一氧化钛表面的润湿性能

钟 晖1, 李庆奎2, 戴艳阳1, 钟海云1

(1.中南大学 冶金科学与工程学院, 湖南 长沙, 410083;

2. 郑州大学 材料工程学院, 河南 郑州, 450002)

摘要: 采用高温座滴法测定了一系列金属及合金在TiO上的接触角。 研究结果表明: 金属Cu, Fe, Co, Ni及Fe-Cr合金与TiO的润湿性均较差, 在熔点温度时其接触角为48°~120°。 Cu与TiO属非反应型润湿; Fe, Co, Ni及Fe-Cr合金与TiO属反应型润湿。 添加某些表面活性剂能提高其润湿性, 向Cu中添加2%以上的Mo2C可明显提高Cu在TiO上的润湿性, 由非反应型润湿转变为反应型润湿; 向Fe-Cr合金中添加1.5%以上的Mn或Si, 可显著提高Fe-Cr合金在TiO上的润湿性, 添加Mn不改变润湿类型, 而添加Si使反应型润湿转变为非反应型润湿。

关键词: 润湿性; 一氧化钛; 表面活性剂

中图分类号:TF123.1 文献标识码:A 文章编号: 1672-7207(2005)03-0437-06

Wettability of titanium monoxide surface

ZHONG Hui1, LI Qing-kui2, DAI Yan-yang1, ZHONG Hai-yun1

(1. School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China;

2. School of Materials Engineering, Zhengzhou University, Zhengzhou 450002, China)

Abstract: The wetting angles of various metals and their alloys were determined by high temperature sessile drop method. The results indicate that the wettability of Cu, Fe, Co, Ni and Fe-Cr alloy on TiO surface is not good, and the contact angles are 48°~120° at melting point temperature; Cu on TiO surface is non-reaction wetting, and the others are reaction wetting. But the wettability can be improved by adding some surfactant. The wettability of Cu on TiO surface can be improved effectively by adding more than 2%Mo2C, and at the same time the non-reaction wetting is changed into reaction wetting. The wettability of Fe-Cr alloy on TiO surface can be improved markedly by adding more than 1.5%Mn or 1.5%Si; the wetting type is not changed by adding Mn, but the reaction wetting is changed into non-reaction wetting by adding Si.

Key words: wettability; titanium monoxide; surfactant

一氧化钛与黄金同属面心立方晶系, 是自然界中颜色最接近黄金的物质[1]。 测试结果表明, TiO的颜色比TiN及Cu基仿金合金等更接近24K金的颜色, 在大气、 雨水及汗液中不变颜色, 具有较强的耐酸、 碱腐蚀性和较高的硬度, 而且制备工艺相对简单, 成本低廉, 是一种极具前途的新型仿金材料。 但是, 和其他陶瓷材料一样,一氧化钛性脆, 只有选择合适的金属(或合金)粘结相使其增韧, 才能具有使用价值[2, 3]。 而粘结相与陶瓷相之间的润湿性能对金属陶瓷的烧结致密化、 组织结构和界面结合强度影响极大, 是陶瓷增韧和制备高质量金属陶瓷的关键因素。 目前, 有关一氧化钛与金属(合金)润湿性能方面的研究报道很少。 为此, 作者对一系列金属及其合金在一氧化钛表面上的润湿性能和作用机理进行研究, 旨在为正确选择和配制一氧化钛基金属陶瓷的粘结相提供实验基础与理论依据。

1 实 验

1.1 测试方法

金属(合金)与一氧化钛表面的润湿性以液态金属(合金)在一氧化钛基片上的接触角表示,采用高温座滴法测试[4,5], 其装置如图1所示。 将一氧化钛基片置于平台中央(热电偶热端的正上方), 基片上放置金属(合金)试样, 调整水平。 在真空度为1×10-2 Pa的条件下, 加热至测定温度, 待金属(合金)液滴经过一定时间在一氧化钛基片上形貌变化达到平衡时, 用照相机水平摄取液滴形状, 同时通过240 mm长焦距放大镜头直接观察;将照相底片置于投影仪上,据投影图直接测定接触角, 即通过三相界面引出切线, 直接测定左、 右角, 取3次测量的平均值。

![]()

1—平行光源; 2—加热炉; 3—长焦距照相机;

4—真空系统; 5—测温电位差计; 6—工作平台

图 1 高温座滴测试装置示意图

Fig. 1 Schematic diagram of high temperature

sessile drop apparatus

1.2 基片的制备

将费氏粒径为1~2 μm的一氧化钛粉末用钢模压制成直径×厚度为26 mm×(5~6) mm的圆片。 为使基片致密化, 抽真空后在氩气保护下, 采用1650 ℃以上的高温烧结并保温1 h, 所得一氧化钛圆基片的相对密度大于99.2%。 将此基片在砂轮上磨去表面层, 然后进行粗磨、 细磨和抛光, 以保证两面平行光滑。 最后, 用溶剂汽油、 蒸馏水和无水乙醇依次清洗干净, 烘干备用。

2 结果及讨论

根据金属陶瓷制备的一般原则和仿金材料的特殊要求, 金属粘结相应具备如下条件: 强度和塑性高、 与一氧化钛润湿性好, 热膨胀及热力学相容、 可形成较高的界面结合强度, 耐蚀性强, 不影响合金成品颜色等。 在此选择铜、 铁族元素、 锰、 硅及铁铬合金等几种体系进行研究。

2.1 铜与一氧化钛的润湿性

在真空条件下, 铜在一氧化钛表面的润湿性测试结果见表1, 其座滴图像如图2所示。

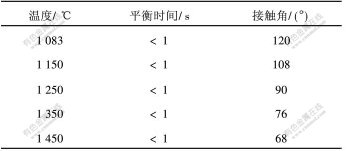

表 1 不同温度下铜在一氧化钛表面的接触角

Table 1 Contact angles of Cu on TiO surface

at different temperatures

![]()

(a) 冷态; (b) 1083 ℃; (c) 1150 ℃;

(d) 1250 ℃; (e) 1350 ℃; (f) 1450 ℃

图 2 不同温度下铜在一氧化钛表面的润湿

座滴图像(冷态→平衡)

Fig. 2 Sessile drop photographs of Cu on TiO

surface at different temperatures

(cooling to stabilization)

由表1及 图2可见, 金属铜在一氧化钛表面的润湿性较差。 此外,在测试过程中发现: 于不同测试温度下铜液滴均能在瞬间达到平衡, 表现为非反应型润湿特征。 由于铜氧化物的标准生成自由焓负值较小, 且金属铜不与钛形成稳定的金属间化合物, 所以, 在润湿过程中TiO/Cu界面无化学反应发生。 随着温度的升高, 接触角减小, 润湿性得到改善, 但由于非反应型润湿主要依靠范德华力及液、固相间的相互溶解等物理作用, 且氧化物与金属间结构、 性质和极性不同, 黏附功较低, 所以, 相间结合强度较低。

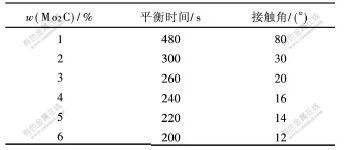

由于Cu在Mo2C表面能完全润湿[2], 为了改善Cu在TiO表面的润湿性, 在Cu粉中加入Mo2C粉,研究Cu对TiO表面润湿性的影响。 当温度为1150 ℃时,Cu在TiO表面的接触角如表2所示。

表 2 1150 ℃时Mo2C添加量对Cu在

一氧化钛上润湿性的影响

Table 2 Effect of content of Mo2C on contact

angles of Cu on TiO surface

可见, 当Mo2C的含量(质量分数)达到2%以上时, 可以有效地改善Cu在TiO表面的润湿性。 由于碳和钛具有很强的亲和力, Mo2C可与一氧化钛发生化学反应, 在润湿过程中Mo2C通过吉布斯化学吸附向TiO/Cu界面富集, 并在界面形成Mo2C与Ti(C, O)的固溶体, 降低了TiO与Cu之间的界面能, 使润湿呈现反应型润湿特征, 接触角大幅度减小。 用电子探针能谱仪对界面进行定点成分分析, 结果表明Mo主要分布在两相的界面处。

2.2 铁族元素与一氧化钛的润湿性

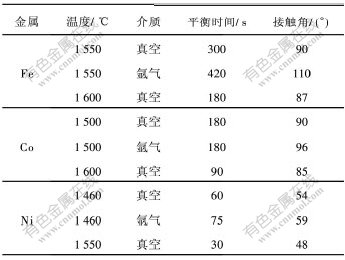

铁族元素与一氧化钛的润湿性能测试结果见表3, 其座滴图像见图3。

表 3 Fe, Co和Ni在一氧化钛表面的接触角

Table 3 Contact angles of Fe, Co and Ni

on TiO surface

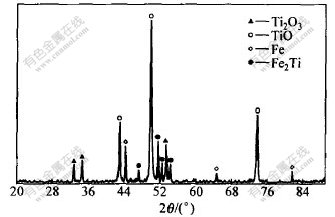

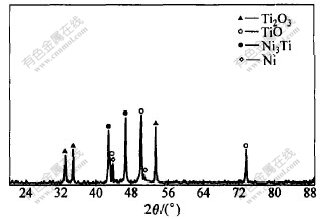

测试结果表明: 金属铁在一氧化钛上的润湿性较差, 接触角在90°左右;其润湿过程需要一定的平衡时间, 即恒温后随着时间的延长, 接触角逐渐减小, 经过一定的时间才能达到平衡, 呈反应型润湿特征;界面反应产物存在Fe2Ti和Ti2O3相(见图4), 界面呈现紫红色, 结合强度弱。

![]()

(a) Fe/TiO, 1550 ℃ , 真空; (b) Co/TiO, 1500 ℃, 真空;

(c) Ni/TiO, 1460℃, 真空

图 3 Fe, Co和Ni在一氧化钛表面的润湿

座滴图像(冷态→平衡)

Fig. 3 Sessile drop photographs of Fe, Co and

Ni on TiO surface (cooling to stabilization)

图 4 Fe/TiO界面的X射线衍射图谱

Fig. 4 XRD pattern of interface of Fe/TiO

金属钴在一氧化钛表面的润湿情况与金属铁极为相似, 亦表现为反应型润湿特征。

金属镍在一氧化钛表面的润湿性优于铁和钴在一氧化钛表面的润湿性, 在温度为1460~1550 ℃时其接触角为48°~59°, 属于界面反应型润湿过程。 但界面破坏试验结果表明,润湿样品的界面结合强度小。 界面的X射线衍射结果表明, 界面反应产物为Ni3Ti和Ti2O3(见图5)。

以上结果表明, 铁族元素与一氧化钛之间的润湿性能均较差。 液态的铁族元素都可与一氧化钛发生界面反应, 生成钛的金属间化合物,如Fe2Ti, Ni3Ti和Ti2O3; Fe与一氧化钛发生界面反应时其剧烈程度比镍的界面反应剧烈程度低。 由于界面化学反应产物属脆性物质, 且Ti2O3的非金属性较强, 使得界面结合强度低, 因此, 润湿性未因界面化学反应而得到明显改善。 可见, 金属铁、 钴及镍不能直接用作一氧化钛陶瓷的粘结相。

图 5 Ni/TiO界面的X射线衍射图谱

Fig. 5 XRD pattern of interface of Ni/TiO

2.3 锰与一氧化钛的润湿性

测试结果表明, 金属锰与一氧化钛之间具有良好的润湿性能。 在锰的熔点温度, 熔融初期接触角为60°左右, 4~10 s后, 金属锰在基片上铺展, 达到完全润湿。 锰在一氧化钛表面的润湿座滴图像如图6所示。

![]()

(a) 冷态; (b) 熔化; (c) 铺展

图 6 Mn在一氧化钛表面的润湿座滴图像(冷态→平衡)

Fig. 6 Sessile drop photographs of Mn on

TiO surface (cooling to stabilization)

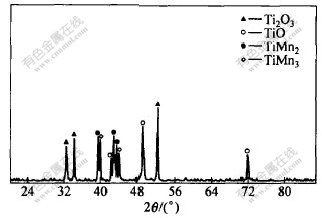

锰在一氧化钛表面能迅速完全润湿, 表明存在剧烈的化学反应。 X射线衍射分析结果表明, 界面反应产物为Ti2O3, TiMn2和TiMn3(见图7)。

图 7 Mn/TiO界面的X射线衍射图谱

Fig. 7 XRD pattern of interface of Mn/TiO

2.4 硅与一氧化钛的润湿性

硅在一氧化钛表面的润湿座滴图像见图8。 可见,硅和一氧化钛亦具有良好的润湿性, 硅熔化后立即在基片上铺展, 达到完全润湿, 呈非反应型润湿特征。 界面X射线衍射分析结果表明: 只有α-TiO和Si存在, 但α-TiO谱线位置稍左移(见图9), 说明TiO晶格发生了变化。 这是因为Si溶入TiO晶格, 使晶格常数发生了变化。 正是元素Si较深地溶入TiO晶格, 使得界面结合十分紧密, 强度较高。

![]()

(a) 冷态; (b) 熔化; (c) 铺展

图 8 Si在一氧化钛上的润湿座滴图像

(冷态→平衡)

Fig. 8 Sessile drop photographs of Si on

TiO surface (cooling to stabilization)

![]()

(a) TiO; (b) Si/TiO

图 9 TiO及Si/TiO界面的X射线衍射图谱

Fig. 9 XRD patterns of TiO and interface of Si/TiO

2.5 铁铬合金与一氧化钛的润湿性

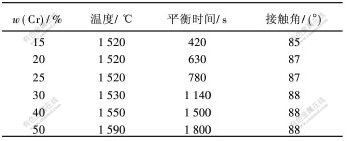

Fe-Cr合金材料来源广泛, 当Cr的质量分数达到12%左右时, 合金在氧化性介质中的耐蚀性迅速增强[6, 7]。 为寻求耐蚀性较强的黏结相材料, 在真空条件下, 测定了不同Cr含量的Fe-Cr合金在一氧化钛表面的接触角, 结果如表4所示。

表 4 Fe-Cr合金在一氧化钛表面的接触角

Table 4 contact angles of Fe-Cr alloy on TiO

surface as function of Cr content

测试结果表明: Fe-Cr合金在一氧化钛表面的润湿性与金属铁在一氧化碳表面的润湿性相似, 接触角均在90°左右, 呈润湿不良的状况。

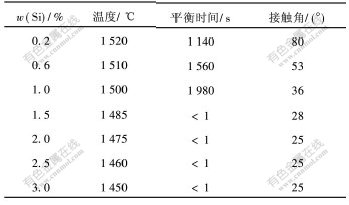

在金属陶瓷的生产中, 为改善陶瓷相与金属黏结相的润湿性能, 向金属黏结相中添加合金元素是一种有效的方法[8-15]。 为此,选择与一氧化钛具有优异润湿性能的硅和锰作为合金添加剂, 以提高其润湿性。 不同Si和Mn含量的Fe-25%Cr合金与TiO的接触角测试结果如表5和表6所示;润湿座滴图像见图10。

表 5 不同Si含量的Fe-25%Cr合金在

一氧化钛表面的接触角

Table 5 Contact angles of Fe-25%Cr alloy on

TiO surface as function of Si content

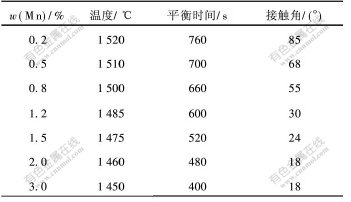

表 6 不同Mn含量的Fe-25%Cr合金

在一氧化钛表面的接触角

Table 6 Contact angles of Fe-25%Cr alloy on

TiO surface as function of Mn content

可见,添加元素Si和Mn均能明显降低Fe-Cr合金在一氧化钛表面的接触角。 当Si含量较低时, 随着Si含量的增加, 接触角迅速减小, 平衡时间也随之增长;当Si含量增至1.5%以后, 接触角变化趋于平缓, 且瞬间即可达到平衡。 润湿界面的X射线衍射分析结果表明, 添加1.5%的Si可抑制Fe与TiO之间的界面反应, 界面已无Fe2Ti和Ti2O3相存在(见图11)。 说明由于Si与TiO具有优异的润湿性能, Si在Fe-Cr合金中表现出表面活性物质的性质。 在润湿过程中, Si富集于Fe-Cr合金与TiO的界面, 降低了界面能和液相表面张力, 不仅自身未参与反应, 而且抑制了Fe2Ti和Ti2O3相的生成, 使润湿过程呈非反应型润湿的特征, 显著地提高了Fe-Cr合金与一氧化钛之间的润湿性能。 但是, Mn在一氧化钛上的润湿与Si的情况明显不同。 将润湿实验后的样品从炉中取出,发现金属Mn已不存在, 在整个润湿区留下很明显的紫黑色凹坑, 坑内为紫黑色粉状生成物,说明金属Mn与一氧化钛发生了剧烈的化学反应。 X射线衍射分析结果表明, 界面反应产物为Ti2O3, TiMn2和TiMn3。

![]()

(a) 0.6%Si; (b) 1.5%Si; (c) 2.0%Si

图 10 不同Si含量的Fe-25%Cr合金在

TiO表面的润湿座滴图像

Fig. 10 Sessile drop photographs of Fe-25%Cr

alloy on TiO surface at different Si contents

![]()

图 11 (Fe-25%Cr-1.5%Si)/TiO界面的X射线衍射图谱

Fig. 11 XRD pattern of interface of

(Fe-25%Cr-1.5%Si)/TiO

3 结 论

a. 金属Cu, Fe, Co, Ni及Fe-Cr合金与TiO的润湿性均较差, 接触角为48°~120°;Cu与TiO属非反应型润湿; Fe, Co, Ni及Fe-Cr合金与TiO之间的润湿属反应型润湿。

b. 在Cu中添加2%以上的Mo2C, 可以明显提高Cu在TiO表面的润湿性, Mo主要分布在相界面, 润湿呈反应型润湿特征。

c. 在Fe-Cr合金中添加1.5%以上的Mn或Si, 均可显著提高Fe-Cr合金在TiO表面的润湿性, Mn使润湿呈反应型润湿特征, Si使润湿呈非反应型润湿特征。

参考文献:

[1]Mark H F, Othmer D F, Overberger C G, et al. Encyclopedia of chemical technology[M]. New York: John Wiley & Sons, 1984.

[2]Yoshio N, Hiroshi H. Sintered alloy of golden color[P]. EP 0520465, 1992-12-30.

[3]李荣九. 陶瓷-金属复合材料[M].北京: 冶金工业出版社, 1995.

LI Rong-jiu. Metal-ceramic composite materials[M]. Beijing: Metallurgical Industry Press, 1995.

[4]陈康华, 包崇玺, 刘红卫.金属/陶瓷润湿性 (上)[J].材料科学与工程, 1997, 15(3): 6-10.

CHEN Kang-hua, BAO Chong-xi, LIU Hong-wei. Wettability between metals and ceramics (PartⅠ)[J]. Materials Science and Engineering, 1997, 15(3): 6-10.

[5]陈康华, 包崇玺, 刘红卫.金属/陶瓷润湿性 (下)[J].材料科学与工程, 1997, 15(4): 27-34.

CHEN Kang-hua, BAO Chong-xi, LIU Hong-wei. Wettability between metals and ceramics (PartⅡ)[J]. Materials Science and Engineering, 1997, 15(4): 27-34.

[6]Donald P, Bernsten I M. Handbook of stainless steels[M]. New York: McGraw-Hill, 1977.

[7]陆世英, 张延凯, 杨长强, 等.不锈钢[M].北京: 原子能出版社, 1995.

LU Shi-ying, ZHANG Yan-kai, YANG Chang-qiang, et al. Stainless steel[M]. Beijing: Atomic Energy Press, 1995.

[8]Fukuhara M, Mitsuda T, Katsumura Y. Sinter-ability and properties of Ti(N1-x,Ox)-(V,Ta)C-Ni sintered alloys having a golden color[J]. Journal of Materials Science, 1985, 20: 710-717.

[9]Park J, Park S T. Densification of TiN-Ni cermets by improving wettability of liquid nickel on TiN grain surface with addition of Mo2C[J]. International Journal of Refractory Metals and Hard Materials, 1999, 7: 295-298.

[10]Than E, Podlesak H, Leonhardt G. On the relations between atomic interface parameters and the wettability and stability in metal-ceramic systems[J]. Vacuum, 1990, 41(7-9): 1750-1752.

[11]周融, 张祥宝, 黄国钦.微量元素Bi和Pb的含量对焊锡可焊性的影响[J].中国有色金属学报, 1998, 8(S1): 192-196.

ZHOU Rong, ZHANG Xiang-bao, HUANG Guo-qin. Influence of trace elements Bi and Pb on solderability of solder[J]. The Chinese Journal of Nonferrous Metals, 1998, 8(S1): 192-196.

[12]隋贤栋, 罗承萍, 欧阳柳章, 等.铸造SiCp/Al-Si复合材料中的“界面Si”行为[J].中国有色金属学报, 1999, 9(S1): 20-24.

SUI Xian-dong, LUO Cheng-ping, OUYANG Liu-zhang, et al. “Interfacial Si” behavior in cast SiCp/Al-Si composites[J]. The Chinese Journal of Nonferrous Metals, 1999, 9(S1): 20-24.

[13]张凯锋, 吴为.TiB2/Cu/TiB2扩散焊的界面反应[J].中国有色金属学报, 2000, 10(1): 17-19.

ZHANG Kai-feng, WU Wei. Interface reaction of TiB2/Cu/TiB2 diffusion welding[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(1): 17-19.

[14]Guidi V, Comini E, Ferroni M, et al. Study on nanosized Ti/WO3 thin film achieved by radio frequency sputtering[J]. Vacuum Science and Technology, 2000, A18(2): 509-514.

[15]Nakae H, Fujji H, Sato K. Reactive wetting of ceramics by liquid metals[J]. Materials Transactions, 1992, 33(4): 400-406.

收稿日期:2004 -08 -24

作者简介:钟 晖(1967-), 男, 湖南长沙人, 教授, 博士, 从事金属材料表面处理、功能材料和电子材料研究

论文联系人: 钟 晖, 男, 教授, 博士; 电话: 0731-8830423; E-mail: zhy@mail.csu.edu.cn