文章编号:1004-0609(2017)-01-112-06

旋转摩擦挤压加工CNTs/Al复合材料的线材组织和性能

刘奋成1, 2,熊其平1,钱 涛1,刘 强2,邢 丽1,柯黎明1

(1. 南昌航空大学 轻合金加工科学与技术国防重点学科实验室,南昌 330063;

2. 西北工业大学 凝固技术国家重点实验室,西安 710072)

摘 要:采用旋转摩擦挤压加工方法制备体积分数分别为0、3.8%、4.5%和5.3%(体积分数)的碳纳米管增强铝基复合材料线材,进行复合材料线材显微组织观察和力学、电学性能分析。结果表明:经旋转摩擦挤压后,复合材料线材的晶粒较搅拌摩擦加工试样有所拉长和长大,但仍为超细晶结构;复合材料线材中的碳纳米管沿着挤压方向呈取向排列均匀分布于铝基体中。随着碳纳米管体积分数的增加,复合材料线材的显微硬度、抗拉强度以及电阻率均逐渐增加,且均高于同CNTs体积分数的搅拌摩擦加工块体复合材料试样,但塑性有所降低。

关键词:旋转摩擦挤压;碳纳米管;CNTs/Al复合材料

中图分类号:TB331 文献标志码:A

铝基复合材料具有密度小,耐腐蚀和加工性能好等优点[1],纳米相增强铝基复合材料是近年迅速发展起来的一种新型材料,表现出优异的物理性能和力学性能[2-3]。在所有纳米增强相中,碳纳米管(Carbon nanotube,CNTs)自1991年被IIJIMA[4]发现以来一直被人们广泛关注,凭借其具有的优良的物理和化学等特性成为复合材料的理想增强相。然而,在传统的复合材料制备技术中,例如真空吸铸法、粉末冶金烧结法、热压法、分子水平方法和无压渗透法等[5-9],CNTs高的比表面积使得其在与基体金属的复合过程中极易团聚,加之CNTs与不同基体金属的浸润性差异大等问题造成CNTs在金属基体中的分散很难均匀,且界面结构复杂,这在一定程度上限制了CNTs增强金属基复合材料性能的进一步提高。

相比于上述方法,搅拌摩擦加工(Friction stir processing, FSP)技术在块体复合材料的制备中也得到了应用[10-11],其过程工艺简单,能够实现大体积分数的CNTs增强铝基复合材料的快速制备。例如研究人员[12-13]采用 FSP制备CNTs增强铝基复合材料,获得了成形性、分散均匀性好的CNTs增强铝基复合材料。LIU等[14]将粉末冶金技术与FSP技术结合起来,实现了CNT/2009Al复合材料的制备,证明CNTs的加入有效提高了材料强度,并对材料的高温力学性能产生了影响。但是,FSP方法存在只能在平板材料上进行加工、加工效率低的问题,且在复合材料制备过程中基体金属材料的利用率低。旋转摩擦挤压(Rotational friction extrusion processing, RFEP)方法是在FSP技术的基础上发展起来的新的复合材料制备技术,它可以针对粉末材料、棒状材料、板状材料等进行加工,可以实现金属材料与增强相材料的一次成形,也可以对已有的复合材料进行二次加工,获得具有特点组织结构和宏观形貌的复合材料。RFEP技术已在铝基复合材料线材的快速制备中获得了应用[15]。

本文作者首先采用FSP方法制备CNTs/Al复合材料块体,初步将碳纳米管均匀的分散在铝基体中,再结合RFEP方法将CNTs/Al块体材料加工成线材,通过RFEP中金属的塑性流动带动其中已经均布的CNTs定向流动,获得具有取向排列的CNTs增强铝基复合材料线材,并对CNTs/Al复合材料块体和线材的显微硬度、拉伸性能及电阻率等进行了对比分析。为研究碳纳米管增强铝基复合材料提供理论支持及试验依据并为铝基复合材料基础性应用研究奠定基础。

1 实验

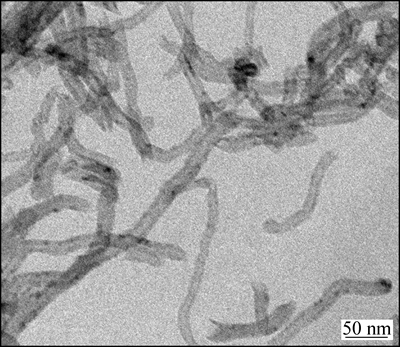

实验用碳纳米管为深圳纳米港有限公司提供的多壁碳纳米管,管壁外径为10~20 nm,长度为5~15 μm,纯度大于97%(质量分数)。实验采用工业纯铝1060板材作为基材,尺寸为300 mm×110 mm×6 mm。图1给出了实验中所用碳纳米管的形貌。所用纯铝1060的化学成分(质量分数,%)为:0.25Si,0.35Fe,0.03Mg,0.03Ti,0.05Zn,0.03Mn,0.05Cu,余量为铝。

首先采用FSP方法制备CNTs/Al复合材料块体材料。在1060铝板中间位置钻孔,将碳纳米管填充在小孔内,通过改变孔径的大小来改变碳纳米管的含量。试验采用FSP设备为X53K型铣床改造的搅拌摩擦加工设备,FSP过程如文献[15]所述。搅拌头的倾角为2°,搅拌头的旋转速度为950 r/min,搅拌头的进给速度为23.5 mm/min。所加工的块体复合材料中所含CNTs体积分数分别为0、3.8%、4.5%和5.3%。

采用线切割从FSP后的CNTs/Al块体复合材料中心复合区切取一定直径的圆形试样,并将其装入自行设计的RREP模具型腔中进行复合材料线材制备。通过挤压型腔高速旋转,挤压型腔中的铝基复合材料与具有特定形状的挤压轴前端挤压头摩擦产热。当温度达到金属的塑化温度时,挤压轴以一定的速度向上运动,塑化的金属从挤压头中间的模孔挤出,从而得到直径为6 mm的复合材料线材。本试验中挤压型腔的旋转速度为950 r/min,挤压轴的挤压速度为8 mm/min,挤压比为56.25。

同样采用线切割从FSP和RFEP后的CNTs/Al复合材料块体材料和线材上截取试样进行组织观察和力学性能测试。采用Tecnai G2 F30型场发射透射电子显微镜(TEM)和FEI QUANTA200型场发射扫描电子显微镜(SEM)对复合材料组织进行分析,为观察CNTs在基体金属中的分布情况,采用金相试样深度腐蚀后SEM观察的方法。采用HVS-1000型维氏硬度计测量复合材料的显微硬度,其中块体材料测试时测试位置位于复合区域横截面中心水平位置,复合材料线材测试时沿试样轴线纵截面中心轴线方向。以一定间距测量多各点。所用载荷为0.49 N,载荷保持时间为10 s。采用WDS-100型材料试验机测量复合材料拉伸强度,所加工试样为哑铃型棒状试样,平行段直径4 mm,长度20 mm。用扫描电子显微镜(SEM)对拉伸断裂试样进行断口分析。复合材料的电阻率在Model-9型综合物性测量系统(PPMS)上进行测试,试样尺寸为2 mm×2 mm×8 mm,测试温度为298 K,每个样品选取5个点分别测试,最后取5个测试点的平均值作为该样品电阻率的最终值。

图1 碳纳米管TEM像

Fig. 1 TEM image of carbon nanotubes

2 结果与讨论

2.1 CNTs/Al复合材料线材的显微组织

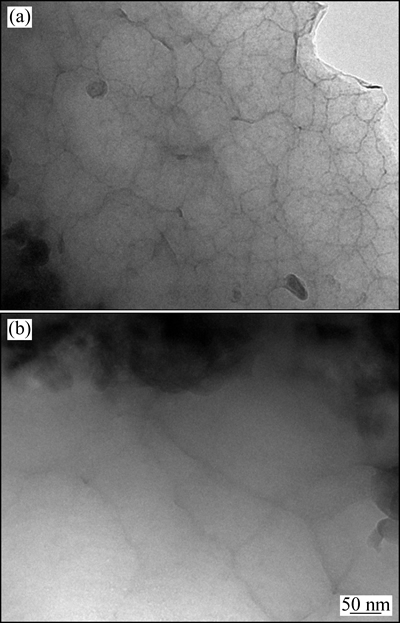

图2所示为FSP和RFEP法制备的CNTs体积分数为5.3%的铝基复合材料块体和线材的显微组织照片。从图2中可见,FSP制备的复合材料块体材料晶粒组织呈均匀、等轴的再结晶组织特征。这是由于FSP过程中搅拌针对铝基体有连续的剪切、挤压、破碎作用使晶粒得到细化;加之搅拌区金属在搅拌针作用力和摩擦热共同作用下发生了动态再结晶,使搅拌区尺寸进一步减小,形成了纳米级的超细晶粒。比较可见,图2(b)所示RFEP法制备的复合材料线材中的晶粒有明显的被拉长和长大现象,最大尺寸达到300~400 nm,仍然为纳米级晶粒。由于RFEP过程中所采用的实验参数以保证塑化后的材料有良好的塑性为前提,旋转速度较快而挤压速度较低,因此,整个过程中摩擦产生的热量较多,材料温度高,再结晶过程充分,且部分晶粒同时发生了晶粒的进一步粗化。

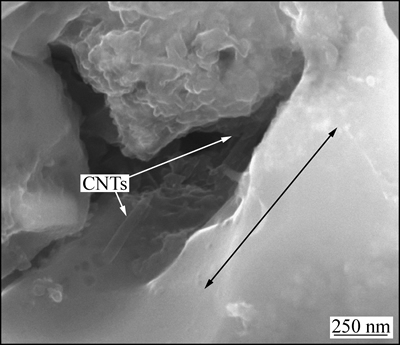

图3所示为复合材料线材CNTs的分布形态。从图3中可以看出,复合材料线材中的CNTs无明显缠结现象,并且部分CNTs沿着挤压方向取向排列。在旋转摩擦挤压过程中,挤压头对块体复合材料进行进一步摩擦加工,此过程可使CNTs更均匀地分散在铝基体中;同时,挤压头与复合材料块体的摩擦产热使金属达到塑化状态,并在挤压轴向上运动时产生的顶锻力的作用下塑化的金属发生塑性流动,带动其中的CNTs向着唯一出口即挤压头中间的出口定向流动。此过程的连续进行可在一定程度上实现部分CNTs在基体金属中的取向排列。

图2 5.3%CNTs/Al复合材料块体和线材的TEM像

Fig. 2 TEM images of FSP block like sample (a) and RFEP wire like sample (b) of 5.3% CNTs/Al composite

图3 CNTs/Al复合材料线材中部分CNTs分布

Fig. 3 Distribution of CNTs in wire composite sample

2.2 CNTs/Al复合材料线材的力学性能

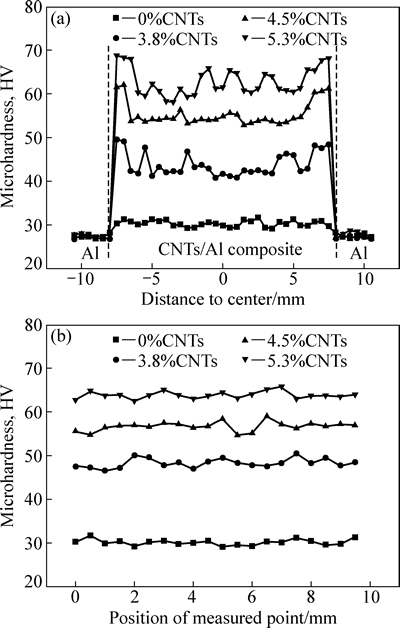

图4所示为FSP和RFEP制备的复合材料块状试样和线材显微硬度分布图。从图4中看出,FSP块体复合材料复合区的显微硬度以及复合材料线材纵截面的显微硬度均随着CNTs含量的增加而增加。CNTs含量为5.3%时,CNTs/Al复合材料线材平均显微硬度为64.0 HV,较块体复合材料复合区的平均显微硬度略有提高。但是从二者硬度分布曲线来看,块体复合材料复合区的显微硬度波动较明显,且随着CNTs量的增加,波动愈加剧烈;同时,发现越靠近复合区边缘显微硬度增加,这说明此区域可能存在CNTs的局部团聚现象。而复合材料线材纵截面的显微硬度无明显波动现象,这说明复合材料经过旋转摩擦挤压后,CNTs在铝基体中的分布均匀性得到进一步改善,CNTs团聚现象有所减小,分布更均匀。

图4 CNTs/Al复合材料块体和线材的显微硬度分布

Fig. 4 Microhardness distribution curves of FSP composite block (a) and RFEP composite wire (b) containing different volume fractions of CNTs

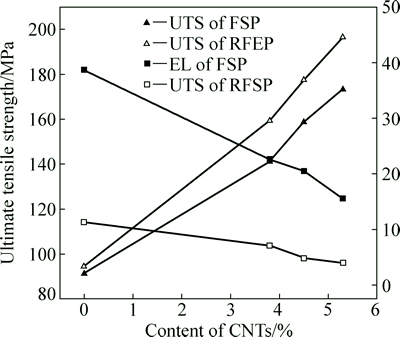

图5所示为不同CNTs含量CNTs/Al复合材料FSP块体材料和RFEP线材室温拉伸测试结果。由图5中可以看出,随着CNTs含量的增加复合材料线材的抗拉强度呈逐渐增加的趋势,且CNTs含量相同时,RFEP线材试样的抗拉强度均高于FSP块体复合材料试样的。以CNTs含量为5.3%试样为例,RFEP复合材料线材的拉伸强度为196.5MPa,较FSP同体积分数CNTs增强块体复合材料的抗拉强度提高了13.4%。分析认为经过RFEP后复合材料线材中的CNTs分布更均匀,并且部分CNTs沿着挤压方向取向排列,具有取向排列的这部分CNTs可更有效的承担载荷,且经过RFEP的再次加工,在热和力的共同作用下,CNTs与基体Al的界面变得更加牢固,这都有利于复合材料线材的拉伸强度的提高。同时可见,RFEP线材的伸长率随着CNTs含量的增加逐渐减小,且CNTs含量相同时,RFEP线材试样的伸长率低于FSP块体复合材料试样。这说明,在FSP和RFEP双重作用导致的超细晶晶粒结构以及CNTs的强化作用条件下,材料的强度得到提高的同时,材料的塑性下降很大。

图5 不同CNTs含量CNTs/Al 复合材料拉伸性能

Fig. 5 Tensile properties of CNTs/Al composite containing different volume fractions of CNTs

需要指出的是,通常影响CNTS增强金属复合材料性能的因素有很多,如团聚、细晶强化、界面状况等,一般随含量的增加CNTS团聚的机率加大,而本研究中两种方法得到的材料,其力学性能都随增强相的增加,性能得到加强,这说明在本实验所添加的体积分数内CNTs借助搅强烈的塑化金属流动作用克服了团聚等问题,实现了增强相在基体金属中的均匀分布,这与LIU等[14]的研究结果一致。另外,图2显示RFEP法制备的相同体积分数CNTs增强铝基复合材料的晶粒尺寸明显大于FSP法制备试样,而图5所示的室温拉伸性能数据显示前者的抗拉强度高于后者的,即本实验中制备的超细晶复合材料的抗拉强度表现出随晶粒尺寸增大而减小的反Hall-Petch关系[16]。

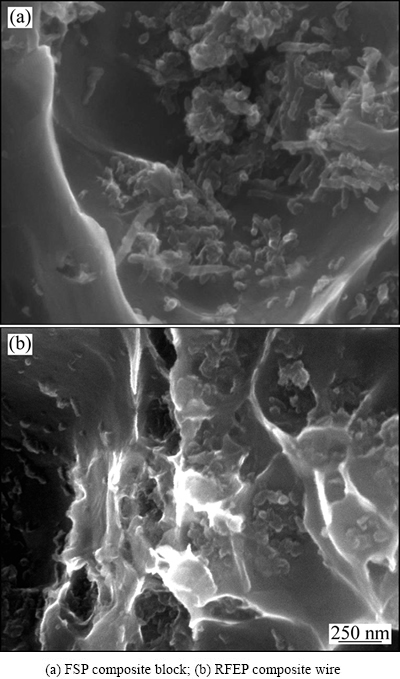

对CNTs含量为5.3%(体积分数)的FSP块体复合材料和RFEP复合材料线材室温拉伸试样断口进行观察,发现FSP块体复合材料和RFEP复合材料线材的断口表面均分布有韧窝,这表明铝基复合材料的断裂方式主要以韧性断裂为主。对韧窝高倍观察发现,在FSP复合材料试样断口韧窝中存在CNTs,且在FSP块体复合材料较大韧窝中发现团聚状CNTs,且部分CNTs存在明显的拔出痕迹,如图6(a)所示;在RFEP复合材料线材试样断口韧窝深处很少发现大量CNTs的团聚现象,大部分CNTs嵌在铝基体中,未发现明显的韧窝中的CNTs被拔的痕迹,如图6(b)所示。这表明经过RFEP后复合材料线材中的CNTs与铝基体结合的更好,对铝基复合材料的力学性能提高有着重要的影响。

图6 CNTs/Al复合材料的室温拉伸断口形貌

Fig. 6 Fracture surface morphologies of CNTs/Al composite samples

2.3 CNTs/Al复合材料线材的电学性能

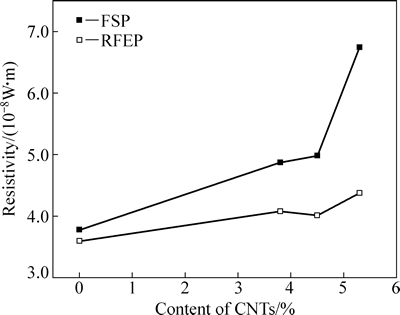

图7所示为FSP体块复合材料和RFEP复合材料线材的室温电阻率随CNTs含量变化曲线。测试结果表明,随着CNTs含量的增加,FSP复合材料块体和RFEP复合材料线材的电阻率均呈现逐渐增加的趋势,且在相同CNTs体积分数下,RFEP复合材料线材的电阻率低于FSP复合材料块体的电阻率,这表明RFEP加工后材料的电阻率得到了降低,例如CNTs含量为5.3%时,RFEP复合材料线材的电阻率为4.381×10-8 Ω·m,较同CNTs体积分数FSP块体复合材料的电阻率下降了约35%。但从测试结果看,二者均高于母材纯铝的电阻率(2.99×10-8 Ω·m),这说明通过FSP和RFEP将CNTs加入到纯铝基体中后,复合材料的导电性能并未得到提高。分析认为,虽然文献报道CNTs具有良好的导电性(电阻率在0.34×10-8~1.00×10-8 Ω·m[17-18] ),但是考虑到CNTs分导体型和半导体型,本文作者采用的CNTs未经特殊工艺处理[19-20],可能其导电性未达到良导体的水平,且随着CNTs的加入及含量的增加,加之FSP和RFEP过程造成的超细晶粒晶界的存在,复合材料的几何界面增加,这将加剧自由电子的散射,所以复合材料的电阻率随着CNTs含量的增加而增大。同时,由于RFEP复合材料线材中CNTs分布较均匀且部分沿挤压方向取向排列,CNTs与基体界面对电子运动影响较小,加之RFEP复合材料线材的致密度的提高,从而使得RFEP复合材料线材的导电性能较优于块体复合材料的导电性能。

图7 CNTs/Al复合材料的电阻率随CNTs含量变化曲线

Fig. 7 Resistivity curves of CNTs/Al composite samples with different contents of CNTs

3 结论

1) 旋转摩擦挤压方法可用于制备CNTs增强Al基复合材料线材,可以实现CNTs更均匀分布,并实现部分CNTs沿着挤压方向取向排列。

2) 随着CNTs含量的增加,旋转摩擦挤压复合材料线材的显微硬度和抗拉强度均明显增加,并且高于同体积分数的搅拌摩擦加工块体复合材料硬度和抗拉强度。

3) 旋转摩擦挤压复合材料线材导电性能优于同CNTs体积分数的搅拌摩擦加工块体复合材料的,且随着CNTs含量的增加,复合材料电阻率均逐渐增加。

REFERENCES

[1] 白 芸, 韩恩厚, 谭若兵, 毕敬. 铝基复合材料性能的研究现状[J]. 材料保护, 2003, 36(9): 5-8.

BAI Yun, HAN En-hou, TAN Ruo-bing, BI Jing. Research on properties of aluminum matrix composites[J]. Materials Protection, 2003, 36(9): 5-8.

[2] 贺春林, 王建明, 于文馨, 才庆魁, 何凤鸣, 孙旭东. 纳米SiC颗粒增强铝基复合材料的结构与拉伸行为[J], 稀有金属材料与工程, 2006, 35(2): 156-160.

HE Chun-lin, WANG Jian-ming, YU Wen-xin, CAI Qing-kui, HE Feng-ming, SUN Xü-dong. Tensile properties of SiC nanoparticle reinforced pure aluminum matrix composite[J]. Rare Metal Materials and Engineering, 2006, 35(2): 156-160.

[3] 黄永攀, 李道火, 黄 伟. 纳米碳管增强纯铝基复合材料的制备及性能[J]. 材料与表面处理, 2004, 33(12): 48-49.

HUANG Yong-pan, LI Dao-huo, HUANG Wei. Preparation and property of pure AM C reinforced by CNTs[J]. New Technology and New Art, 2004, 33(12): 48-49.

[4] IIJIMA S. Helical microtubules of graphitic carbon[J]. Nature, 1991, 354(1): 56-58.

[5] LI Q Q, ROTTMAIR C A, SINGER R F. CNT reinforced light metal composites produced by melt stirring and by high pressure die casting[J]. Composites Science and Technology, 2010, 70(16): 2242-2247.

[6] ESAWI A M K, MORSI K, SAYED A, SAYED A, GAWAD A A. Fabrication and properties of dispersed carbon nanotube-aluminum composites[J]. Materials Science and Engineering A, 2009, 508(1/2): 167-173.

[7] KWON H S, ESTILI M, TAKAGI K, MIYAZAKI T, KAWASAKI A. Combination of hot extrusion and spark plasma sintering for producing carbon nanotube reinforced aluminum matrix composites[J]. Carbon, 2009, 47: 570-577.

[8] CHA S I, KIM K T, LEE K H, MO C B, HONG S H. Strengthening and toughening of carbon nanotube reinforced alumina nanocomposite fabricated by molecular level mixing process[J]. Scripta Materialia, 2005, 53(7): 793-797.

[9] CAI A H, XIONG X, LIU Y, AN W K, ZHOU G J, LOU Y, LI T L, LI X S. A Cu-based bulk amorphous alloy composite reinforced by carbon nanotube[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(9): 2191-2197.

[10] MISHRA R S, MA Z Y, CHARIT I. Friction stir processing: a novel technique for fabrication of surface composite[J]. Materials Science and Engineering A, 2002, 341(1/2): 307-313.

[11] WANG W, SHI Q Y, LI P, LI H K, LI T. A novel way to produce bulk SiCp reinforced aluminum metal matrix composites by friction stir processing[J]. Journal of Materials Processing Technology, 2009, 209(4): 2099-2103.

[12] LIU Q, KE L, LIU F C, HUANG C P, XING L. Microstructure and mechanical property of multi-walled carbon nanotubes reinforced aluminum matrix composites fabricated by friction stir processing[J]. Materials and Design, 2013, 45: 342-348.

[13] 林毛古, 徐卫平, 柯黎明, 刘 强. 旋转摩擦挤压制备MWCNTs/Al复合材料的界面微观结构[J]. 中国有色金属学报, 2015, 25(1): 98-102.

LIN Mao-gu,  Wei-ping, KE Li-ming, LIU Qiang. Interface microstructures of MWCNTs/Al composites prepared by rotational friction extrusion[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(1): 98-102.

Wei-ping, KE Li-ming, LIU Qiang. Interface microstructures of MWCNTs/Al composites prepared by rotational friction extrusion[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(1): 98-102.

[14] LIU Z Y, XIAO B L, WANG W G, MA Z Y. Singly dispersed carbon nanotube/aluminum composites fabricated by powder metallurgy combined with friction stir processing[J]. Carbon, 2012, 50(5): 1843-1852.

[15] XIONG Q P, KE L M, LIU FC, LIU Q, CHEN X L. Preparation and mechanical property of MWNTs/Al composite wires by rotational friction extrusion processing[J]. Advanced Materials Research, 2014, 833: 261-265.

[16] YAMAKOV V, WOLF D, PHILLPOT S R, MUKHERJEE A K, GLEITER H. Deformation mechanism map for nanocrystaIline metals by molecular- dynamics simulation[J]. Nature Materials, 2004, 3: 43-47.

[17] THESS A, LEE R, NIKOLAVE P, DAI H. Crystalline ropes of metallic carbon nanotubes[J]. Science, 1996, 273(5274): 483-487.

[18] ELETSKS A V. Carbon nanotubes[J]. Physics-Uspekis, 1997, 40(9): 899-924.

[19] 石国娴, 徐学诚. 卤素掺杂对多壁碳纳米管导电性能的影响[J]. 华东师范大学学报, 2013(6): 120-126.

SHI Xuo-xian, XU Xue-cheng. Influence of electrical conductivity of multi-walled carbon nanotubes by halogen- deping[J]. Journal of East China Normal University, 2013(6): 120-126.

[20] LI Q H, ZHOU Q H, DENG D, YU Q Z, GU L, GONG K D, XU K H. Enhanced thermal and electrical properties of poly (D,L-lactide)/ multi-walled carbon nanotubes composites by in-situ polymerization[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(5): 1421-1427.

Microstructures and properties of CNTs/Al matrix composites prepared by rotational friction extruded processing

LIU Fen-cheng1, 2, XIONG Qi-ping1, QIAN tao1, LIU Qiang2, XING Li1, KE Li-ming1

(1. National Defense Key Disciplines Laboratory of Light Alloy Processing Science and Technology, Nanchang Hangkong University, Nanchang 330063, China;

2. State Key Laboratory of Solidification Processing, Northwestern Polytechnical University, Xi’an 710072, China)

Abstrate: Carbon nanotubes (CNTs) reinforced aluminum matrix composite wires containing 0, 3.8%, 4.5% and 5.3% CNTs (volume fraction) were prepared by rotational friction extruded processing (RFEP). The microstructures, mechanical property and electric property were characterized by scanning electron microscopy and transmission electron microscopy. The results show that the grains of composite wires are elongated and grow after RFEP, but the grain size is still remained in extra fine scale. CNTs are homogenously distributed in the aluminum matrix, and some CNTs are orientational aligned along the extrusion direction in the composites. With the content of the CNTs increasing, the microhardness, tensile strength and electrical resistivity increase, respectively, and all of these are higher than those of FSP composite blocks.

Key words: rotational friction extruded processing; carbon nanotube; CNTs /Al composite

Foundation item: Projects(51565041, 51201087) supported by National Natural Science Foundation of China; Project (KJLD12074) supported by the Landed Plan of Science and Technology in Colleges and Universities of Jiangxi Province, China; Project(GJJ150710) supported by the Project of Education Department of Jiangxi Province, China; Project supported by the Open Project of Shanxi Key Laboratory of Advanced Magnesium-based Materials (Taiyuan University of Technology), China

Received date: 2014-11-04; Accepted date: 2016-12-05

Corresponding author: LIU Fen-cheng; Tel: +86-791-83863028; E-mail: fencheng999@163.com

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51565041,51364037);江西省高等学校科技落地计划项目(KJLD12074);江西省教育厅科研项目(GJJ150710);先进镁基材料山西省重点实验室(太原理工大学)开放课题

收稿日期:2014-11-04;修订日期:2016-12-05

通信作者:刘奋成,副教授,博士;电话:0791-83863028;E-mail:fencheng999@163.com