高速电弧喷涂Fe-TiB2/Al2O3复合涂层的组织及性能

栗卓新, 方建筠, 史耀武, 汤春天

(北京工业大学 材料科学与工程学院, 北京 100022)

摘 要: 采用低碳钢包覆0~70%TiB2/Al2O3硬质相的粉芯丝材和高速电弧喷涂(HVAS)原位合成MMC 涂层, 分析和测试了涂层的组织、 相组成及耐磨粒磨损性能。 结果表明: 涂层的性能由其组织和相组成决定, HVAS的非平衡制造过程在涂层中形成多种相: 在Fe基固溶体上存在TiB2、 Al2O3、 FexB及少量的金属间化合物AlFe3和NiAl; 随着TiB2及Al2O3在涂层中体积分数的增加, 涂层的耐磨粒磨损性能明显提高, 磨损质量损失随陶瓷相体积分数的增加呈线性减少; 添加合金元素Ni和Al可降低孔隙率, 增加涂层耐磨性。 使用HVAS方法制备了含TiB2的高性能耐磨复合陶瓷涂层。

关键词: TiB2复合材料; 高速电弧喷涂; 涂层; 显微组织; 耐磨性 中图分类号: TG706

文献标识码: A

Microstructures and properties of Fe-TiB2/Al2O3 composite ceramic coatings prepared by high velocity arc spraying

LI Zhuo-xin, FANG Jian-jun, SHI Yao-wu, TANG Chun-tian

(Colledge of Materials Science and Engineering,Beijing University of Technology, Beijing 100022, China)

Abstract: High velocity arc spraying(HVAS) was utilized to in-situ deposit a series of comprising TiB2(0~70%TiB2/Al2O3 in cored powder)composite coating on soft steel substrate. The microstructure、 phase characterization and properties of composite coatings were investigated. The results demonstrate that the microstructure and wear performance of composite coatings are influenced by metallurgical transformation during spraying process. As a consequence of non-equilibrium synthesis by HVAS processing, several phases such as TiB2, Al2O3, FexB, AlFe3 and NiAl in Fe matrix form. The anti-friction of composite coatings is improved with increasing ceramic phase content, and the friction mass loss follows a linear rule with ceramic phase volume fraction. TiB2 decomposition results in reduced hardness and wear resistance of the coatings. Coatings with Al, Ni show lower porosity and higher wear resistance. Thus, coatings of high wear resistance with TiB2 phase can be produced using high velocity arc spraying.

Key words: TiB2 composite material; high velocity arc spraying; coatings; microstructure; wear resistance

TiB2是一种特殊的陶瓷材料, 具有高熔点、 高硬度、 良好的耐磨性和导电性能[1-3]。 热喷涂制备的TiB2及其复合材料涂层具有硬度高、 耐磨性好、 抗熔融金属腐蚀等特点[4-7]。 有关热喷涂制备TiB2复合陶瓷涂层的报道多在科技比较发达的美、 英及日本等国家, 且多为等离子喷涂和HVOF喷涂技术, 而电弧喷涂技术[8]由于其高效、 低成本、 操作简便、 适合现场操作等优点具有极大的吸引力[9], 随着TiB2及其复合材料粉体制备工艺技术的发展, 尤其是自蔓延高温合成(SHS)技术的出现[10], 必将推动电弧喷涂技术制备TiB2及其复合材料陶瓷涂层的发展。

国内外电弧喷涂的研究多集中于喷涂工艺参数与涂层微观组织、 力学性能之间的相互关系[9, 11, 12], 而对于含陶瓷相的电弧喷涂过程中发生的冶金反应、 陶瓷相与为改善性能加入的合金元素对液滴特性的影响及对最终组织和性能的影响的研究很少[13]。 本文作者利用高速电弧喷涂不同配方的Fe-TiB2/Al2O3管状丝材, 在低碳钢基体上制备了含TiB2的复合涂层, 分析了涂层的显微组织及相组成, 研究涂层的耐磨粒磨损性能, 探讨涂层中的陶瓷相及合金元素Al、 Ni与耐磨性的关系, 为高性能TiB2复合陶瓷涂层的工业应用提供理论依据。

1 实验

1.1 喷涂丝材配方设计

电弧喷涂金属Fe基外皮包裹TiB2/Al2O3陶瓷和少量合金粉末的粉芯丝材时, 电阻热和电弧加热使金属陶瓷喷涂材料全部熔化或部分熔化, 经雾化气体吹离丝材端部且雾化成微小颗粒, 撞击基材表面沉积形成颗粒增强金属基复合涂层[13]。 复合涂层是以金属或合金作为粘接相, 陶瓷为硬质相的金属与陶瓷的复合。 采用自蔓延方法制备的TiB2/Al2O3复合陶瓷材料作为硬质添加相, 其中TiB2与Al2O3陶瓷的相容性好, 与Fe基体之间的润湿性也较好[4-6, 9, 10]。 为改善TiB2陶瓷与Fe基体的润湿性, 加入Ni粉和Al粉作为合金元素。 实验中研究了涂层成分、 显微组织与硬度、 耐磨损性能之间的相互关系, 配方设计采用均匀化设计表U5(54), 具体配方列于表1。

1.2 涂层制备

基体材料为正火态的20#钢, 使用直径d2.0mm的粉芯丝材, 粉芯丝材的外皮均选用10mm×0.3mm的高级优质低碳钢08F钢带。 对基体进行清洗、 喷砂, 使用CDM AS300电弧喷涂设备和装备再制造技术国防科技重点实验室研制的HAS-01高速喷枪, 通过优化的最佳喷涂工艺参数为: 喷涂电压32V, 喷涂电流180A, 空气压力0.6MPa, 喷涂距离180mm。

1.3 显微组织及涂层性能分析

采用Olympus PMG3金相显微镜和Olycia v3.0图像分析系统按照GB 3365—82标准测量涂层中

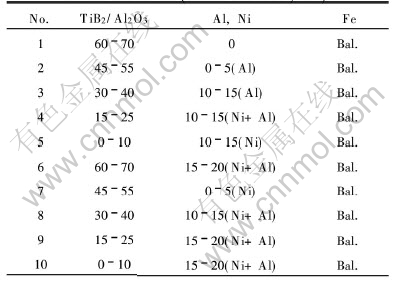

表1 粉芯丝材的主要成分

Table 1 Main composition of cored material (mass fraction, %)

的孔隙率, 分析涂层结构。 用X射线衍射仪分析涂层的相组成。 采用扫描电子显微镜(SEM)观察涂层的显微组织形貌, 用能谱仪(EDAX)分析涂层的化学成分。 在HV1000显微硬度计上测试涂层的表面和横截面的显微硬度, 载荷为9.8N, 加载时间15s, 沿厚度和宽度方向分别取5个点测量, 计算其平均值作为涂层的维氏显微硬度值。 采用MLS-23型湿砂橡胶轮式磨损试验机测试涂层的耐磨粒磨损性能, 试样尺寸为: 57mm×25.5mm×6mm, 涂层厚度2mm, 橡胶轮硬度为HS60, 载荷为正压力68.6N, 主轴转速为240r/min, 磨粒为0.2~0.4μm的石英砂, 砂浆配比为砂子1.5kg, 水1kg, 先预磨500转, 再磨1000转。

2 结果与讨论

2.1 涂层的组织

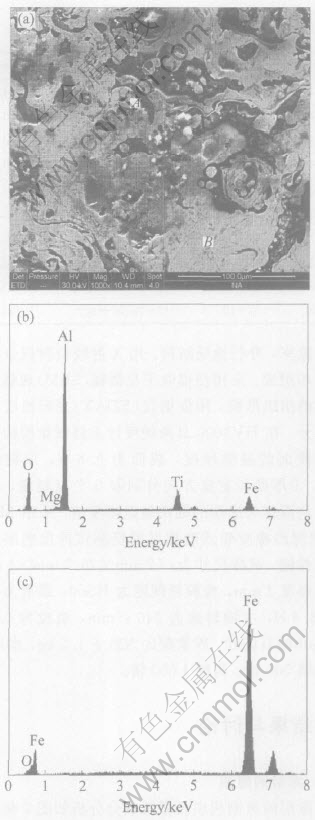

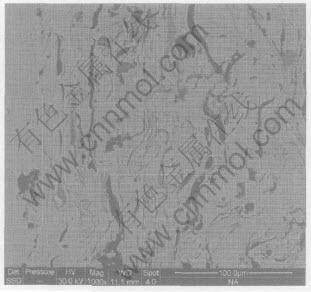

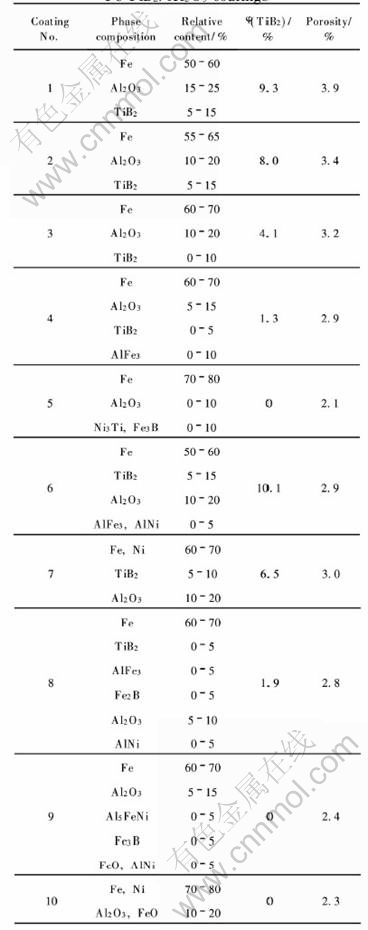

涂层的典型组织及微区成分分析如图1和2所示。 孔隙率测试和X射线衍射结果列于表2。 所有Fe-TiB2/Al2O3涂层均为致密的层状结构, 由金属薄层及陶瓷TiB2、 Al2O3以及少量的FeO薄层组成, 孔隙率较低, 均在2%~4%之间。 扫描电镜观察涂层时, 在陶瓷相含量较高的1号和6号涂层中存在较多不规则的陶瓷增强颗粒相TiB2及Al2O3, 在扫描电镜照片中由于氧化物颗粒导电性差而呈白亮颗粒点, 而硼化物和氧化物复合的陶瓷相为暗灰黑色。

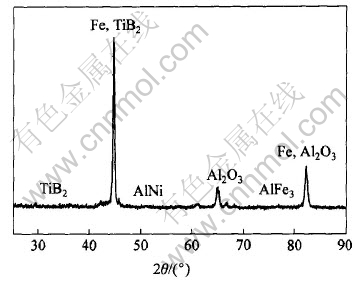

图1所示样品的X射线衍射结果表明相组成为Fe、 TiB2、 Al2O3、 AlFe3、 AlNi, 在灰黑点A处的EDS分析表明样品含有较多的Ti、 Al及O元素, 由于B元素无法准确用EDS检测, 可以推断点

图1 6号涂层的表面形貌(a)及A区(b)和B区成分(c)的EDS谱

Fig.1 Morphology(a) of coatings 6# and EDS patterns of zones A(b) and B(c)

图2 Fe-TiB2/Al2O3涂层的典型SEM像

Fig.2 Typical SEM image of Fe-TiB2/Al2O3 coating

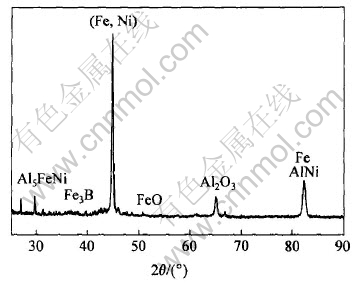

A处是陶瓷增强颗粒TiB2及Al2O3; 基体B点主要由Fe和少量的FeO组成。 10种涂层表现出相似的组织结构特征, 其相组成及相对含量列于表2, 相组成差别较大的6号和9号涂层X射线衍射结果见图3和图4。

2.2 Al, Ni对组织和性能的影响

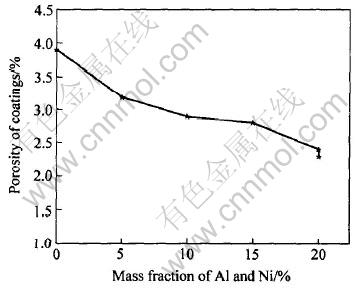

图5所示为高速电弧喷涂技术原位合成Fe-TiB2/ Al2O3复合涂层孔隙率随合金元素Al、 Ni加入量的变化趋势。

从表2和图5的结果可以看出: 在相同陶瓷含量时, 如1号和6号涂层, 加入Al和Ni使涂层致密度增加, 但孔隙率下降, 质脆且疏松的氧化铁含量极低, 有金属间化合物NiAl、 AlFe3相产生, 涂层的耐磨粒磨损性能也相对较高, 这是因为加入Al, Ni可改善陶瓷与基体的润湿性[8-10]。 在喷涂过程中Al, Ni首先熔化, 形成液相, 增加熔融颗粒的流动性, 提高其在基体表面的铺展能力, 可改善金属与陶瓷的润湿性, 从而改善涂层的微观结构和性能。 陶瓷硬质相若与Fe基体润湿性差, 则在磨损过程中先行剥落, 形成的硬质磨粒加重对涂层表面的磨损, 因此有必要对提高其润湿性作进一步研究。 虽然形成金属陶瓷材料的电弧喷涂过程和烧结过程不同, 但烧结过程机理也同样适用于热喷涂, 在烧结Fe基TiB2复合材料时加入2%的Al可使烧结温度大大降低, 同时提高烧结材料的致密度及力学性能[4, 11-16], 在热喷涂制备金属陶瓷过程中存在同样的规律。 同时, 活性元素Al的加入使涂层中几乎不存在FeO, 这也使涂层层间致密, 结合度提高, 增加涂层的耐磨性。

2.3 陶瓷相含量对耐磨粒磨损性能的影响

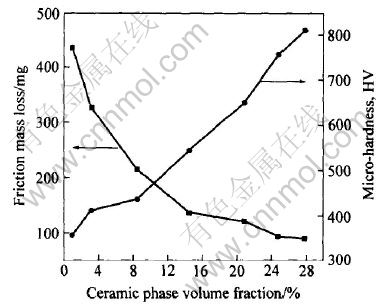

高速电弧喷涂低碳钢包覆0~70%TiB2/Al2O3硬质相的粉芯丝材原位合成一系列复合涂层, 其中耐磨粒磨损性能最好的涂层为6号涂层。 涂层的磨粒磨损实验中质量损失与TiB2在涂层中体积分数的关系如图6所示, 二者呈现线性关系。

表2 喷涂涂层中的相分析及孔隙率

Table 2 Phases composition and porosity of Fe-TiB2/Al2O3 coatings

涂层的磨损属于三体磨损类型, 磨料处于两个相对运动的固体表面之间, 在试样表面作有限的滚动,使试样表面产生月牙坑。 含TiB2的复合涂层的磨

图3 6号涂层的X射线衍射谱

Fig.3 XRD pattern of coating-6

图4 9号涂层的X射线衍射谱

Fig.4 XRD pattern of coating-9

图5 涂层孔隙率随合金元素加入量的变化

Fig.5 Relationship of porosity and Al and Ni contents

图6 涂层性能与陶瓷相含量的关系

Fig.6 Micro-hardness and friction mass loss curves at different ceramic contents

粒磨损机理是磨粒对金属表面进行显微切削的过程, 在摩擦力的作用下, 磨粒颗粒压入材料表面产生压痕, 或从表面层挤压出剥落物, 造成表面磨损。 从涂层的显微组织和相组成分析可以看出, 含TiB2复合涂层主要由以韧性的Fe或(Fe, Ni)固溶体为基体, 硬质陶瓷相(TiB2、 Al2O3)为颗粒增强相构成, 因此, 显微切削过程为主要磨损机制, 磨粒磨损性能遵循阿恰德方程关系, 即

式中 w为磨损率; F为作用在摩擦副的法向载荷; K为磨损系数; H为材料的硬度。 式(1)表明涂层的磨损量w与载荷及距离成正比, 与材料的屈服强度或硬度成反比。

在磨损实验过程中, 当磨屑压入涂层表面时, 随着陶瓷相颗粒的增多, 磨屑压痕变小, 不易从表面挤压出剥落物, 且显微切削时碰到硬质相颗粒, 使磨粒而不是切削表面挤碎。

有关多相复合材料的磨损模型[15-17]也指出: 材料的耐磨性受各组成相的耐磨性能及其相对含量的影响, 而且在大多数磨损条件下, 耐磨的颗粒相将承担与其含量不成比例的大部分载荷, 因此对多相复合材料的耐磨性起决定性作用。

综上所述, 高速电弧喷涂Fe-TiB2/Al2O3复合涂层的耐磨粒磨损质量损失随硬质陶瓷相TiB2和Al2O3体积分数的增大而减少, 材料耐磨性增加。

3 结论

1) 高速电弧喷涂技术可原位合成高性能Fe-TiB2/Al2O3复合涂层, 随陶瓷相(尤其是超硬的TiB2相)含量的增加, 涂层的显微硬度增加, 耐磨粒磨损质量损失下降。 含TiB2等陶瓷硬质相的复合涂层的磨粒磨损机理为磨粒对表面进行显微切削。

2) 高速电弧喷涂Fe-TiB2/Al2O3复合涂层是一个非平衡沉积过程, 产生的主要相为TiB2、 Al2O3, 同时也生成少量的FexB、 AlFe3、 AlNi相。

3) 合金元素Al、 Ni可改善金属Fe与陶瓷相TiB2的润湿性, 增强涂层的耐磨性能。

REFERENCES

[1]Huang F, Liu W J, Sullivan J F. Room-temperature oxidation of ultrathin TiB2 films[J]. Journal of Materials Research, 2002, 17(4): 805-813.

[2]Pierson H O, Randich E. Titanium diboride coatings and their interaction with the substrates[J]. Thin Solid Films, 1978, 54(1): 119-128.

[3]Ananthapadmanabhan P V, Sreekumar K P, Ravindran P V, et al. Electrical resistivity of plasma-sprayed titanium diboride coatings[J]. 1993, 28(6): 1655-1658.

[4]杨丽祥, 陈敬超. TiB2陶瓷覆层的磨粒磨损性能研究[J]. 云南冶金, 1999, 28(2): 50-56.

YANG Li-xiang, CHEN Jing-chao. Investigations of abrasive wear property of ceramic TiB2 coating[J]. Journal of Yunnan Metallurgy, 1999, 28(2): 50-56.

[5]Gruner H. Vacuum plasma spray quality control[J]. Thin Solid Films, 1984, 118(4): 409-420.

[6]Dallaire S, Champagne B. Plasma spray synthesis of TiB2-Fe coatings[J]. Thin Solid Films, 1984, 118(4): 477-483.

[7]Tamura H, Wei F G, Kodama T. TiN-TiB2/composite coatings reactively produced by electrothermally exploded powder spray[J].Journal of Thermal Spray Technology, 2002, 11(1): 100-106.

[8]Sreekumar K P, Ravindran P V, Venkatramani N. Effect of oxygen pich-up on the properties of plasma sprayed titanium diboride coatings[J].Thin Solid films, 1993, 224(2): 148-152.

[9]Jandin G, Liao H, Feng Z Q, et al. Correlations between operating conditions, microstructure and mechanical properties of twin wire arc sprayed steel coatings[J]. Materials Science and Engineering, 2003, A349: 298-305.

[10]张金咏, 傅正义, 王为民. 陶瓷-金属复合材料制备与研究[J]. 武汉工业大学学报, 1999, 21(2): 10-13.

ZHANG Jin-yong, FU Zheng-yi, WANG Wei-min. Preparation and study on metal-ceramic composites[J]. Journal of Wuhan University of Technology, 1999, 21(2): 10-13.

[11]Watanabe T, Wang X, Pfender E, et al. Correlations between electrode phenomena and coating properties in wire arc spraying[J]. Thin Solid Films, 1998, 316: 169-173.

[12]Fang J C, Xu W J, Zhao Z Y, et al. Arc spray forming[J]. Materials Processing Technology, 2005, 164-165: 1032-1037.

[13]ZHAO Li-dong, Jochen Z, Erich L. The influence of milling parameters on the properties of the milled powders and the resultant coatings[J]. Surface and Coatings Technology, 2003, 168(2-3): 179-185.

[14]Jones M, Horlock A J, Shipway P H, et al. A comparison of the abrasive wear behavior of HVOF sprayed titanium carbide and titanium boride-based cermet coatings[J]. Wear, 2001, 251: 1009-1016.

[15]Axén N, Hutchings I M, Jacobson S. A model for the friction of multiphase materials in abrasion[J]. Tribology International, 1996, 29(6): 467-475.

[16]Jongsang L, Jung J Y, Eon-Sik L, et al. Microstructure and properties of titanium boride dispersed Cu alloys fabricated by spray forming[J]. Materials Science and Engineering, 2000, A227: 274-283.

[17]Faran E, Gotman I, Gutmanas E Y. Coating of BN via solid state reaction with Ti powder[J]. Materials Letters, 2000(4): 192-196.

(编辑龙怀中)

基金项目: 国家自然科学基金资助项目(50375004)

收稿日期: 2005-07-15; 修订日期: 2005-08-20

作者简介: 栗卓新(1963-), 男, 教授

通讯作者: 栗卓新, 教授; 电话: 010-67392168; E-mail: zhxlee@bjut.edu.cn