DOI: 10.11817/j.issn.1672-7207.2019.11.012

某轿车车门轻量化与疲劳寿命多目标综合优化

龙岩1, 2,蒋凌山2,刘雪强2,熊海林2,陈志勇1,钟慧卿2

(1. 吉林大学 汽车仿真与控制国家重点实验室,吉林 长春,130022;

2. 一汽-大众汽车有限公司 技术开发部,吉林 长春,130011)

摘要:为了提高某轿车车门的综合性能,对车门总成进行轻量化和疲劳寿命的多目标综合优化设计。首先建立并试验验证车身及车门总成有限元模型,基于模型分析车门总成装备件质量、结构尺寸、刚度和安装位置等8项参数对车门疲劳寿命的影响;然后,以这8项参数作为优化设计变量建立车门总成多目标综合优化参数模型,以车门总成质量和疲劳寿命为优化目标,以车门框刚度为约束条件,应用多目标粒子群优化算法对车门总成进行综合优化计算,得到Pareto最优解集,依据工程实际选取1组最优解,并依此进行样件试验以验证优化方法的有效性。研究结果表明:在保证车门总成刚度和提高疲劳寿命的同时,车门总成质量减少2.44 kg,说明优化方法是有效的。

关键词:疲劳寿命;轻量化;刚度;粒子群优化

中图分类号:U463.83+4 文献标志码:A 文章编号:1672-7207(2019)11-2732-11

Multi-objective optimization of lightweight and fatigue life for car door

LONG Yan1, 2, JIANG Lingshan2, LIU Xueqiang2, XIONG Hailin2, CHEN Zhiyong1, ZHONG Huiqing2

(1. State Key Laboratory of Automotive Simulation and Control, Jilin University, Changchun 130022, China;

2. Department of Technology Development, FAW-Volkswagen Automotive Co. Ltd., Changchun 130011, China)

Abstract: In order to improve the performance of a domestic car door synthetic, a multi-objective optimization method considering lightweight and fatigue life was implemented. Firstly, the finite element models (FEM) of car body and door were established and validated by test. Based on FEM, eight parameters that have effect on car door fatigue life were calculated and analyzed, which include mass, structure parameters, stiffness, positioning errors and so on. Then, a car door parametric optimization model was established, in which the eight parameters were used as the design variables. The mass and fatigue life were defined as the optimization objective, and the door stiffness was taken as the constraints, with the particle swarm algorithm being adopted to perform the multi-objective optimization of car door. The Pareto optimal set was obtained and one of the optimal solutions was selected by sample test to validate the effectiveness of the optimization method. The results show that the mass of the optimized door is reduced by 2.44 kg, while door stiffness and fatigue life satisfy the design requirement, which indicates that the optimization method is effective.

Key words: fatigue life; lightweight; stiffness; particle swarm optimization

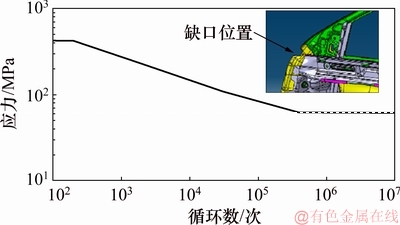

图1 材料应力-寿命曲线

Fig. 1 Stress-life curve and notch location of material

目前汽车轻量化已成为汽车研究领域中的重要研究方向之一[1],同时,轻量化对汽车疲劳耐久性能和安全性能提出更高要求。近些年国内外的许多学者对汽车车身轻量化进行了大量研究,并取得了很多研究成果[2-3]。通常车身轻量化设计方法主要以钣金件的厚度等参数作为设计变量,以质量最小为目标进行优化设计,再通过疲劳强度验证优化设计的可靠性[4-5],开发周期较长,而同时将质量和疲劳寿命作为优化目标进行轻量化优化设计的研究并不多见[6-7]。另外,对车身上众多装备件质量与疲劳寿命的关系进行研究并综合各因素进行系统多性能综合优化的研究也较少。车门作为驾驶员和乘员出入车辆的通道,需要承受经常开关车门的动态冲击载荷作用,作为用户操作最频繁的总成之一,车门开关操作疲劳寿命是车门开发必须设计并验证的主要性能,也是用户直接体验度很高的一项性能。人们通常对车门钣金件结构尺寸进行优化设计,虽然轻量化效果直接但往往会提高车门结构应力水平,降低其开关疲劳寿命,因此车门总成轻量化设计同时必须满足刚度和疲劳寿命性能要求,综合考虑车门各装备件的质量和刚度等参数对车门疲劳寿命的影响进行车门总成级别的多部件多目标综合优化。本文作者以某车型的车门总成轻量化和疲劳寿命为研究目标,建立车门总成及车身总成的有限元模型,通过模拟用户开关车门的习惯进行车门开关疲劳试验和车门刚度试验以验证模型正确性,同时研究车门装备件主要参数对车门疲劳寿命的影响,以质量和疲劳寿命为优化目标,以各个装备件参数为设计变量,以保证车门刚度作为约束条件,采用粒子群优化算法对车门进行多目标综合优化,以期在保证车门刚度并提高疲劳寿命的同时完成轻量化设计。

1 车门疲劳损伤与寿命

本文车门采用某镀锌钢板材料,钣金厚度为0.70 mm,开关疲劳试验中钣金疲劳破坏的主要形式为由局部应力集中导致的钣金裂纹,开关疲劳寿命设计要求不低于1×105次,因此本文通过仿真计算得到车门开关过程中裂纹形成部位的局部应力,应用局部应力-应变法对危险点处进行疲劳损伤分析[8],计算得到危险点处的疲劳寿命,危险点处的应变-寿命关系如下:

(1)

(1)

式中: 为应变幅值;

为应变幅值; 为f级载荷下疲劳强度系数;E为材料弹性模量;

为f级载荷下疲劳强度系数;E为材料弹性模量; 为f级载荷下疲劳延伸系数;b为疲劳强度指数;c为疲劳延性指数;

为f级载荷下疲劳延伸系数;b为疲劳强度指数;c为疲劳延性指数; 为f级疲劳载荷下的疲劳寿命。

为f级疲劳载荷下的疲劳寿命。

零部件载荷循环应力-应变关系如下:

(2)

(2)

式中: 为应力幅值;

为应力幅值; 为强度系数;

为强度系数; 为应变硬化指数。

为应变硬化指数。

车门开关疲劳试验中钣金件危险点处所受到的应力与脉动循环应力类似,钣金件主要受到局部拉伸应力作用而产生疲劳裂纹,Smith-Watson-Topper(SWT)平均应力修正方法较适用于拉伸平均应力的修正且偏于保守,如式(3)所示。

(3)

(3)

式中: ,

, 为平均应力。

为平均应力。

根据Miner疲劳损伤累积法则可计算测试循环过程中零部件局部载荷伪损伤。

(4)

(4)

式中: 为第f级载荷的损伤循环数;

为第f级载荷的损伤循环数; 为第f级载荷的实际加载循环数;D为总损伤,当总损伤

为第f级载荷的实际加载循环数;D为总损伤,当总损伤 时,认为失效发生。修正后车门钣金缺口相应材料的应力-寿命曲线和缺口位置如图1所示。

时,认为失效发生。修正后车门钣金缺口相应材料的应力-寿命曲线和缺口位置如图1所示。

2 车门总成模型建立及验证

2.1 车门刚度仿真与试验验证

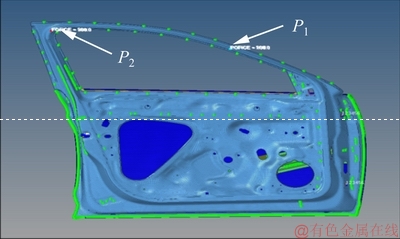

使用Hypermesh软件对车门三维模型进行几何简化和清理,选用板壳单元划分网格,网格单元边长为4 mm,较多地使用四节点直边单元(QUAD4),通过局部网格加密方式提高应力精度,选用三节点直边单元(TRIA3)提高过渡网格质量,采用块单元和短梁模拟焊点,采用点面接触连接方式模拟黏胶部分,得到车门有限元模型如图2所示,其中,P1和P2为加载点(测量点),模型单元总数为161 154个。

图2 左前车门总成有限元模型

Fig. 2 FEM of left-front car door

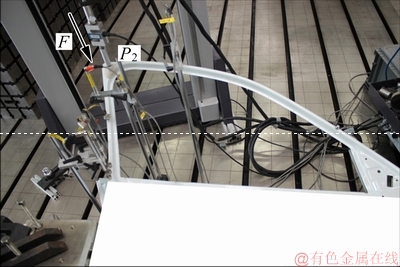

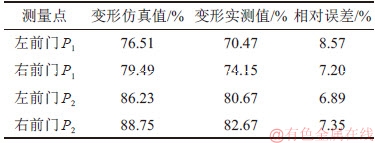

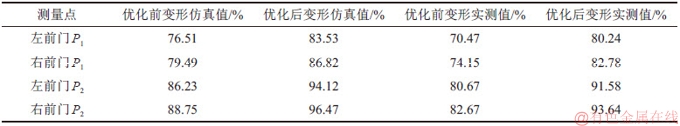

有限元模型的精度直接影响疲劳寿命分析和优化的准确程度,为验证模型的准确性,试制车门总成样件进行试验验证。依据经验,车门框的静态变形(即刚度)对车门疲劳寿命有直接影响,车门框静态变形测量如图3所示(其中F为在P2点施加的试验载荷)。在试验载荷下,变形仿真计算结果与实测结果对比如表1所示。表1中,所示数值为计算变形和实测变形与设计要求极限值的比值。数值大于100%则说明产品变形超过设计要求,即产品不合格。由表1对比结果可知仿真结果与实测结果存在一定误差,且误差在可以接受的范围内,故该车门总成刚度合格且模型精度满足工程要求。但该车门框变形计算值接近设计要求值,因此在优化计算时应合理约束车门框变形范围,以保证车门框静刚度满足设计要求。

图3 车门P2点静刚度测试装置

Fig. 3 Static stiffness measurement device of P2 point of car door

表1 计算变形与实测变形对比

Table 1 Contrast of simulated and tested deformation

2.2 车门开关疲劳仿真与试验验证

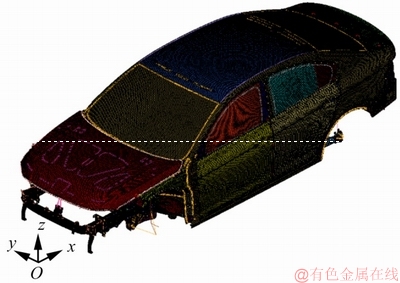

为保证仿真与疲劳试验相一致,分别建立白车身、门洞条、车窗导轨、车门玻璃、车门铰链、门锁和锁销等部件的有限元模型,后视镜和门护板作为质量集中载荷,装配建立车门和车身系统有限元模型[9],对于质量集中单元采用节点刚体的连接方式,如后视镜作为一个质量集中载荷通过RB2单元连接。门洞条模型采用OGDEN材料模型[10],通过调整模型参数使得门洞条模型的密封力曲线与设计要求保持一致。车门和车身系统有限元模型单元总数为1 309 855个,如图4所示[11]。

图4 车门车身系统有限元模型

Fig. 4 FEM of door and body of car

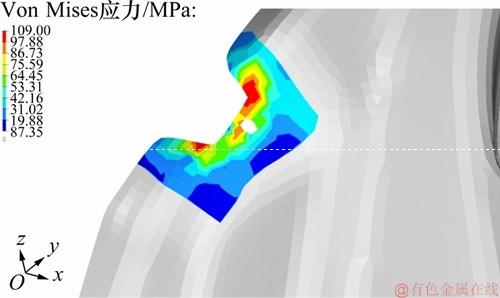

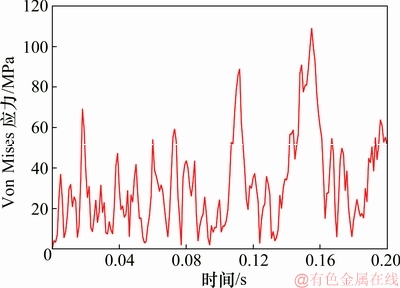

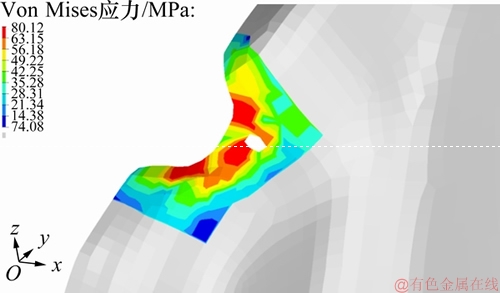

按照车门开关疲劳试验标准要求设置模型,使车门关闭速度和关闭能量与实车疲劳试验中的保持一致,应用Hyperworks软件中的RADIOSS求解器进行动态仿真计算[12-13],结果表明在车门内板三角窗切口处(如图5所示)存在较大应力集中,应力最大危险单元为181 192,仿真得到该危险单元在车门关闭过程中的Von Mises应力曲线如图6所示。由图6可见:危险单元处的应力类似脉冲循环应力,最大应力约为109.0 MPa,应力幅值也约为109.0 MPa,应用疲劳损伤理论通过FEMFAT软件进行疲劳寿命计算,预测该车门开关疲劳试验在3.1×104次左右可能会发生疲劳破坏,疲劳寿命远低于1×105次的要求,存在较高疲劳寿命风险 [14-15]。

图5 原设计车门有限元Von Mises应力计算结果

Fig. 5 Calculation results of door Von Mises stress before optimization

图6 车门关闭时危险单元181 192处Von Mises应力曲线

Fig. 6 Von Mises stress curve of cell 181 192 during door close

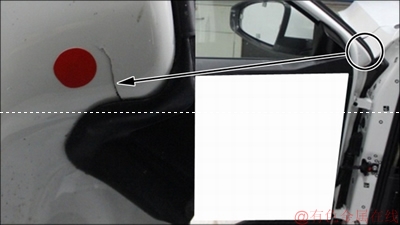

图7 车门经27 743次开关疲劳试验结果

Fig. 7 Test results after 27 743 times of door on-off fatigue tests

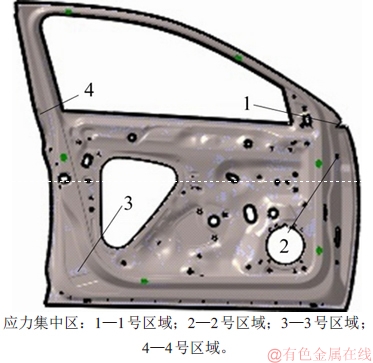

图8 车门内板钣金可能出现疲劳问题的区域

Fig. 8 Potential fatigue regions of inner plate of car door

将试制的车门总成安装在车身上进行车门开关疲劳试验,门内板三角窗切口处钣金在车门开关27 743次左右时发现裂纹,如图7所示。相同位置处疲劳仿真寿命约为3.1×104次,疲劳计算寿命与试验结果的相对误差约为14.81%,可知所建仿真模型计算结果与实际试验结果比较接近,车门和车身系统模型精度满足工程要求,并且车门总成设计存在较大疲劳寿命问题。

3 车门总成疲劳寿命影响因素

由于车门总成在用户使用过程中容易出现疲劳破坏问题的主要是金属钣金件,基于已建立的有限元模型,本文选取与金属钣金件疲劳寿命相关的8个参数进行研究[16-17],即锁钩扭转刚度、锁销位置偏移量、切口钣金圆角、车门玻璃厚度、门内护板质量、门内板钣金厚度、后视镜质量和门洞条密封力。由于车门外板钣金关系到外观造型等方面的原因,本次优化将车门内板钣金作为主要优化对象。图8所示为内板钣金可能出现疲劳寿命问题的主要区域示意图。

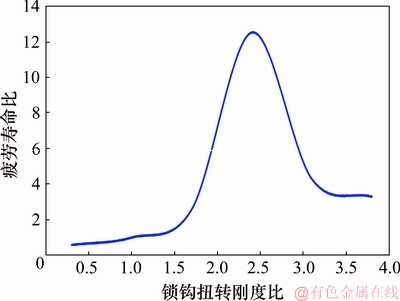

3.1 锁钩扭转刚度对车门疲劳寿命的影响

车门关闭撞击瞬间,锁钩扭转刚度对从门锁传递到车门钣金的冲击载荷有直接影响,仿真结果如图9所示。其中,锁钩扭转刚度比为车门关闭时锁钩扭转刚度仿真值与原车状态锁钩扭转刚度的比值,疲劳寿命比为某一锁钩扭转刚度下车门疲劳寿命仿真值与原车状态车门疲劳寿命的比值。由图9可见:随着锁钩扭转刚度比增加,车门疲劳寿命比先增加后减小;最大应力点从图8所示的4号区域转移到2号区域,锁钩扭转刚度存在对车门疲劳寿命影响的最优值,在优化和设计时应找到并合理利用该最优值。

图9 锁钩扭转刚度对车门疲劳寿命的影响

Fig. 9 Influence of lock claw torsion stiffness on fatigue life of car door

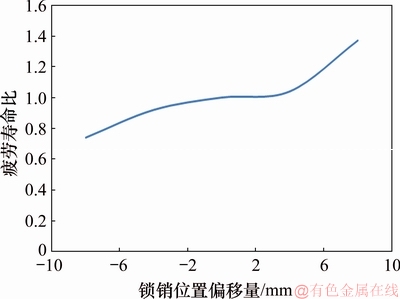

3.2 锁销位置偏移量对车门疲劳寿命的影响

门锁销偏移量直接影响车门内间隙,从而影响门洞密封条的压缩量及锁销与门锁撞击程度,最终影响车门总成所受载荷。计算时定义锁销位置向门外侧偏移为正方向,向门内侧偏移为负方向,锁销位置偏移量对车门疲劳寿命的影响仿真结果如图10所示。由图10可见:锁销向外侧偏移,内间隙增大,车门疲劳寿命增加,锁销向内侧偏移,内间隙减小,车门疲劳寿命降低,危险点从图8所示3号区域转移到4号区域。

图10 锁销位置偏移量对车门疲劳寿命的影响

Fig. 10 Influence of lockpin location displacement on fatigue life of car door

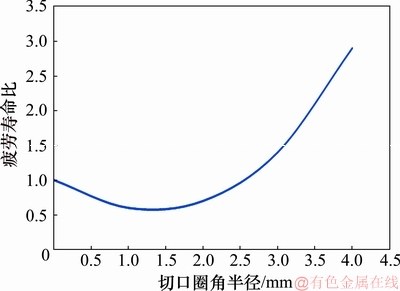

3.3 门内板钣金切口圆角对车门疲劳寿命的影响

门内板三角窗处切口是容易发生疲劳问题的区域,其过渡圆角的半径对消除应力集中并增加该区域的疲劳寿命具有积极作用,门内板钣金切口圆角对车门疲劳寿命的影响仿真结果如图11所示。由图11可见:随切口圆角半径增加,切口区域疲劳寿命先减小后增加,存在1个疲劳寿命最小值,危险点为图8所示1号区域,可知切口处过渡圆角并不是越平滑疲劳寿命就越高,在优化和设计时应该找到该疲劳寿命转折点,并合理设计过渡圆角半径。

图11 内板切口过渡半径对车门疲劳寿命的影响

Fig. 11 Influence of kerf radius on fatigue life of car door

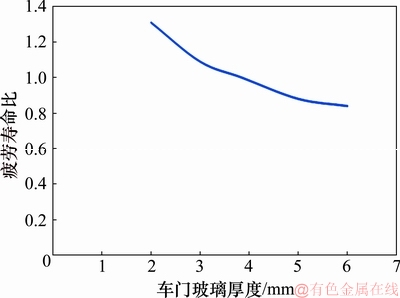

3.4 车门玻璃厚度对车门疲劳寿命的影响

车门玻璃厚度直接影响到车门总成质量和车门总成刚度,进而对车门的疲劳寿命产生影响,仿真结果如图12所示。由图12可见:随着车门玻璃的厚度增加,车门疲劳寿命降低,但玻璃厚度增大到6 mm后再继续增加对车门疲劳寿命的影响较小,危险点主要为图8所示的4号区域。

图12 车门玻璃厚度对车门疲劳寿命的影响

Fig. 12 Influence of door glass thickness on fatigue life of car door

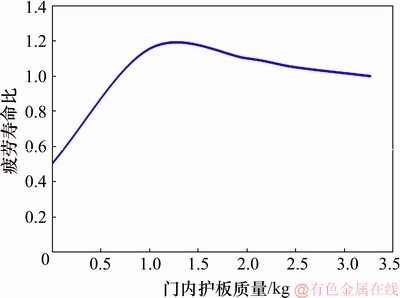

3.5 门内护板质量对车门疲劳寿命的影响

车门内护板除主要承载一些功能键以及美观功能外,其质量对车门疲劳寿命也具有一定影响,门内护板质量对车门疲劳寿命的影响仿真结果如图13所示。由图13可见:门内护板质量的存在可以提高车门疲劳寿命,但存在1个极值,超过该质量极值后车门疲劳寿命会有所下降,继续增加质量,车门疲劳寿命下降趋于稳定,说明门内护板的质量不宜过小,而过大的质量不利于车门轻量化和疲劳寿命,恰当地设计门护板质量有利于兼顾车门轻量化和疲劳寿命要求。危险点为图8所示的4号区域。

图13 车门内护板质量对车门疲劳寿命的影响

Fig. 13 Influences of door trim mass on fatigue life of car door

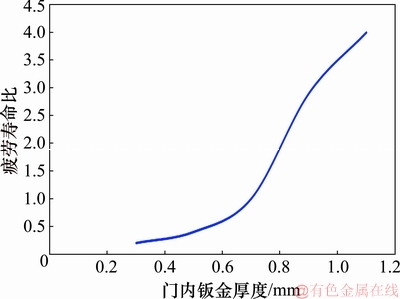

3.6 门内板钣金厚度对车门疲劳寿命的影响

门内板钣金的厚度直接影响车门总成的质量、疲劳寿命和刚度,门内板钣金厚度对车门疲劳寿命的影响仿真结果如图14所示。由图14可见:门内板钣金厚度增加,车门质量增加,疲劳寿命随之增加并且在厚度约为0.70 mm时迅速增加,设计时需合理利用厚度小于0.70 mm时斜率较小部分的特性,通过较少地降低疲劳寿命以获得较大的轻量化结果,危险点由图8所示的4号区域转移到1号区域。

图14 车门内板钣金厚度对车门疲劳寿命的影响

Fig. 14 Influence of door armor plate thickness on fatigue life of car door

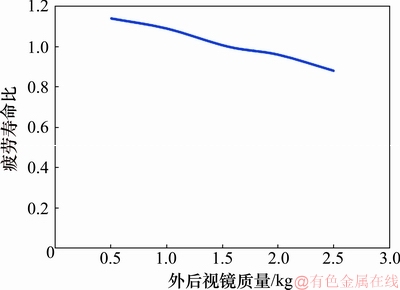

3.7 外后视镜质量对车门疲劳寿命的影响

外后视镜质量对门内板三角窗处钣金局部应力具有直接影响,从而影响车门疲劳寿命。外后视镜质量对车门疲劳寿命的影响仿真结果如图15所示。由图15可见:同样的位置外后视镜质量减小,车门疲劳寿命增加,且曲线斜率不大,危险点为图8所示的1号区域,因此在设计时应该合理匹配外后视镜质量,增加车门疲劳寿命。

图15 外后视镜质量对车门疲劳寿命的影响

Fig. 15 Influence of exterior rearview mirror mass on fatigue life of car door

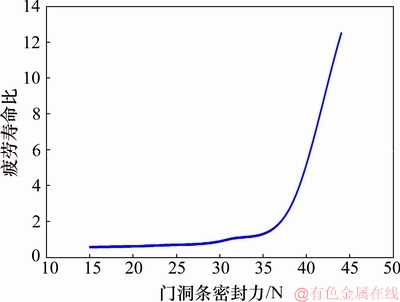

3.8 门洞条密封对车门疲劳寿命的影响

车门洞密封条位于车门与车身之间,填补门内间隙,为车门提供支撑,其密封力直接影响车门关闭瞬间的冲击载荷,从而影响车门疲劳寿命。采用软件中OGDEN材料模型,调整模型参数使门洞条模型的密封力曲线与设计要求保持一致,通过软件设定自动修改参数调整门洞条密封力进行仿真计算,得到密封力对门内板疲劳寿命的影响,如图16所示。由图16可见:随着门洞条密封力增大,车门疲劳寿命有所增加,经过曲线斜率拐点后增大密封力,车门疲劳寿命会迅速增加,优化和设计时需找到该斜率拐点,合理利用该斜率较大部分的特性,通过合理增加密封力获得较大的疲劳寿命提升效果。另外,密封力变化对车门总成质量影响很小,危险点为图8所示的1号区域。

图16 门洞条密封力对车门疲劳寿命的影响

Fig. 16 Influence of door sealed strip on fatigue life of car door

4 车门质量和疲劳寿命综合优化

4.1 设计变量

以上述8个影响参数为设计变量,其中4个参数为质量参数,其余4个非质量参数参与优化计算有利于得到较合适的优化结果。结合设计师建议和参考文献[18-20]中的设计变量取值范围,依据各参数变量特性曲线范围确定,如表2所示。表2中,初始值为车门总成各参数实际数值,上限和下限为各参数变量优化计算的约束值。

表2 设计变量

Table 2 Design variables

4.2 优化目标

以车门4个优化件的质量(M)为优化目标,其表达式为

(5)

(5)

式中: 为车门玻璃质量;

为车门玻璃质量; 为车门内护板质量;

为车门内护板质量; 为车门内钣金质量;

为车门内钣金质量; 为后视镜质量。

为后视镜质量。

以车门部件的疲劳寿命(L)作为优化目标,其表达式为:

(6)

(6)

式中: 为第i个部件的疲劳寿命;i为车门某部件,本文取i=1,8。

为第i个部件的疲劳寿命;i为车门某部件,本文取i=1,8。

4.3 车门总成多目标综合优化

综合考虑车门质量、疲劳寿命和刚度(变形)性能指标,对车门总成进行多目标综合优化设计。以质量和疲劳寿命性能作为优化目标,刚度(变形)保持现状为约束条件,优化数学模型可表示为

(7)

(7)

式中: 为车门总成质量;

为车门总成质量; 为车门总成疲劳寿命;

为车门总成疲劳寿命; 和

和 分别为车门框

分别为车门框 点变形及初始值,

点变形及初始值, ;

; 和

和 分别为车门框

分别为车门框 点变形及初始值,

点变形及初始值, ;

; 和

和 分别为车门框

分别为车门框 和

和 点的约束系数,基于

点的约束系数,基于 和

和 的初始值,本文取

的初始值,本文取 ,车门框静刚度变化量为[-10%,10%],以保证优化后车门框变形合格(<100%);

,车门框静刚度变化量为[-10%,10%],以保证优化后车门框变形合格(<100%); 为设计变量,

为设计变量, 和

和 分别为各设计变量的下限和上限。

分别为各设计变量的下限和上限。

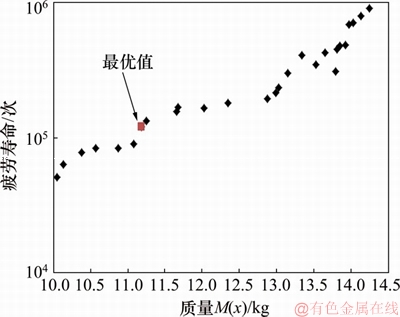

本文选用粒子群多目标优化算法,定义粒子群算法的粒子群规模为60,迭代的代数为100,优化得到车门质量与疲劳寿命的关系如图17所示。

图17 车门质量与疲劳寿命的关系

Fig. 17 Relationship between car door mass and fatigue life

由图17可见:车门4个部件的质量目标与车门疲劳寿命目标大体相互矛盾,基于综合性能提高的考虑,应在满足疲劳寿命(1×105 次)要求同时尽量选择车门质量最小的优化结果,考虑模型计算误差(约14.81%),选择疲劳寿命约为1.21×105 次,质量约为11.18 kg的优化结果,以保证物理样件能够接近理想的设计目标。各设计参数变量的优化结果经过圆整后如表3所示。优化后车门危险点为车门内板三角窗切口处(1号区域),计算得到危险单元(174 624)的Von Mises最大应力为80.1 MPa,如图18所示。由图18和表3可见:优化后危险点应力较优化前有明显减小,疲劳寿命约为优化前的4倍,车门总成质量较优化前减少2.44 kg。

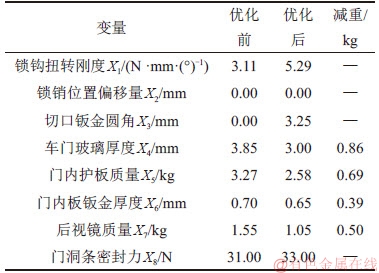

表3 设计变量优化结果

Table 3 Optimization results of design variables

图18 优化后缺口危险点处Von Mises应力计算结果

Fig. 18 Calculation results of kerf region Von Mises stress after optimization

4.4 优化结果仿真验证

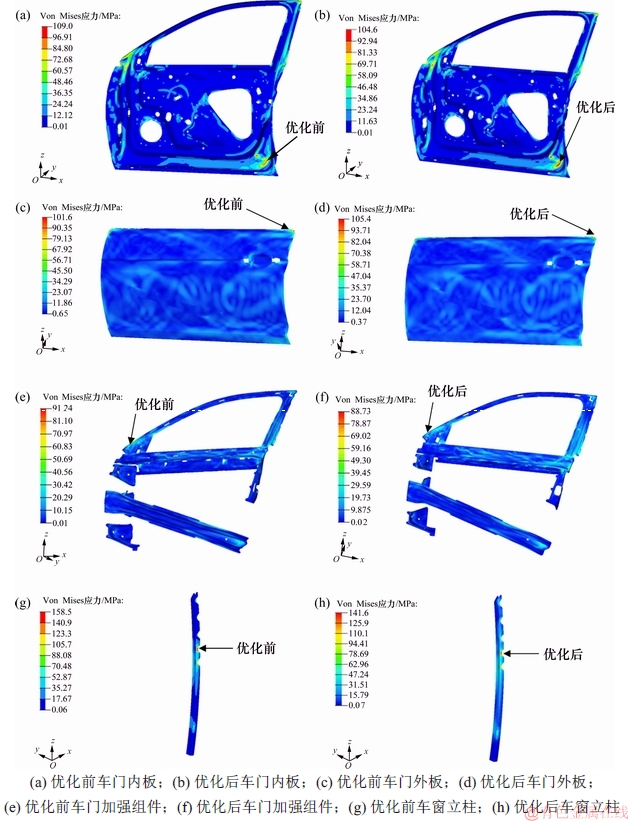

对车门总成主要部件优化前后的应力进行疲劳仿真计算,结果如图19所示,图中箭头指向部分为最大应力集中区域。

图19 优化前后车门主要部件Von Mises应力分布对比

Fig. 19 Contrasts of Von Mises stress of major components of car door before and after optimization

由图19 (a)和(b)可知:优化后车门内板三角窗钣金切口处的应力分布得到改善,整个车门内板的应力分布没有太大变化,局部最大应力点为3号区域,其应力由优化前的98.9 MPa增大为104.6 MPa,考虑具体结构形式,疲劳计算表明该最大应力点不构成疲劳寿命危险点,车门其他各应力集中点疲劳寿命均超过1×105次,试验亦证明这些位置并未发生疲劳破坏。由图19 (c)和(d)可知:优化后车门外板的应力分布并未发生太大变化,其最大应力点应力由101.6 MPa增大为105.4 MPa,计算表明该点不会发生疲劳破坏。由图19(e)和(f)可知:优化后车门加强组件的局部最大应力由91.2 MPa降低为88.7 MPa且不会发生疲劳破坏。由图19 (g)和(h)可知:优化后车窗立柱的局部最大应力由158.5 MPa降低为141.6 MPa且不会发生疲劳破坏。综上可知,车门总成优化后没有对车门其他结构件的应力分布产生较大影响,部分结构件局部最大应力降低,同时没有产生新的疲劳寿命危险点,车门优化方法可行。

5 车门总成优化试验验证

按照优化结果试制车门样件,将质量减轻的装备件快速成型或改制为保证装配位置和质量要求的替代件,按照同样的方法进行车门框静态变形量测量并与优化前的仿真和实测结果对比,如表4所示。由表4可见:优化后的车门框变形虽有增大,但亦满足车门框变形设计要求,达到保证车门刚度基本不变的优化要求。

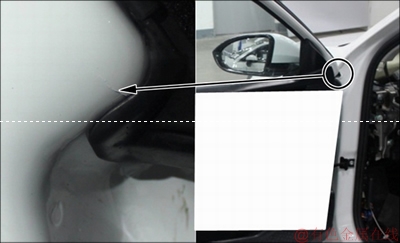

将试制车门总成安装到车身上进行车门开关疲劳试验,经过1×105次车门开关后,对试验车门进行目视检查,车门总成优化试验验证如图20所示。由图20可见车门没有发生疲劳破坏,说明优化后的车门满足设计要求。为验证仿真计算的准确性,继续进行车门开关疲劳试验直至发生疲劳破坏,当经过109 428次左右车门开关后,疲劳试验结果如图21所示。由图21可见:在车门三角窗的钣金切口处发现钣金裂纹,优化后计算疲劳寿命与试验结果的相对误差约为10.57%,车门拆检后未在其他部位发现疲劳破坏,证明了优化方法和结果的正确性。

图20 改进车门开关疲劳试验结果

Fig. 20 Results of optimized car door after door on-off fatigue test

图21 改进车门经109 428次开关疲劳试验结果

Fig. 21 Results of optimized car door after 109 428 times of door on-off fatigue tests

表4 优化前后计算变形与实测变形对比

Table 4 Contrast of simulated and tested deformations before and after optimization

6 结论

1) 建立车门总成及车身系统有限元模型,通过车门刚度试验和开关疲劳试验验证模型的准确性,为车门总成疲劳寿命计算和分析提供基础。

2) 对影响车门疲劳寿命的8项参数进行分析,揭示了车门装备件质量、刚度、尺寸和安装位置等参数与车门疲劳寿命的关系,为车门综合优化计算提供基础,优化计算时选择非质量相关参数作为设计变量有利于得到合适结果,各参数影响分析也可为设计人员提供设计和改进思路。

3) 同时以车门质量和疲劳寿命为目标,以保证车门静态刚度为约束,应用多目标粒子群优化算法,对车门总成进行多目标综合优化计算,得到Pareto最优解集。

4) 考虑计算误差和工程实际选取1组最优解,对最优解进行试验验证车门总成优化效果,结果表明,在满足车门刚度和疲劳寿命要求的同时,优化后车门总成质量减少2.44 kg,优化效果较明显。

参考文献:

[1] 郑松林, 王彦生, 卢曦, 等. 基于强度变化特征的汽车结构件轻量化设计方法[J]. 机械工程学报, 2008, 44(2): 129-133.

ZHENG Songlin, WANG Yansheng, LU Xi, et al. Weight-reduction design of auto structures based on strength features[J]. Chinese Journal of Mechanical Engineering, 2008, 44(2): 129-133.

[2] 王平, 郑松林, 吴光强. 基于协同优化和多目标遗传算法的车身结构多学科优化设计[J]. 机械工程学报, 2011, 47(2): 102-108.

WANG Ping, ZHENG Songlin, WU Guangqiang. Multidisciplinary design optimization of vehicle body structure based on collaborative optimization and multi-objective genetic algorithm[J]. Journal of Mechanical Engineering, 2011, 47(2): 102-108.

[3] 王新宇, 王登峰, 陈静, 等. 重型商用车驾驶室轻量化设计[J]. 农业机械学报, 2012, 43(8): 13-18.

WANG Xinyu, WANG Dengfeng, CHEN Jing, et al. Lightweight design for heavy-duty truck cab[J]. Transactions of the Chinese Society for Agricultural Machinery, 2012, 43(8): 13-18.

[4] 王书亭, 刘啸, 吴义忠, 等. 基于灵敏度分析的车架轻量化及疲劳寿命估算[J]. 中国机械工程, 2011, 22(16): 2001-2006.

WANG Shuting, LIU Xiao, WU Yizhong, et al. Sensitivity-based analysis of light weighting and fatigue life estimation for truck frame[J]. China Mechanical Engineering, 2011, 22(16): 2001-2006.

[5] 曹正林, 李骏, 郭孔辉. 基于虚拟试车场的轿车悬架耐久性强化试验仿真研究[J]. 机械工程学报, 2012, 48(10): 122-127.

CAO Zhenglin, LI Jun, GUO Konghui. Research on passenger car suspension durability using virtual proving ground[J]. Journal of Mechanical Engineering, 2012, 48(10): 122-127.

[6] 高云凯, 申振宇, 冯兆玄, 等. 多目标优化在车门轻量化设计中的应用[J]. 同济大学学报(自然科学版), 2017, 45(2): 275-280.

GAO Yunkai, SHEN Zhenyu, FENG Zhaoxuan, et al. Application of multi-objective optimization in vehicle door lightweight[J]. Journal of Tongji University (Natural Science), 2017, 45(2): 275-280.

[7] 王岩, 陈无畏, 谢有浩, 等. 多目标遗传算法在车身动态性能优化中的应用[J]. 汽车工程, 2017, 39(11): 1298-1304.

WANG Yan, CHEN Wuwei, XIE Youhao, et al. Application of multi-objective genetic algorithm to body-in-white dynamic performance optimization[J]. Automotive Engineering, 2017, 39(11): 1298-1304.

[8] 卢延辉, 王文阁, 郑联珠. 疲劳可靠性计算方法中迈纳理论与概率累加理论之间的关系[J]. 吉林大学学报(工学版), 2007, 37(2): 383-384.

LU Yanhui, WANG Wenge, ZHENG Lianzhu. Relation between Miner theory and probability accumulation theory in calculation methods of fatigue reliability[J]. Journal of Jilin University (Engineering and Technology Edition), 2007, 37(2): 383-384.

[9] 朱文峰, 林佩剑, 周辉, 等. 基于非线性刚度拟合的车窗系统约束分析与建模[J]. 机械工程学报, 2015, 51(20): 171-176.

ZHU Wenfeng, LIN Peijian ,ZHOU Hui, et al. Constraint analysis and modeling of automotive window based on nonlinear stiffness fitting[J]. Journal of Mechanical Engineering, 2015, 51(20): 171-176.

[10] 叶刚. 车门疲劳耐久性仿真分析研究[D]. 上海:同济大学汽车学院, 2014: 44-61.

YE Gang. Study on the door slam durability simulation analysis[D]. Shanghai: Tongji University. School of Automotive Studies, 2014: 44-61.

[11] 高云凯, 李翠, 崔玲, 等. 燃料电池大客车车身疲劳寿命仿真分析[J]. 汽车工程, 2010, 32(1): 7-12.

GAO Yunkai, LI Cui, CUI Ling, et al. A simulation analysis on the fatigue life of fuel cell bus body[J]. Automotive Engineering, 2010, 32(1): 7-12.

[12] 邓雄志, 王力, 申苗. 基于Abaqus的汽车车门瞬态应力分析[J]. 汽车技术, 2013(7): 5-9.

DENG Xiongzhi, WANG Li, SHEN Miao. Transient stress analysis of automotive door based on Abaqus[J]. Automobile Technology, 2013(7): 5-9.

[13] PETRACCONI C L, FERREIRA S E, PALMA E S. Fatigue life simulation of a rear tow hook assembly of a passenger car[J]. Engineering Failure Analysis, 2010, 17(2): 455-463.

[14] 蒋荣超, 王登峰, 秦民, 等. 基于疲劳寿命的轿车后悬架扭转梁轻量化设计[J]. 吉林大学学报(工学版), 2016, 46(1): 35-42.

JIANG Rongchao, WANG Dengfeng, QIN Min, et al. Lightweight design of twist beam of rear suspension of passenger car based on fatigue life[J]. Journal of Jilin University(Engineering and Technology Edition), 2016,46(1): 35-42.

[15] 赵国伟, 唐进元, 张质子. ISIGHT集成CATIA和ABAQUS的制动蹄轻量化设计[J]. 中南大学学报(自然科学版), 2016, 47(7): 2260-2265.

ZHAO Guowei, TANG Jinyuan, ZHANG Zhizi. Brake shoe’s lightweight design based on ISIGHT integrated CATIA and ABAQUS[J]. Journal of Central South University(Science and Technology), 2016, 47(7): 2260-2265.

[16] 周兵, 曾凡沂, 吴晓建, 等. 扭力梁疲劳寿命与减振器阻尼关系的研究[J]. 中南大学学报(自然科学版), 2018, 49(10): 2472-2479.

ZHOU Bing, ZENG Fanyi, WU Xiaojian, et al. Study of relationship between fatigue life of torsion beam and shock absorber damping[J]. Journal of Central South University(Science and Technology), 2018, 49(10): 2472-2479.

[17] 谢然, 兰凤崇, 陈吉清, 等. 满足可靠性要求的轻量化车身结构多目标优化方法[J]. 机械工程学报, 2011, 47(4): 117-124.

XIE Ran, LAN Fengchong, CHEN Jiqing, et al. Multi-objective optimization method in car-body structure light-weight design with reliability requirement[J]. Journal of Mechanical Engineering, 2011, 47(4): 117-124.

[18] 朱国华, 成艾国, 王振, 等. 电动车轻量化复合材料车身骨架多尺度分析[J]. 机械工程学报, 2016, 52(6): 145-152.

ZHU Guohua, CHENG Aiguo, WANG Zhen, et al. Analysis of lightweight composite body structure for electrical vehicle using the multiscale approach[J]. Journal of Mechanical Engineering, 2016, 52(6): 145-152.

[19] 马芳武, 陈实现, 赵花垒, 等. 强度、刚度与模态约束下的FSC赛车车架轻量化[J]. 湖南大学学报(自然科学版), 2018, 45(4): 18-25.

MA Fangwu, CHEN Shixian, ZHAO Hualei, et al. Lightweight on frame of FSC with constraints of strength, stiffness and modal[J]. Journal of Hunan University (Natural Sciences), 2018, 45(4): 18-25.

[20] 刘保公, 刘子建, 周小龙, 等. 基于刚度链的纯电动汽车车身主断面优化设计[J]. 中南大学学报(自然科学版), 2017, 48(4): 959-967.

LIU Baogong, LIU Zijian, ZHOU Xiaolong, et al. Main section optimization design of pure electric car body based on stiffness chain[J]. Journal of Central South University (Science and Technology), 2017, 48(4): 959-967.

(编辑 伍锦花)

收稿日期: 2019 -01 -26; 修回日期: 2019 -03 -11

基金项目(Foundation item):国家重点研发计划项目(2018YFB0106200) (Project(2018YFB0106200) supported by the National Key R&D Program of China)

通信作者:陈志勇,博士,副教授,从事汽车系统动力学与控制研究;E-mail: chen_zy@jlu.edu.cn