压力和超声耦合作用对Al-5.0Cu合金凝固组织和硬度的影响

来源期刊:中国有色金属学报(英文版)2016年第9期

论文作者:张杨 李风雷 罗执 赵愈亮 夏伟 张卫文

文章页码:2296 - 2303

关键词:Al-Cu合金;压力场;功率超声场;复合场;显微组织;硬度

Key words:Al-Cu alloy; squeeze pressure field; power ultrasonic field; combined field; microstructure; microhardness

摘 要:在Al-5.0Cu合金的凝固过程中同时施加压力和功率超声,在此基础上采用光学显微镜、扫描电镜、定量金相分析以及显微硬度测试仪分别研究单独施加压力、超声及二者的耦合作用对合金凝固组织和显微硬度的影响。结果表明:外场(单一压力或功率超声)的施加可以改善α(Al)和θ(Al2Cu)相的形貌以及分布,同时提高合金的硬度;相对于单一场,耦合场改善显微组织和提升性能的效果更加明显,且其有效作用区域更广。

Abstract: The squeeze pressure field and power ultrasonic field were applied during the conventional casting process of Al-5.0Cu alloy simultaneously. The effects of individual squeeze pressure or power ultrasonic and their coupling on the microstructures and microhardness of Al-5.0Cu alloy were studied by optical microscopy, scanning electron microscopy, image analysis and micro Vickers hardness test. The results show that compared with the conventional casting, refined microstructures, homogeneous distribution of α(Al) and θ(Al2Cu) and improved microhardness can be obtained when squeeze pressure or power ultrasonic is applied individually. For the case of combined fields, both the treated region and the improvement of microstructure and properties can be enhanced.

Trans. Nonferrous Met. Soc. China 26(2016) 2296-2303

Yang ZHANG, Feng-lei LI, Zhi LUO, Yu-liang ZHAO, Wei XIA, Wei-wen ZHANG

School of Mechanical and Automotive Engineering, South China University of Technology, Guangzhou 510640, China

Received 22 September 2015; accepted 18 April 2016

Abstract: The squeeze pressure field and power ultrasonic field were applied during the conventional casting process of Al-5.0Cu alloy simultaneously. The effects of individual squeeze pressure or power ultrasonic and their coupling on the microstructures and microhardness of Al-5.0Cu alloy were studied by optical microscopy, scanning electron microscopy, image analysis and micro Vickers hardness test. The results show that compared with the conventional casting, refined microstructures, homogeneous distribution of α(Al) and θ(Al2Cu) and improved microhardness can be obtained when squeeze pressure or power ultrasonic is applied individually. For the case of combined fields, both the treated region and the improvement of microstructure and properties can be enhanced.

Key words: Al-Cu alloy; squeeze pressure field; power ultrasonic field; combined field; microstructure; microhardness

1 Introduction

Al-Cu cast alloys have been widely used in the transportation, aerospace and military industry owing to their excellent mechanical and physical properties [1,2]. However, gas and shrinkage porosities have greatly limited the application of Al-Cu cast alloy [3,4]. Nowadays, the microstructure refinement of Al-Cu cast alloy has become an important research field because mechanical properties can be significantly enhanced by microstructure refinement [5,6]. Many efforts have been done, including: 1) chemical modification, some alloying rare earth elements such as sodium [7] and strontium [8] and other elements are added to modify the microstructure of the Al-Cu alloys; 2) superheat treatment [9-11], overheating the melt several hundred degrees higher than its melting point and then quickly cooling to pouring temperature before casting; 3) physical field, using the specific effect, for instance, ultrasonic field [12,13], magnetic field [14-16] or mechanical agitation [17] to modify the solidification microstructure of both α(Al) and secondary phases, which has been widely used in producing semisolid process feedstock [18,19]. Among those methods, many investigations have demonstrated that the physical field modification method has the advantages of being environmentally friendly, lower cost and being easy to be combined with other technologies, so it has a very good prospect in industry application.

Squeeze casting is a method of producing near-net-shape components with high integrity and very low defects level. The process, suitable for shaping both cast and wrought alloys, improves product quality by pressurized solidification, which prevents the formation of shrinkage defects, retains dissolved gases in solution until freezing has completed and has the priority to form the equiaxed grain structure [6,7]. Squeeze casting has been an effective forming process to prepare high strength and high performance cast Al-Cu alloys. Nowadays, ultrasonic treatment has been proved to be a simple and effective physical method for solidification control and microstructure refinement. Many studies on ultrasonic treatment of low-melting alloys, aluminum alloys and magnesium alloys have been reported [20,21], the ultrasonic treatment is beneficial to stimulating nucleation and forming equiaxed grain structure.

However, the ultrasonic technology is limited by the relatively small treated region [22]. Hence, a wider area of ultrasonic refined effect is required for a better application. ABRAMOV et al [23] utilized ultrasonic vibration and static magnetic field together to reduce the gravity segregation of Pb element in Al-Pb alloy and got satisfied results. TSUNEKAWA et al [24] combined electromagnetic field and power ultrasonic field together to stir molten Al-Mg alloy and increase the wettability of the SiO2 particle, then successfully used in in-situ fabrication of metal matrix composites (MMC). LI et al [25] firstly used power ultrasonic filed and rotating electromagnetic field together to refine the A356 alloy and discussed the mechanism of combined fields. The results have shown that the primary aluminum in A356 was significantly refined and spheroidized due to the collective effects of ultrasonic cavitation, acoustic streaming and electromagnetic stirring. In the present work, the combined fields (squeeze pressure and power ultrasonic) are firstly developed to overcome the undesirable difference of microstructure refinement caused by the individual physical field. The effects of combined squeeze pressure and power ultrasonic on solidification microstructure and microhardness of Al-5.0Cu ingots were studied. The interaction mechanism of these two fields on solidification was also discussed.

2 Experimental

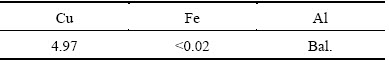

Commercially pure Al (99.5%) and Al-50%Cu master alloy were used in this experiment and the chemical composition analyzed by an optical emission spectrometer is given in Table 1.

Table 1 Chemical composition of experiment alloy (mass fraction, %)

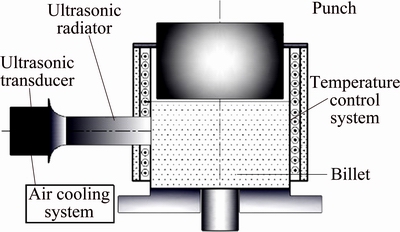

Combined fields were developed in this experiment to treat the Al-5.0Cu melt. The schematic view of the equipment setup is shown in Fig. 1. The whole apparatus was composed of two parts: power ultrasonic vibration system and squeeze casting unit. The former consisted of an air-cooled 20 kHz ultrasonic generator, a transducer made of piezoelectric lead zirconate titanate (PZT) crystals, and an amplitude transformer horn. The maximum power of the ultrasonic system was 1 kW and the amplitude transformer horn was made of titanium alloy, a layer of nitride prepared by magnetron sputtering was sprayed into the horn to keep it from being fretted by the melt. The power ultrasound was inflicted by the transformer horn partly immersed into the melt with the depth of 15 mm. The squeeze casting unit contained a vertical four-column hydraulic press and a device for monitoring the temperature in real time. The pressure of the hydraulic press was adjustable and the maximal pressure could reach 1 MN.

Fig. 1 Schematic diagram of combined experiment apparatus

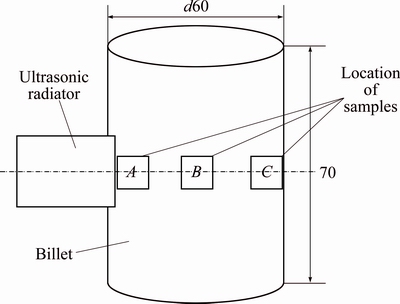

The raw materials were melted at 1053 K in a clay-graphite crucible using an electric resistance furnace. The melts of about 8 kg were degassed by 0.5% C2Cl6 to minimize hydrogen content. Then, the melts were poured into a cylindrical die and processed under different conditions. The temperature of die was limited to approximately 473 K and the pouring temperature was kept at 983 K. At first, the Al-Cu melt was poured into the mold, then the temperature and pressure started to be monitored. At the same time, the physical fields were applied, including power ultrasonic and squeeze pressure, and the detailed parameters of the individual conditions were 800 W and 50 MPa. For the case of combined fields, the squeeze pressure and power ultrasonic were applied simultaneously with the same parameters as the individual condition, and the entire treating time was fixed at 30 s. The ingot with the size of 70 mm in height and 60 mm × 60 mm in section was obtained. Samples taken from different positions (A, B and C as illustrated in Fig. 2) in the cross section of the ingots were prepared for microstructural observation and microhardness testing. All samples for metallographic analysis were cut into d12 mm × 10 mm by line-cutting machine from the same locations of the castings. Metallographic samples were etched with 0.5% HF solution for 30 s. A Leica optical microscopy equipped with the image analysis software Leica Materials Workstation V3.6.1 was used to quantitatively analyze the sizes of the intermetallic compounds and the α(Al) dendrite. In order to get statistically significant data, approximately 50 different regions each at magnification of 500 times around the center of the etched specimen were measured. The average compositions of the phases were analyzed using Nova Nano SEM 430, equipped with an energy- dispersive X-ray analyzer (EDX). To obtain more accurate solid solubility of Cu in the α(Al) matrix, the minimum Cu content in the α(Al) matrix was taken from 5 data by an EPMA-1600 electron probe micro-analyzer. The density was measured using the standard Archimedes method and the porosity percentage can be calculated by the density.

Fig. 2 Positions of samples taken from cross section of ingots

3 Results

3.1 Effects of ultrasonic vibration and squeeze pressure on microstructure of Al-5.0Cu alloy

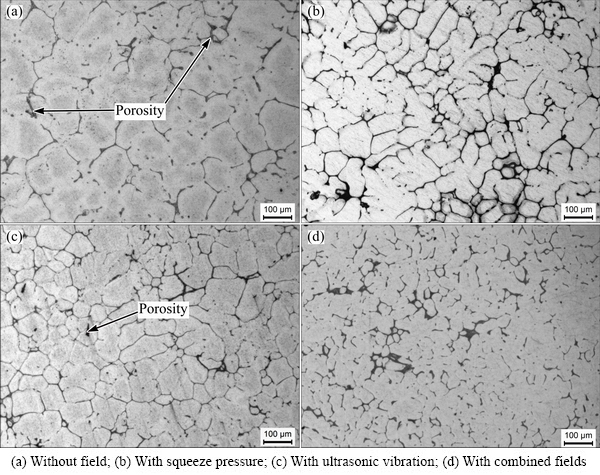

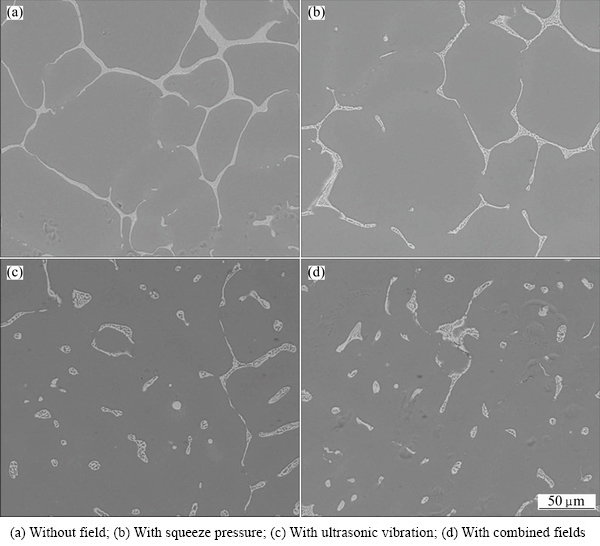

Figure 3 shows the microstructures of Al-5.0Cu alloy under different conditions, where the samples are taken from position A, as shown in Fig. 2. The EDS results show that the copper-containing intermetallics contains 35.94% Cu and 64.96% Al (mole fraction), which is in agreement with θ(Al2Cu) phase. In Fig. 3(a), the acicular-like θ(Al2Cu) phases with size of more than 100 μm in length and 11 μm in width disperse among all the α(Al) dendrites. The shrinkage porosities associated with the θ(Al2Cu) phase can be seen in Fig. 3(a), due to the long freezing range of Al-Cu alloy. In Fig. 3(b), the secondary dendrite arm spacing (SDAS) will be reduced to some extent when the squeeze pressure of 50 MPa is applied. It is because squeeze pressure plays an active role in the diffusion of heat and thus enlarges the solidification rate. As shown in Fig. 3(c), the primary aluminum is transformed into globular shape and the SDAS size decreases to the level of 30 μm. Owing to acoustic cavitation and induced streaming in the melt, the solidification rate of ultrasonic process is higher and the SDAS size is smaller than those with squeeze casting process. In Fig. 3(d), with combined fields of power ultrasonic and squeeze pressure, the microstructure of the Al-5.0Cu alloy displays finer globular grains and the shrinkage porosities are less compared with those under individual field.

SEM images of different samples are shown in Fig. 4. The coarse acicular θ(Al2Cu) phase exhibits in the untreated melt (Fig. 4(a)). With individual squeeze pressure, the morphology of θ(Al2Cu) phase is refined to some degree and it has the trend to be broken into short sticks (Fig. 4(b)). With the process of ultrasonic vibration (Fig. 4(c)), the rod-like θ(Al2Cu) phase is present as the main intermetallics and its size becomes a bit smaller than that under the squeeze pressure. As shown in Fig. 4(d), the θ(Al2Cu) phase is transformed to rod-like shape in the sample processed by combined fields. The results indicate that the combination of squeeze pressure and ultrasonic vibration can not only effectively refine the microstructures of Al-5.0Cu alloy, but also make the θ phase distribute much more evenly than those produced by other processes.

Fig. 3 Microstructures of samples taken from position A in Fig. 2

Fig. 4 SEM images of samples

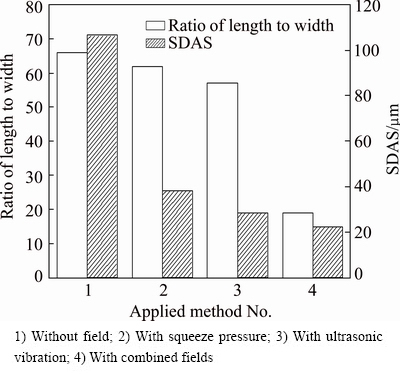

The ratio of length to width of θ(Al2Cu) phase, average secondary dendrite arm spacing(SDAS) of α(Al), volume fraction of θ(Al2Cu) phase, density, volume fraction of porosities of the samples prepared by different processes were examined, with the results shown in Fig. 5, Table 2 and Fig. 6, respectively. In Fig. 5, the SDAS decreases from 106.72 μm without field to 38.45 μm under squeeze casting, from 28.64 μm under ultrasonic vibration to 22.53 μm under combined fields, it is clear that the SDAS size is much smaller when both squeeze pressure and ultrasonic vibration are applied. When the individual squeeze pressure or ultrasonic vibration is applied, the ratio of length to width of θ(Al2Cu) phase decreases from 66 without field to 60 and 54, respectively. With the combination of squeeze pressure and ultrasonic vibration, the ratio of length to width of θ(Al2Cu) phase decreases to 19, which is remarkably less than the counterparts by any of other process. The results indicate that the θ(Al2Cu) phase under combined fields is significantly refined when the combination of squeeze pressure and ultrasonic vibration are applied.

Fig. 5 Ratio of length to width of θ phase and second dendrite arm spacing of α(Al) of samples under different conditions

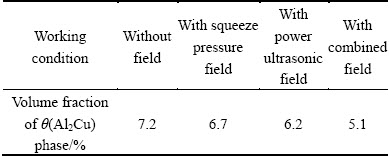

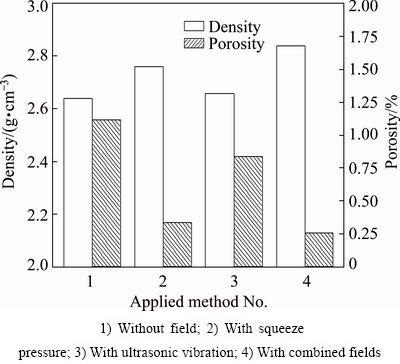

Table 2 presents the volume fractions of θ(Al2Cu) phase in the samples by different processes, the volume fractions of θ(Al2Cu) phase were 7.2%, 6.7%, 6.2% and 5.1% under no field, individual squeeze pressure, individual power ultrasonic field and combined fields, respectively. The θ(Al2Cu) phase somewhat decreases under the combined effects. As shown in Fig. 6, it is obvious that the density under combined fields (2.84 g/cm3) is higher than that without field (2.64 g/cm3) or under the individual field (2.76 or 2.66 g/cm3), the results of volume fraction of porosity are also shown in Fig. 6. When the physical field is applied, the shrinkage porosities decrease to some extent, especially under the combined fields.

Table 2 Volume fractions of θ(Al2Cu) phase in samples under different conditions

Fig. 6 Density and volume fraction of porosity of samples under different conditions

As mentioned before, the SDAS size, the volume fractions of θ(Al2Cu) phases and the amount of shrinkage porosities under combined fields are remarkably smaller than those by other processes. The results indicate that the combination of squeeze pressure and ultrasonic vibration can refine the microstructure of Al-5.0Cu alloy and decrease the shrinkage porosities more effectively. The preliminary mechanism to explain the refinement of microstructures under combined fields is due to the synergy of squeeze pressure and ultrasonic vibration.

3.2 Effects of squeeze pressure and ultrasonic vibration on treated regions of Al-5.0Cu ingot

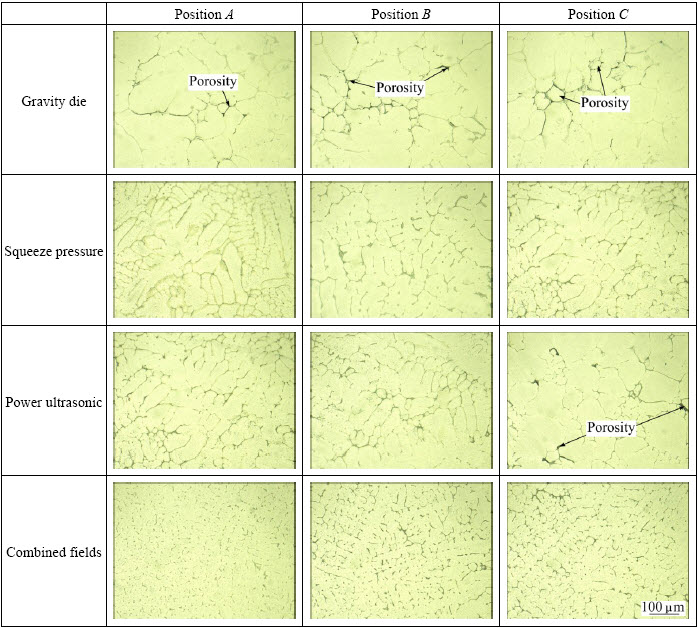

Figure 7 presents the microstructures taken from different positions (as shown in Fig. 2) of ingot under different conditions. For conventional casting without any treatments, the microstructure consists of developed α(Al) dendrites, and the large dendrites are formed in the whole section. With squeeze pressure, it can be seen that the size of primary α(Al) is refined, and the microstructures at different positions seem to be similar. However, the microstructural evolution from positions A to C with power ultrasonic is different from that with squeeze pressure, the microstructure is evidently refined at position A; in position B, some developed dendrites are substituted by globular α(Al). By contrast, the microstructure at position C, which is beyond the ultrasonic effective region, is as coarse as that without any treatment. However, with the combination of squeeze pressure and power ultrasonic, the microstructures from positions A to C are finer and more uniform compared with those under other conditions.

3.3 Effects of squeeze pressure and ultrasonic vibration on microhardness of Al-5.0Cu alloy

The microhardness of the Al-5.0Cu alloy prepared under different conditions was examined. The results are shown in Table 3. It can be found that the microhardness processed by the combination of squeeze pressure and ultrasonic vibration is higher than that of the counterparts by other processes. The microhardness value is HV 53.6 under combined fields, HV 49.2 under ultrasonic vibration, HV 46.1 under squeeze pressure, HV 42.1 without field. It is clear that, with the assist of squeeze pressure or ultrasonic vibration, the microhardness of Al-5.0Cu alloy is improved, which is also in good agreement with the previous experiment results of the volume fraction of θ(Al2Cu) phase.

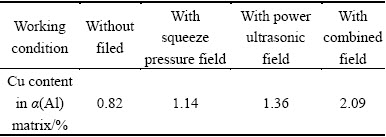

The effects of combined fields on microhardness of Al-5.0Cu alloy is directly related to their effects on solution strengthening of α(Al). Table 4 shows the Cu content in the α(Al) matrix in the cast alloys under different conditions, including the combined fields (800 W and 50 MPa), individual field (800 W or 50 MPa) and without field. Without the effect of squeeze pressure or power ultrasonic, the Cu content is 0.82%. When individual physical field is applied, the Cu content increases to some degree, which is 1.14% (50 MPa) and 1.36% (800 W), respectively. It is also noticeable that the Cu content in the α(Al) matrix is the highest under the combined fields. That is to say, the increase of microhardness in Al-Cu alloy under combined field is due to the higher Cu content in α(Al). For the Al-5.0Cu alloy in the present work, the change of volume fraction of θ(Al2Cu) phase is also closely related to the microhardness. As indicated in Table 2, the volume fraction of θ(Al2Cu) phase reduces to the least level, which also predicts that more Cu element penetrates into the α(Al) matrix under the combined fields.

Fig. 7 Microstructures of samples under different conditions from different locations of ingots

Table 3 Microhardness of samples under different conditions

Table 4 Cu content (mass fraction) in α(Al) matrix under different conditions

4 Discussion

Generally, the SDAS size during solidification mainly depends on the heterogeneous nucleation of the solid phase and the subsequent growth of the newly formed nuclei. A sufficient amount of nuclei is of great importance for microstructure refinement. And a rapid cooling rate is in favor of the survival of the nuclei and the formation of fine grains [3]. As mentioned above, the application of individual squeeze pressure field, power ultrasonic field and combined fields during the casting contributes to different results in the nucleation stage and the growth stage of the solid phase.

Different investigations on a number of alloy systems have shown that the application of squeeze pressure during the solidification of molten metal could cause a decrease of the SDAS size, refine the microstructure as well as the macrostructure to a certain degree and reduce the gas and shrinkage porosity of the castings [5,6]. A few points need to be considered in this regard. The first point is the sudden increase in the cooling rate caused by the improved contact between the metal and the die surface. The second point is that the melting point (liquid temperature) of most metals and alloys increases under pressure according to Clausius-Clapeyron equation [4]. Therefore, under the experimental conditions used in this study, the melting point of the alloy increases by more than 8-10 K upon application of the external pressure. This characteristic can be utilized to create a sudden and large undercooling in the melt if the melt temperature and time of pressure application are accurately controlled [1,2]. Actually, as the solidification nuclei distributed unevenly in the melt, and the effect of squeeze casting was not strong enough, the size and the shape of θ(Al2Cu) phase show little change with the individual squeeze pressure.

When power ultrasonic vibration propagates in the melt, it can enhance the remelting of the dendrites and promote the stir in the melt more intensely because of two main effects, which are ultrasonic cavitation and acoustic streaming [23]. During the propagation of ultrasonic field in the melt, it generates alternating expanding and compressing pressure fluctuation. If the pressure exceeds the cavitation threshold, numerous cavities are generated. The cavities start to collapse under the compression stresses of sound wave. The collapsing cavity generates tiny particles and the energy of the collapse is transformed into pressure pulsing up to 1000 MPa and into cumulative jets up to 100 m/s [13]. As mentioned before, the liquids temperature of the alloy is the function of pressure and it decreases with increasing pressure. By applying ultrasonic energy to metal melt, it can generate pressure pulse in the melt and some regions in the melt might be superheated while others may be under-cooled. A great number of solidification nuclei can be generated during cavitation although the temperature is higher than its melting point and they can be dispersed all around by acoustic streaming. Thus, nuclei formed at the die/melt interfaces were dispersed into the melt, which in turn offers plenty of nucleation sources. Therefore, nucleation could take place in more areas of the melt simultaneously. Also, cavitation cleans the surface of particles that are poorly wetted by the melt, thereby enhancing heterogeneous nucleation [13,14]. At the same time, streaming also promotes mass transfer and temperature fluctuation, which facilitate the remelting of dendrites at their roots [15]. If the nuclei can be held and dispersed into the whole melt, fine globular structures can be obtained.

For taking advantages of both squeeze pressure and power ultrasonic vibration, in this study, we utilized them together to attain the microstructure evolution of Al-5.0Cu alloy. The combined fields have the features of squeeze pressure field and power ultrasonic field. Both squeeze pressure field and power ultrasonic field can enhance the formation of nuclei in the melt; meanwhile, the acoustic streaming generated by power ultrasonic vibration can vigorously stir the melt and transport the nuclei into the whole melt. When squeeze pressure and ultrasonic vibration are processed simultaneously, the applied pressure and ultrasonic cavitation corporate to generate more nuclei. Then, these nuclei are kept and dispersed evenly all around the melt by acoustic streaming. Thus, the poor effect of microstructure refinement by individual application of squeeze pressure is greatly improved by power ultrasonic vibration. All of these effects produce the favorable changes in microstructures and microhardness, as shown in Figs. 2, 3 and Table 3. Above all, the combined fields of squeeze pressure and ultrasonic vibration during the casting of Al-5.0Cu alloy can generate the pressure fluctuation, ultrasonic cavitation and acoustic streaming, and these effects cooperate to contribute to the microstructure refinement and microhardness improvement of the alloy. This technique is easy to be adapted in industry.

However, the mechanism of the microstructure evolution under combined field has not been clarified at the moment and which field plays the dominant role is still unknown. Further research is needed to fully understand the refinement mechanism under combined fields.

5 Conclusions

1) By comparison with individual application of squeeze pressure and ultrasonic vibration, the combined fields can refine the microstructure of Al-5.0Cu alloy more effectively in the whole melt.

2) The microhardness of Al-5.0Cu alloy under combined fields is higher than that under individual squeeze pressure or power ultrasonic.

3) The mechanism of combine fields in the melt is that the synergy of squeeze pressure, ultrasonic cavitation and acoustic streaming promotes the formation of nuclei, and the forced convection further distributes those nuclei across the whole melt.

References

[1] ZHANG Wei-wen, LIN Bo, CHENG Pei, ZHANG Da-tong, LI Yuan-yuan. Effects of Mn content on microstructures and mechanical properties of Al-5.0Cu-0.5Fe alloys prepared by squeeze casting [J]. Transactions of Nonferrous Metals Society of China, 2013, 23(6): 1525-1531.

[2] ZHENG Cheng-kun, ZHANG Wei-wen, ZHANG Da-tong, LI Yuan-yuan. Low cycle fatigue behavior of T4-treated Al-Zn-Mg-Cu alloys prepared by squeeze casting and gravity die casting [J]. Transactions of Nonferrous Metals Society of China, 2015, 25(11): 3505-3514.

[3] TIAN Chen, XIE Zhi-wen, LUO Zhuang-zhu, YANG Qin, TAN Sheng, WANG Yun-jiao, LUO Yi-min. Microstructure evolution and tensile mechanical properties of thixformed AZ61 magnesium alloy prepared by squeeze casting [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(11): 3421-3428.

[4] LIN Bo, ZHANG Wei-wen, CHENG Pei, WANG Xian-song, LI Yuan-yuan. Microstructures and mechanical properties of Al-5.0Cu-0.6Mn-0.5Fe alloy prepared by squeeze casting [J]. The Chinese Journal of Nonferrous Metals, 2013, 23(5): 1195-1201. (in Chinese)

[5] MORTON J R, BARLOW J. Squeeze casting: From a theory to profit and a future [J]. The Foundryman, 1994, 87(1): 23-28.

[6] MALEKI A, SHAFYEI A, NIROUMAND B. Effects of squeeze casting parameters on the microstructure of LM13 alloy [J]. Journal of Materials Processing Technology, 2009, 209: 3790-3797.

[7] DAHEL A, NOGITA K, MCDONALD S. Eutectic nucleation and growth in hypoeutectic Al-Si alloys at different strontium levels [J]. Metallurgical and Materials Transactions A, 2001, 32: 949-960.

[8] JUNG B I, JUNG C H, HAN T K. Electromagnetic stirring and Sr modification in A356 alloy [J]. Journal of Materials Processing Technology, 2001, 111(1-3): 69-73.

[9] XU C L, JIANG Q C, YANG Y F. Growth of octahedral primary silicon in cast hypereutectic Al-Si alloys [J]. Journal of Crystal Growth, 2006, 291: 540-547.

[10] GU Z H, WANG H Y, ZHANG N, ZHA M, JIANG L L, WANG W, JIANG Q C. Effect of melt superheating treatment on the cast microstructure of Mg-1.5Si-1Zn alloy [J]. Journal of Material Science, 2008, 43: 980-984.

[11] JIE W Q, CHEN Z W, REIF W. Superheat treatment of Al-7Si-0.55Mg melt and its influences on the solidification structures and the mechanical properties [J]. Metallurgical and Materials Transactions A, 2003, 34: 799-806.

[12] WU Li, KANG Hui-jun, CHEN Zong-ning, LIU Ning, WANG Tong-min. Horizontal continuous casting process under electromagnetic field for preparing AA3003/AA4045 clad composite hollow billets [J]. Transactions of Nonferrous Metals Society of China, 2015, 25(8): 2675-2685.

[13] ZHANG Hai-bo, ZHAI Qi-jie, QI Fei-peng, GONG Yong-yong. Effect of side transmission of power ultrasonic on structure of AZ81 magnesium alloy [J]. Transactions of Nonferrous Metals Society of China, 2004, 14(2): 302-305.

[14] ZHANG S, ZHANG Y, CHEN X, CHEN G, DAI Q. High-energy ultrasonic filed effects on the microstructures and mechanical behaviors of A356 alloy [J]. Journal of Alloys and Compounds, 2009, 470: 168-172.

[15] JIAN X, XU H, MEEK T T, HAN Q. Effect of power ultrasound on solidification of aluminum A356 alloy [J]. Materials Letters, 2005, 59: 190-193.

[16] WU S S, ZHONG G, WAN L, AN P, MAO Y W. Microstructure and properties of reho-diecast Al-20Si-2Cu-1Ni-0.4Mg alloy with direct ultrasonic vibration process [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(S3): s763-s767.

[17] MAO W M, ZHEN Z S, CHEN H T. Microstructures of AZ91D alloy solidified during electromagnetic stirring [J]. Transactions of Nonferrous Metals Society of China, 2005, 15(1): 72-76.

[18] LIU T, WANG Q, ZHANG H, WANG K, PANG X, HE J. Effects of high magnetic fields on the microstructures and grain boundaries in binary Al-Li alloy [J]. Journal of Alloys and Compounds, 2009, 469: 258-263.

[19] ZHANG X I, LI T J, TENG H T, XIE S S, JIN J Z. Semisolid processing AZ91 magnesium alloy by electromagnetic stirring after near-liquids isothermal heat treatment [J]. Materials Science and Engineering A, 2008, 475: 194-201.

[20] LIU Z, MAO W, ZHAO Z. Research on semi-solid slurry of a hypoeutectic Al-Si alloy prepared by low superheat pouring and weak electromagnetic stirring [J]. Rare Metals, 2006, 25: 177-183.

[21] YANG Yue-shuang, WANG Jin-cheng, WANG Tao, LIU Cheng-ming, ZHANG Zhong-ming. Effects of ultrasonic treatment on microstructures of AZ91 alloy [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(1): 76-81.

[22] ESKIN G I. Ultrasonic treatment of light alloy melts [M]. Amsterdam: Gordon and Breach Science Publishers, 1998.

[23] ABRAMOV V O, ABRAMOV O V, SOMMER F, ORLOV D. Properties of Al-Pb base alloys applying electromagnetic forces and ultrasonic vibration during casting [J]. Material Letters, 1995, 23: 17-20.

[24] TSUNEKAWA Y, SUZUKI H, GENMA Y. Application of ultrasonic vibration to in situ MMC process by electromagnetic melt stirring [J]. Materials and Design, 2001, 22: 467-472.

[25] ZHANG Z T, LI J, YUE H Y, ZHANG J, LI T J. Microstructure evolution of A356 under compound filed [J]. Journal of Alloys and Compounds, 2009, 484: 458-462.

张 杨,李风雷,罗 执,赵愈亮,夏 伟,张卫文

华南理工大学 机械与汽车工程学院,广州 510640

摘 要:在Al-5.0Cu合金的凝固过程中同时施加压力和功率超声,在此基础上采用光学显微镜、扫描电镜、定量金相分析以及显微硬度测试仪分别研究单独施加压力、超声及二者的耦合作用对合金凝固组织和显微硬度的影响。结果表明:外场(单一压力或功率超声)的施加可以改善α(Al)和θ(Al2Cu)相的形貌以及分布,同时提高合金的硬度;相对于单一场,耦合场改善显微组织和提升性能的效果更加明显,且其有效作用区域更广。

关键词:Al-Cu合金;压力场;功率超声场;复合场;显微组织;硬度

(Edited by Wei-ping CHEN)

Foundation item: Project (51374110) supported by the National Natural Science Foundation of China; Project (2015A030312003) supported by the Natural Science Foundation of Guangdong Province for Research Team, China

Corresponding author: Wei-wen ZHANG; Tel: +86-20-87112272; Fax: +86-20-87112111; E-mail: mewzhang@scut.edu.cn

DOI: 10.1016/S1003-6326(16)64348-0