Mechanical properties of nano SiO2 filled gypsum particleboard

LEI Wen(雷 文)1, DENG Yu-he(邓玉和)2, ZHOU Mei(周 梅)2,

XUAN Ling(宣 玲)2, FENG Qian(冯 谦)3

1.College of Information Science and Technology, Nanjing Forestry University, Jiangsu 210037, China;

2.College of Wood Science and Technology, Nanjing Forestry University, Jiangsu 210037, China;

3.College of Mechanic Engineering, Nanjing Forestry University, Jiangsu 210037, China

Received 10 April 2006; accepted 25 April 2006

Abstract: Nano SiO2 was filled into gypsum particleboard. Effect of the amount of nano SiO2 particles filled, ultrasonic dissipating duration and treating the nano particles with different coupling agents on the mechanical properties of the board were studied respectively. The results show that nano SiO2 is helpful for the improvement of the properties. Adding 3%(mass fraction) nano SiO2 is the best for the improvement of both modulus of rupture(MOR) and modulus of elasticity(MOE) of the boards formed at 30 ℃ or 40 ℃. For the boards formed at 30 ℃, their MOR and MOE can be improved by 8.77% and 12.24%, and MOR and MOE of the boards formed at 40 ℃ can be improved by 44.44% and 108.38%.3% is also the best addition proportion to improve internal bond(IB) of the boards formed at 30 ℃, while 5% is the best for that of the boards formed at 40 ℃. At room temperature, dissipating nano SiO2 into flake by ultrasonic has better effect on the properties of the final products. Through ultrasonic treating for 1 h and the best treating duration, the MOR and MOE can be increased by 41.99% and 47.80%. In addition, different coupling agents have different effects on the final properties too, and silane coupling agent KH570 is better for the improvement of properties of the boards formed at room temperature.

Key words: nano SiO2; gypsum particleboard; rupture modulus; elastic modulus; internal bond

1 Introduction

Gypsum particleboard, as a new kind of green building material, has many advantages such as no formaldehyde emission, fire retardancy, heat-resistance, light mass, high efficiency to produce[1], it is used widely and has attracted much attention since it appeared[2]. But the lower strength than that of the boards bonded by synthetic polymer limits its applications.

Nano particle is a kind of particle which is at least smaller than 100 nm in one dimension, it has also attracted much attentions of material researchers and manufacturers because of its many advantages over conventional large sized particles[3-5]. Nano-SiO2 has been added to polymer to increase its strength, flexibility and aging resistance[6, 7]. In consideration of nanoparticles with many novel properties and significant improvement on some properties of materials mixed with nanoparticles[8, 9], the effect of nano-SiO2 in improving the mechanical properties of gypsum particleboards was studied. The effects of treating duration by ultrasonic, kinds and amount of coupling agents used to enhance the bonding between nano particles and flake and the proportion of nano particles to flake on the properties of the boards were investigated.

2 Experimental

Tap water was poured into an ultrasonic cleansing device to a referred level, then nano SiO2 was put into the water and the nano particles were stirred together with water by hand homogeneously, the ultrasonic device was turned on and kept at work for 15 min, some weighed flake was added into the device after the water solution hade been cooled down for 30 min. After stirred homogeneously by hand, the equipment was turned on again to treat the mixture of nano particles and flake in the water for 30 min, another 30 min was necessary for cooling the water solution once more, then the solution should be ultrasonic treated continuously or cooled for 30 min alternatively. The total treating time was decided by requirement.

In order to enhance the bonding between nano SiO2 particles and flake, two kinds of coupling agents, i.e, titanated NDZ401 and silane KH570 were selected to treat the surface of the nano particles by mixing each one with the particles in a proper proportion very quickly and then sealed for 24 h before ultrasonic treatment.

Gypsum particleboards are formed by weighing proper amount of flake with or without nano particles, gypsum and other additives, mixing them homogeneously and then compressing under a pressure of 3 MPa at a designed temperature for a definite time. The amount of raw materials used for each board is decided by the apparent density of the board.

All the mechanical properties including MOR,MOE and IB are measured according to Chinese national standards.

(1)

(1)

where R is the relative property; P1 is the property including MOR,MOE and IB of any particleboard; P0 is the property of pure gypsum particleboard which is formed from original flake and gypsum, neither any nano SiO2 particles is filled nor the flake is ultrasonic treated.

3 Results and discussion

3.1 Effect of duration of ultrasonic treatment on mechanical properties of gypsum particleboards

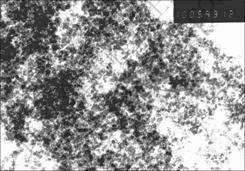

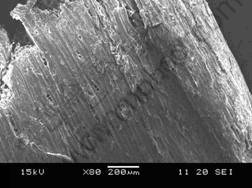

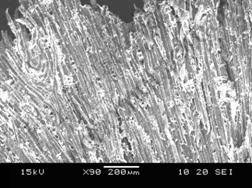

The nano SiO2 used in this study is spherical (Fig.1) whose diameter is 10-20 nm. The flake has much damage in processing, as shown in Fig.2. When the nano particles are treated together with flake by ultrasonic, the particles can be dissipated into the damaged part and even the inside of the flake(Fig.3).

In order to study the effect of the duration of ultrasonic treatment on the mechanical properties of gypsum particleboards, three different durations, i.e, 30 min, 60 min and 90 min are selected. Actually, the duration of treatment by ultrasonic has effect on both the MOR and MOE of the nano SiO2 filled gypsum particle- boards, as shown in Fig.4.

From Fig.4, it can be concluded that treating the mixture of nano SiO2 and flake by ultrasonic can get higher relative values of MOR and MOE, and when the duration of ultrasonic treatment is 1 h, MOR and MOE can be improved to a maximum extent by 41.99% and 47.80% respectively compared with the properties of those boards without being ultrasonic treated. The main reason may lie in the adequate structural alternation of the flake because of the high frequency from ultrasonic,

Fig.1 TEM micrograph of nano SiO2 (Presented by Nanjing Haitai Nano-particle Co Ltd)

Fig.2 SEM micrograph of original flake

Fig.3 SEM micrograph of nano filled flake

Fig.4 Effect of duration of ultrasonic treatment on properties of nano SiO2 filled gypsum particleboards

the change allows the fine nano particles to enter the inside of the flake, as a result, the flake is reinforced, and the mechanical properties of the board are improved accordingly. The duration of ultrasonic treatment is 60 min may be the best duration for the structural change, 30 min is too short for the structure to change enough, while 90 min is too long and may destroy the structure more heavily.

3.2 Effect of amount of nano-SiO2 filled on mechanical properties of gypsum particleboards

Figs.5-7 show the changes of relative MOR,MOE and IB with the proportion of nano SiO2 added into the gypsum particleboards formed at 30 ℃ and 40 ℃. All the relative mechanical properties including relative MOR,MOE and IB can be improved when nano SiO2 is used in compressing the boards. As for the relative MOR and MOE, 3% of nano SiO2 may be the best addition for their improvement. MOR for the boards pressed at 30 ℃ and 40 ℃ can be increased by 8.77% and 44.44% from those boards without nano SiO2, and MOE increases by 12.24% and 108.38% compared with those of boards without any nano particles.

Fig.5 Variation of relative RMO of board with proportion of nano particles to flake

However, the best proportion for the improvement of IB differs from each other for those boards formed at 30 ℃ and 40 ℃, 3% is the best for the board formed at 30 ℃, IB will be increased by 16.67%, while 5% is the best for the board formed at 40 ℃, in this situation, IB can be increased by 50%.

3.3 Effect of treating nano SiO2 by coupling agents on mechanical properties of gypsum particleboards

Coupling agent is a kind of compound which has two parts. One is hydrophilic, and the other is hydrophobic. It is often used to improve the adhesion between inorganic particles and organic matrix[10].

Nano SiO2 is a typical kind of inorganic particles, while flake should be organic because there are much

Fig.6 Variation of relative MOE of board with proportion of nano particles to flake

Fig.7 Variation of relative IB of board with proportion of nano particles to flake

cellulose, semi-cellulose and lignin-cellulose, coupling agent may be good for the adhesion between nano SiO2 and flake. In this study, titanated coupling agent NDZ 401 and silane coupling agent KH570 are selected to treat nano-SiO2 by quick mixing in related solvents. Then the treated nano particles are dissipated into flake by 5% in mass fraction. Figs.8 and 9 show the effects of the mass fraction of coupling agent to nano SiO2 on the relative MOR and MOE of gypsum particleboads. From these two figures, it can be seen that whether it is KH570 or NDZ401 treating nano SiO2 with coupling agent, it

Fig.8 Variation of relative properties of board with proportion is of NDZ401 to nano SiO2 good for the improvement of MOR and MOE, though no definite tendency appears. And generally, KH570 has better effect on the mechanical properties than NDZ401. Yet this effect is not so great as that of the duration of ultrasonic treatment and the addition proportion of nano-SiO2 do.

Fig.9 Variation of relative properties of board with proportion of KH570 to nano SiO2

4 Conclusions

1) Treating the mixture of flake and nano SiO2 by ultrasonic has a positive effect on the mechanical properties of the gypsum particleboards. And 1 h is the best duration for the treatment. When the mass fraction of nano-SiO2 to flake is 5%, MOR and MOE of the board can be improved by 41.99% and 47.80% respectively after 1 h treating.

2) Addition of nano SiO2 can increase the values of MOR, MOE and IB of gypsum particleboards formed at 30 ℃ or 40 ℃.

3) Treating nano SiO2 with coupling agents is also helpful for the improvement of the mechanical properties of the gypsum particleboards, but the effect not only does not have a definite tendency but also may differ from the kind and amount of the coupling agent. Generally, KH570, a silane coupling agent, is better for the improvement.

4) Based on the testing results, the mechanism for the improvement of the mechanical properties of gypsum particleboard by adding nano SiO2 may be described as follows: high frequency of ultra-sonic makes it possible for the fine nano particles to enter the inside of flake , the flake is reinforced accordingly. And the bonding between nano SiO2 and flake may also have effect on the strength of the final board. In other words, the reason for the improvement of the mechanical properties of gypsum particleboard with the addition of nano SiO2 mainly lies in the increase of strength of flake, not in the improvement of bonding between flake and gypsum. Certainly, the details of the mechanism are not available yet, more studies should be carried out in the future.

References

[1] DENG Yu-he, Furuno T, WU Yu-fei. Effect of buffers on gypsum particleboard properties[J]. J Wood Sci, 2001, 47: 356-361.

[2] LIU Xian-miao, FU Feng, ZHANG Shuang-tie, GAO Li, CHENG Yong-ping. Production technique and application prospect of gypsum particleboard[J].Wood Machinery, 2003, 5: 12-15, 38.(in Chinese)

[3] LIN C W, Hung C L, Venkateswarlu M, HWANG B J. Influence of TiO2 nano-particles on the transport properties of composite polymer electrolyte for lithium-ion batteries[J]. Journal of Power Sources, 2005, 146: 397-401.

[4] LU Yan, YU Shui-li, CHAI Bao-xiang. Preparation of poly(vinylidene fluoride)(pvdf) ultrafiltration membrane modified by nano-sized alumina (Al2O3) and its antifouling research[J]. Polymer, 2005, 46: 7701-7706.

[5] Bhagwat M, Shah P, Ramaswamy V. Synthesis of nanocrystalline SnO2 powder by amorphous citrate route[J]. Materials Letters, 2003, 57: 1604-1611.

[6] Wang Q J, Cheng S. Study on the CPE/Nano SiO2 blends J Funct Polym, 2002, 5(3): 271-275.

[7] Bauer B J, LIU D, Jackson C L, et al. Epoxy/SiO2 interpenetrating polymer net works.Polym[J]. Adv Technol, 1996, 7: 333-339.

[8] Lau K T, HUI D. The revolutionary creation of new advanced materials–carbon nanotube composites[J]. Composites: Part B, 2002, 33: 63-277.

[9] YU X M, HE Y L. Piezo-resistance effect of hydrogenated nano-crystalline silicon films with PECVD deposition method[J]. Journal of Beijing University of Aeronautics and Astronautics, 1996, 22(1): 84-87.(in Chinese)

[10] ZHANG Ling, CAI Tao, YAO Ying-zheng, WU Qing. Preparation and characterization of silica-titania binaries and its hybrid materials[J]. Chinese Journal of Applied Chemistry, 2005, 22(9): 984-988.(in Chinese)

(Edited by CHEN Can-hua)

Foundation item: Project (30371130) supported by the National Natural Science Foundation of China

Corresponding author: LEI Wen; Tel: +86-25-81777389; E-mail: nfuleiwen@163.com