5Co0.2Mn0.3(OH)2前驱体和碳酸锂为原料,采用固相烧结法、添加适量的H3BO3制备了高压实密度LiNi0.5Co0.2Mn0.3O2正极材料,H3BO3在晶体生长过程中起到了助熔作用。随着H3BO3添加量的增加,材料的一次颗粒长大,致密度增加,晶体结构没有发生变化,粒度、pH、比表面积、振实密度稍有变化。

2) H3BO3添加量为0.6%时,LiNi0.5Co0.2Mn0.3O2制成的极片具有最高的使用极限压实密度3.9 g/cm3,体积能量密度提高约11.4%。

3) 全电池测试结果显示,添加H3BO3仅对倍率 性能有明显不利影响。H3BO3添加量为0.6%时,LiNi0.5Co0.2Mn0.3O2极片随着压实密度的增大,0.5C首次充放电比容量基本不变,而倍率和循环性能提升;压实密度为3.9 g/cm3时,0.5C首次充放电比容量为153.64 (mA·h)/g,1C循环首次放电比容量为152.22 (mA·h)/g,100次循环容量保持率为96.99%,综合电化学性能优异。

REFERENCES

[1] GOODENOUGH J B, KIM Y. Challenges of rechargeable lithium batteries[J]. Chemistry of Materials, 2010, 22: 587-603.

[2] CHEBIAM R V, KANNAN A M, PRADO F, MANTHIRAM A. Comparison of the chemical stability of high energy density cathodes of lithium-ion batteries[J]. Electrochemistry Communications, 2001, 3(11): 624-627.

[3] MYUNG S T, LEE M H, KOMABA S, KUMAGAI N, SUN Y K. Hydrothermal synthesis of layered Li[Ni1/3Co1/3 Mn1/3]O2 as positive electrode material for lithium secondary battery[J]. Electrochimica Acta, 2005, 50(24): 4800-4806.

[4] KAGEYAMA M, LI D C, KOBAYAKAWA K. Structural and electrochemical properties of LiNi1/3Mn1/3Co1/3O2-xFx prepared by solid state reaction[J]. Journal of Power Sources, 2006, 157(1): 494-500.

[5] 衡 凯, 赵志兵, 王燕舞, 万国莉. 高压实密度镍钴锰酸锂NCM523三元材料的制备方法: 中国, CN103825015 A [P]. 2014-05-28.

HENG Kai, ZHAO Zhi-bing, WANG Yan-wu, WANG Guo-li. The preparation method of LiNi0.5Co0.2Mn0.3O2 with high compacted density: China, CN103825015 A[P]. 2014-05-28.

[6] 曾跃武, 黄连友. 高压实密度锂电池正极材料的制备方法: 中国, CN 102593442 A[P]. 2012-07-18.

ZENG Yue-wu, HUANG Lian-you. The preparation method of cathode materials for lithium ion battery: China, CN 102593442 A[P]. 2012-07-18.

[7] ALACNTARA R, LAVELA P, TIRADO J L. Structure and electrochemical properties of boron-doped LiCoO2[J]. Journal of Solid State Chemistry, 1997, 134: 265-273.

[8] JOUANNEAU S, BAHMET W, EHERMAN K W, KRAUSE L J, DAHN J R. Effect of the sintering agent, B2O3, on Li[NixCo1-2xMnx]O2 materials density, structure, and electrochemical properties[J]. Journal of the Electrochemical Society, 2004, 151(11): A1789-A1796.

[9] 胡东阁, 王张志, 刘佳丽, 黄 桃, 余爱水. 前驱体对三元正极材料LiNi0.5Co0.2Mn0.3O2性能的影响[J]. 电化学, 2013, 19(3): 205-206.

HU Dong-ge, WANG Zhang-zhi, LIU Jia-li, HUANG Tao, YU Ai-shui. The effect of precursors on performance of LiNi0.5Co0.2Mn0.3O2 cathode material[J]. Journal of Electrochemistry, 2013, 19(3): 205-206.

[10] 李运姣, 任苗苗, 韩 强, 明宪权, 李普良, 许 虎, 李 林. 热处理过程中锂离子电池正极材料LiNi0.5Co0.2Mn0.3O2的结构变化及电化学性能[J]. 中国有色金属学报, 2014, 24(7): 1785-1791.

LI Yun-jiao, REN Miao-miao, HAN Qiang, MING Xian-quan, LI Pu-liang, XU Hu, LI Lin. Structural change and electrochemical performance of LiNi0.5Co0.2Mn0.3O2as cathode material for lithium ion batteries[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(7): 1785-1791.

[11] HUANG C L, CHIANG K H. Dielectric properties of B2O3-doped (1-x)LaAlO3–xSrTiO3ceramic system at microwave frequency[J]. Materials Research Bulletin, 2002, 37(12): 1941-1948.

[12] 马全新, 孟军霞, 杨 磊, 曹 文. 锂离子电池正极材料LiNi0.5Co0.2Mn0.3O2的制备及电化学性能[J]. 中国有色金属学报, 2013, 23(2): 456-462.

MA Quan-xin, MENG Jun-xia, YANG Lei, CAO Wen. Preparation of Li-ion battery cathode material LiNi0.5Co0.2Mn0.3O2 and its electrochemical performance[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(2): 456-462.

[13] NOH H J, YOUN S, YOON C S, SUN Y K. Comparison of the structural and electrochemical properties of layered Li[NixCoyMnz]O2(x=1/3, 0.5, 0.6, 0.7, 0.8 and 0.85 ) cathode material for lithium-ion batteries[J]. Journal of Power Sources, 2013, 233: 121-130.

[14] 杨 志, 李新海, 王志兴, 彭文杰, 郭华军. 高振实密度球形LiNi0.5Co0.3Mn0.2O2粉末的合成及性能[J]. 中国有色金属学报, 2010, 20(1): 106-111.

YANG Zhi, LI Xin-hai, WANG Zhi-xing, PENG Wen-jie, GUO Hua-jun. Synthesis and characterization of high tap density spherical LiNi0.5Co0.3Mn0.2O2 powders[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(1): 106-111.

[15] 张继斌, 滑纬博, 郑 卓, 刘文元, 郭孝东. 高倍率性能锂离子电池Li[Ni1/3Co1/3Mn1/3]O2正极材料的制备及其电化学性能[J]. 物理化学学报, 2015, 31(5): 905-912.

ZHANG Ji-bin, HUA Wei-bo, ZHENG Zhuo, LIU Wen-yuan, GUO Xiao-dong. Preparation and electrochemical performance of Li[Ni1/3Co1/3Mn1/3]O2 cathode material for high-rate lithium-ion batteries[J]. Acta Physico-Chimica Sinica, 2015, 31(5): 905-912.

[16] WANG J, LIU X M, YANG H. Synthesis and electrochemical properties of highly dispersed Li4Ti5O12 nanocrystalline for lithium secondary batteries[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(3): 613-620.

[17] HONG T E, JEONG E D, BAEK S R, BYEON M R, LEE Y S, KHAN F N, YANG H S. Nano SIMS characterization of boron- and aluminum-coated LiNi1/3Co1/3Mn1/3O2 cathode materials for lithium secondary ion batteries[J]. Journal of Applied Electrochemistry, 2012, 42: 41-46.

(编辑 龙怀中)

收稿日期:2015-03-26;修订日期:2015-09-17

通信作者:唐朝辉,工程师,博士;电话:0731-82022648;E-mail: tangzh106@126.com