Trans. Nonferrous Met. Soc. China 22(2012) 2541-2547

Synthesis of spinel LiMn2O4 microspheres with durable high rate capability

ZHOU Yu-bo1, 3, DENG Yuan-fu2, 3, YUAN Wei-hao2, SHI Zhi-cong3, CHEN Guo-hua3

1. School of Environmental Science and Technology, Dalian University of Technology, Dalian 116024, China;

2. The Key Laboratory of Fuel Cell Technology of Guangdong Province,

School of Chemistry and Chemical Engineering, South China University of Technology, Guangzhou 510640, China;

3. Centre for Green Products and Processing Technologies,

Guangzhou HKUST Fok Ying Tung Research Institute, Guangzhou 511458, China

Received 9 July 2012; accepted 19 August 2012

Abstract: Spinel LiMn2O4 microspheres with durable high rate capability were synthesized by a facile route using spherical MnCO3 precursors as the self-supported templates, combined with the calcinations of LiNO3 at 700 ℃ for 8 h. The spherical MnCO3 precursors were obtained from the control of the crystallizing process of Mn2+ ions and NH4HCO3 in aqueous solution. The effects of the mole ratio of the raw materials, reaction time, and reaction temperature on the morphology and yield of the MnCO3 were investigated. The as-synthesized MnCO3 and LiMn2O4 microspheres were characterized by powder X-ray diffractometry (XRD) and scanning electron microscopy (SEM). Galvanostatic charge/discharge tests indicate that the spinel LiMn2O4 microspheres deliver a discharge capacity of 90 mA·h/g at 10C rate show good capacity retention capability (75% of their initial capacity after 800 cycles at 10C rate). The durable high rate capability suggests that the as-synthesized LiMn2O4 microspheres are promising cathode materials for high power lithium ion batteries.

Key words: MnCO3 microspheres; self-supported template; LiMn2O4 microspheres; rate capability

1 Introduction

Lithium ion batteries (LIBs) have become revolutionized portable electronic devices in the past two decades [1]. They are also expected to make a great impact on the pure electric vehicles (EV) and hybrid electric vehicles (HEV) [2]. The battery performance depends critically on the materials, and therefore the development of new materials is important for advancing battery technology. The current commercial lithium ion batteries commonly based on the layered cobalt oxides cathode materials can hardly fulfill the requirement of high power applications such as HEV and EV [3]. Thus, the novel cathode materials with high energy and power density have received considerable interest [4-6]. Spinel LiMn2O4 is a prospective candidate for the cathode material for EV and HEV because of its intrinsic advantages of suitable Mn4+/Mn3+ redox potential (4.0 V, vs Li+/Li), low cost, high abundance, better safety, and environmental compatibility. Especially, the three- dimensional lithium ion channels of the three- dimensional crystal structure LiMn2O4 is beneficial for the intercalation and deintercalation of lithium ion at high rate [7]. However, the application of spinel LiMn2O4 materials is hampered by the problem of capacity decay during cycling, which mainly results from Mn dissolution via a disproportionation reaction (2Mn3+→Mn2++Mn4+) and structural transformation from cubic to tetragonal phase that is induced by Jahn– Teller distortion of Mn(III) with high spin [8]. Previous studies demonstrated that the discharge capacities, cycling life, and rate performance of rechargeable lithium ion batteries are dramatically affected by the particle size, surface morphology and synthesized method of the active materials [9]. It is commonly acknowledged that the nanostructured electrode materials can overcome the limits, especially the power density. Various nanostructured LiMn2O4, such as nanoparticles [10], mesoporous materials [11], double-shelled hollow micro- spheres [12], and one-dimensional (1-D) nanomaterials (nanowires [13], nanorods [3] and nanotube [14]) have been investigated aiming at the application in high-power LIBs. Although nanometer- sized LiMn2O4 has demonstrated improvement in rate capability, its tap density is very low compared with that of the conventional oxide electrode material. Low tap density results in low volumetric energy density, and consequently, nano-LiMn2O4 cathodes are not suitable for lithium-ion batteries designed for applications in plug-in hybrid vehicles (PHEVs) or electric vehicles. In addition, the electrodes prepared with nano-scaled cathode materials turn out to be easily loosened and slough off, which results in bad cycleability of the electrode. Therefore, it is of great importance, to develop a facile and scalable method to synthesize the electrode materials with spherical morphology (high tap-density) and reasonable and uniform size distribution (high rate performance).

Herein, the preparation of LiMn2O4 microspheres using spherical MnCO3 precursors was reported, which were obtained from the control of the crystallizing process of Mn2+ ions and NH4HCO3 in aqueous solution, as the self-supporting templates. Without surface coating or cation doping, the as-prepared LiMn2O4 microspheres could deliver good durability at high charge/discharge rates after 800 cycles.

2 Experimental

2.1 Synthesis

2.1.1 Synthesis of spherical MnCO3

The synthesis of spherical MnCO3 was carried out by controlling the crystallizing process of the following reaction equation in aqueous solution.

MnCl2·4H2O+2NH4HCO3→

MnCO3↓+2NH4Cl+CO2↑+5H2O (1)

In a typical experiment, NH4HCO3 (2.752 g, 40 mmol) was dissolved in 50 mL deionized water and added to 10 mL solution containing 3.444 g MnCl2·4H2O. After being stirred at 35 ℃ for 20 min, some pale yellow powders were precipitated from the reaction solution. After filtration, the pale yellow powders were washed with distilled water and ethanol three times and dried at 80 ℃ in vacuum. In addition, the effects of the mole ratio of the raw materials, reaction time, reaction temperature and surfactant on the morphology and yield of the MnCO3 were investigated.

2.1.2 Synthesis of LiMn2O4 microspheres

The LiMn2O4 microspheres were prepared according to the following equation:

MnCO3+LiNO3→LiMn2O4+NxOy↑ (2)

In a typical experiment, the obtained spherical MnCO3 powders were mixed with LiNO3 in stoichiometric ratio of 2.00:1.05, and then the mixture was ground to obtain a homogeneous mixture. After that, the homogeneous mixture was calcined at 700 ℃ for 8 h to obtain black LiMn2O4 microspheres.

2.2 Characterization

The structures and morphologies of the as-prepared materials were characterized by powder X-ray diffractometry (XRD, Bruker D8 Advance powder diffractometer) using Cu Kα radiation at 40 kV, 40 mA and steps of 0.020 and field emission scanning electron microscopy (SEM, Jeol JSM—6390).

The electrochemical characterizations of the sample were performed using CR2025 coin-type cell. The electrode was prepared by mixing the as-prepared active material (80%, mass fraction), acetylene black (10%) and polyvinylidene fluoride (PVDF) binder (10%) with a mass ratio of 8:1:1. After these materials were thoroughly mixed in N-methyl-2-pyrrolidone (NMP) solution, the prepared slurry was coated on Al foil in the N-methyl pyrrolidinone (NMP). The slurry was coated on an aluminum foil and dried at 90 ℃ for 2 h in a vacuum oven. The electrode was incorporated into the coin cell with a lithium foil anode and a Celgard 2325 microporous membrane separator in a dry glove box under argon. The electrolyte used was 1.0 mol/L LiPF6 ethylene carbonate (EC) solution and ethyl methyl carbonate (EMC) (3:7 in volume). The electrochemical charge-discharge measurements were carried out in the voltage range from 3.2 to 4.4 V (vs Li+/Li) at different rates.

3 Results and discussion

3.1 Effect of reaction temperature on MnCO3 yield and morphology

Table 1 shows the yield of MnCO3 obtained at different reaction temperatures (35, 45 and 55 ℃) when the reactions were kept in aqueous solution with the mixture of MnCl2·4H2O and NH4HCO3 at a mole ratio of 1:2. The reaction time was 20 min.

Table 1 Yield of MnCO3 at different reaction temperatures

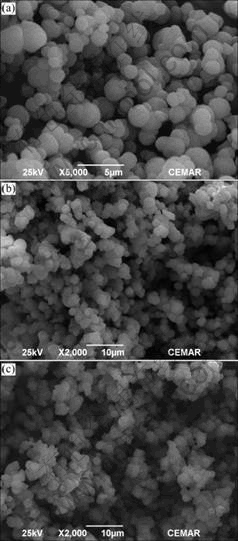

The above results clearly reveal that a little high yield of MnCO3 can be obtained at 35 ℃, which probably can be attributed to the fast decomposition of NH4HCO3 at a high temperature. Figure 1 shows the typical morphologies of the MnCO3 obtained at different temperatures. As seen in Fig. 1(a), the MnCO3 precursors obtained at 35 ℃ are uniform spheres with average diameters of around 1 μm. However, the SEM images of MnCO3 prepared at 45 and 55 ℃ (Figs. 1(b) and 1(c)) show square structure and some agglomeration. Thus, 35 ℃ was selected as the optimum temperature for the synthesis of MnCO3 microspheres.

Fig. 1 SEM images of MnCO3 obtained at different reaction temperatures: (a) 35 ℃; (b) 45 ℃; (c) 55 ℃

3.2 Effect of reaction time on MnCO3 yield and morphology

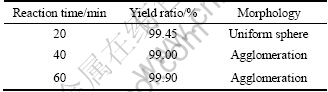

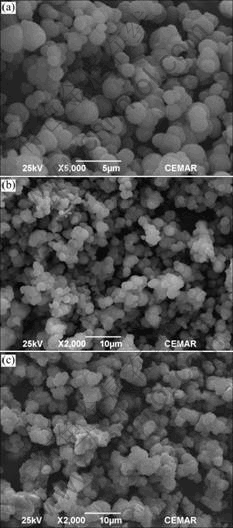

When the reaction was kept at 35 ℃, the effect of reaction time on the MnCO3 yields was investigated. As shown in Table 2, the MnCO3 yields were all above 99% with no obvious difference when the reactions were kept at different reaction time. Because of some disadvantages including time consumption, energy wastage and some agglomeration of the obtained products, we selected 20 min as the most suitable condition for the synthesis of MnCO3. Figure 2 shows the morphology of the MnCO3 obtained for different reaction times.

Table 2 Yield of MnCO3 obtained at 35 ℃ for different reaction times

Fig. 2 SEM images of MnCO3 obtained at 35 ℃ for different reaction times: (a) 20 min; (b) 40 min; (c) 60 min

3.3 Effect of ratio of MnCl·4H2O and NH4HCO3 on MnCO3 yield and morphology

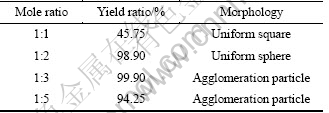

Table 3 lists the yield of MnCO3 at different ratios of MnCl·4H2O to NH4HCO3. The experiments were conducted at 35 ℃ for 20 min. The results reveal that the yield of the MnCO3 increases with the increase of the mole ratio of MnCl·4H2O to NH4HCO3. When the ratio is 1:1, the yield of MnCO3 is only 45.75%. When the ratio is 1:2, the yield is nearly up to 100%. These results can be explained by the fact that the chemical equilibrium moves right if the concentration of reactants increases. However, when the ratio increases to 1:5, the yield is only 94.25%, which is probably attributed to the side reactions in the high pH value solution by the addition of surplus NH4HCO3. Combining with the decrease of cost and the increase of purity of products, the ratio of 1:2 was selected as the optimal experimental condition.

Table 3 Yield and morphology of MnCO3 at different mole ratios of MnCl·4H2O to NH4HCO3

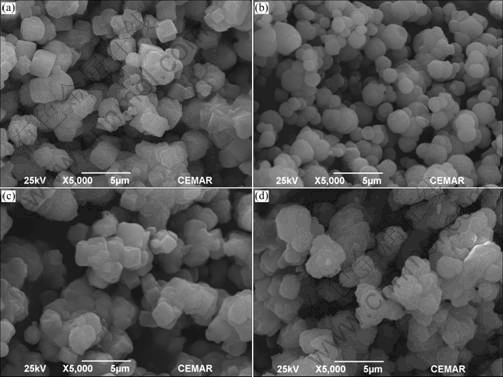

Figure 3 shows the morphologies of the MnCO3 obtained from different mole ratios of MnCl·4H2O to NH4HCO3. As shown in Fig. 3(a), the MnCO3 prepared with the ratio of 1:1 shows the uniform squares with average diameters of around 1 μm. However, the MnCO3 prepared at the ratios of 1:3 and 1:4 (Figs. 3(b) and 3(c)) clearly display to some degree agglomeration.

Based on the above observations, we selected the mole ratio of 1:2, temperature 35 ℃ and reaction time 20 min as the optimal parameters to obtain the MnCO3 with good morphology and high yield.

3.4 Characterizations of MnCO3 precursor and LiMn2O4 microspheres

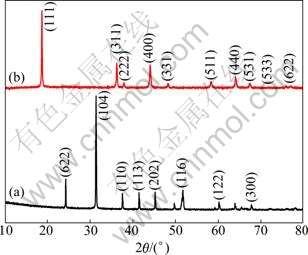

Figure 4(a) shows the XRD pattern of the MnCO3 obtained from the optimal experimental conditions. All the diffraction peaks are consistent with the standard card (JCPDS card 00-044-1472), which demonstrated that the as-synthesized MnCO3 is with high purity and crystallinity.

Figure 4(b) displays the XRD pattern of the LiMn2O4 microspheres produced from the calcination of the mixture of LiNO3 and spherical MnCO3 precursors at 700 ℃ for 8 h. The diffraction peaks can be assigned to well-crystallized cubic spinel LiMn2O4 (JPSDS card 35-0782). The refinement cell parameter is 8.196 ? (calculated using the Jade Software), which is smaller than the standard value of 8.248 ?. This result demonstrates that the manganese ions in the octahedral sites are partially replaced by lithium ions in the spinel lattice [3].

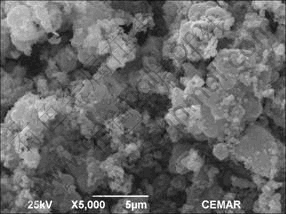

Figure 5 shows the typical SEM image of the LiMn2O4 microspheres produced from the calcination of the mixture of LiNO3 and spherical MnCO3 precursors at 700 ℃ for 8 h. In Fig. 5, most of the obtained LiMn2O4 sample preserved the spherical morphology of the MnCO3 precursor except for some aggregation because of the calcination at high temperature. In addition, some small particles were observed on the surface of the LiMn2O4 microspheres, which probably results from the gas evolution caused by the thermal decomposition of MnCO3 and LiNO3.

3.5 Electrochemical properties of LiMn2O4 micro- spheres

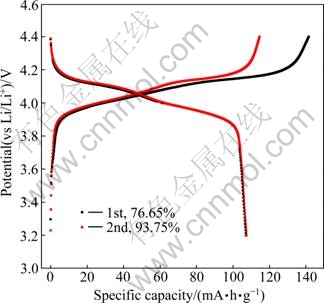

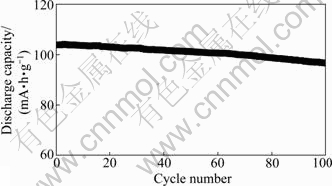

Figure 6 shows the typical galvanostatic charge- discharge profiles of LiMn2O4 microspheres tested at potential range of 3.2-4.4 V and current rate of 0.1C. Both of the charge and discharge curves exhibit two distinguishable pseudo plateaus, which are attributed to the two-phase transformation of λ-MnO2/ Li0.5Mn2O4 and Li0.5Mn2O4/LiMn2O4 [14], respectively. The initial specific capacity is 109 mA·h/g at 0.1C, with a coulomb efficiency of 75.65%. Although the initial specific capacity of the as-synthesized material is lower than the most recently reported results [3, 9-14], the specific capacity of the as-synthesized material of 103.0 mA·h/g (as shown in Fig. 7) is comparable to some of the reported results [15-17]. Furthermore, the specific capacity of 96 mA·h/g and the retention capability of larger than 93% after 100 cycles at 1.0C of the LiMn2O4 microspheres demonstrate that they exhibit good cycling stability, which can be attributed to their reasonable particle size, stable spherical structure and small surface areas (0.6 m2/g).

Fig. 3 SEM images of MnCO3 obtained of different mole ratios of MnCl·4H2O to NH4HCO3: (a) 1:1; (b) 1:2; (c) 1:3; (d) 1:5

Fig. 4 XRD patterns of MnCO3 obtained from optimal experimental condition (a) and LiMn2O4 microspheres produced from calcination of mixture of LiNO3 and MnCO3 (b)

Fig. 5 SEM image of LiMn2O4 microspheres

Fig. 6 Charge-discharge curves of LiMn2O4 microspheres at 0.1C

Fig. 7 Cycling performance of LiMn2O4 microspheres at 1.0C rate

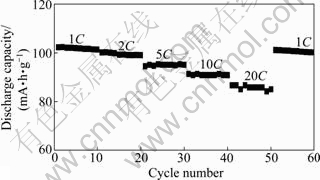

To evaluate the high-power capability, the LiMn2O4 microspheres prepared at 700 ℃ were cycled at different discharge/charge current densities ranging from 1 to 20C. Figure 8 shows the discharge curves of the as-synthesized material at different discharge current densities. As anticipated, the profiles at low charge/ discharge rates clearly show two distinguished plateaus located at about 4.1 and 4.0 V (vs Li/Li+). When the charge/discharge rate is over 10C, the separation of the two discharge plateaus gradually becomes blurred and the plateau voltages shift lower due to the increased cell polarization at very high current rates.

Fig. 8 Discharge curves of LiMn2O4 microspheres at different rates

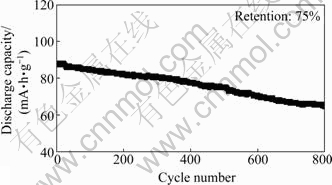

Figure 9 displays the rate performance of the electrode made from LiMn2O4 microspheres. As the current density increased from 1 to 20C, the discharge capacity decreased slightly from 103 to 86.4 mA·h/g. At a rate of 10C, a discharge capacity of 91 mA·h/g can be obtained. When the current density was decreased from 20 to 1C, the discharge capacity went back up to 101 mA·h/g, revealing the superior reversibility of the LiMn2O4 microspheres and their suitability as a high rate cathode material. In addition, the capacities remained at 68 mA·h/g even after 800 discharge/charge cycles at 10C (as shown in Fig. 10), and the corresponding capacity retentions were 75%. It is safe to say that the as-prepared LiMn2O4 microspheres exhibit good rate capability and cycleability.

Fig. 9 Rate and cycling performance of LiMn2O4 micro- spheres

Fig. 10 Cycling performance of LiMn2O4 microspheres at 10C rate

4 Conclusions

1) Spinel LiMn2O4 microspheres with durable high rate capability were synthesized by a facile route using spherical MnCO3 precursors as the self-supported templates, combined with the calcinations of LiNO3 at 700 ℃ for 8 h.

2) The reactant ratio, reaction time and reaction temperature have significant effects on the morphology and yield of the MnCO3 precursors.

3) The obtained LiMn2O4 microspheres exhibited remarkable high rate capability with 85 mA·h/g at 20C current density and durable capacity retention capability at 1.0 and 10C (the capacity retention capabilities are larger than 93% at 1.0C for 100 cycles and 75% at 10C for 800 cycles, respectively).

4) The excellent electrochemical properties are attributed to the reasonable particle size, stable spherical structure and small surface areas.

References

[1] JEONG G J, KIM Y U, KIM Y J, SOHN H J. Prospective materials and applications for Li secondary batteries [J]. Energy Environmental Science, 2011, 4(6): 1986-2002.

[2] TARSCON J M, RECHAM N, ARMAND M, CHOTARD J N, BARPANDDA P, WALKER W, DUPONT L. Hunting for better Li-based electrode materials via low temperature [J]. Chemistry of Materials, 2010, 22(3): 724-739.

[3] CHENG F Y, WANG H B, ZHU Z Q, WANG Y Y, ZHANG T R, TAO Z L, CHEN J. Porous LiMn2O4 nanorods with durable high-rate capability for rechargeable Li-ion batteries [J]. Energy Environmental Science, 2011, 4(9): 3668-3675.

[4] ELLIS B L, LEE K T, NAZARL F. Positive electrode materials for Li-ion and Li-batteries [J]. Chemistry of Materials, 2010, 22(3): 691-714.

[5] GAO X P, YANG H X. Multi-electron reaction materials for high energy density batteries [J]. Energy Environmental Science, 2010, 3(2): 174-189.

[6] COURTEL F M, DUNCAN H, ABU-LEBDEH Y, DAVIDSON I J. High capacity anode materials for Li-ion batteries based on spinel metal oxides AMn2O4 [J]. Journal of Materials Chemistry, 2011, 21(27): 10206-10218.

[7] LIU W, KOWAL K, FARRINGTON G C. Mechanism of the electrochemical insertion of lithium into LiMn2O4 spinels [J]. Journal of the Electrochemical Society, 1998, 145(2): 459-465.

[8] YANG X, TANG W, LIU Z, MAKITA Y, OOI K. Synthesis of lithium-rich LixMn2O4 spinels by lithiation and heat-treatment of defective spinels [J]. Journal of Materials Chemistry, 2002, 12(3): 489-495.

[9] WANG Z Y, ZHOU L, LOU X W. Metal oxide hollow structures are promising electrode materials [J]. Advanced Materials, 2012, 24(14): 1903-1911.

[10] OKUBOM, HOSONO E, KIM J, ENOMOTO M, KOJIMA N, KUDO T, ZHOU H S, HONMA I. Nanosize effect on high-rate Li-ion intercalation in LiCoO2 electrode [J]. Journal of the American Chemical Society, 2007, 129 (23): 7444-7452.

[11] JIAO F, BAO J, HILL A H, BRUCE P G. Synthesis of ordered mesoporous Li-Mn-O spinel as a positive electrode for rechargeable lithium batteries [J]. Angewandte Chemie International Edition, 2008, 47: 9711-9716.

[12] DING Y L, ZHAO X B, XIE J, CAO G S, ZHU T J, YU H M, SUN C Y. Double-shelled hollow microspheres of LiMn2O4 for high-performance lithium ion batteries [J]. Journal of Materials Chemistry, 2011, 21(26): 9475-9479.

[13] LEE H W, MYRALIDHARAN P, RUFFO R, MARI C M, CUI Y, KIM D K. Ultrathin spinel LiMn2O4 nanowires as high power cathode materials for Li-ion batteries [J]. Nano Letters, 2010, 10(10): 3852-3856.

[14] DING Y L, XIE J, CAO G S, ZHU T J, YU H M, ZHAO X B. Single-crystalline LiMn2O4 nanotubes synthesized via template- engaged reaction as cathodes for high-power lithium ion batteries [J]. Advanced Functional Materials, 2011, 21(2): 348-355.

[15] LUO J Y, XIONG H M, XIA Y Y. LiMn2O4 nanorods, nanothorn microspheres, and hollow nanospheres as enhanced cathode materials of lithium ion battery [J]. The Journal of Physical Chemistry C, 2008, 112(31): 12051-12057.

[16] YUE H J, HUANG X K, LV D P, YANG Y. Hydrothermal synthesis of LiMn2O4/C composite as a cathode for rechargeable lithium-ion battery with excellent rate capability [J]. Electrochimica Acta, 2009, 54: 5363-5367.

[17] AHN D, GIM J, SHIN N, KOOY M, KIM J, SHIN T J. Nanorod-assembled spinel Li1.05Mn1.95O4 rods with a central tunnel along the rod-axis for high rate capability of rechargeable lithium-ion batteries [J]. Electrochimica Acta, 2010, 55: 8888-8893.

耐久型高倍率性能锰酸锂微球的合成

周玉波1, 3,邓远富2, 3,袁伟豪2,施志聪3,陈国华3

1. 大连理工大学 环境科学与工程学院,大连 116024;

2. 华南理工大学 化学与化工学院 广东省燃料电池技术重点实验室,广州 510640;

3. 广州市香港科大霍英东研究院,广州 511458

摘 要:以Mn2+和NH4HCO3为原料,通过控制结晶法合成球形MnCO3前驱体模板。以LiNO3和MnCO3为原料,按照一定的摩尔比机械混合,在700 ℃下煅烧8 h,合成高倍率性能和长循环性能的球形尖晶石LiMn2O4材料。分别考查原料的摩尔比、反应时间以及反应温度对前驱体MnCO3形貌和产率的影响。采用X射线粉末衍射和扫描电镜对合成的MnCO3和LiMn2O4进行表征,对LiMn2O4样品进行室温条件下的充放电性能测试。电化学测试结果表明:尖晶石锰酸锂微球在10C的放电倍率下的首次放电容量达90 mA·h/g (1C放电容量为148 mA/g),800次循环后容量保持率达到75%。该方法合成的LiMn2O4微球作为高功率型锂离子电池的正极材料有着较好的应用前景。

关键词:碳酸锰微球;模板法;锰酸锂微球;高倍率性能

(Edited by LONG Huai-zhong)

Foundation item: Project (2011M501090) supported by the China Postdoctoral Science Foundation; Project (SCUT2012ZZ0042) supported by the Fundamental Research Funds for the Central Universities; Project supported by the “SPR-2011”of South China University of Technology; Project (NRC07/08.EG01) supprted by the Fok Ying Tung Foundation

Corresponding author: DENG Yuan-fu; Tel: +86-20-87112053; Fax: +86-20-34685679; E-mail: chyfdeng@scut.edu.cn

DOI: 10.1016/S1003-6326(11)61498-2