高压酸浸镍钼矿提取钼和镍

来源期刊:中国有色金属学报(英文版)2013年第10期

论文作者:王私富 魏 昶 邓志敢 李存兄 李兴彬 吴 钧 王明双 张 帆

文章页码:3083 - 3088

关键词:镍钼矿;高压酸浸;常压碱浸;镍;钼

Key words:nickel-molybdenum ore; pressure leaching; alkaline leaching; nickel; molybdenum

摘 要:研究一项针对镍钼矿用高压酸浸的方法回收镍和钼的全湿法工艺。采用该工艺避免了传统工艺焙烧镍钼矿(15%~25% S)带来的大量SO2和As2O3排放,减小了对环境的污染;与现有的湿法碱浸回收钼工艺相比,本工艺在酸浸过程中回收了几乎全部的镍和大部分的钼。在氧压环境下,几乎全部的镍和大部分的钼都进入溶液,少部分的钼留在酸浸渣中,酸浸渣进一步用碱(NaOH)浸出。在最佳的实验条件下,97%的镍和96%的钼分别被浸出。

Abstract: A direct hydrometallurgical route for nickel and molybdenum extraction from a nickel-molybdenum (Ni-Mo) ore using pressure acid leaching was studied. The nickel and molybdenum were extracted by acid leaching under oxygen pressure. Compared with traditional roasting methods, this hydrometallurgical method eliminates SO2 and As2O3 emission (the Ni-Mo ore containing 15%-25% S). Compared with existing alkali leaching recovery of molybdenum process, almost all the nickel and considerable molybdenum were extracted in the acid leaching process. Under oxygen pressure conditions, almost all the nickel and a substantial part of the molybdenum were dissolved into the acid leaching liquor and the other part of the molybdenum was left in the acid leach residue. The acid leach residue was further leached under alkaline (NaOH) conditions. Under optimal experimental conditions, the extraction rates nickel and molybdenum reached 97% and 96%, respectively.

Trans. Nonferrous Met. Soc. China 23(2013) 3083-3088

Si-fu WANG1,2, Chang WEI1, Zhi-gan DENG1, Cun-xiong LI1, Xin-bing LI1, Jun WU1, Ming-shuang WANG1, Fan ZHANG1

1. Faculty of Metallurgical and Energy Engineering, Kunming University of Science and Technology, Kunming 650093, China;

2. Yunnan Hualian Zinc and Indium Limited by Share Ltd., Wenshan 663701, China

Received 4 September 2012; accepted 26 April 2013

Abstract: A direct hydrometallurgical route for nickel and molybdenum extraction from a nickel-molybdenum (Ni-Mo) ore using pressure acid leaching was studied. The nickel and molybdenum were extracted by acid leaching under oxygen pressure. Compared with traditional roasting methods, this hydrometallurgical method eliminates SO2 and As2O3 emission (the Ni-Mo ore containing 15%-25% S). Compared with existing alkali leaching recovery of molybdenum process, almost all the nickel and considerable molybdenum were extracted in the acid leaching process. Under oxygen pressure conditions, almost all the nickel and a substantial part of the molybdenum were dissolved into the acid leaching liquor and the other part of the molybdenum was left in the acid leach residue. The acid leach residue was further leached under alkaline (NaOH) conditions. Under optimal experimental conditions, the extraction rates nickel and molybdenum reached 97% and 96%, respectively.

Key words: nickel-molybdenum ore; pressure leaching; alkaline leaching; nickel; molybdenum

1 Introduction

In southern China, the Ni-Mo ore as a sediment- hosted ore layer of the lower Cambrian black shale has been known to local geologists for at least 40 years [1,2]. A partial evaluation of the Ni-Mo ore deposits and their genesis has been attempted in past decades. In general, the Ni-Mo ore enriches in nickel, molybdenum and vanadium and is used for extracting nickel and molybdenum raw materials with a gross reserve of 9.37 million tons [1,3].

For the Ni-Mo ore, the classical process for nickel and molybdenum recovery is roasting, melting and concentration to produce a high impurity nickel- molybdenum alloy. In the process, sulfur dioxide (SO2) and arsenic trioxide (As2O3) release may cause serious environmental pollution. Mineral processing routes have been proposed for the Ni-Mo ore [4,5]; however, it is inefficient to enrich nickel and molybdenum through ore-dressing owing to the ore’s complex mineralogical characteristics. Research has therefore been initiated into treating Ni-Mo ores by direct metallurgical processes.

Several processes have been proposed to recover molybdenum from the Ni-Mo ore, such as roasting, NaOH/Na2CO3 leaching under active oxygen conditions [6,7], direct leaching with NaOH+Na2CO3/NaClO3 [8,9], direct NaOH leaching under active oxygen conditions [10] and direct leaching with H2SO4 for nickel recovery only [11]. Moreover, direct bioleaching of molybdenum and nickel from the Ni-Mo ore has been investigated using a molybdenum-resistant thermophilic bacterium sulfolobus metallicus, but the leaching rate is not very high and it requires further research [12].

Although an increasing number of articles have dealt with the Ni-Mo ore, few studies report the leaching of both molybdenum and nickel by direct metallurgical processes. In this work, the extraction behavior of nickel and molybdenum from the Ni-Mo ore is studied during the oxygen pressure leaching process, characterized by no sulfuric acid. Various characteristics of the Ni-Mo ore are used beneficially and partial sulfur is transformed into sulfuric acid under oxygen pressure. The effects of parameters including leaching time, leaching temperature, liquid-to-solid ratio and initial sulfuric acid concentration on leaching efficiency are investigated. After oxygen pressure leaching, the acid leach residue is further leached by the alkaline solution for molybdenum recovery. Optimal time, temperature, liquid-to-solid ratio and initial sulfuric acid concentration are determined for the extraction of nickel and molybdenum to examine the economic viability of the process.

2 Experimental

2.1 Materials

The Ni-Mo ore was collected from Guizhou Province in China. Analytical grade reagents, including sulfuric acid, were purchased from Chengdu Union Institute Chemical & Reagent and commercial pure oxygen was from Messer Company (Kunming, Yunnan). All aqueous solutions were prepared using distilled water.

2.2 Experimental procedure

The samples were crushed and ball milled to 85% <0.074 mm and dried at 75 °C in an oven for 24 h. Leaching experiments were conducted at an oxygen partial pressure of 1.2 MPa in an autoclave (1 L titanium alloy cylinder reactor with thermometer and stainless steel tube for injection of industrial oxygen by industrial compressor). The reactor was heated with a thermostatically controlled disc-type electric heater and liquid samples were withdrawn during the experiment. For each experiment (excluding those that sulfuric acid was added), 400 mL of distilled water and 200 g of sample were poured into the reactor, industrial oxygen was injected and the contents were heated to the desired temperature under magnetic stirring (500 r/min) and well-agitated for the desired reaction time by a diaphragm pump. The acid residue was separated from the liquid phase by filtration, washed twice with water, dried at 75 °C and the nickel and molybdenum contents were analyzed.

After oxygen pressure leaching, the acid residue was leached under alkaline (NaOH) conditions in an agitated flask, heated by an electric jacket. The supernatant was filtered and the acid residue cake was washed twice with water for 20 min, dried at 75 °C and the molybdenum content was analyzed.

2.3 Analytical methods

The metal contents of the sample and leaching residue were determined by atomic absorption spectrometry (Shanghai Morning Field Equipment Co., Ltd) and X-ray diffraction (XRD), and the pH value of the leaching liquor was measured using a PHS-3C digital pH meter from Shanghai Hongyi Instrument Co., Ltd.

3 Results and discussion

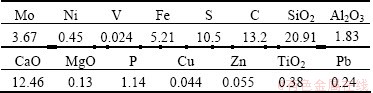

3.1 Characterization of Ni-Mo ore

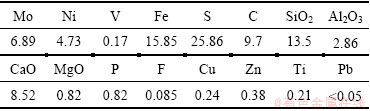

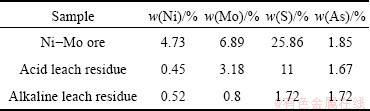

The compositions of the Ni-Mo ore are listed in Table 1. The XRD pattern of the raw ore shown in Fig. 1 confirms that the Ni-Mo ore consists of crystalline pyrite, quartz, muscovite, millerite and elemental sulfur, but molybdenum (6.89%) was not detected, which occurs mainly in the form of amorphous sulfide (MoS2) and co-exists with clay, quartz [13-15]. Nickel occurs mainly as vaesite (NiS2) and millerite (NiS) [13,16,17].

Table 1 Chemical compositions of Ni-Mo ore (mass fraction, %)

Fig. 1 XRD pattern of Ni-Mo ore

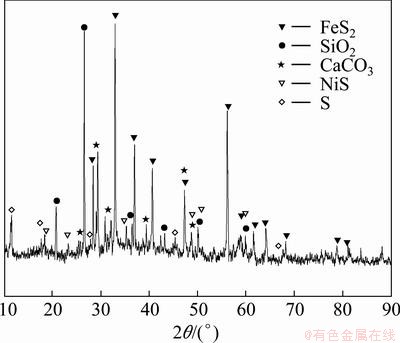

3.2 Effect of initial sulfuric acid concentration on extraction of nickel and molybdenum

To investigate the effect of sulfuric acid concentration on the extraction of molybdenum and nickel, a series of experiments were carried out under the following conditions: initial H2SO4 concentration of 0- 100 g/L, leaching time of 5 h, leaching temperature of 150 °C, oxygen partial pressure of 1.2 MPa and liquid- to-solid ratio of 2.0 mL/g. As shown in Fig. 2, over 97% of nickel and 76% of molybdenum were leached when the initial sulfuric acid concentration was 25 g/L. The increase in nickel extraction was insignificant and molybdenum extraction decreased slightly with an increase in initial sulfuric acid concentration. Furthermore, sulfuric acid consumption increased and more impurities were produced. Compared with the experiment that no sulfuric acid was added, the results revealed that the initial sulfuric acid concentration has little impact on the leaching of nickel and molybdenum from the Ni-Mo ore. Therefore, water leaching of the Ni-Mo ore was optimal under these conditions.

Fig. 2 Effect of initial sulfuric acid concentration on extraction rates of nickel and molybdenum

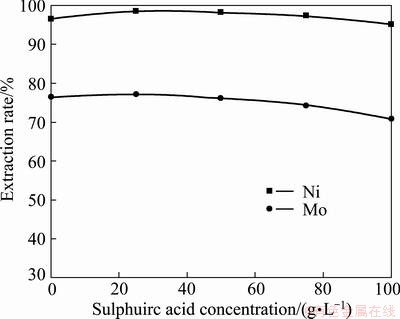

3.3 Effect of leaching time on extraction of nickel and molybdenum

To study the role of leaching time on the extraction of molybdenum and nickel, the reaction time was varied between 3 and 9 h. As shown in Fig. 3, the extraction of nickel increases strongly with the increase in leaching time from 3 to 5 h at 150 °C under the condition of a liquid to solid (L/S) ratio of 2.0 mL/g, without sulfuric acid and oxygen partial pressure of 1.2 MPa. 97% nickel extraction was obtained in 5 h. This is probably because the nickel sulfide oxidizes to NiSO4, which dissolves easily into the acid solution under such conditions. Therefore, 5 h is sufficient for nickel extraction. While the extraction of molybdenum increases gradually with an increase in leaching time from 3 to 5 h and a maximum extraction of 76% is reached at 5 h. Therefore, to obtain high nickel and molybdenum recoveries, in subsequent experiments, the leaching time was chosen to be 5 h.

Fig. 3 Effect of leaching time on extraction rates of nickel and molybdenum

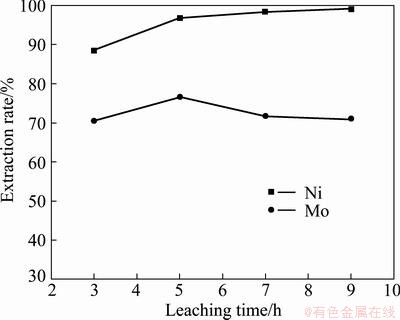

3.4 Effect of leaching temperature on extraction of nickel and molybdenum

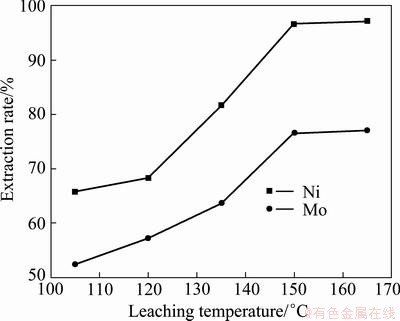

The effect of temperature on molybdenum and nickel extraction was investigated from 105 to 165 °C with distilled water, under an oxygen partial pressure of 1.2 MPa, without sulfuric acid and a liquid-to-solid (L/S) ratio of 2.0 mL/g for 5 h. It can be seen from Fig. 4 that nickel extraction increased with the increase in leaching temperature from 105 to 150 °C. Beyond 155 °C, the extraction rate of nickel increased slowly with an increase in temperature. Molybdenum extraction rate increased with increasing temperature and increased only slightly beyond 150 °C. Therefore, in subsequent experiments, the leaching temperature was chosen to be 150 °C.

Fig. 4 Effect of leaching temperature on extraction rates of nickel and molybdenum

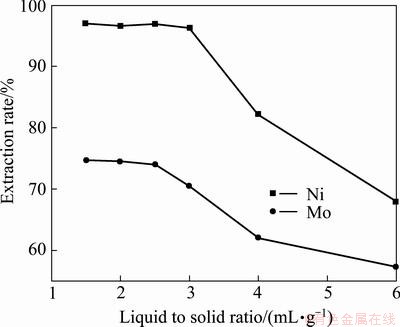

3.5 Effect of liquid-to-solid ratio on extraction of nickel and molybdenum

The effect of liquid-to-solid ratio on molybdenum and nickel extraction was examined at an oxygen partial pressure of 1.2 MPa, without sulfuric acid and temperature of 150 °C for 5 h. A series of experiments were carried out by varying the liquid-to-solid ratio in the range of 1.5-6.0 mL/g. It can be seen from Fig. 5 that nickel extraction rate decreased slightly from 98% to 96% with increasing liquid-to-solid ratio from 1.5 to 3.0 mL/g and decreased sharply with increase in liquid-to-solid ratio from 3.0 to 6.0 mL/g. Molybdenum extraction rate decreased slowly from 76% to 75% with increase in liquid-to-solid ratio from 1.5 to 2.5 mL/g and also decreased sharply with increase in liquid-to-solid ratio from 3.0 to 6.0 mL/g. The extraction rates of molybdenum and nickel decreased sharply with increase in liquid-to-solid ratio from 3.0 to 6.0 mL/g.

Considering various other factors such as agitation and pipe-line delivery in industrial plants, in subsequent experiments, the leaching liquid to solid (L/S) ratio was chosen to be 2.0 mL/g.

Fig. 5 Effect of liquid-to-solid ratio on extraction rates of nickel and molybdenum

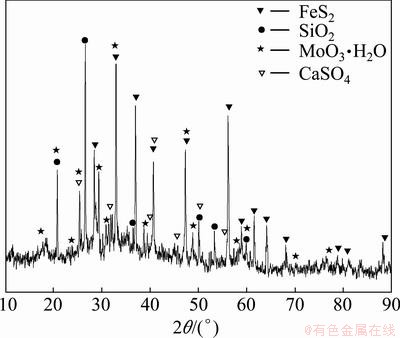

3.6 Characterization of acid leach residue

The acid leach residue used in this study (composition in Table 2) was obtained after oxygen pressure leaching. Almost all nickel and a substantial part of the molybdenum were leached. The X-ray diffraction pattern of the acid leach residue shown in Fig. 6 indicates that the amorphous phase molybdenum disulfide (MoS2) in the Ni-Mo ore changed into crystalline phase MoO3·H2O in the pressure leaching process.

Table 2 Chemical compositions of acid leach residue (mass fraction, %)

Fig. 6 XRD pattern of acid leach residue

3.7 Alkaline leaching of acid leach residue

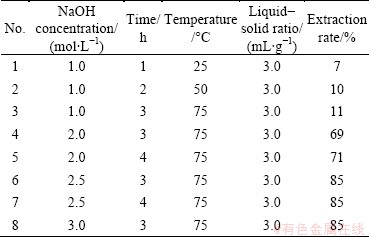

After pressure leaching under optimum conditions, based on the fact that the oxidized molybdenum leaches easily under alkaline conditions [7,8], experiments of alkaline (NaOH) leaching of the acid leach residue under conditions close to hydrometallurgical practice also showed good results. The data presented in Table 3 illustrate that nearly 85% Mo extraction can be achieved by alkaline leaching. Coupled with 76% Mo extraction rate in the pressure oxidation leaching process, the total molybdenum extraction rate was 96%.

Table 3 Experimental data of alkaline leaching

3.8 Phase changes during oxygen pressure leaching

XRD analysis was conducted to understand the mechanism of pressure leaching. Figure 1 shows the XRD pattern of the acid leaching residue, which reveals that there are four crystalline mineral phases: quartz (SiO2), anhydrite (CaSO4), pyrite (FeS2) and MoO3·H2O. Comparing Fig. 6 with Fig. 1 shows that the crystalline millerite (NiS), muscovite (CaCO3) and elemental sulfur (S) phases all disappeared after leaching. The main chemical reactions can be expressed by the following equations:

MoS2(s)+4.5O2(g)+3H2O(l)=MoO3·H2O(s)+4H++ (1)

(1)

S(s)+H2O(l)+1.5O2(g) =2H++ (2)

(2)

NiS(s)+2O2(g)=Ni2++ (3)

(3)

CaCO3(s)+2H+=Ca2++CO2(g)+H2O(l) (4)

Based on the previous work [18], the monomeric molybdate ions transform to the molybdenum cations when the leach solution pH is reduced to less than 1.0. Therefore, in the pressure leaching process, the leach liquor pH was 0.5 and the molybdenum dissolution process can be expressed by the following equation:

MoO3·H2O(s)+2H+= +2H2O(l) (5)

+2H2O(l) (5)

After pressure leaching, the acid leach residue was alkaline leached for molybdenum recovery, with the chemical reaction expressed by the following equation:

MoO3·H2O(s)+2OH-= +2H2O(l) (6)

+2H2O(l) (6)

Thus, the leaching process can be summarized as follows: 1) in the oxygen pressure process, oxidation of the sulfide forms sulfuric acid and the molybdenum (IV) is oxidized to molybdenum (VI) (Eqs. (1) and 2)); 2) the increase in generated sulfuric acid enhances further dissolution of crystalline NiS, MoS2, CaCO3 (Eqs. (3), (4) and (5)); 3) the molybdenum in the acid leach residue further dissolves in the alkaline leach process (Eq. (6)).

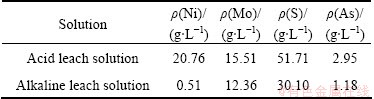

3.9 Comprehensive experimental analysis of Ni-Mo ore

The Ni-Mo ore was investigated by single factor, and then verification experiment was carried out under the optimum conditions, and the results are shown in Table 4. At the oxygen pressure acid leaching stage, the leaching rates of nickel, molybdenum, sulfur, and arsenic achieved respectively 97%, 75%, 80% and 45%, and in the process, most of sulfide was oxidized to sulfate, whereas arsenic oxidation for arsenate portioned into the acid leaching solution. The acid leach residue was further alkaline leached. In alkaline leaching process, the leaching rates of molybdenum, sulfur, and arsenic achieved 86%, 80% and 70%, respectively. The component analyses of acid leaching solution and alkaline leaching solution are shown in Table 5. The arsenic contents of acid leaching and alkaline leaching solution were 2.95 g/L and 1.18 g/L, respectively, and 85% arsenic was leached in the leaching process. The arsenic in leaching solution is removed through regulation of pH using magnesium salt precipitation method [19]. The results showed that this hydrometallurgical method can replace traditional roasting methods and can avoid environmental pollution caused by As. The acid waste solution with pH=0.5 was neutralized with alkali waste solution, and the neutralized solution can be used for leaching.

Table 4 Chemical compositions of leach residues

Table 5 Chemical composition of leaching liquid

4 Conclusions

1) The oxygen pressure leaching of the Ni-Mo ore was studied. The optimum parameters were: without sulfuric acid, leaching time of 5 h, leaching temperature of 150 °C, liquid-to-solid ratio of 2.0 mL/g, oxygen partial pressure of 1.2 MPa and stirring rate of 500 r/min. Under these conditions, the extraction rate of nickel was 97% and molybdenum 76%. The acid leach residue was further leached for molybdenum recovery under alkaline conditions and the results indicated that the molybdenum recovery reached 85% during the leaching process within 3 h. Under the condition of 75 °C, atmospheric pressure, liquid-to-solid ratio of 3.0 mL/g and NaOH of 2.5 g/L, the total extraction rate of molybdenum was 96%. The treatment of the Ni-Mo ore by oxygen pressure leaching-alkaline leaching process is reasonable and feasible.

2) Furthermore, 80% sulfur in the Ni-Mo ore was transformed into H2SO4, yielding a leach liquor of pH 0.5. This provided sufficient acid for the leaching of nickel and molybdenum.

References

[1] FAN D L, ZHANG T, JIE Y, PAAVA J, KRIBEK B, DOBES P, VARRIN I, ZAK K. Geochemistry and origin of tin-polymetallic sulfide deposits hosted by the Devonian black shale series near Dachang, Guangxi, China [J]. Ore Geology Reviews, 2004, 241(1-2): 103-120.

[2] WANG Xu-wen, PENG Jun, WANG Ming-yu, YE Pu-hong. The role of CaO in the extraction of Ni and Mo from the Ni-Mo ore by calcification roasting, sulphation roasting and water leaching [J]. International Journal of Mineral Processing, 2011, 100: 130-135.

[3] BAO Zheng-xiang. Geological features and metallogenic condition (including Au, Ag mineralization) of Ni-Mo-V ore deposits in the northwest Hunan Province [J]. Geology and Mineral Resources Research, 1990, 5(3): 49-62.

[4] CHEN Dai-xiong, TANG Mei-lian, XUE Wei, XU Yan, XIE Chao. Study on dressing concentrate of high carbon nickel–molybdenum ore [J]. Hunan Nonferrous Metallurgy, 2006, 22(6): 9-11. (in Chinese)

[5] WANG Ming-yu, WANG Xue-wen. Extraction of molybdenum and nickel from the Ni-Mo ore by oxidation roasting, sulphation roasting and water leaching [J]. Hydrometallurgy, 2010, 102: 50-54.

[6] PI Guan-hua, XU Hui, CHEN Bai-zhen, SHI Xi-chang, LI Jun-li. Study on recovering molybdenum from refractory Ni-Mo ore [J]. Hunan Nonferrous Metallurgy, 2007, 23(1): 9-12. (in Chinese)

[7] WANG Ming-yu, WANG Xue-wen, LIU Wan-li. A novel technology of molybdenum extraction from low grade Ni-Mo ore [J]. Hydrometallurgy, 2009, 97: 126-130.

[8] LI Qing-gang, XIAO Lian-sheng, ZHANG Gui-qing, ZHANG Qi-xue. Process and practice of ammonium molybdate production from Ni-Mo ore by hydrometallurgy [J]. Chinese Journal of Research Metallurgy, 2007, 31(5): 85-89. (in Chinese)

[9] ZHAO Zhong-wei, XU Xiao-yang, CHEN Xing-yu, HUO Guang-sheng, CHEN Ai-liang, LIU Xu-heng, XU Hui. Thermodynamics and kinetics of adsorption of molybdenum blue with D301 ion exchange resin [J]. Transactions of Nonferrons Metals Society of China, 2012, 22: 686-692.

[10] ZHAO Zhong-wei, LI Jiang-tao, CAO Cai-fang, HUO Guang-sheng, ZHANG Gang, LI Hong-gui. Recovery and purification of molybdenum from Ni-Mo ore by direct air oxidation in alkaline solution [J]. Hydrometallurgy, 2010, 103: 68-73.

[11] ZHU Ying, ZOU Gui-tian. Extracting Ni from Ni-Mo ore [J]. Journal of Guizhou Education Institute: Natural Science, 2007, 18(4): 52-53. (in Chinese)

[12] CHEN Jia-wu, GAO Cong-jie, ZHANG Qi-xiu, XIAO Lian-sheng. Leaching of nickel-molybdenum sulfide ore in membrane biological reactor [J]. Transactions of Nonferrons Metals Society of China, 2010, 21: 135-140.

[13] ZHANG Ai-yun, WU Da-mao, GUO Li-na. The geochemistry of marine black shale formation and its metallogenic significance [M]. Beijing: Science Press, 1987. (in Chinese)

[14] BAO Zheng-xiang, WAN Rong-jiang, BAO Jue-min. Metallogenic characteristics and genesis of the Ni-Mo deposits in northwestern [J]. Hunan, Hubei Geology & Mineral Resources, 2001, 15(1): 14-21. (in Chinese)

[15] LIU Wei-ping, XU Hui, YANG Xi-yun, SHI Xi-chang. Extraction of molybdenum from low-grade Ni-Mo ore in sodium hypochlorite solution under mechanical activation [J]. Minerals Engineering, 2011, 24: 1580-1585.

[16] JUNEJA J M, SOHAN SINGH, BOSE D K. Investigations on the extraction of molybdenum and rhenium values from low grade molybdenite [J]. Hydrometallurgy, 1996, 41: 201-209.

[17] STEINER M, WALLIS E, ERDTMANN B D, ZHAO Y L, YANG R D. Submarine-hydrothermal exhalative ore layers in black shales from South China and associated fossils-insighs into a Lower Cambrian facies and bio-evolution [J]. Palaeogeography, Palaeoclimatology, Palaeoecology, 2001, 169: 165-191.

[18] KONONOVA O N, KHOLMOGOROV A G, KACHIN S V, KALYAKINA O P, SADOVSKAY E V. Ion exchange recovery of molybdenum from nitric acidic solutions using macroporous anion exchangers with long-chained cross-linking agents [J]. Hydrometallurgy, 2003, 68: 83-87.

[19] YANG Liang, ZHAO Zhong-wei, CHEN Ai-liang. Research on arsenic removal from ammonium molybdate solution [J]. Journal of Central South University: Science and Technology, 2011, 42(8): 2193-2197. (in Chinese).

王私富1,2,魏 昶1,邓志敢1,李存兄1,李兴彬1,吴 钧1,王明双1,张 帆1

1. 昆明理工大学 冶金与能源工程学院,昆明 650093;

2. 云南华联锌铟股份有限公司,文山 663701

摘 要:研究一项针对镍钼矿用高压酸浸的方法回收镍和钼的全湿法工艺。采用该工艺避免了传统工艺焙烧镍钼矿(15%~25% S)带来的大量SO2和As2O3排放,减小了对环境的污染;与现有的湿法碱浸回收钼工艺相比,本工艺在酸浸过程中回收了几乎全部的镍和大部分的钼。在氧压环境下,几乎全部的镍和大部分的钼都进入溶液,少部分的钼留在酸浸渣中,酸浸渣进一步用碱(NaOH)浸出。在最佳的实验条件下,97%的镍和96%的钼分别被浸出。

关键词:镍钼矿;高压酸浸;常压碱浸;镍;钼

(Edited by Hua YANG)

Foundation item: Projects (51174104, 50874053) supported by the National Natural Science Foundation of China; Project (2009AA06Z106) supported by Hi-Tech Research and Development Program of China; Project (20115314110001) supported by Doctoral Fund of Ministry of Education of China

Corresponding author: Chang WEI; Tel/Fax: +86-871-5188819; E-mail: weichang502@sina.cn

DOI: 10.1016/S1003-6326(13)62837-X